Patents

Literature

241results about How to "Reduced risk of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

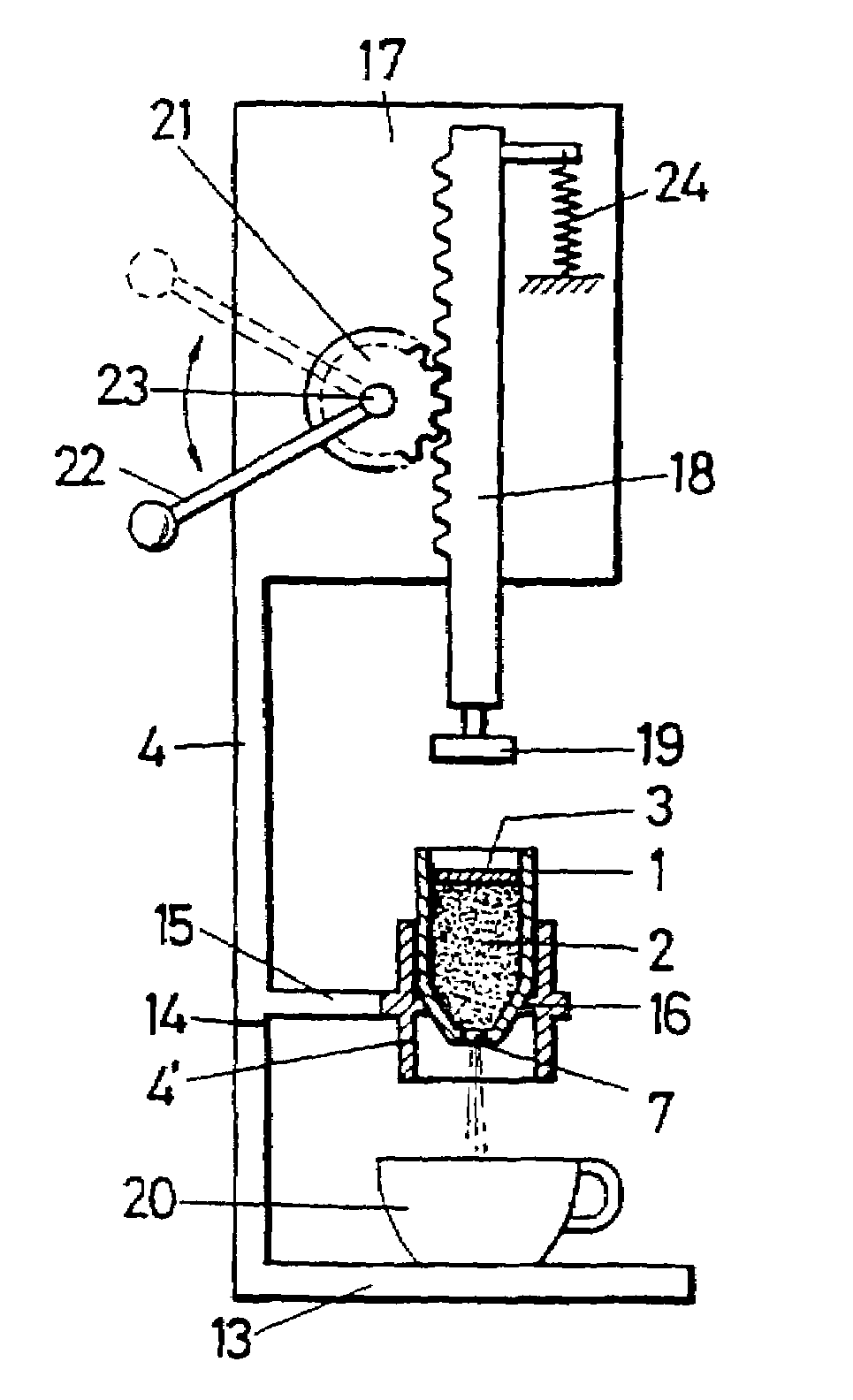

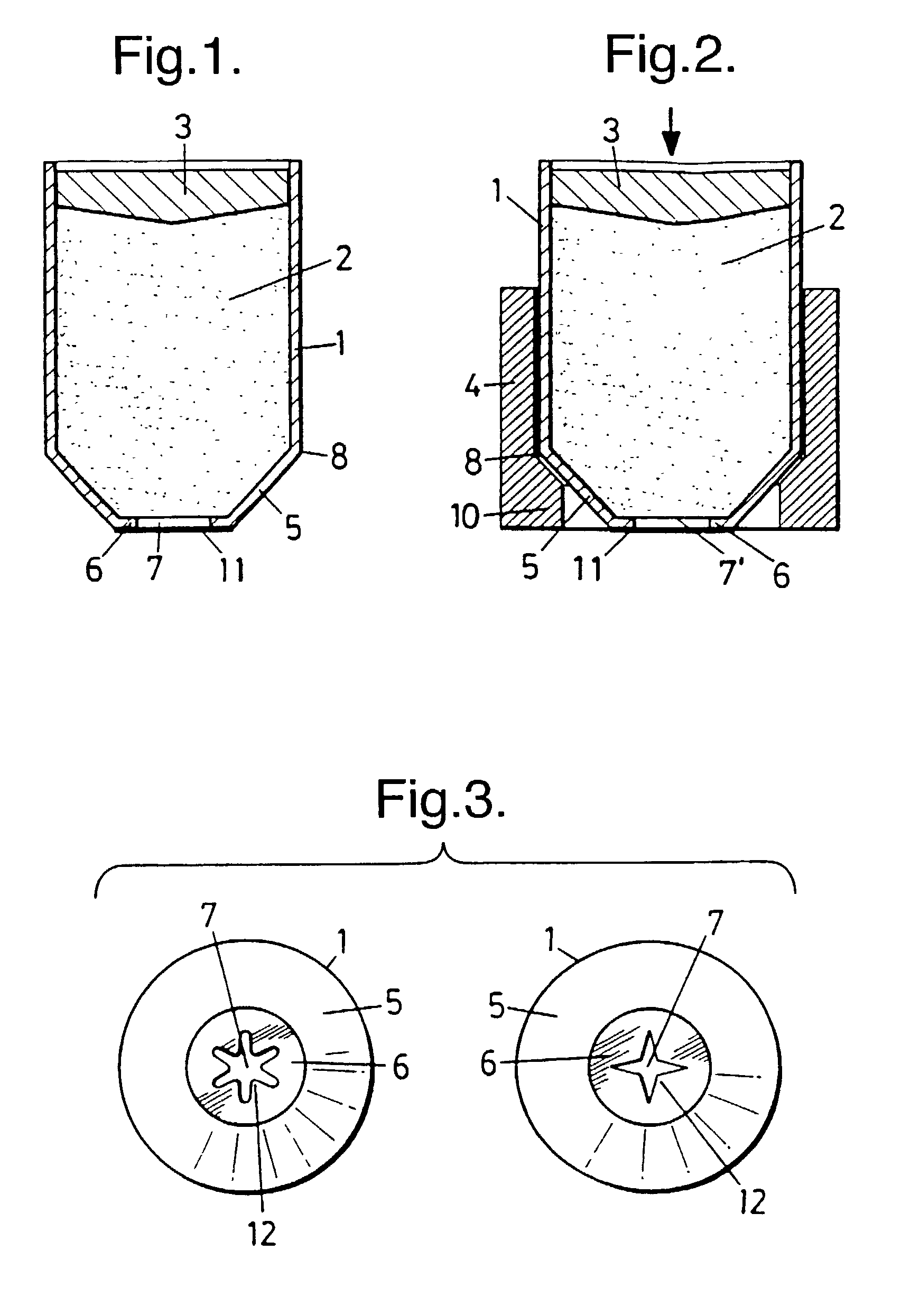

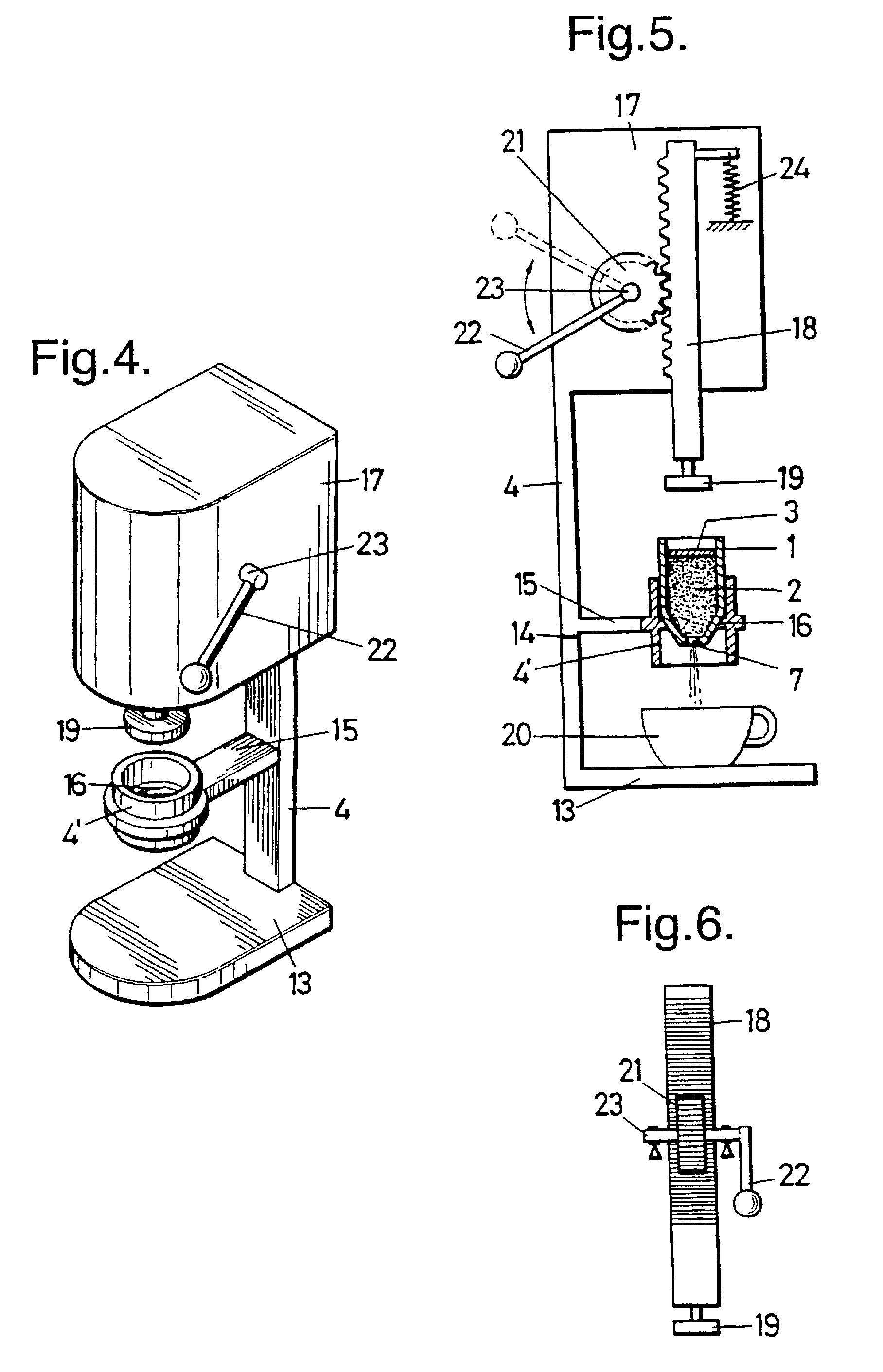

Dispensing pack and machine

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

Polyamide composition with high dimensional stability and preparation method thereof

InactiveCN101857723AReduce the degree of orderLow water absorptionHeat deflection temperaturePolyamide

The invention relates to a polyamide composition with high dimensional stability and a preparation method thereof. The polyamide composition comprises the following components in parts by weight: 60 to 90 of fatty polyamide composition, 2 to 10 of compatilizer, 1 to 10 of inorganic metal compound, 0 to 5 of polysiloxane with low molecular weight and 0 to 2 of auxiliary agent. The preparation method comprises the following steps of: premixing the raw materials in a high-speed mixer for 10 to 30min, controlling the temperature to be 40 to 60 DEG C, then adding premix into a double-screw extruder, conveying, melting, shearing, extruding, cooling and granulating so as to prepare a polyamide composition product with high dimensional stability. Compared with the prior art, the invention shows excellent dimensional stability and heat distortion temperature with high retention rate, is suitable for occasions with higher requirement to the dimensional stability, such as the panel of the air conditioner of an automobile, an instrument panel, a camera bracket, a sports apparatus and the like, and can be directly processed by injection molding or other forming methods.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

