Evaluation method for condensation effect of hydrogen iodide in iodine-containing hydriodic acid by using electrolysis-electrodialysis device

An evaluation method, electrodialysis technology, applied in the field of electrochemistry, can solve problems such as heavy workload and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

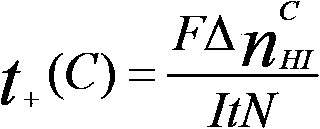

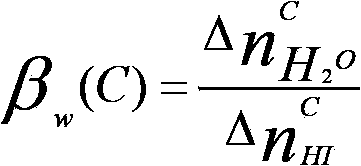

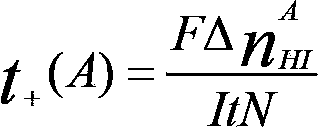

[0071] Embodiment 1: the effective membrane area of proton selective permeable membrane is 25cm 2 The 2-piece electrolysis-electrodialysis device (including 1 electrolysis-electrodialysis unit, that is, only includes one cathode area and one anode area) is used for performance evaluation, in which, the volume V of the cathode area and the auxiliary pipeline of the cathode area c is 40ml, the volume V of the anode area and the auxiliary pipeline in the anode area a Be 50ml, take by weighing the iodine-containing hydroiodic acid feed liquid that determines each component concentration to form by titration and material balance, in this hydroiodic acid feed liquid, HI, I 2 、H 2 The molar ratio of O is 1:1.42:5.50, and 530.55g and 538.03g of the hydroiodic acid feed liquid are respectively used as the initial feed liquid of the cathode and anode bipolar regions. At 60°C, the current intensity I=3.75A (that is, the current density is 0.15 A / cm 2 ) conditions, keep the feed liqu...

Embodiment 2

[0076] Embodiment 2: To 5 stacked electrolysis-electrodialysis devices (containing 4 electrolysis-electrodialysis units, the effective membrane area of each unit is 25cm 2 ) for performance evaluation, wherein, the volume V of the cathode area and the auxiliary pipeline of the cathode area c is 60ml, the volume V of the anode area and the auxiliary pipeline in the anode area a Be 75ml, take by weighing the iodine-containing hydroiodic acid feed liquid that determines each component concentration to form by titration and material balance, this hydroiodic acid feed liquid HI, I 2 、H 2 The molar ratio of O is 1:1.80:5.50, and 523.82g and 543.45g of this hydriodic acid feed solution are respectively used as the initial feed solution of the cathode and anode bipolar regions. A / cm 2 ) conditions, keep the feed liquid in the cathode and anode regions circulating in the cathode and anode pools, corresponding storage tanks, and auxiliary pipelines respectively, and the electrolysi...

Embodiment 3

[0081] Embodiment 3: to 11 stacked electrolysis-electrodialysis devices (containing 10 electrolysis-electrodialysis units, the effective membrane area of each unit is 100cm 2 ) for performance evaluation, wherein, the volume V of the cathode area and the auxiliary pipeline of the cathode area c is 270ml, the volume V of the anode area and the auxiliary pipeline in the anode area a Be 297ml, take by weighing the iodine hydroiodic acid feed solution that determines each component concentration to form by titration and material balance, with 5003.3g HI, I 2 、H 2 O mol ratio is the hydroiodic acid feed liquid of 1:2.60:5.20 and 5018.1gHI, I 2 、H 2 The hydriodic acid feed solution with O molar ratio of 1:2.60:5.20 is used as the initial feed solution of the cathode and anode bipolar regions respectively. At 100°C, the current intensity I=15A (that is, the current density is 0.15A / cm 2 ) conditions, keep the feed liquid in the cathode and anode regions circulated in the cathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com