Wastewater zero-emission industrial sewage treatment system and treatment method

A technology for industrial sewage and treatment systems, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply conservation, etc., can solve the problems of inability to achieve effective separation and utilization of sewage substances, secondary environmental pollution, sewage Environmental risks and hidden dangers of the temporary storage pool, etc., to achieve the effect of convenient and reliable use, reasonable structural composition, and reduced impact and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

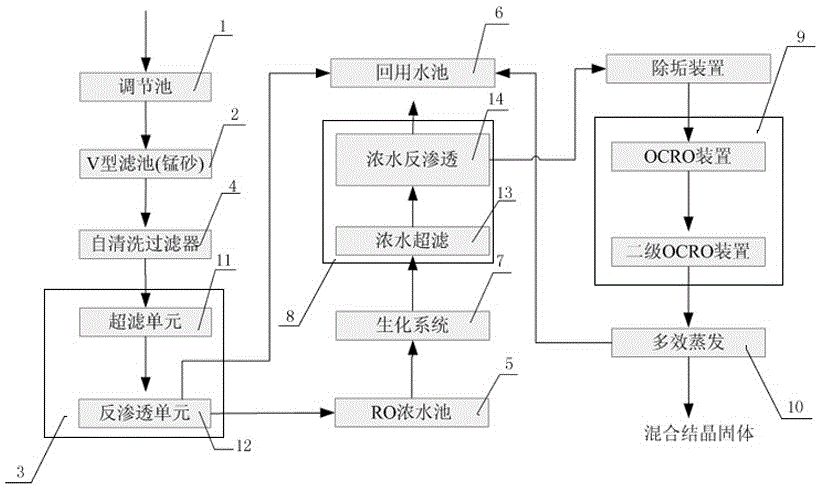

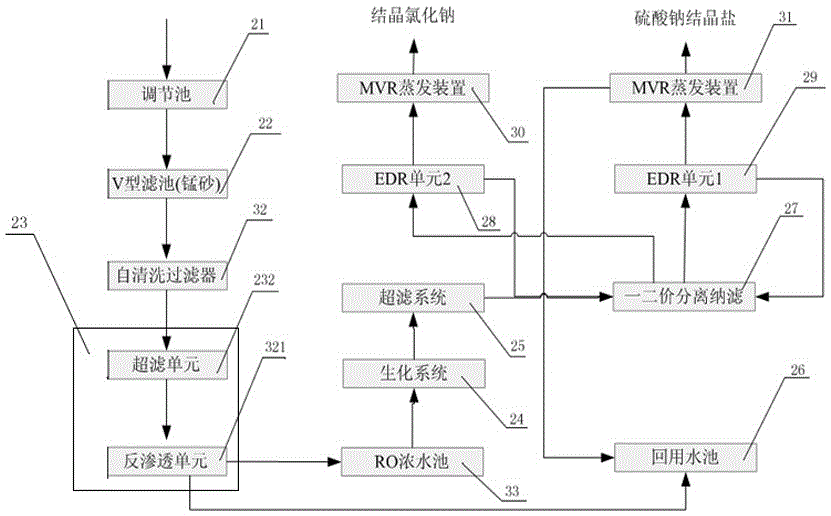

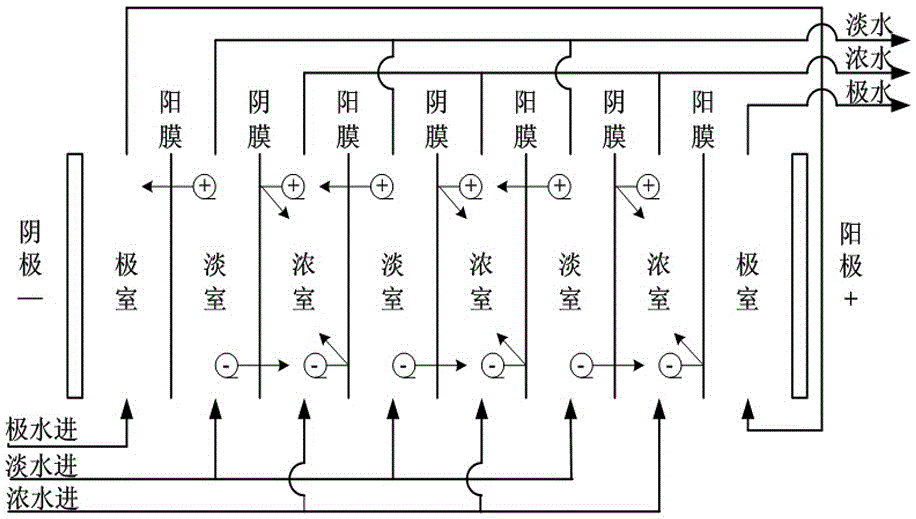

[0072] figure 2 As shown, the sewage treatment system adopted in the present invention mainly includes: "ultrafiltration + reverse osmosis + nanofiltration (NF) + frequent reversed electrodialysis system (EDR) + MVR evaporation device".

[0073] After the biochemical treatment, each stream of influent first enters the adjustment tank of the water recycling device, and then is homogenized and uniformly upgraded to the pretreatment system, namely the V-shaped filter tank. The suspended solids and colloidal substances in the sewage are removed by sand filtration. The filter material in the filter tank adopts a special filter material, which has the function of removing cobalt and manganese ions. The sand filtered water enters the "ultrafiltration + reverse osmosis". The main function of the ultrafiltration device is to separate suspended solids, macromolecular colloids, slime, microorganisms, organic matter and other impurities that can block the reverse osmosis membrane, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com