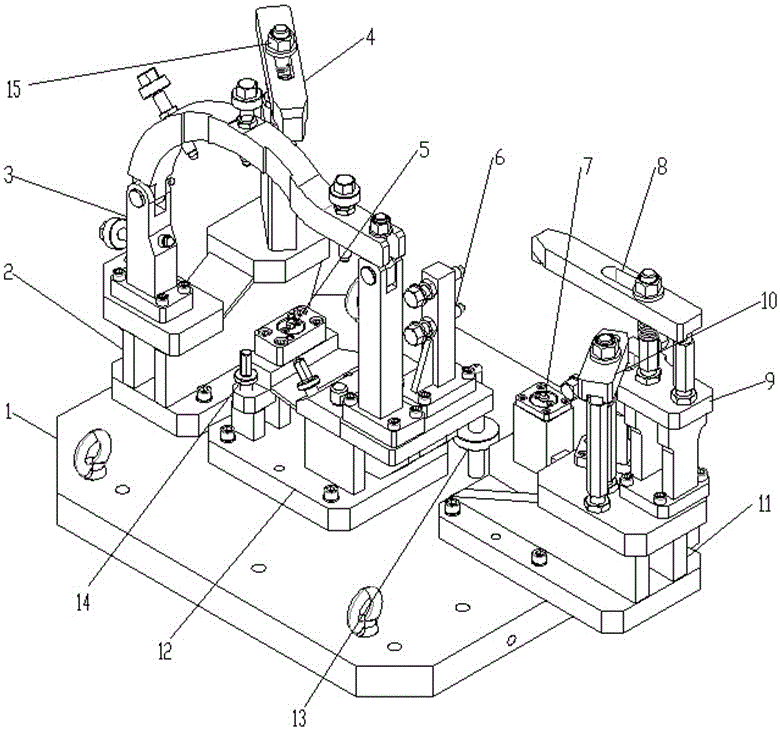

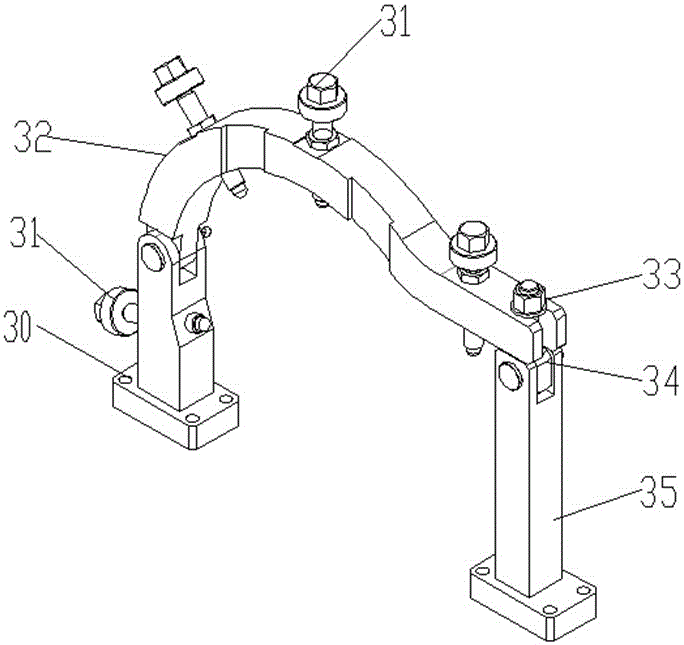

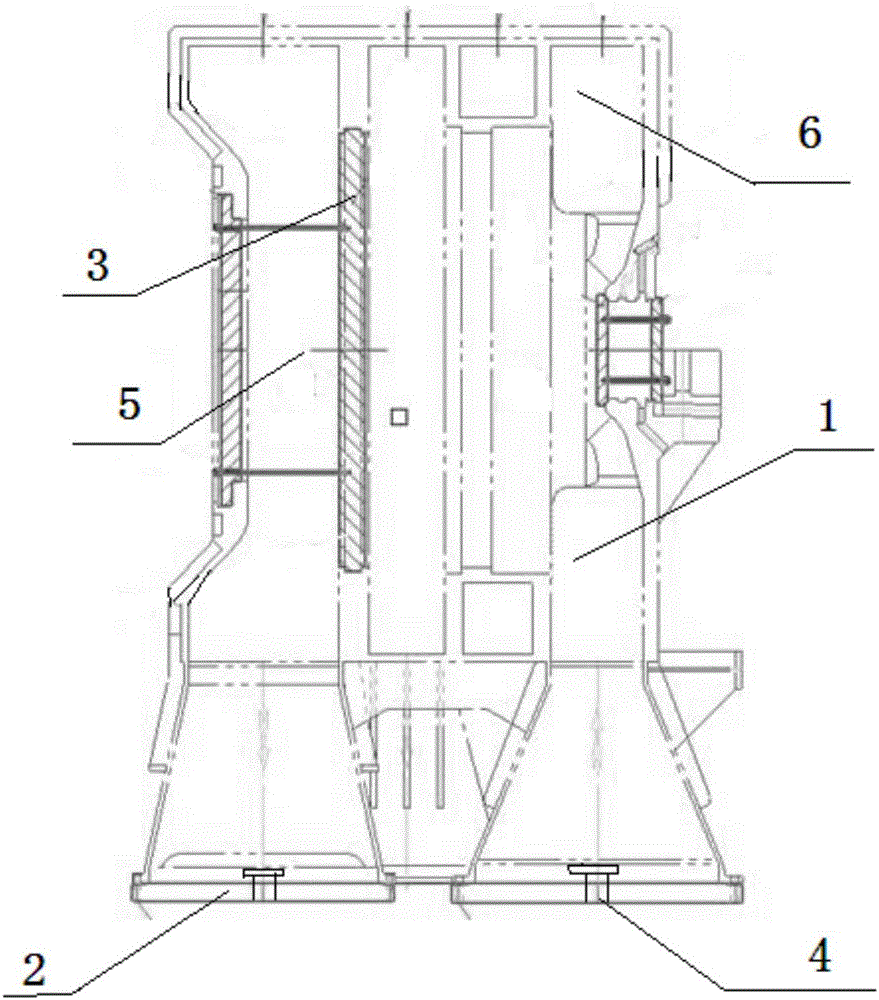

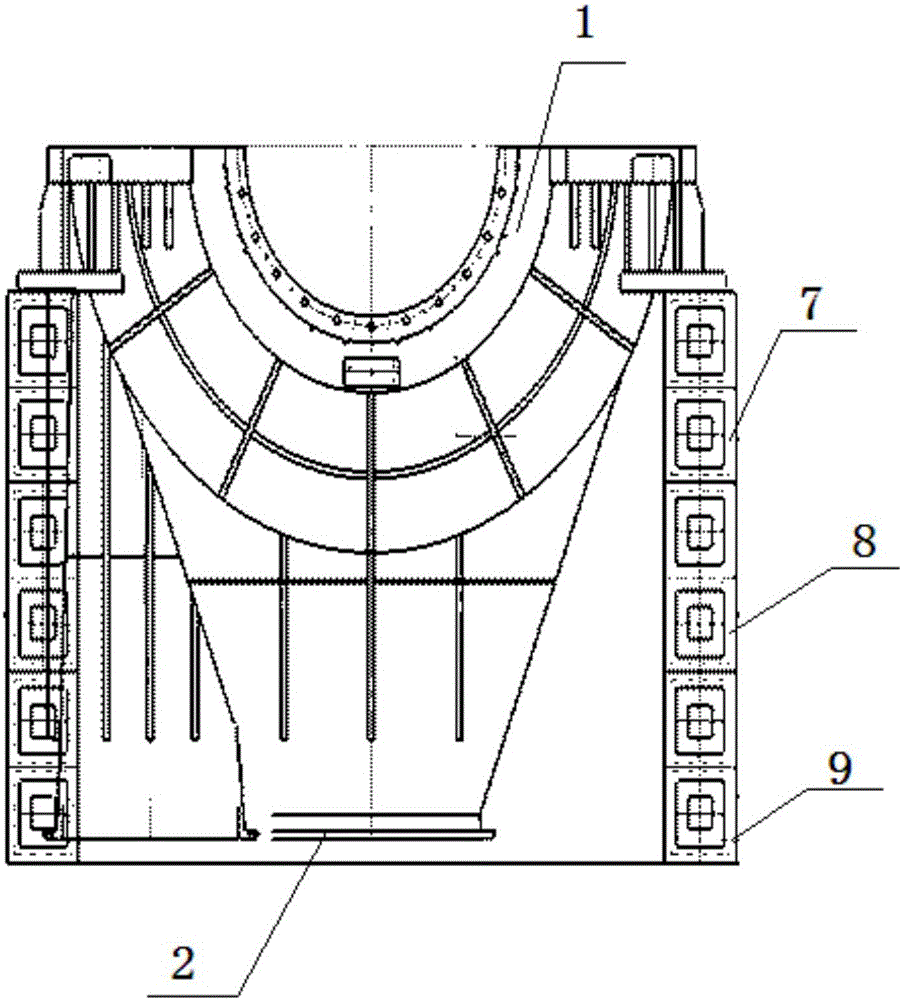

Clamp for processing gearbox body of forklift

ActiveCN105149985ASolve the processing vibration problemReliable compressionPositioning apparatusMetal-working holdersEngineeringMulti point

The invention relates to a clamp for processing a gearbox body of a forklift. The specific structure of the clamp is that a left pressing plate mechanism, an intermediate mechanism and a right pressing plate mechanism are correspondingly arranged on a bottom plate, wherein a first locating pin and a second locating pin are correspondingly arranged on the bottom plate parts at two sides of the intermediate mechanism; the left pressing plate mechanism comprises an arc-shaped pressing plate and a left pressing plate; the right pressing plate mechanism comprises a locating pressing plate and a right pressing plate; one side of the gearbox body to be processed, of the forklift, is a differential housing and the other side of the gearbox body to be processed, of the forklift, is a motor mounting housing; when the clamp is put into use, the gearbox body to be processed, of the forklift, is positioned on the first locating pin and the second locating pin, the arc-shaped pressing plate and the left pressing plate are pressed to the top part of the differential housing, the right pressing plate is pressed to the top part of the motor mounting housing, and the locating pressing plate is pressed onto a lug on the motor mounting housing, so that the gearbox body to be processed, of the forklift, can be positioned and clamped. The clamp is reliable to locate and compress; the problem of vibrating in processing can be solved; the one-point compressing in the prior art is adjusted to be multi-point compressing, thereby removing the influence of human factors on the workpiece clamping effect.

