Composite flat-sheet polysulfone membrane doped with active carbon and nanometer zinc oxide and preparation method thereof

A technology of nano-zinc oxide and activated carbon, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as membrane pollution, achieve the effects of improving hydrophilicity, strong practical applicability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

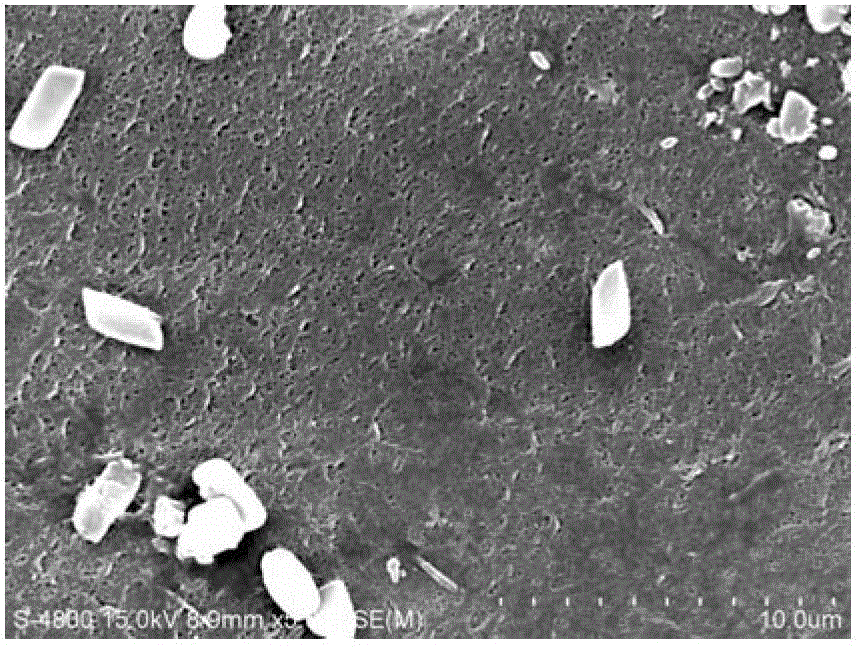

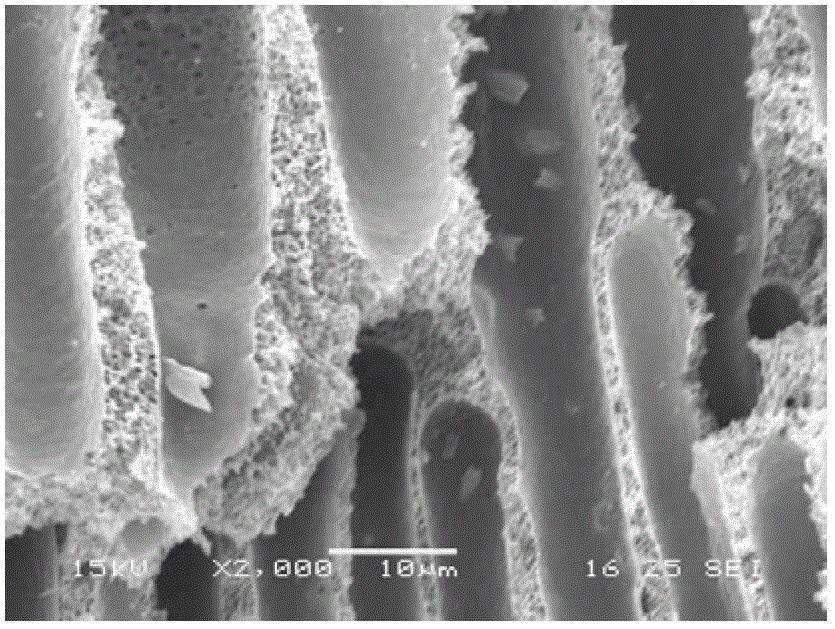

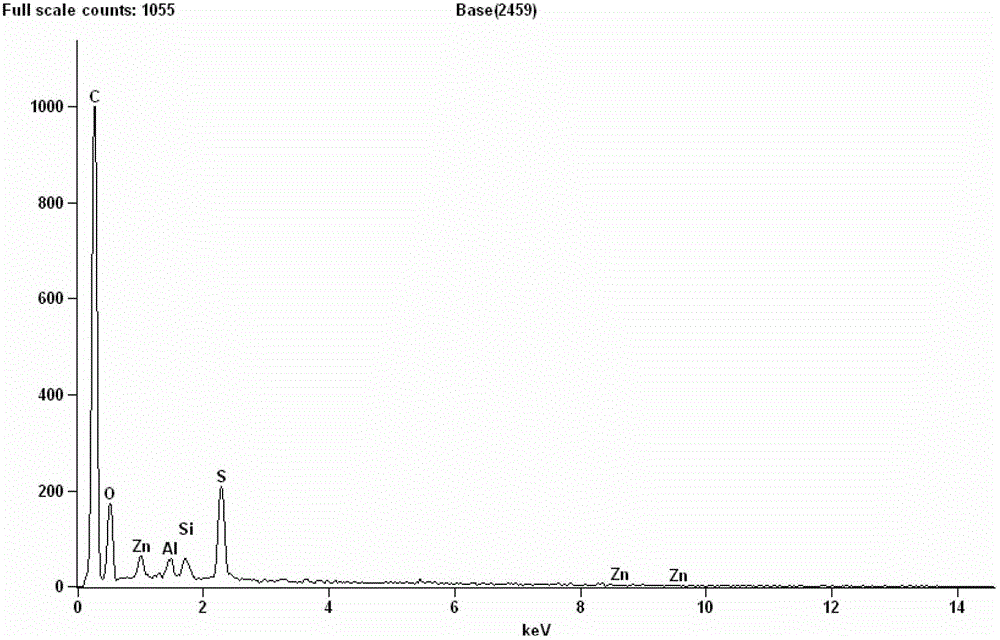

Image

Examples

Embodiment 1

[0021] (1) A preparation method of a composite flat polysulfone membrane doped with activated carbon and nano-zinc oxide of the present invention:

[0022] In the first step, the activated carbon and nano-zinc oxide were cleaned with deionized water, and then centrifuged after ultrasonication for 40 minutes. The polysulfone was washed with deionized water and ultrasonically for 40 minutes. In the drying box, the drying time is 24h.

[0023] In the second step, take nano-zinc oxide, activated carbon, polysulfone, and 1-methyl-2-pyrrolidone at a mass percentage of 0.5:5:20:100 to prepare a casting solution: take 100g of 1-methyl-2-pyrrolidone and place it in a conical bottle; then put 0.5g of nano-zinc oxide in the above-mentioned conical flask, disperse and stir evenly through ultrasonic vibration; then place 5g of activated carbon in the above-mentioned conical flask, disperse and stir evenly through ultrasonic vibration; finally put 20g polysulfone The particles were placed ...

Embodiment 2

[0030] (1) A preparation method of a composite flat polysulfone membrane doped with activated carbon and nano-zinc oxide of the present invention:

