Method for desalting sewage by using membrane separation technology

A membrane separation and sewage technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low water production rate, long pretreatment process, membrane pollution, etc. Achieve the effect of reducing pollution, low hardness of produced water and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

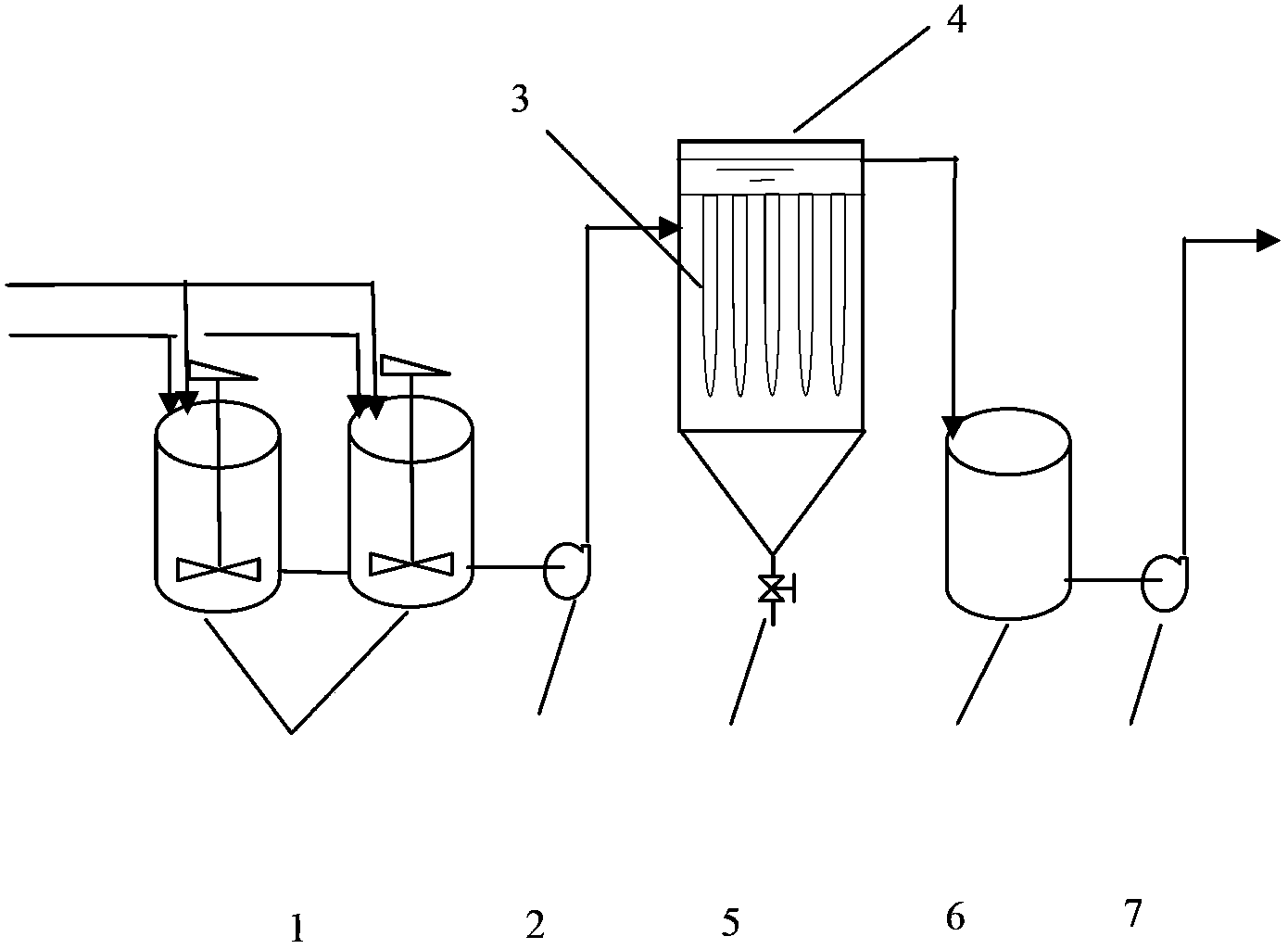

[0029] like figure 1 As mentioned above, the reverse osmosis concentrated water after reuse of sewage from a petrochemical enterprise enters the stirring reaction tank 1, and sodium hydroxide is added to adjust the pH to 10.4-11.0. Microfiltration tubular membrane filter 4. The microfiltration tubular membrane 3 has a pore size of 0.2 μm, and the filtration method is dead-end filtration. The produced water enters the water production tank 6 and enters the reverse osmosis system through the pump 7, and the concentrated water enters the sludge tank through the slag discharge pipeline 5. The reverse osmosis water production rate is 67-85%. See attached table 1 for the water quality, microfiltration and reverse osmosis treatment effects.

