Method for directly producing hydrogen by catalyzing methane conversion through microwaves

A microwave catalyzed methane, direct technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of unsatisfactory methane conversion rate, hydrogen yield, poor carbon deposition resistance and poor stability of the catalyst and other problems, to achieve the effect of reduced apparent activation energy, high catalytic activity and selectivity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

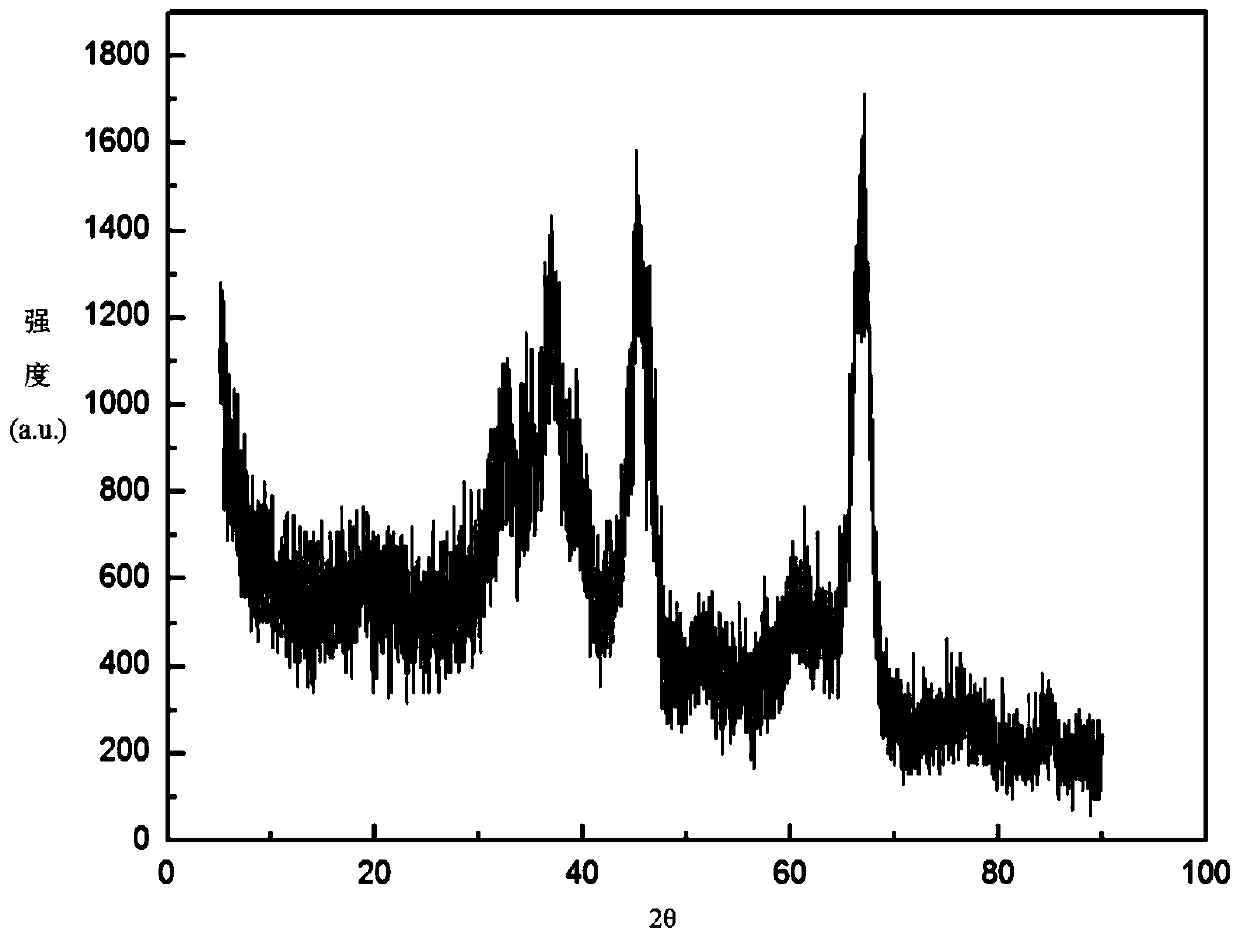

Embodiment 1

[0023] γ-Al 2 o 3 Add 80ml of isopropanol, sonicate for 60min to get treated γ-Al 2 o 3 and isopropanol mixture. Under stirring conditions, the ammonium molybdate solution was added dropwise to the above solution, stirred for 10 minutes, and then ultrasonicated for 30 minutes. Stirring in a water bath at 40°C for 8h, the resulting product was dried overnight in a drying oven at 110°C, and then calcined in a muffle furnace at 500°C for 4h to obtain the composite carrier MoO 3 / γ-Al 2 o 3 . Put the above composite carrier into the solution containing 20% CH 4 / H 2 (volume ratio) carbonization in a tube furnace to obtain 10% Mo 2 C / γ-Al 2 o 3 (Mo in the composite carrier 2 The content of C is 10wt%). Take 0.261g nickel nitrate hexahydrate and dissolve it in 10ml water, take 1g Mo 2 C / γ-Al 2 o 3 The composite carrier was placed in 40ml of isopropanol and ultrasonicated for 1h. The above solution was added dropwise to Mo 2 C / γ-Al 2 o 3 complex carrier and isop...