[0031] In the first step, the activated carbon and nano-zinc oxide were cleaned with deionized water, and then centrifuged after ultrasonication for 40 minutes. The polysulfone was washed with deionized water and ultrasonically for 40 minutes. In the drying box, the drying time is 24h.

[0032] In the second step, take nano-zinc oxide, activated carbon, polysulfone, and 1-methyl-2-pyrrolidone at a mass percentage of 1:5:20:100 to prepare a casting solution: take 100g of 1-methyl-2-pyrrolidone in 250ml Erlenmeyer flask; then 1g of nano zinc oxide is placed in the above-mentioned conical flask, dispersed and stirred uniformly through ultrasonic vibration; then 5g of activated carbon is placed in the above-mentioned conical flask, dispersed and uniformly stirred through ultrasonic vibration; finally 20g poly The sulfone particles we...

Embodiment 3

[0039] (1) Preparation method of composite flat polysulfone membrane only doped with activated carbon

[0040] In the first step, the activated carbon is cleaned with deionized water, and then centrifuged after ultrasonication for 40 minutes, then the polysulfone is washed with deionized water, ultrasonicated for 40 minutes, and then the activated carbon and polysulfone are placed in a vacuum drying oven at 80°C for 24 hours. .

[0041] In the second step, take activated carbon, polysulfone, and 1-methyl-2-pyrrolidone to prepare a casting solution with a mass percentage of 1:4:20: take 100g of 1-methyl-2-pyrrolidone and place it in a 250ml Erlenmeyer flask; Put 5g of activated carbon in the above-mentioned conical flask, disperse and stir evenly through ultrasonic vibration; finally put 20g of polysulfone particles in the above-mentioned conical flask, stir on a magnetic stirrer at 60°C for 8h until the solution is completely dissolved; put the dissolved The solution was plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com