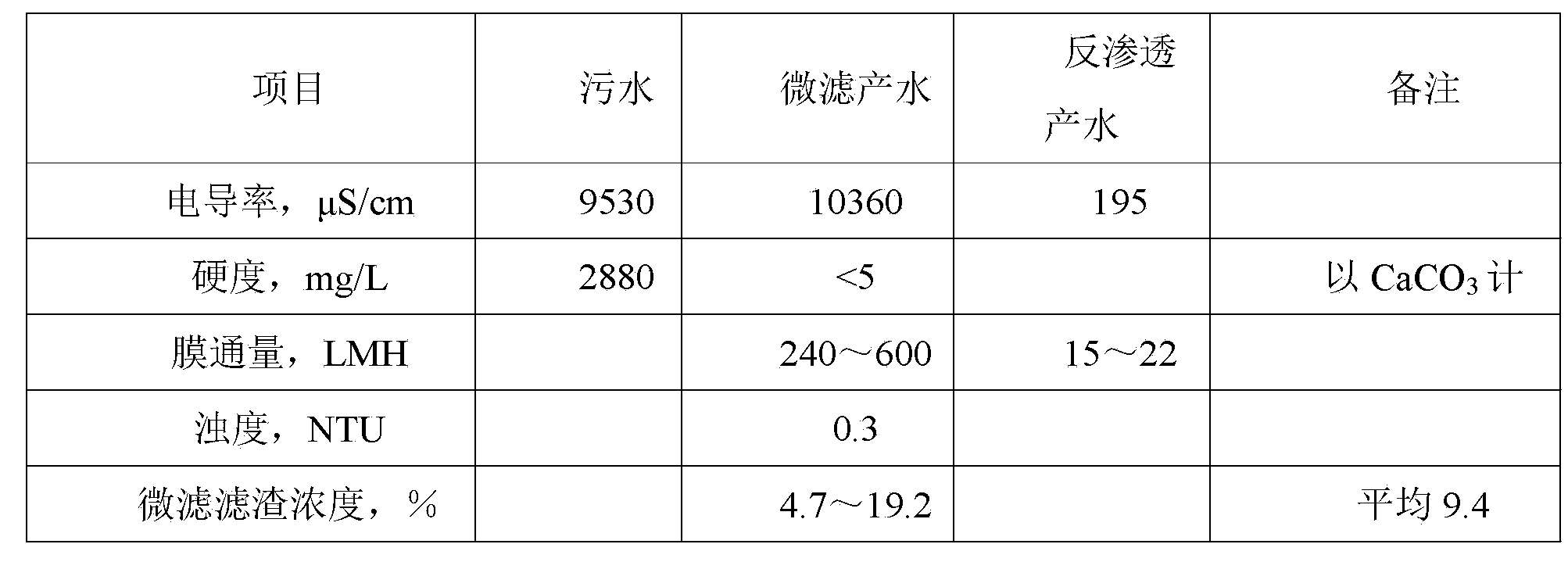

[0030] Table 1

[0031]