Embodiment 2

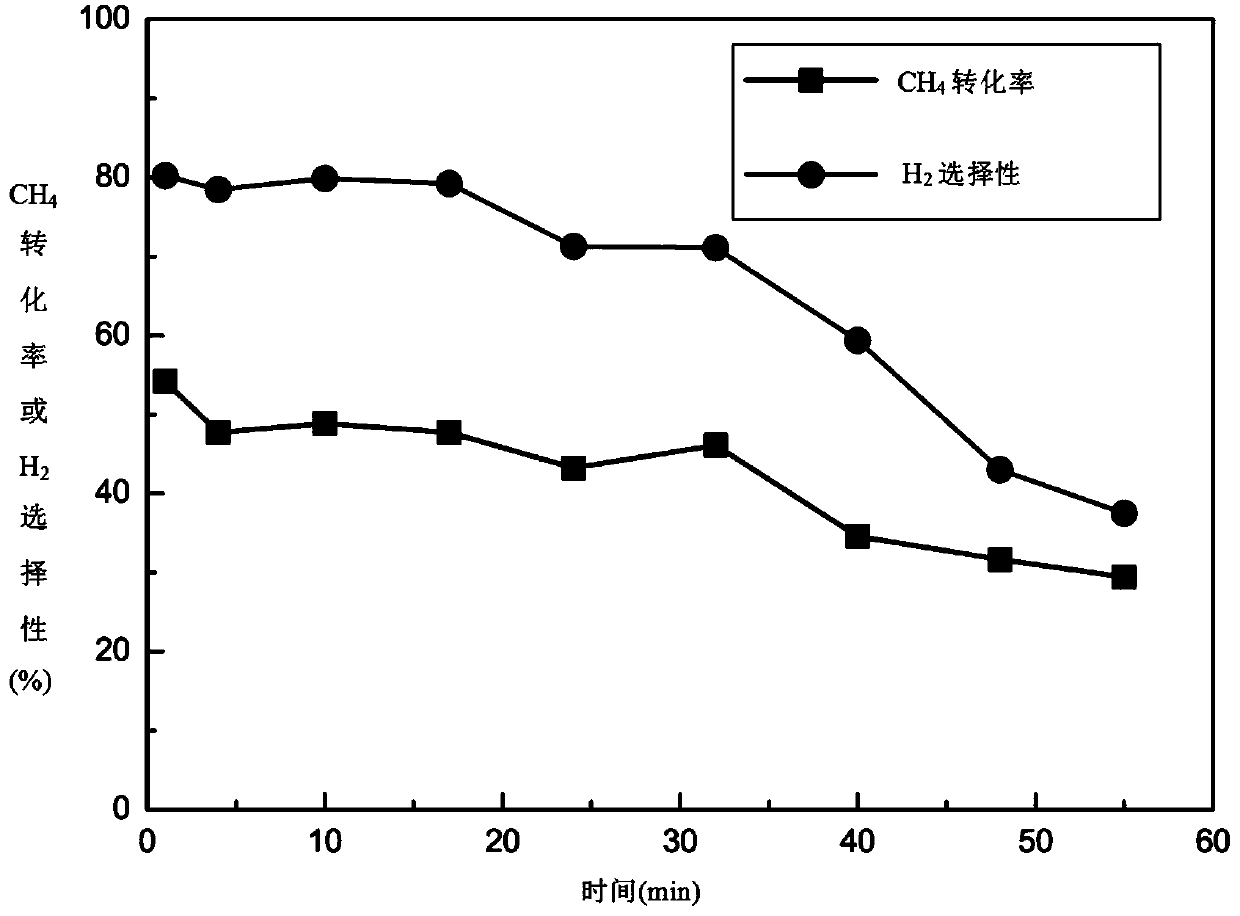

[0025] The microwave catalyst obtained according to Example 1 is used to catalyze the direct conversion of methane to hydrogen production, and the specific steps are as follows:

[0026] 1) Take a certain amount of Ni / Mo 2 C / γ-Al 2 o 3 The catalyst is placed in a microwave reactor device, and N 2 The flow rate was 80ml / min and the air was purged for 15min to remove the air in the reactor. Set the microwave power to 300-900W, start the microwave device, set the reaction temperature to 650°C, start the reaction device, and the instrument starts to heat up;

[0027] 2) When the reactor temperature reaches the set temperature, feed methane to start the reaction;

[0028] 3) Take the reacted gas with a gas sampling needle and pass it into an Agilent GC-7890A gas chromatograph for product analysis. Among them, TCD is used as a detector, N 2 As carrier gas, use Hayesep D packed column. Simultaneously record the reaction time and reaction temperature;

