Microtreatment and microstructure of carbide containing iron-based alloy

A technology of iron-based alloys and carbides, used in heat treatment equipment, manufacturing tools, quenching agents, etc., can solve problems such as reduced weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] According to the present invention, a new method of metal treatment is disclosed which results in the transformation of low-grade iron-based alloys into high-strength steels by extremely rapid heating of the metal followed by immediate rapid quenching of the material. The resulting steel is a heterogeneous composition of at least martensite, bainite, ferrite and other structures discussed in more detail below.

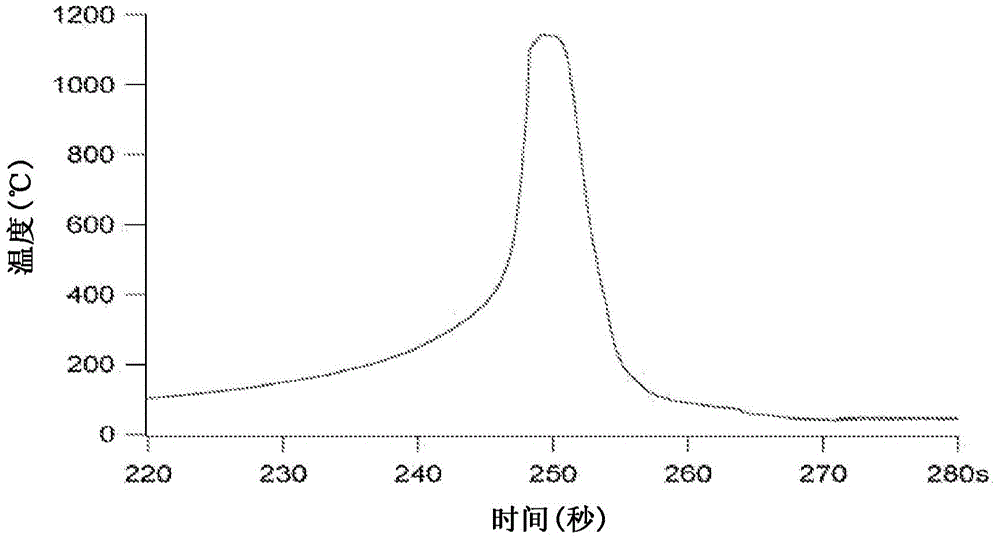

[0031] In this regard, our experiments show that rapid austenitization followed by rapid quenching has demonstrated the formation of a dual hardness microstructure, as illustrated in the accompanying drawings. Experiments have shown that rapid processing of materials with the designation AISI 4130 results in multiple hardness peaks around 525 and 625 Vickers hardness. The combination of hardness has been confirmed by single sensor differential thermal analysis, which shows a transition between the two temperature ranges during a single quenching operation. In A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com