Embodiment 2

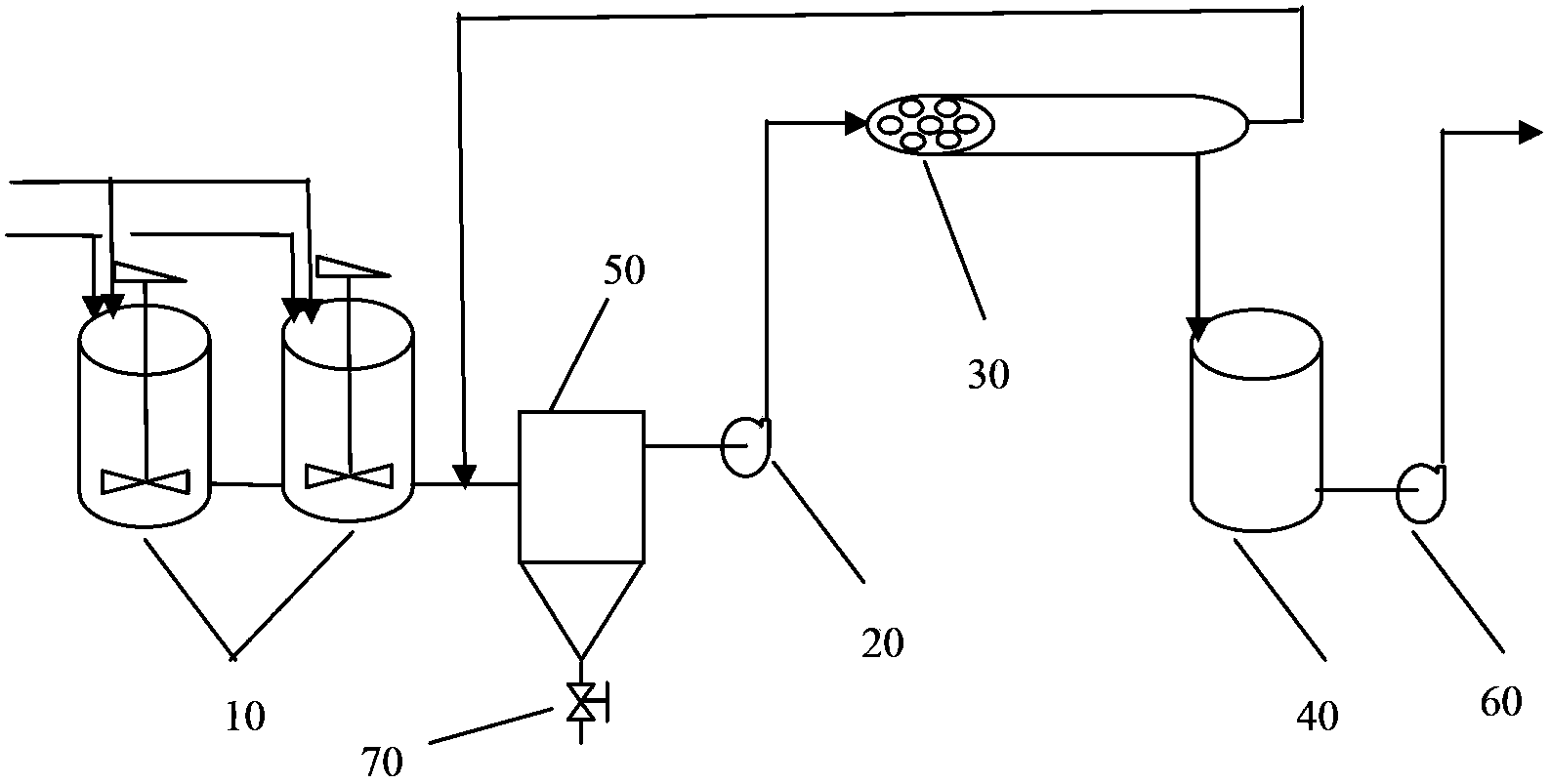

[0033] like figure 2 As shown, a certain oilfield sewage enters the stirring reaction tank 10, and sodium hydroxide is added to adjust the pH to 9.5 to 10.2, and sodium carbonate is added according to the molar ratio of calcium, magnesium and carbonate of 1:1.1 to 1.3, and the stirring time is 1 hour respectively. The 2-stage mixing and stirring is transported to the internal pressure type microfiltration tube type microfiltration membrane 30 through the pump 20, the membrane pore size is 0.1 μm, the filtration method is cross-flow filtration, the control flux is 400-800LMH, the cross-flow rate is 260-400%, and the filtration The last concentrated water enters the concentrated water tank 50 and enters the sludge thickening tank through the slag discharge pipeline 70 . The water produced by the microfiltration enters the water production tank 40, and enters the reverse osmosis system through the pump 60, and the reverse osmosis water production rate is 60-70%. See attached ta...

Embodiment 3

[0037] Calcium hydroxide was added to the sewage of a coal chemical industry to adjust the pH to 9.3-10.5. Carbon dioxide is added according to the molar ratio of calcium, magnesium and carbonate of 1:1.1-1.5. After 2-stage mixing and stirring with a stirring time of 40 minutes, it was lifted to a microfiltration hollow fiber filter by a pump. The pore size of the microfiltration membrane is 0.2 μm, the filtration method is dead-end filtration, and the concentrated water is discharged to the sludge tank. The water produced by microfiltration enters the reverse osmosis system, and the water production rate is 65-74%. See attached table 3 for the water quality, microfiltration and reverse osmosis treatment effects.

[0038] table 3

[0039] Analysis Project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com