Owner:ANHUI HELI CO LTD

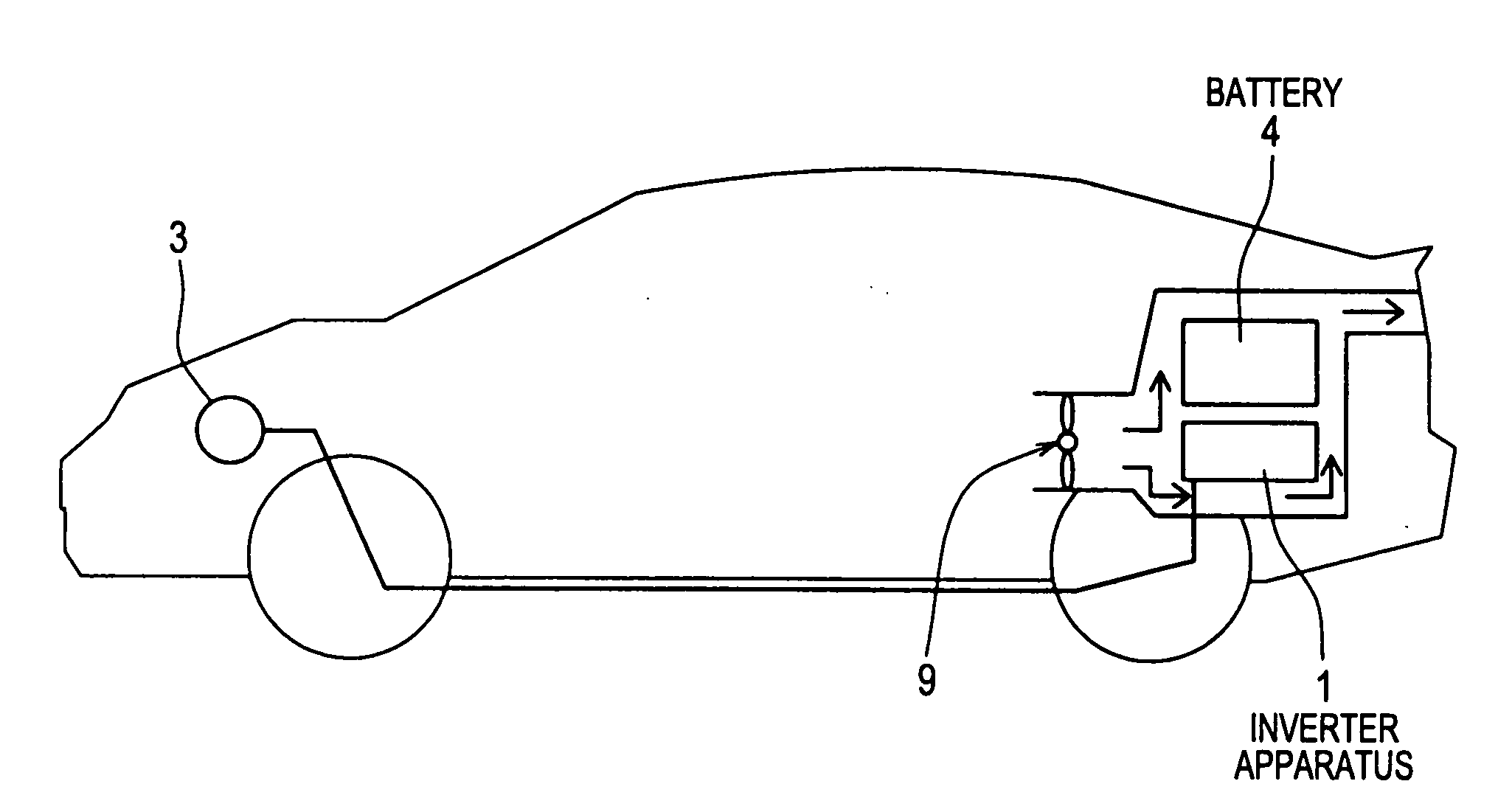

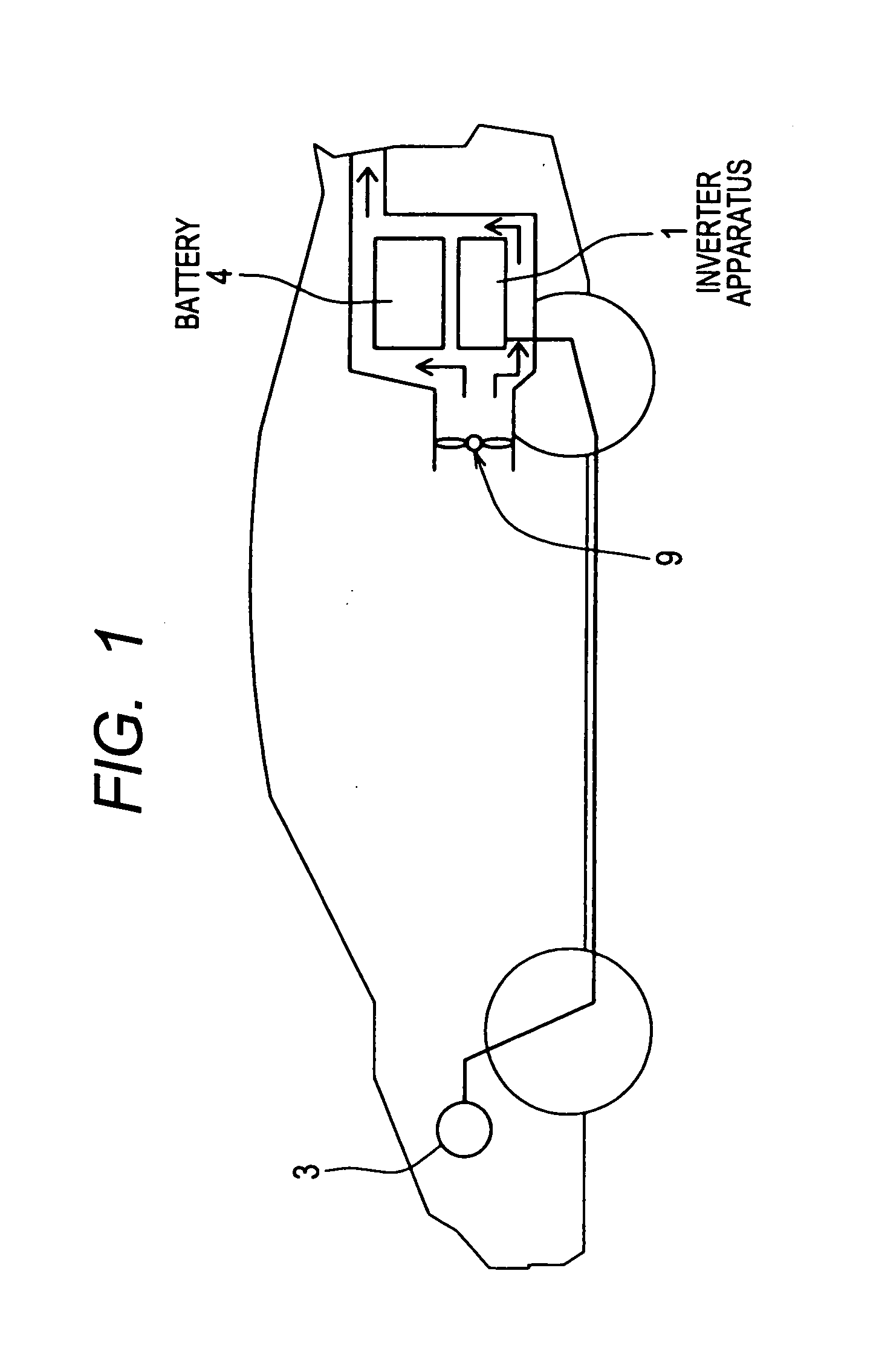

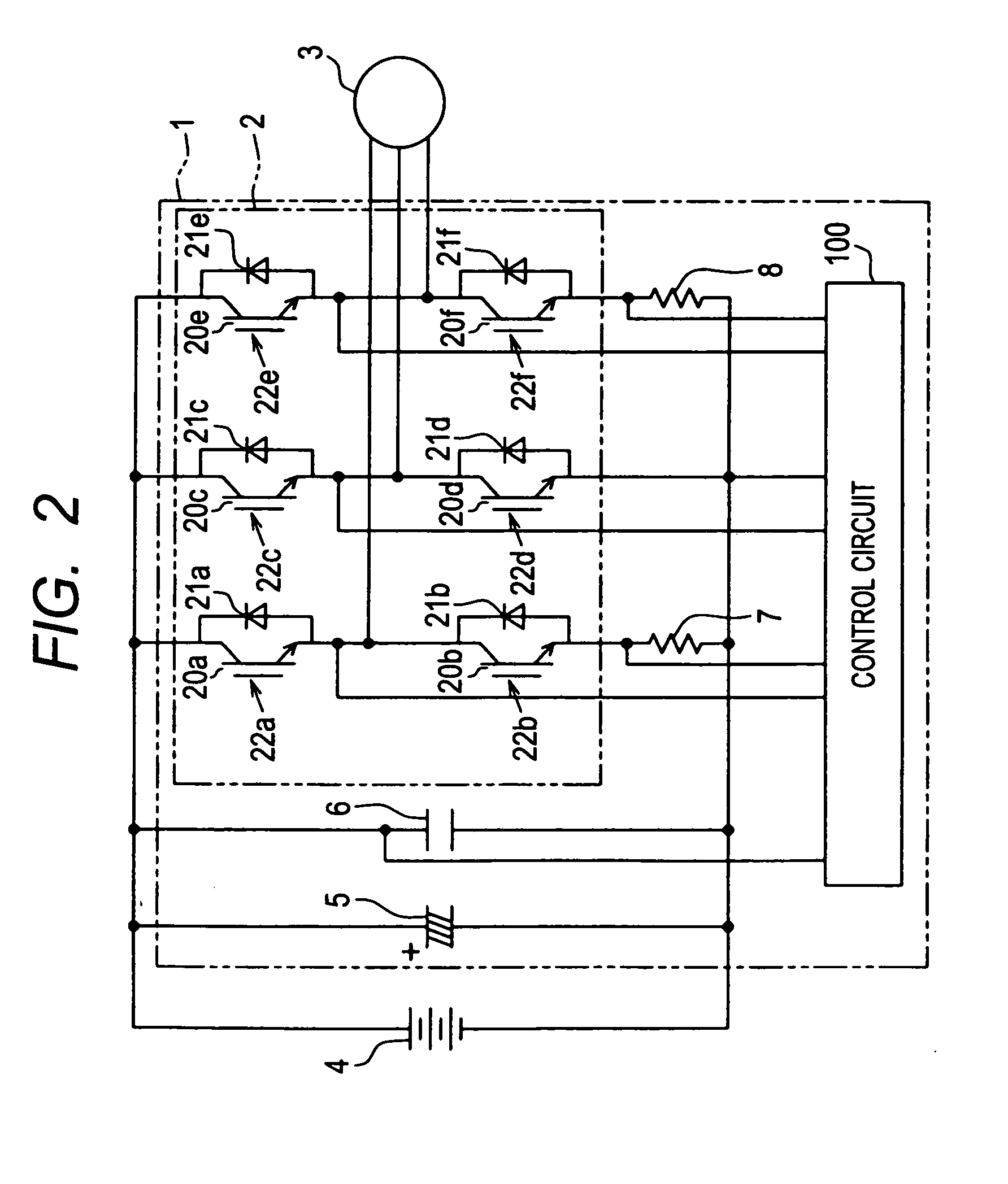

Semiconductor apparatus having semiconductor module cooled by heat sinks which have increased strength together with increased thermal mass

InactiveUS20110194253A1Fixed securityEfficient transferConversion constructional detailsSemiconductor/solid-state device detailsEngineeringSemiconductor

In a semiconductor apparatus, a semiconductor module containing semiconductor elements is enclosed between a pair of heat sinks which are held attached together by spring clips. Each heat sink has one side thermally coupled to a corresponding main face of the semiconductor module and has an array of primary fins and a pair of secondary fin protruding from the other side, with the secondary fins being located at opposing ends of the array of primary fins, beyond the outermost primary fins. At least part of each secondary fin is made thicker than each primary fin, to provide greater strength and greater thermal mass for each secondary fin than each primary fin.

Owner:DENSO CORP

Method of preparing high size precision profiled molybdenum parts

InactiveCN1686642AUniform densityConsistent shrinkagePolyureas/polyurethane adhesivesParaffin waxHigh density

A process for preparing molybdenum part with high size precision and compactness includes preparing adhesive from paraffin wax, high-density polyethene, polypropene and stearic acid through proportionally mixing, mixing it with molybdenum powder, injection moulding, degreasing, presintering, sintering, holding the temp for 1-10 hr, and post treating.

