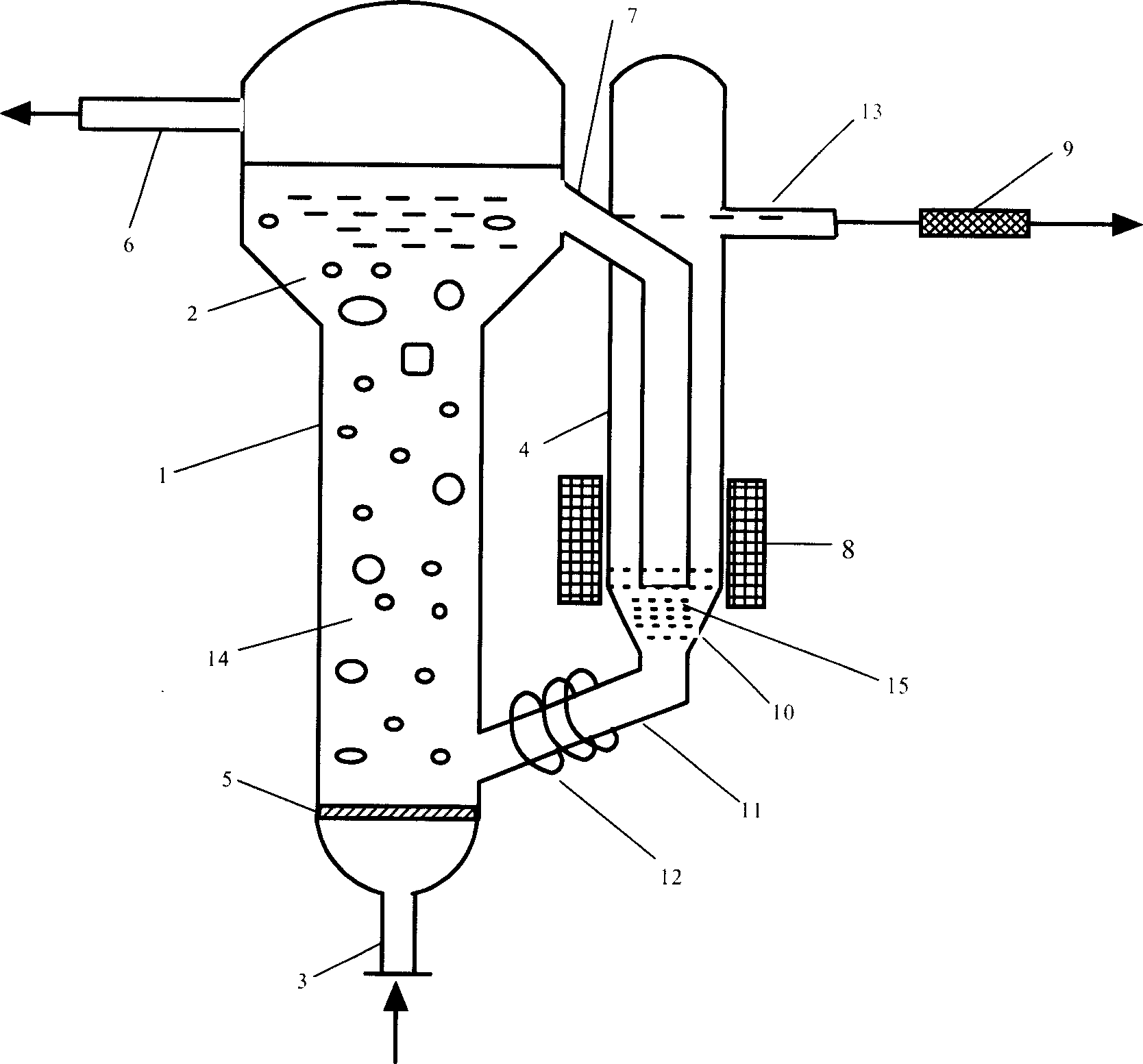

Slurry ¿Cbed reaction unit and method of use thereof

A reaction equipment and slurry bed technology, which is applied to slurry bed reaction equipment and its application fields, can solve the problems of heavy equipment, difficulty in generating a uniform magnetic field in a reactor, demagnetization of catalysts, etc., so as to improve space utilization and achieve continuous and efficient separation. , the effect of small size of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The height of the reactor is 10m, the pipe diameter of the reaction zone is 300mm, the pipe diameter of the settling zone is 600mm, and the height of the settling zone is 25% of the total height of the reactor; the reaction raw material is synthesis gas, wherein the volume percentage is: hydrogen is 66 %, carbon monoxide is 34%, the volumetric space velocity is: 1200h -1 The catalyst is a cobalt-based catalyst produced by DEGUSSA Company, the brand is B2112Z, and the average particle size of the catalyst is 80 microns; the reaction temperature of the reactor is 260 ° C, and the pressure is 1.8 MPa; The degaussing area adopts an alternating current of 150 kilohertz; the filter system adopts a ceramic membrane with an average pore size of 0.5 micron as the filter medium, adopts the method provided by the invention to react, and the solid particle size in the product is detected below 1 micron. The solid particle content within the diameter range is 0.1% of the total amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com