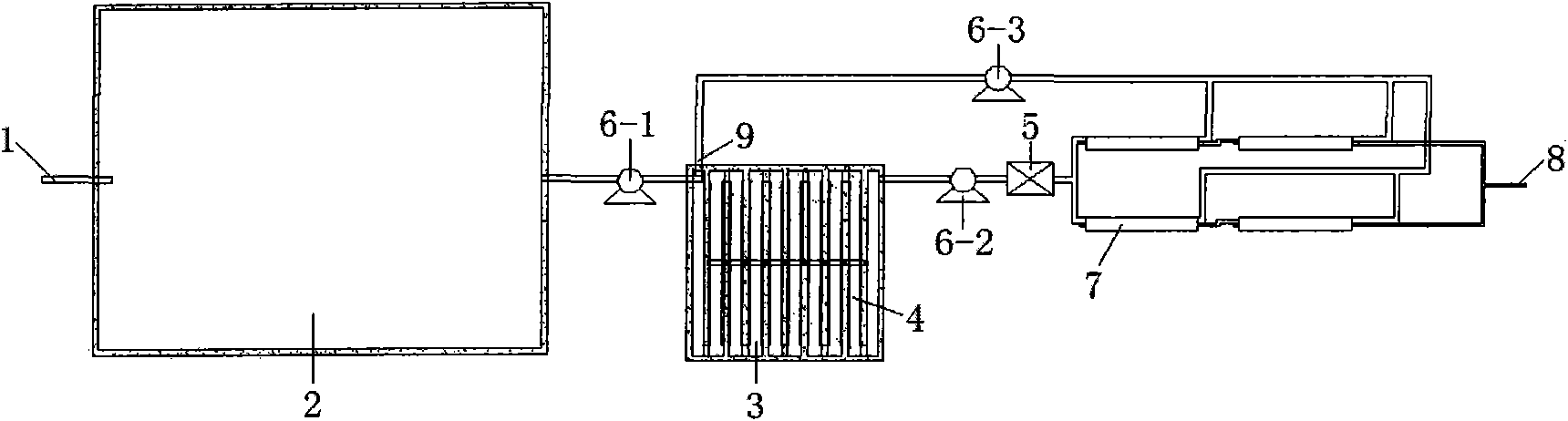

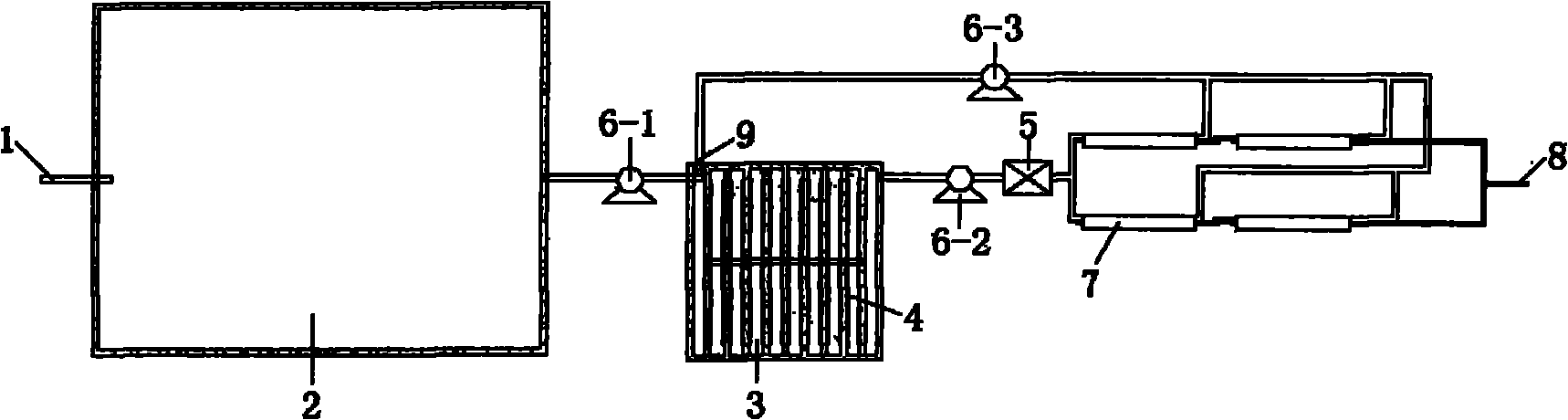

Electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater

An electrodeposition device and treatment device technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of excessive heavy metal content in wastewater, limit chemical sedimentation process, and treatment efficiency Low-level problems, to achieve the effect of large processing capacity, low energy consumption, and easy manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The wastewater passes through the adjustment tank 2 from the liquid inlet pipe 1, and then enters the electrodeposition device 3 from the adjustment tank to deposit heavy metals. The terminal part of the electrodeposition device 3 is added with conductive fillers to form a three-dimensional fixed bed device 4. After a certain period of chemical After reduction, oxidation, adsorption and other reactions, the waste water flows into the security filter 5, where the preliminary separation is realized. The clear liquid can be directly discharged from the clear water outlet 8 for reuse, and the concentrated liquid returns to the electrodeposition device 3 through the concentrated liquid return hole 9, and the system completes a batch of circulating work. Multistage low pressure reverse osmosis membrane, the operating pressure is 1.0 MPa, and the operating temperature is 40 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com