Owner:UNIV OF SCI & TECH BEIJING

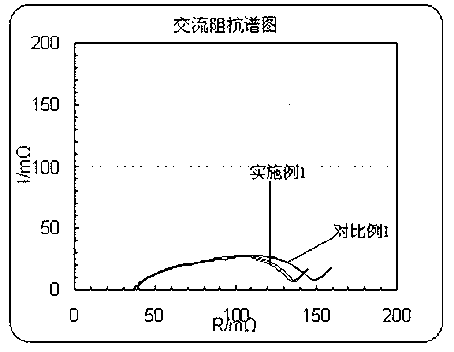

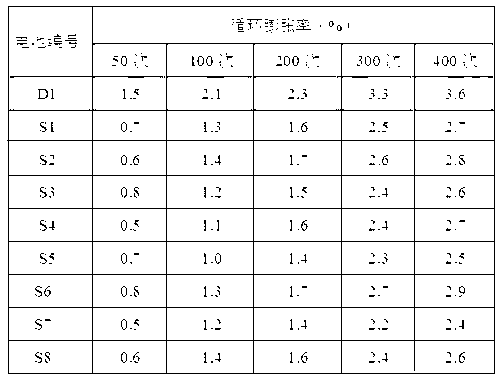

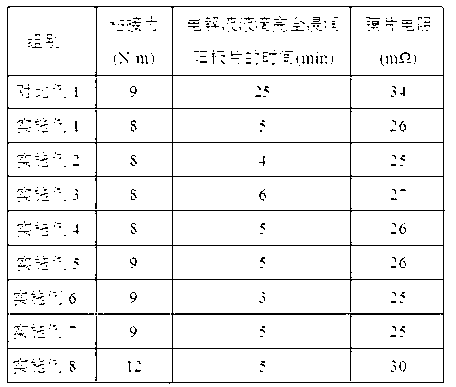

Making method of lithium ion battery anode sheet

ActiveCN103178241AGood flexibilityReduce the number of defective productsElectrode manufacturing processesHigh absorptionAdhesive

The invention belongs to the technical field of lithium ion batteries, and especially relates to a making method of a lithium ion battery anode sheet. The method comprises the following steps: 1, anode slurry preparation: adding an anode active substance, an aqueous thickening agent, an aqueous adhesive and a conductive agent to water, and uniformly stirring to prepare an anode slurry; 2, anode sheet preparation: uniformly coating the anode slurry on an anode current collector, and drying in a 60-120DEG C drying box to prepare an anode sheet; and 3, anode sheet post-treatment: carrying out secondary baking softening treatment of the anode sheet obtained in step 2 in a 250-450DEG C environment. Compared with anode sheets made through the prior art, the anode sheet made through adopting the method has the characteristics of good flexibility, high absorption performance, low impedance and the like; and a lithium ion battery containing the anode sheet made through adopting method has the characteristics of good low temperature discharge performance, long cycle life, and low cycle thickness expansion rate.

