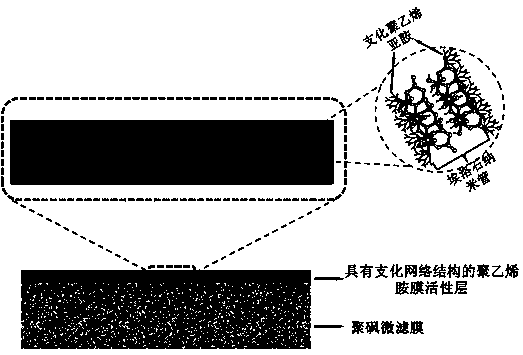

Polyvinylamine film with branched network structure as well as preparation method and application of film

A polyvinylamine membrane and network structure technology, applied in chemical instruments and methods, separation methods, membranes, etc., can solve the problems of low transfer efficiency and poor molecular chain mobility, and achieve cheap and easy-to-obtain materials and good interface compatibility. , The effect of the film making method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: The preparation of the polyvinylamine film with branched network structure according to the present invention, the steps are as follows:

[0037] (1) Take a porous polysulfone filter membrane with a molecular weight cut-off of 6000 as a supporting membrane, soak it in 2% ethylenediamine aqueous solution at 30°C for 72 hours, wash and dry it before use, and name it product A.

[0038](2) Preparation of polyethyleneimine-modified halloysite nanotube composite material: 0.00625 g of polyethyleneimine was added to 50 mL of deionized water to prepare polyethyleneimine aqueous solution. Under the magnetic stirring condition that the temperature is 25 °C and the rotating speed is 60rpm, 1g halloysite nanotubes are added to the above-mentioned polyethyleneimine aqueous solution according to 50mg / min to obtain the mixture of polyethyleneimine and halloysite nanotubes. Mix the solution and keep stirring for 90 min, so that the polyethyleneimine is loaded on the hall...

Embodiment 2

[0041] Embodiment 2: The preparation of the polyvinylamine film with branched network structure according to the present invention, the steps are as follows:

[0042] (1) Take a porous polysulfone filter membrane with a molecular weight cut-off of 6000 as a supporting membrane, soak it in 2% ethylenediamine aqueous solution at 30°C for 72 hours, wash and dry it before use, and name it product A.

[0043] (2) Preparation of polyethyleneimine-modified halloysite nanotube composite material: 0.0125 g of polyethyleneimine was added to 50 mL of deionized water to prepare polyethyleneimine aqueous solution. Under the magnetic stirring condition that the temperature is 25 °C and the rotating speed is 60rpm, 1g halloysite nanotubes are added to the above-mentioned polyethyleneimine aqueous solution according to 50mg / min to obtain the mixture of polyethyleneimine and halloysite nanotubes. Mix the solution and keep stirring for 90 min, so that the polyethyleneimine is loaded on the hall...

Embodiment 3

[0046] Embodiment 3: The preparation of the polyvinylamine film with branched network structure according to the present invention, the steps are as follows:

[0047] (1) Take a porous polysulfone filter membrane with a molecular weight cut-off of 6000 as a supporting membrane, soak it in 2% ethylenediamine aqueous solution at 30°C for 72 hours, wash and dry it before use, and name it product A.

[0048] (2) Preparation of polyethyleneimine-modified halloysite nanotube composite material: 0.025 g of polyethyleneimine was added to 50 mL of deionized water to prepare polyethyleneimine aqueous solution. Under the magnetic stirring condition that the temperature is 25 °C and the rotating speed is 60rpm, 1g halloysite nanotubes are added to the above-mentioned polyethyleneimine aqueous solution according to 50mg / min to obtain the mixture of polyethyleneimine and halloysite nanotubes. Mix the solution and keep stirring for 90 min, so that the polyethyleneimine is loaded on the hallo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com