New structure multifunctional composite pumping device

A multi-functional, composite pump technology, applied to pump devices, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as complex power sources, reduced pump operating life, and excessive axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of this patent will be further described below in conjunction with the accompanying drawings.

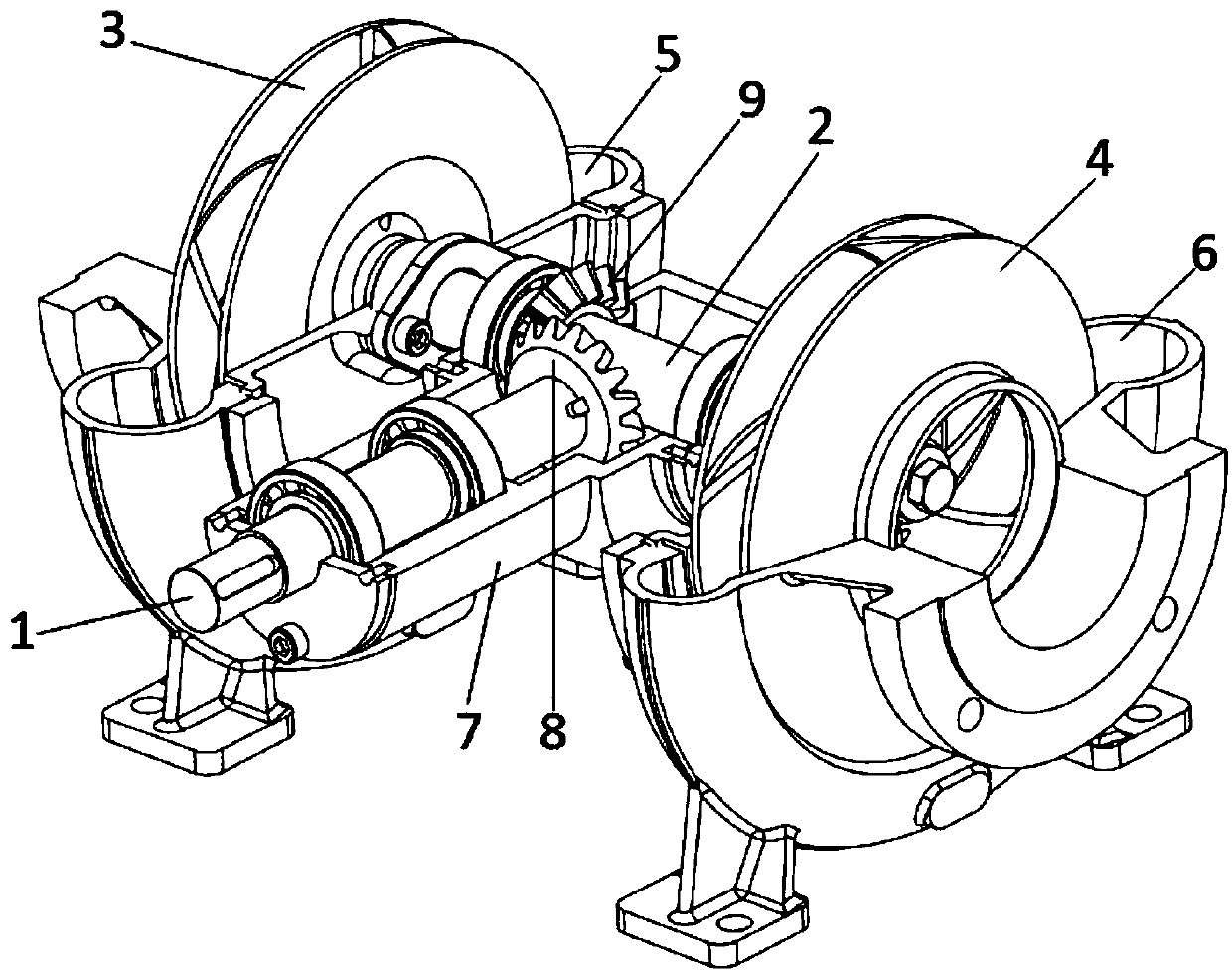

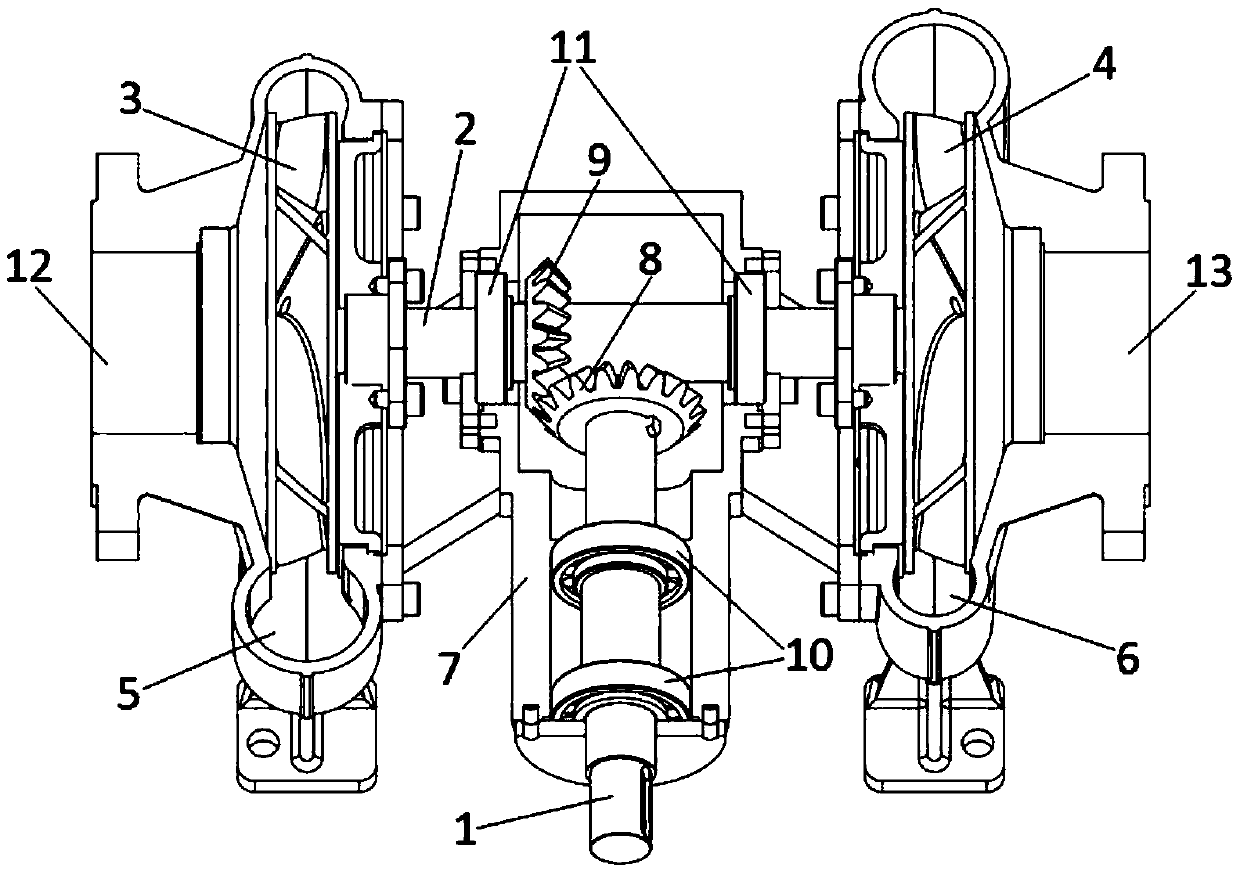

