Three-layer structural resin-based composite material and application thereof

A composite material and three-layer structure technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve problems such as low energy storage density, low breakdown strength, and large dielectric loss, and achieve Effects of high energy storage density, low dielectric constant, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

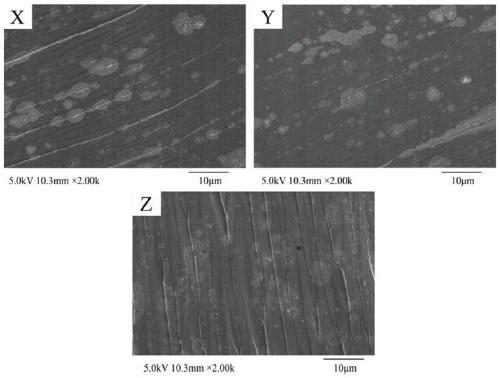

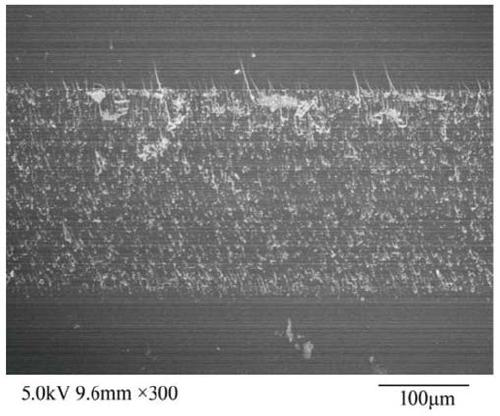

[0054] (1) Mix 0.12g of aligned carbon nanotube bundles without surface treatment (20-100μm in length, 2-5μm in diameter) and 20g of bisphenol A epoxy resin (brand E-51), and ultrasonically vibrate at 60°C After stirring for 10 min, add 0.8 g of 2-ethyl-4-methylimidazole, continue stirring for 10 min, and vacuum degassing at 60° C. for 20 min to obtain prepolymer A; divide prepolymer A into two parts equally, For the first prepolymer and the second prepolymer, take the first prepolymer and pour it into a preheated mold, then put the mold into a microwave oven and irradiate it for 5 cycles (each cycle of irradiation process medium heat, heating for 30 s, cooling for 10 s), and after natural cooling, an aligned carbon nanotube / epoxy cured resin composite pre-cured sheet B with a curing degree of 60% was obtained.

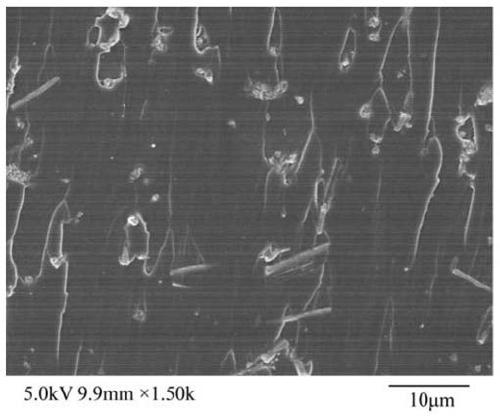

[0055] (2) Add 4.38g of barium acetate and 5.84g of tetrabutyl titanate into acetic acid (20mL) and mix well under magnetic stirring at 50°C, and add 5g of polyvinylp...

Embodiment 2

[0078] (1) Mix 0.02g of aligned carbon nanotube bundles without surface treatment (20-100μm in length, 2-5μm in diameter) and 20g of bisphenol A epoxy resin (brand E-51), and ultrasonically vibrate at 60°C After stirring for 10 min, add 0.8 g of 2-ethyl-4-methylimidazole, continue stirring for 10 min, and vacuum degassing at 60° C. for 20 min to obtain prepolymer A; divide prepolymer A into two parts equally, Take a part and pour it into a preheated mold, then put the mold into a microwave oven, and irradiate it for 5 cycles (each cycle of irradiation process is medium heat, heating for 30s, cooling for 10s), after natural cooling, it is solidified Oriented carbon nanotubes / epoxy cured resin composite material precured sheet B with a density of 60%.

[0079] (2) Mix 2g of the polydopamine-coated barium titanate nanofiber PDA@BTnf prepared in Example 1 with 20g of bisphenol A epoxy resin (brand E-51), and stir with ultrasonic vibration at 60°C for 10min. Add 0.8 g of 2-ethyl-4...

Embodiment 3

[0082] (1) Mix 0.12g of aligned carbon nanotube bundles without surface treatment (20-100μm in length, 2-5μm in diameter) and 20g of bisphenol A epoxy resin (brand E-51), and ultrasonically vibrate at 60°C After stirring for 10 min, add 0.8 g of 2-ethyl-4-methylimidazole, continue stirring for 10 min, and vacuum degassing at 60° C. for 20 min to obtain prepolymer A; divide prepolymer A into two parts equally, Take a part and pour it into a preheated mold, then put the mold into a microwave oven, and irradiate it for 5 cycles (each cycle of irradiation process is medium heat, heating for 30s, cooling for 10s), after natural cooling, it is solidified Oriented carbon nanotubes / epoxy cured resin composite material precured sheet B with a density of 60%.

[0083] (2) Mix 6g of polydopamine-coated barium 0 acid nanofiber PDA@BTnf prepared in Example 1 and 20g of bisphenol A epoxy resin (brand E-51), and stir at 60°C for 10min with ultrasonic vibration, Add 0.8 g of 2-ethyl-4-methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com