Owner:DONGGUAN AMPEREX TECH

Construction method for manufacturing box type column and beam

The invention relates to the technical field of construction, and aims to provide a construction method for manufacturing a box type column and beam. The construction method can effectively reduce welding deformation and reduce the later correction cost. According to the technical scheme adopted in the method, the construction method for manufacturing the box type column and beam comprises the steps of A, marking off, B, marking out, C, discharging, D, groove machining, E, body assembling, F, end plate assembling and G, rust removing and painting. According to the construction method, throughthe reasonable welding sequence and welding manner, deformation is effectively reduced, the later correction cost is reduced, and the economic benefits are improved.

Owner:云南建投机械制造安装工程有限公司

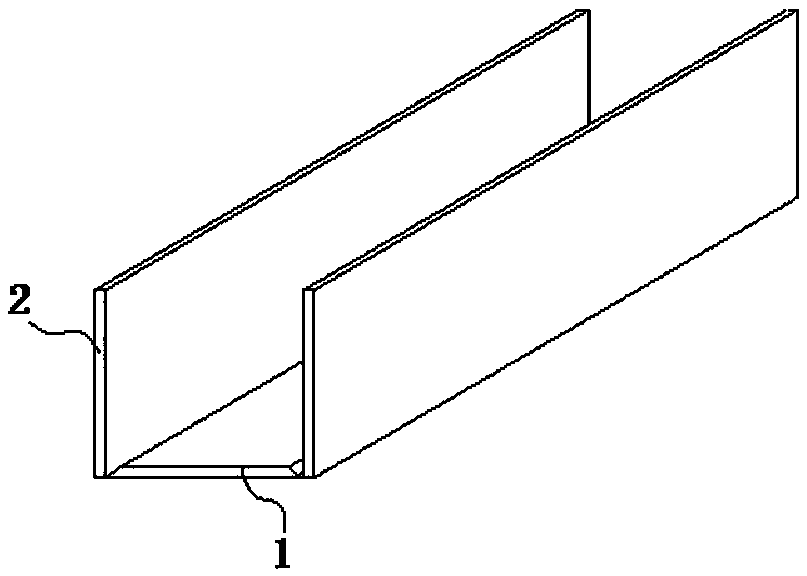

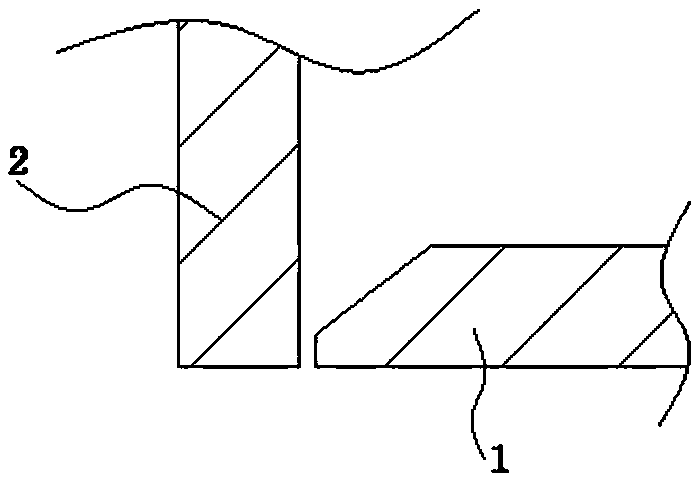

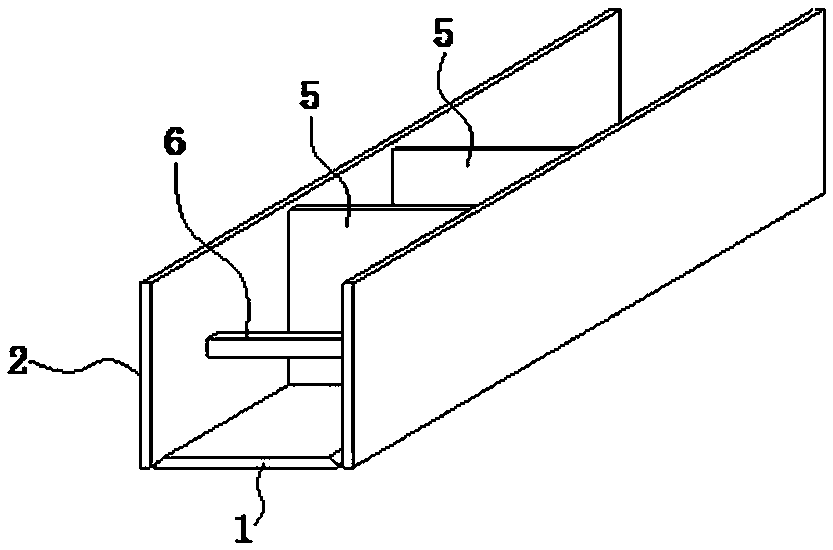

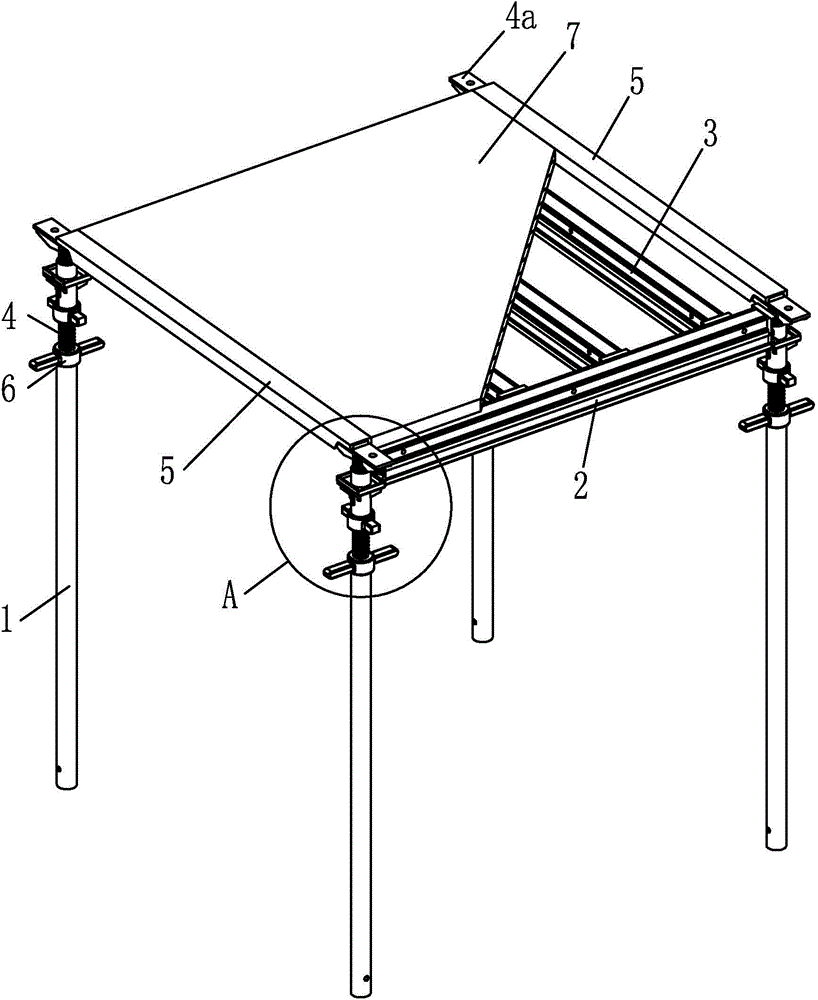

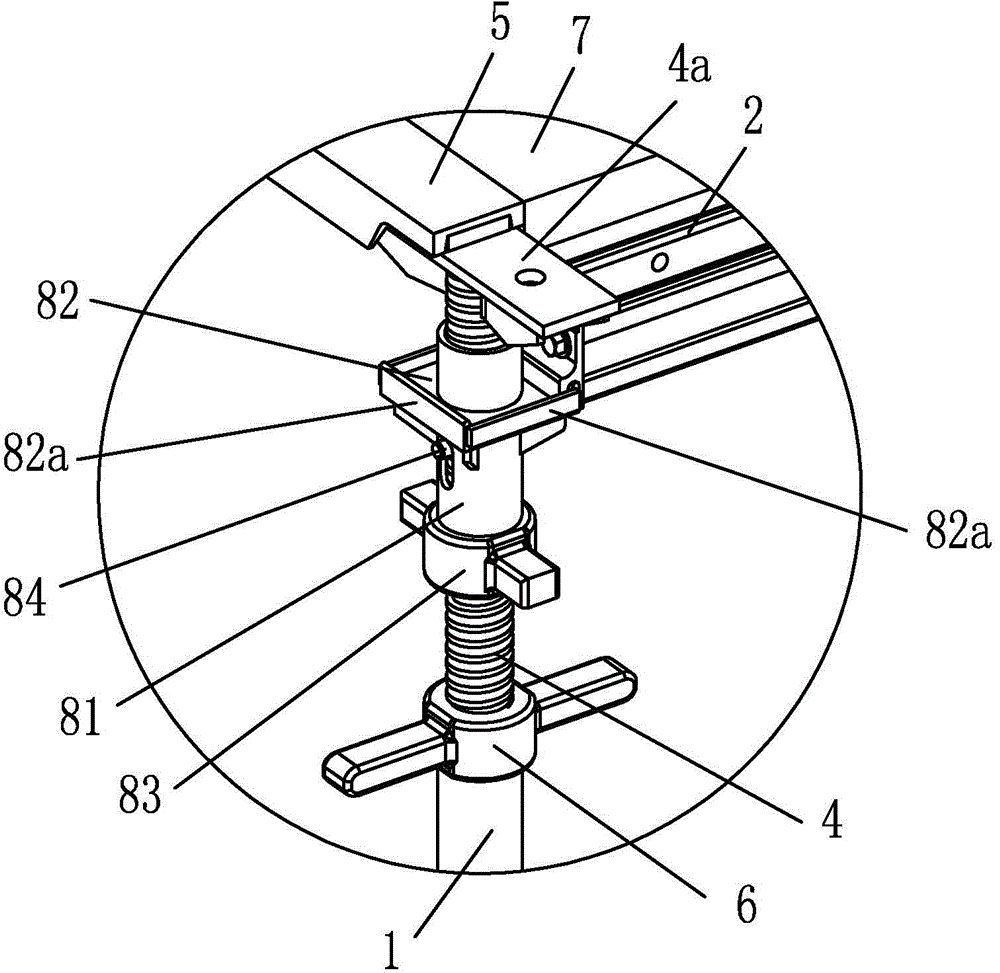

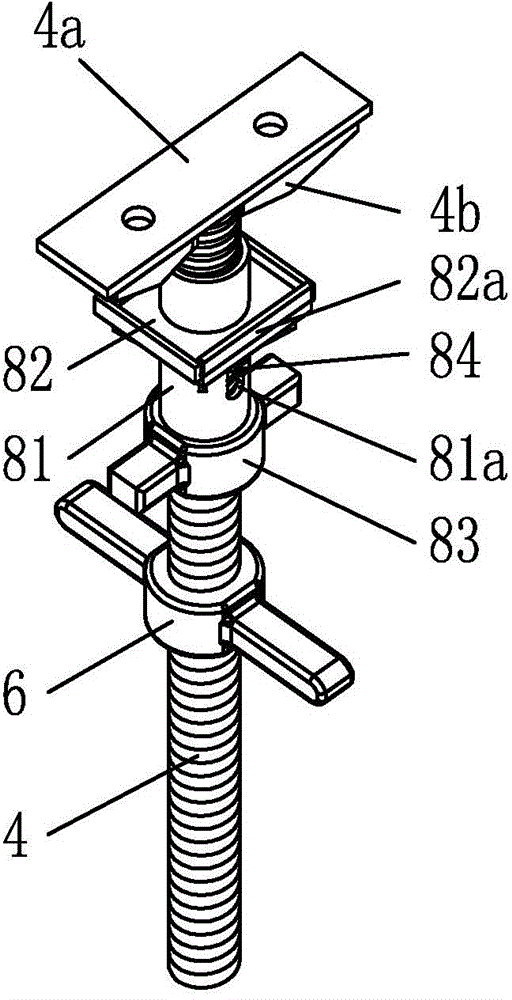

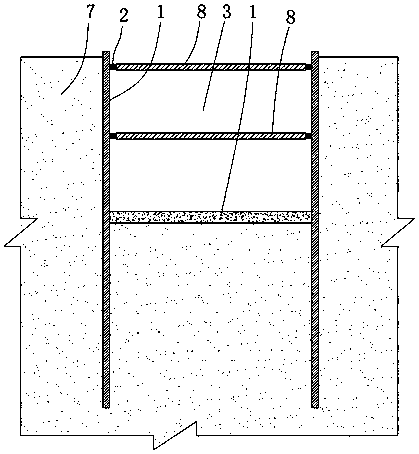

Supporting system for casting concrete floor slab and beam bottom template

The invention discloses a supporting system for casting a concrete floor slab and a beam bottom template. The supporting system comprises a supporting post, main beams and secondary beams, wherein lifting supporting posts which can be adjusted by screw threads are arranged on the supporting post; a rectangular post cap is formed at the top end of each lifting supporting post; the main beams and the secondary beams are mainly made of an aluminum or steel profile material; an early detaching head is arranged on the middle part of each lifting supporting post; two lifting supporting posts are connected by supporting pressing strips to form detachment-delaying supporting groups; the supporting pressing strips are respectively lapped to the top surfaces