A filter cartridge dust collector with uniform air supply

A filter cartridge dust collector and dust collector technology, applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problem of uneven dust removal load of filter cartridges, uneven airflow into the filter cartridge dust collector, and low dust removal efficiency and other problems, to achieve the effect of improving the dust removal effect, uniform airflow size, and consistent dust removal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

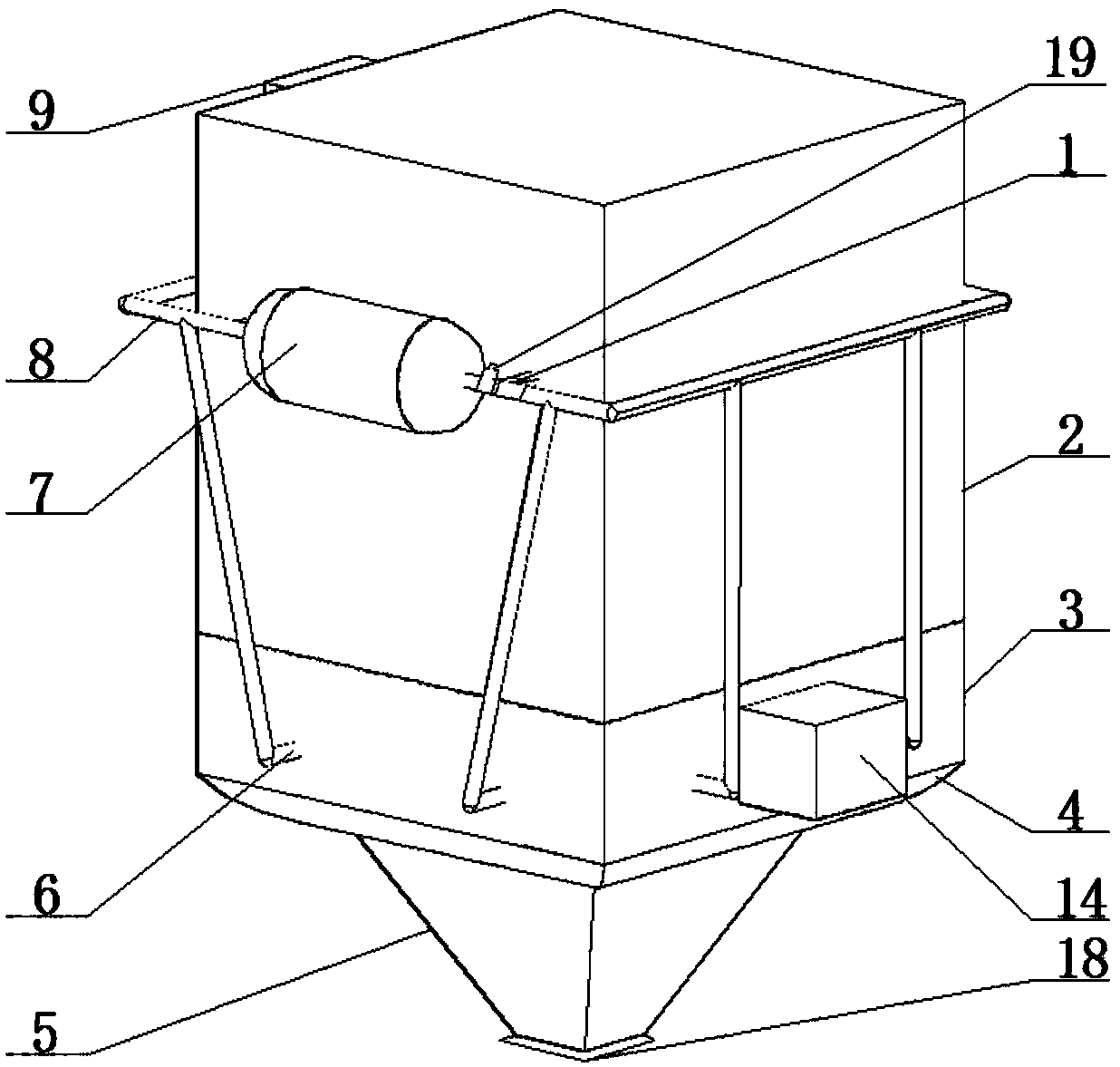

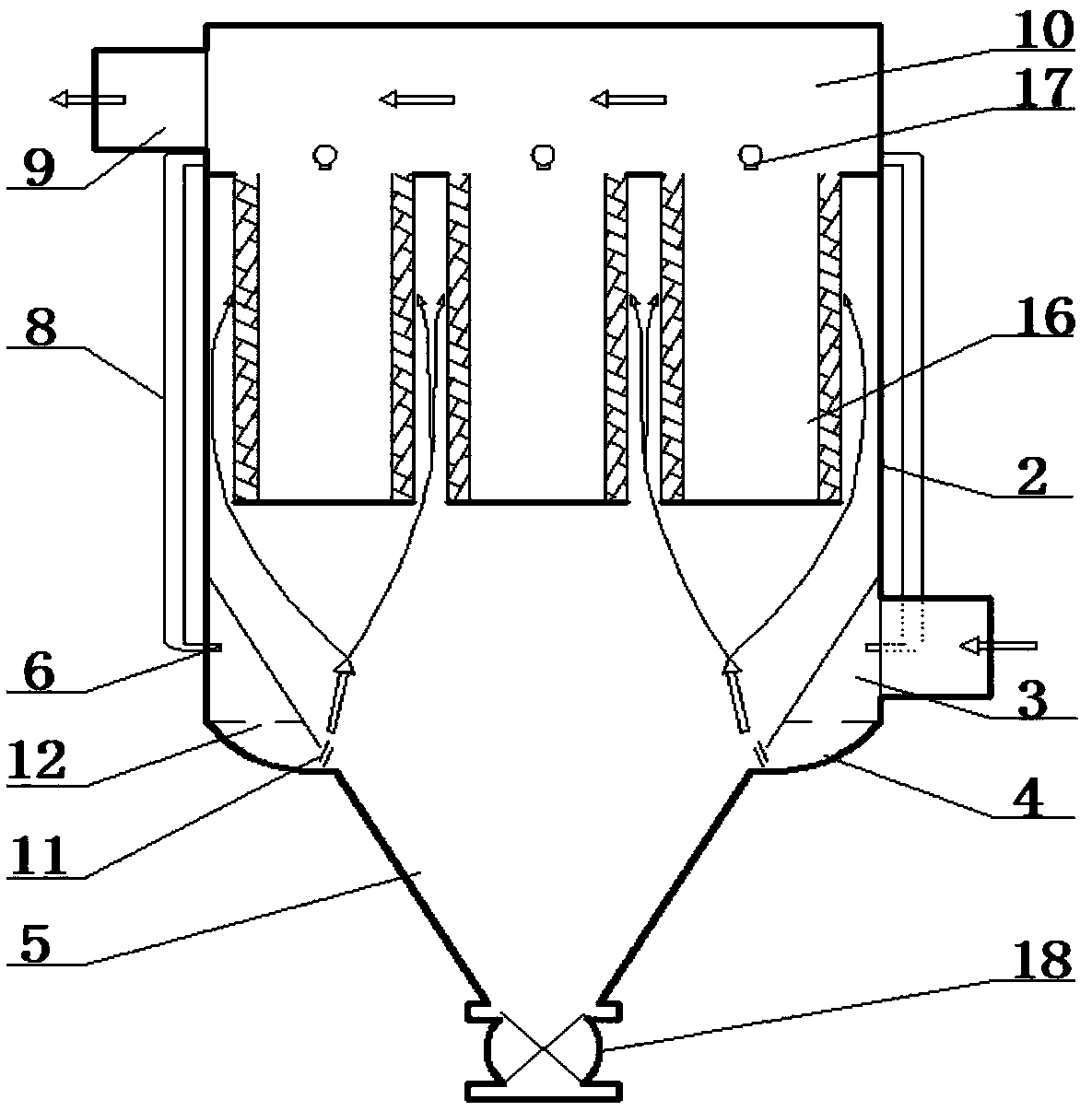

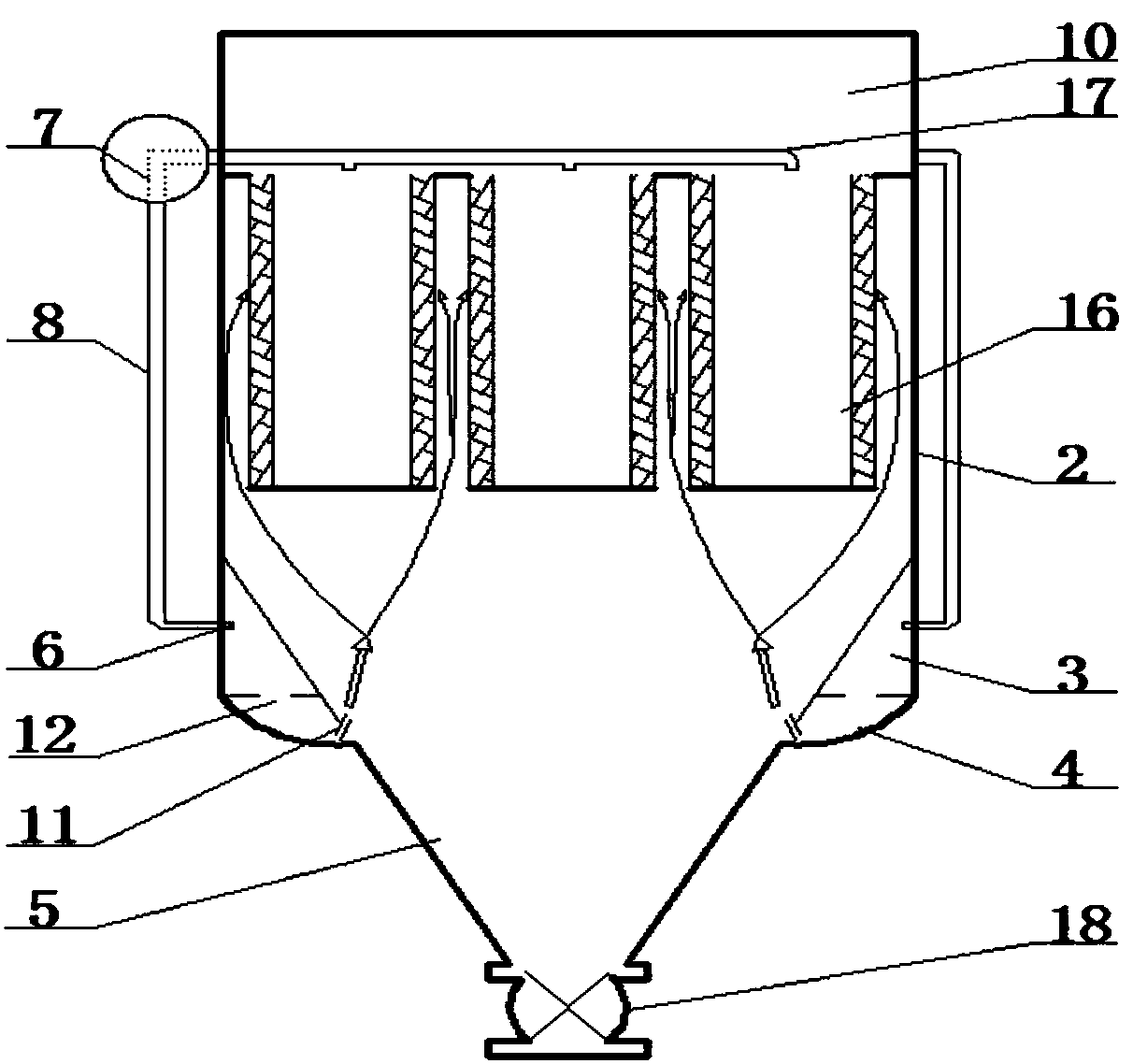

[0026] Such as Figure 1-5 , a filter cartridge dust collector with uniform air supply, including a dust collector box 2 and an ash hopper 5, the ash hopper 5 is arranged below the dust collector box 2 and communicates with it; it also includes an air