Method for treating aromatic compound nitrification wastewater

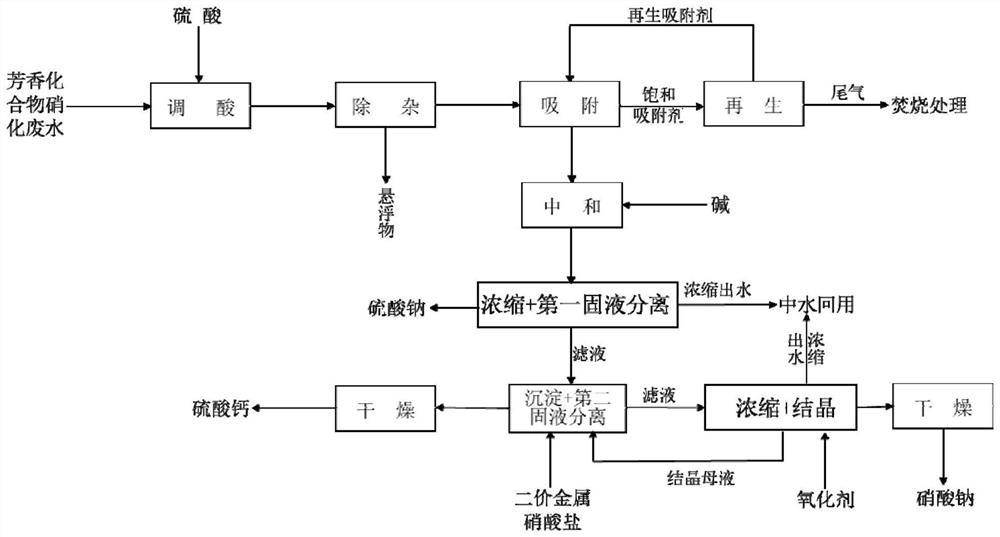

A technology for aromatic compounds and nitrification wastewater, which is applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., and can solve the problems of secondary pollutants, such as solid waste iron sludge, ineffective decomposition of ozone, and increased treatment costs. Achieve the effect of recycling and zero emissions, reducing impact and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

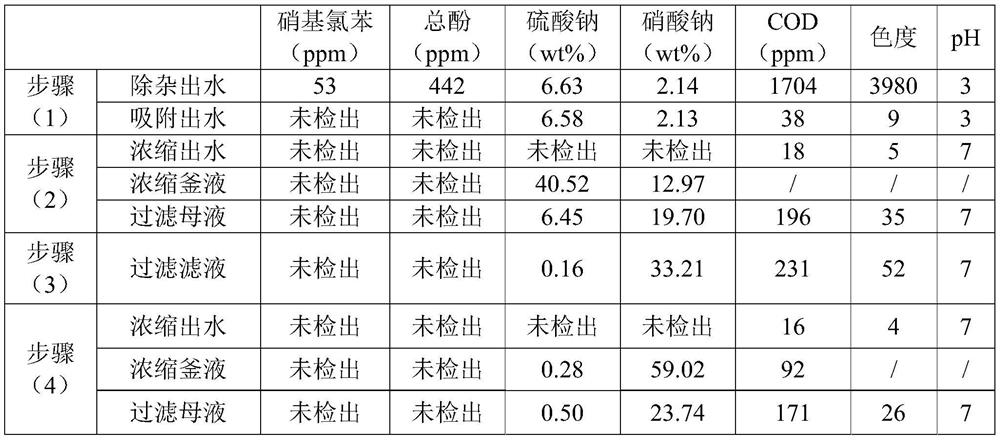

[0090] The present embodiment provides a kind of treatment method to adjacent nitric acid waste water, and described treatment method comprises the following steps:

[0091] (1) pump the adjacent nitric acid wastewater into the acid adjustment tank, add sulfuric acid to adjust the acid until the pH is 3, acidify the sodium phenate in the wastewater into phenol, remove the suspended solids in the wastewater through a 300-mesh filter, and obtain the impurity-removed effluent;

[0092] The adsorption tower is filled with coal-based columnar activated carbon with an iodine value of about 1100. The adsorption tower adopts the form of 3 towers in series, adopts the method of top in and bottom out, the temperature is 30°C, and the inflow flow rate is 1BV / h to obtain the adsorption effluent;

[0093] When the effluent COD of the first adsorption tower reaches 500ppm and reaches saturation, switch to regeneration. After washing, drying, thermal cracking and other processes, the saturate...

Embodiment 2

[0104] The present embodiment provides a kind of treatment method to adjacent nitric acid waste water, and described treatment method comprises the following steps:

[0105] (1) pump the adjacent nitric acid wastewater into the acid adjustment tank, add sulfuric acid to adjust the acid until the pH is 1, acidify the sodium phenate in the wastewater into phenol, remove the suspended solids in the wastewater through a 300 mesh filter, and obtain the impurity-removed effluent;

[0106] The adsorption tower is filled with coal-based columnar activated carbon with an iodine value of about 1100. The adsorption tower adopts the form of 3 towers in series, adopts the method of top in and bottom out, the temperature is 5°C, and the inflow flow rate is 10BV / h to obtain the adsorption effluent;

[0107] When the effluent COD of the first adsorption tower reaches 500ppm and reaches saturation, switch to regeneration. After washing, drying, thermal cracking and other processes, the saturate...

Embodiment 3

[0118] The present embodiment provides a kind of treatment method to adjacent nitric acid waste water, and described treatment method comprises the following steps:

[0119] (1) pump the adjacent nitric acid wastewater into the acid adjustment tank, add sulfuric acid to adjust the acid until the pH is 6, acidify the sodium phenate in the wastewater into phenol, remove the suspended matter in the wastewater through a 300 mesh filter, and obtain the impurity-removed effluent;

[0120] The adsorption tower is filled with coal-based columnar activated carbon with an iodine value of about 1100. The adsorption tower adopts the form of 3 towers in series, adopts the method of top in and bottom out, the temperature is 35°C, and the inflow flow rate is 0.1BV / h to obtain the adsorption effluent;

[0121] When the effluent COD of the first adsorption tower reaches 500ppm and reaches saturation, switch to regeneration. After washing, drying, thermal cracking and other processes, the satura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com