[0029] 4) According to ...

Embodiment 3

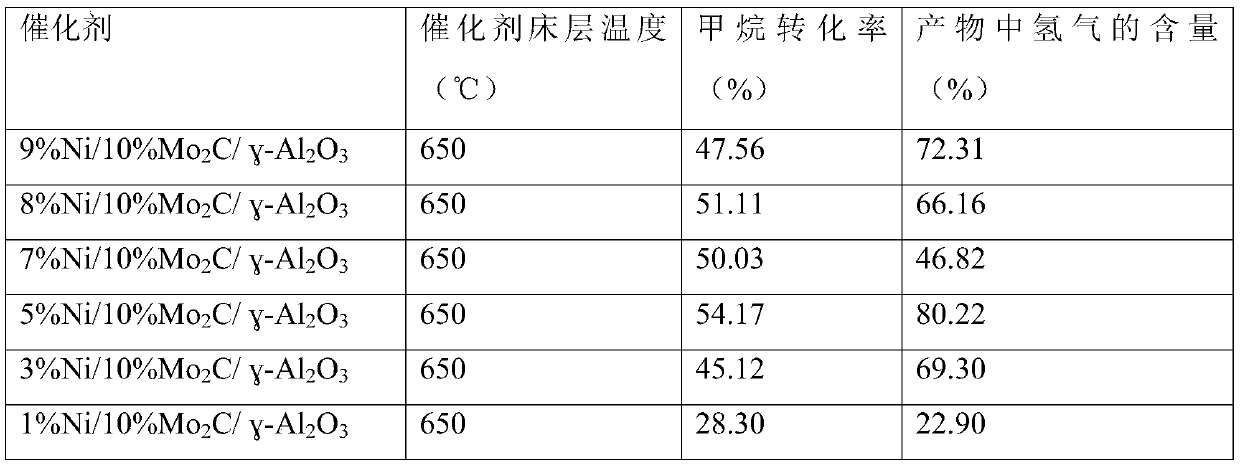

[0040] The consumption of catalyst is 1g, and catalyst bed temperature is 650 ℃, and reaction gas flow rate is 80ml / min, and reaction pressure is normal pressure, adopts 5%Ni / x%Mo 2 C / γ-Al 2 o 3 Composite nanostructured catalysts, investigating the same active components, different Mo 2 The effect of C loading on microwave catalytic methane conversion to hydrogen is shown in Table 3 for details.

[0041] table 3

[0042]

[0043] It can be seen from Table 3 that under microwave irradiation conditions, 5%Ni / x%Mo 2 C / γ-Al 2 o 3 Composite nanostructured catalysts for microwave-catalyzed methane reactions with 5% Ni / 10% Mo 2 C / γ-Al 2 o 3 The catalyst has the best effect, the methane conversion rate is 54.17%, and the hydrogen content in the product is 80.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com