supply device, and the air supply device includes an annular The air duct 3 and the annular static pressure box 4; the annular air duct 3 is set on the outer side of the upper end of the ash bucket 5 and communicated with the ash bucket 5; the annular static pressure box 4 is set on the outer side of the upper end of the ash bucket 5, and the annular static pressure box 4 The upper end surface and the lower end surface of the annular air duct 3 are attached and connected, and the two communicate through a plurality of vents 12 evenly arranged; one side of the annular air duct 3 is provided with an air inlet 14; the diameter of the plurality of vents 12 is It is satisfied that the gas flow rate of the annular air duct 3 entering t...

Embodiment 2

[0045] 1. Design and theory of circular air duct tuyere

[0046] When the air supply device of the present invention works, as Figure 4 As shown, the airflow enters the 8 air outlets on both sides of the circular air duct. In order to supply air evenly, the air volume of each air outlet is equal, and the distance between the air outlets is 0.2m. The air volume of the air duct on both sides of the air duct containing dust is approximately equal, so only one side is considered, and the air volume at the inlet end of the annular air duct is Q 0 , with a size of 2880m 3 / h Number each opening once from the end of the duct to the inlet. Area f of No. i+1 tuyere i+1 for:

[0047] f i+1 =Q 0 / nv i+1 (1)

[0048] n—the number of tuyere, n=8.

[0049] The outflow velocity of No. i+1 tuyere is:

[0050]

[0051] In the formula, μ—the flow coefficient of the air outlet, the circular side air outlet of the air duct is taken as μ=0.62;

[0052]ρ—air density, take ρ=1.2kg / m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com