A fully automatic high temperature plasma solid waste gasification melting furnace

A plasma, fully automatic technology, applied in the direction of plasma, incinerator, electrical components, etc., can solve problems such as occupying large land and space, secondary pollution, polluting the environment and groundwater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

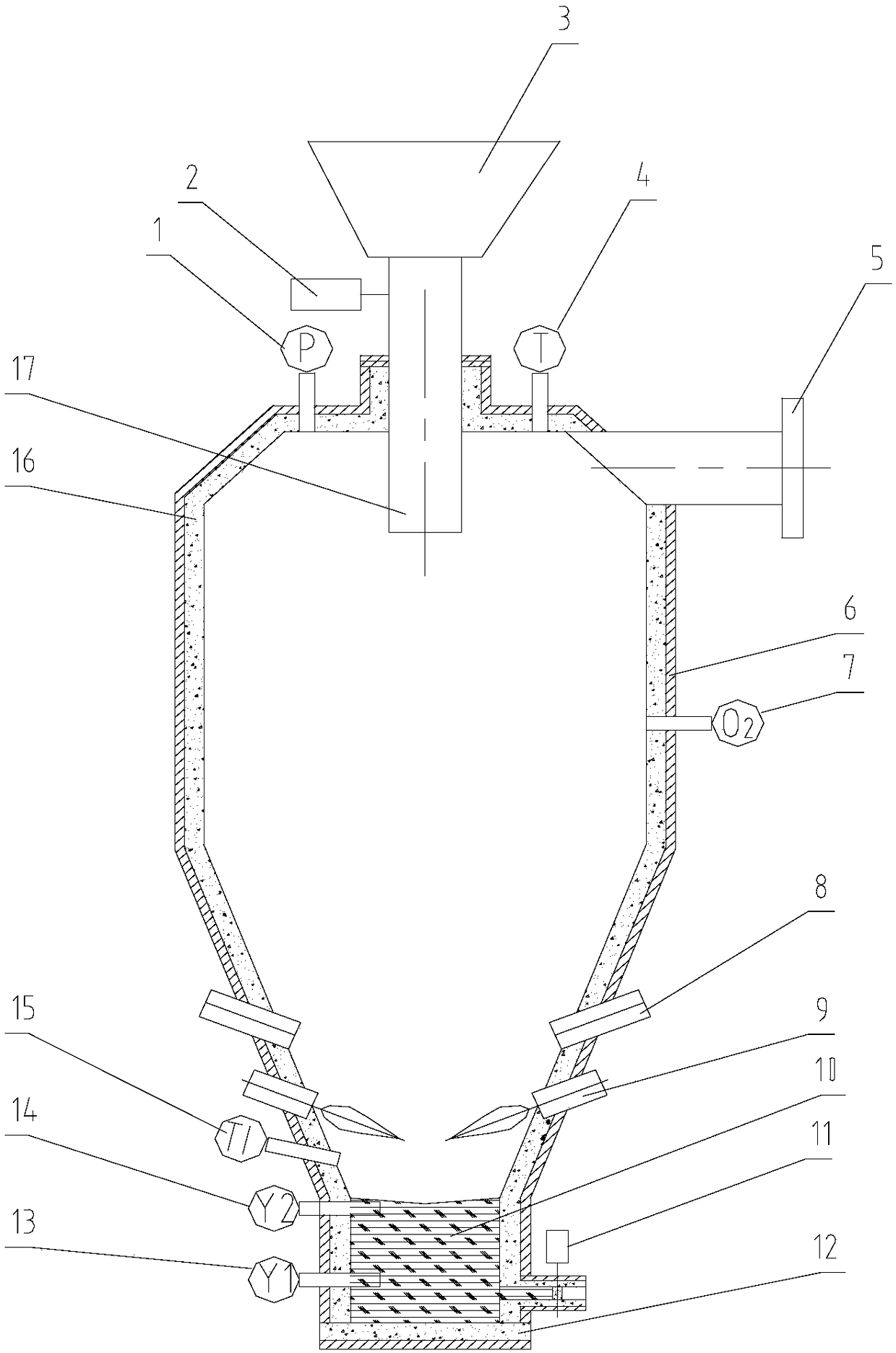

[0029] Such as figure 1 As shown, a fully automatic high-temperature plasma solid waste gasification melting furnace includes a furnace body 6, a frequency conversion feeding system arranged on the top of the furnace body 6, a melting pool 10 arranged at the bottom of the furnace body 6 and a discharge tank connected to the melting pool 10. The slurry valve is located at the gas outlet 5 on one side of the upper part of the furnace body 6; the lower end of the furnace body 6 is provided with a group of plasma generators 9, which are arranged at the upper end of the ion generator and form a certain angle with the vertical line of the center of the furnace body 6. A set of swirl nozzles 8, a temperature thermocouple 15 and an oxygen level detector 7 are respectively provided outside the furnace body 6, and a first liquid level detector 13 and a second liquid level detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com