of the two rectangular post caps from the two ends; the main beams are lapped to the two early detaching heads of two adjacent detachment-delaying supporting groups; the secondary beams are lapped to two parallel main beams through the two ends; the top surfaces of the secondary beams and the main beams are positioned in the same horizontal plane and support early detaching panels together; the top surfaces of the early detaching panels and the top surfaces of the supporting pressing strips are positioned in the same plane. The supporting system has the beneficial effects that early detachment can be realized by the supporting system, deformation of the cast floor slab and a cast beam is low, and the supporting system is light in weight, convenient to carry, high in erecting and detaching efficiency and low in manufacturing cost.

Owner:泰博新型建筑科技(苏州)有限公司

3D Printing material

InactiveCN109354843AImproved appearance finenessShort curing timeAdditive manufacturing apparatusRosinPlasticizer

The invention discloses a 3D printing material, made by mixing component A and component B in a mass ratio of 1:(1-2), wherein the component A includes, by mass, 80-100 parts of composite plastic, 50-70 parts of modified phenolic resin, 8-15 parts of nano titanium dioxide, 20-25 parts of polytetrafluoroethylene, 10-13 parts of a nano pigment, 3-6 parts of polyether sulfone, 6-10 parts of a nano metal material, 4-5 parts of polyisocyanates, 2-4 parts of a stabilizer, 3-5 parts of a thickener, 6-8 parts of a color fixing agent, and 2-3 parts of a quick setting agent; the component B includes, bymass, 50-60 parts of polylactic acid, 15-20 parts of nano silica, 13-18 parts of tributyl acetocitrate, 10-15 parts of nano calcium carbonate, 1-2 parts of rosin, 8-13 parts of barium sulfate, 15-22parts of graphite micro powder, 20-30 parts of butanediol adipate-butylene terephthalate copolymer, 15-25 parts of modified gypsum powder, 2-4 parts of barium metaborate and 3-5 parts of a plasticizer.