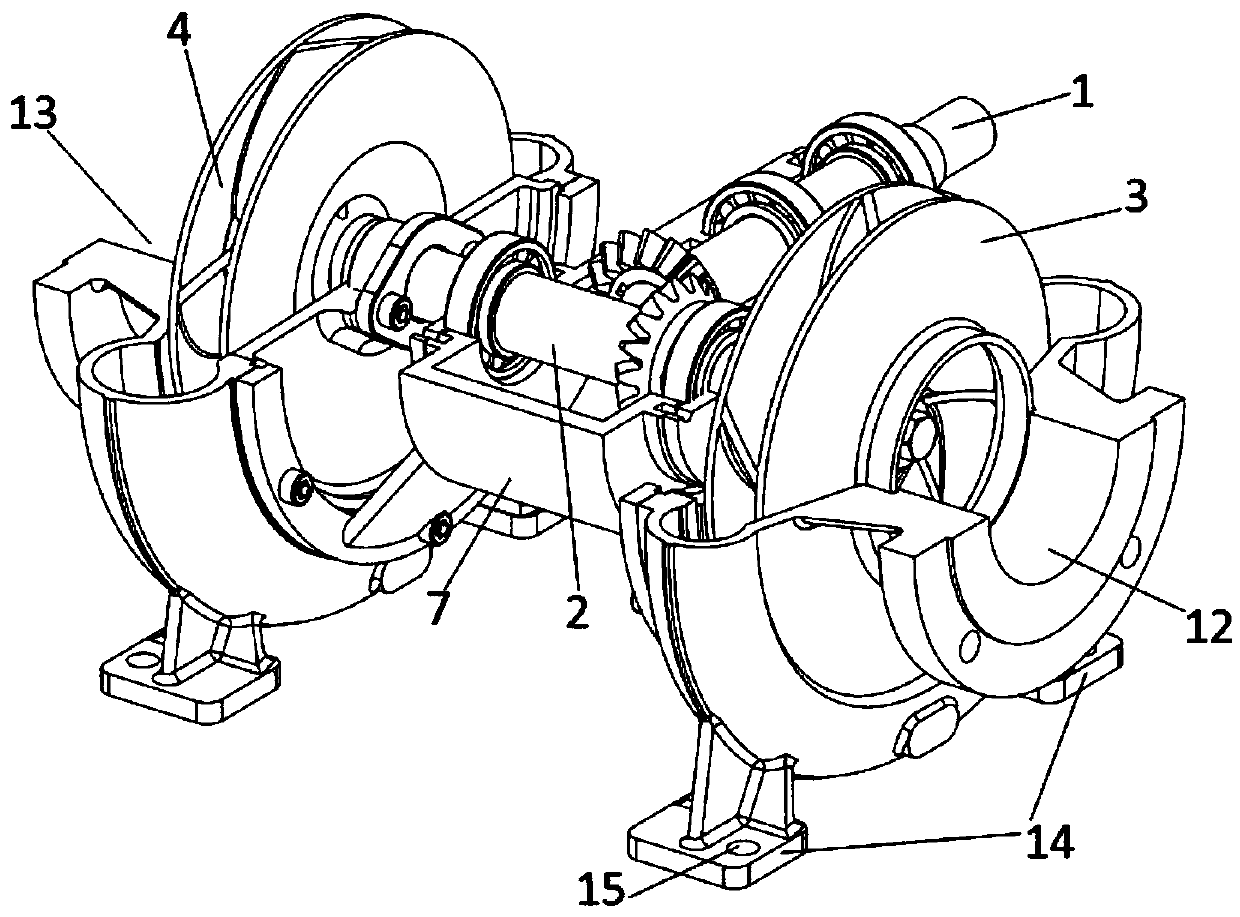

[0023] Such as Figure 1 to Figure 5 Shown, a new structure multifunctional compound pumping device, including transmission device, delivery device and auxiliary device. The transmission device includes a driving shaft 1, a driven shaft 2, a driving bevel gear 8 and a driven bevel gear 9; the conveying device includes a left impeller 3, a right impeller 4, a left volute 5 and a right volute 6; the auxiliary device includes a bridge 7 , Driving shaft bearing 10, driven shaft bearing 11, upper sealing cover 16 and front sealing cover 17.

[0024] Such as Figure 1 ~ Figure 3 As shown, two driving shaft bearings 10 are installed on the side of the driving shaft 1 close to the front sealing cover 17, and the two driving shaft bearings 10 are placed in the bridge frame 7, and cooperate with it, and the driving shaft bearings 10 play a role in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com