Method for measuring heat conductivity of heat insulation material under different water contents

A technology of thermal conductivity and thermal insulation materials, applied in the field of thermal conductivity of thermal insulation materials, can solve problems such as changes in thermal conductivity, achieve high accuracy, ensure uniformity, and simple test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The measurement of the thermal conductivity of the hydrated rock wool board includes the following steps in sequence:

[0036] (1) First of all, for a rock wool board product, take two plate-shaped samples with a length of 300±2mm, a width of 300±2mm, and a thickness equal to the original thickness of the sample, which are named sample 1 and sample 2 respectively. Weigh immediately after drying to constant weight in an oven at 105°C. The masses of sample 1 and sample 2 weighed at this time are respectively m 1 = 695.58g and m 2 = 698.15 g.

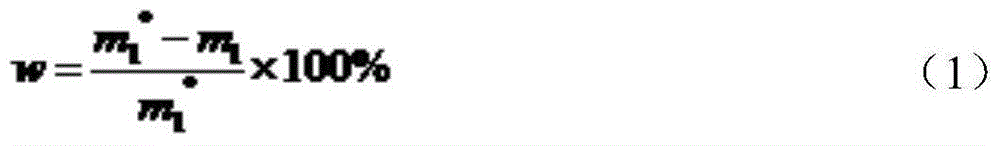

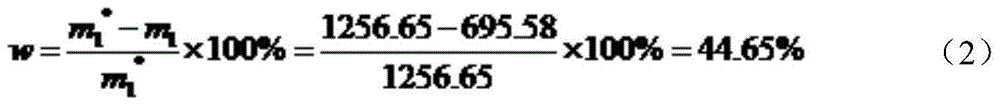

[0037] (2) Put sample 1 into a container filled with a certain amount of water by full immersion, and carry out water absorption treatment. During this period, the sample quality is weighed every 24 hours. Use absorbent paper to quickly dip off the surface water droplets, and immediately weigh the sample at this time 1 mass m 1 * =1256.65g, obtain the moisture content of wet basis of sample 1:

[0038]

[0039] (3) Immediate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com