A method for preparing nanofiber-based composite nanofiltration membranes by low-temperature reverse interfacial polymerization

A composite nanofiltration membrane and nanofiber technology, which is applied in the field of preparation of separation composite membranes, can solve problems such as surface defects and infiltration of polyamide skins, and achieves the effect of being beneficial to practical application and popularization, and the membrane preparation method is simple and feasible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

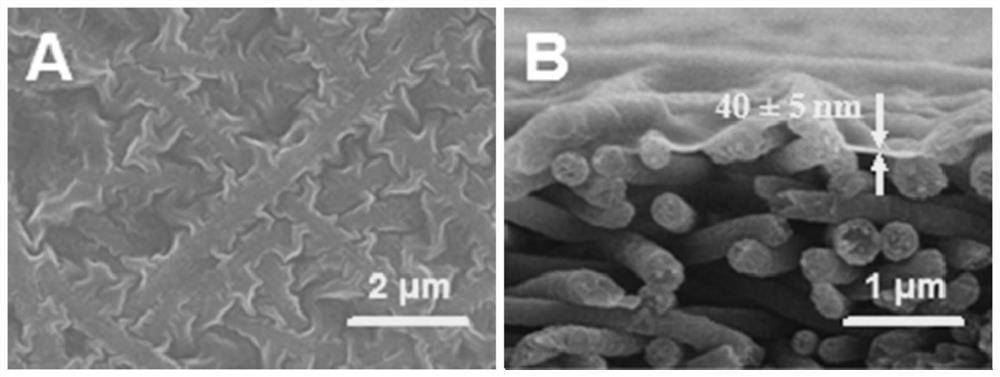

Embodiment 1

[0037] This example provides a method for preparing a nanofiber-based composite nanofiltration membrane by low-temperature reverse interfacial polymerization, and the specific steps are:

[0038] (1) Polyacrylonitrile (M w =120,000g / mol) powder was placed in a vacuum oven at 40°C and dried for 48h, then an appropriate amount of polyacrylonitrile powder was taken to prepare polyacrylonitrile (PAN) / N,N-dimethylformamide (PAN) / N,N-dimethylformamide ( DMF) solution, stirred at 40°C for 6h to obtain a transparent and uniform electrospinning solution;

[0039] (2) Add the electrospinning solution in step (1) into the syringe for electrospinning. The electrospinning parameters are as follows: the voltage is 19kV, the inner diameter of the spinneret is 0.2mm, and the solution supply rate is 1mL / h. The ambient temperature of the silk is 25°C, the relative humidity of the air is 35%, the receiving distance is 12cm, and the rotating speed of the receiving drum is 800r / min. After the ele...

Embodiment 2

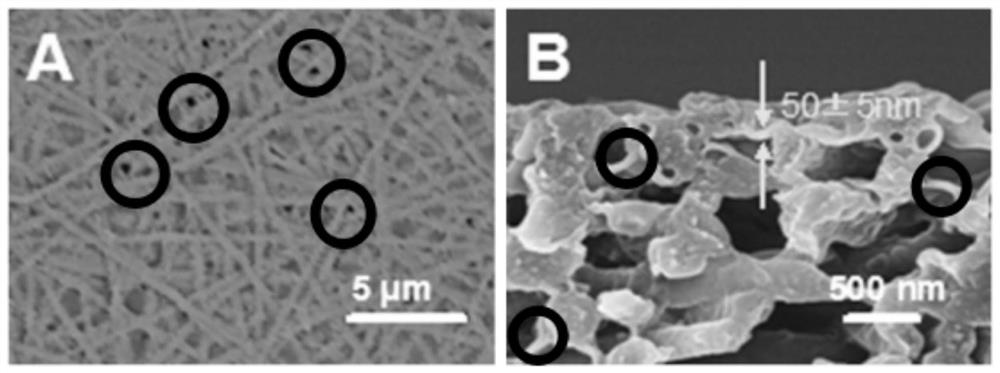

[0046] This example provides a method for preparing a nanofiber-based composite nanofiltration membrane by low-temperature reverse interfacial polymerization, and the specific steps are:

[0047] (1) Polyacrylonitrile (M w =120,000g / mol) powder was placed in a vacuum oven at 40°C and dried for 48h, then an appropriate amount of polyacrylonitrile powder was taken to prepare polyacrylonitrile (PAN) / N,N-dimethylformamide (PAN) / N,N-dimethylformamide ( DMF) solution, stirred at 40°C for 6h to obtain a transparent and uniform electrospinning solution;

[0048] (2) Add the electrospinning solution in step (1) into the syringe for electrospinning. The electrospinning parameters are as follows: the voltage is 19kV, the inner diameter of the spinneret is 0.2mm, and the solution supply rate is 1mL / h. The ambient temperature of the silk is 25°C, the relative humidity of the air is 35%, the receiving distance is 12cm, and the rotating speed of the receiving drum is 300r / min. After the ele...

Embodiment 3

[0055] This example provides a method for preparing a nanofiber-based composite nanofiltration membrane by low-temperature reverse interfacial polymerization, and the specific steps are:

[0056] (1) Polyacrylonitrile (M w =120,000g / mol) powder was placed in a vacuum oven at 40°C and dried for 48h, then an appropriate amount of polyacrylonitrile powder was taken to prepare polyacrylonitrile (PAN) / N,N-dimethylformamide (PAN) / N,N-dimethylformamide ( DMF) solution, stirred at 40°C for 6h to obtain a transparent and uniform electrospinning solution;

[0057] (2) Add the electrospinning solution in step (1) into the syringe for electrospinning. The electrospinning parameters are as follows: the voltage is 19kV, the inner diameter of the spinneret is 0.2mm, and the solution supply rate is 1mL / h. The ambient temperature of the silk is 25°C, the relative humidity of the air is 35%, the receiving distance is 12cm, and the rotating speed of the receiving drum is 300r / min. After the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com