Owner:江苏天泽教育咨询有限公司

Method for making a lithographic printing plate

InactiveCN101272914AShort manufacturing timeReduced risk of deformationLithographyForme preparationVitrificationImage recording

A method for making a lithographic printing plate is disclosed which comprises the steps of (i) providing a lithographic printing plate precursor comprising a support having a hydrophilic surface or which is provided with a hydrophilic layer, and a coating provided on said hydrophilic surface or said hydrophilic layer, wherein the coating comprises an image recording layer comprising hydrophobic thermoplastic polymer particles and wherein the image recording layer or an optional other layer of said coating further comprises an infrared light absorbing agent; (ii) image-wise exposing the precursor to infrared light having an energy density of 190 mJ / cm 2 or less; (iii) developing the exposed precursor by removing unexposed areas in a processing liquid; (iv) baking the plate thus obtained by keeping the plate at a temperature above the glass transition temperature of the thermoplastic particles during a period between 5 seconds and 2 minutes.

Owner:AGFA NV

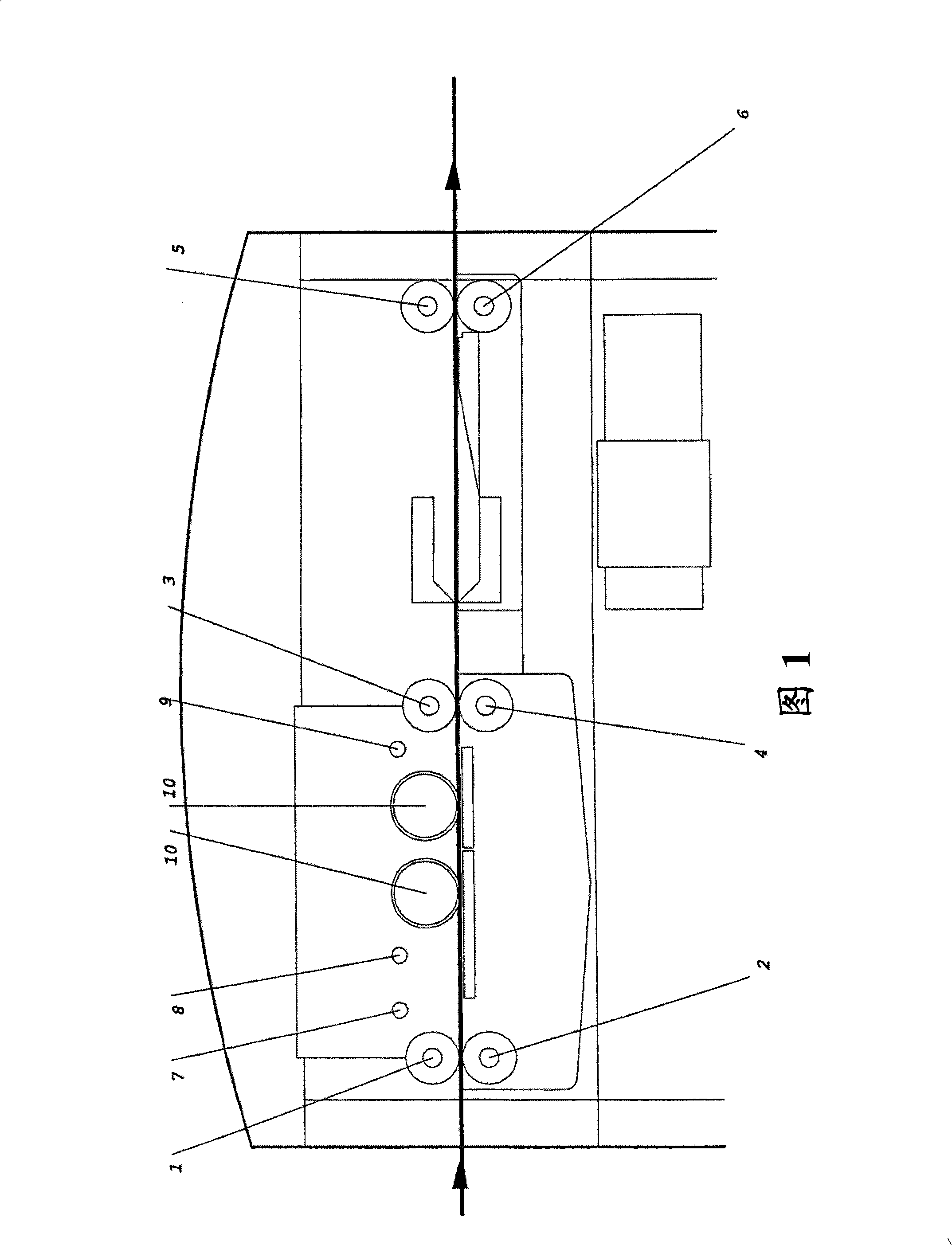

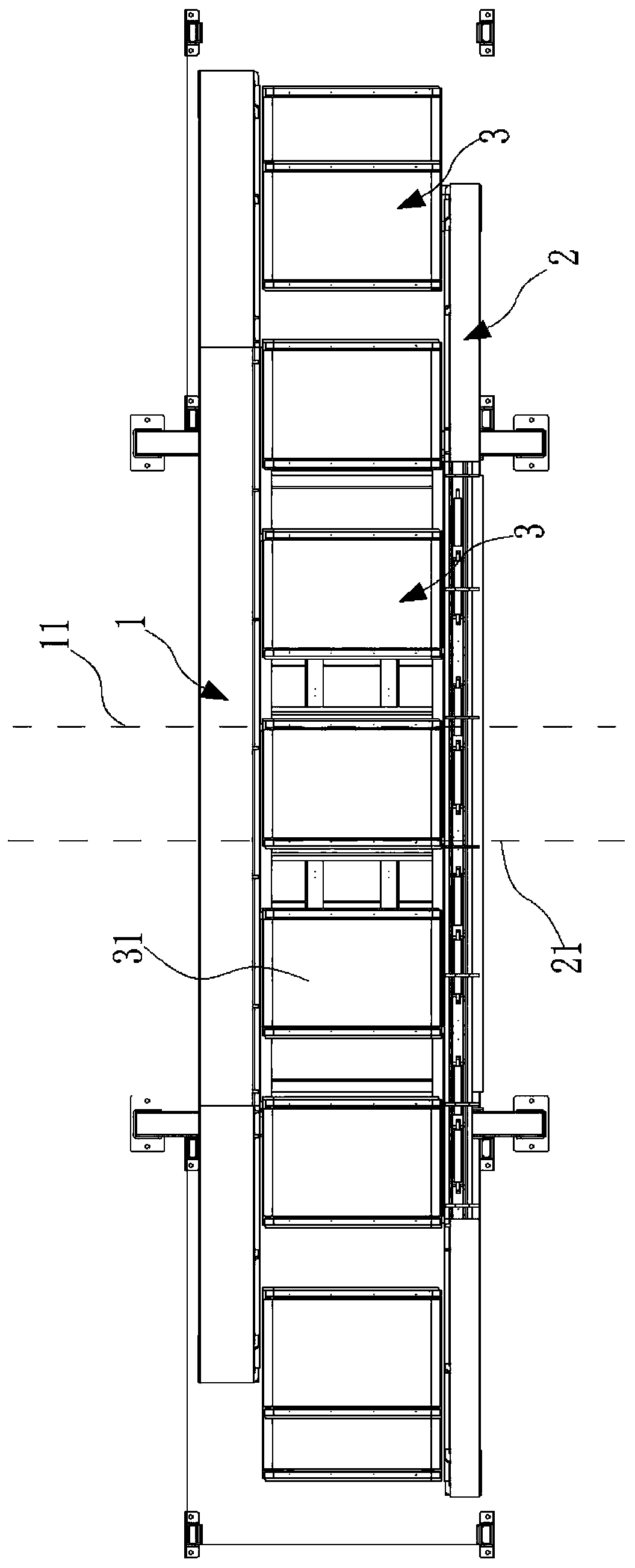

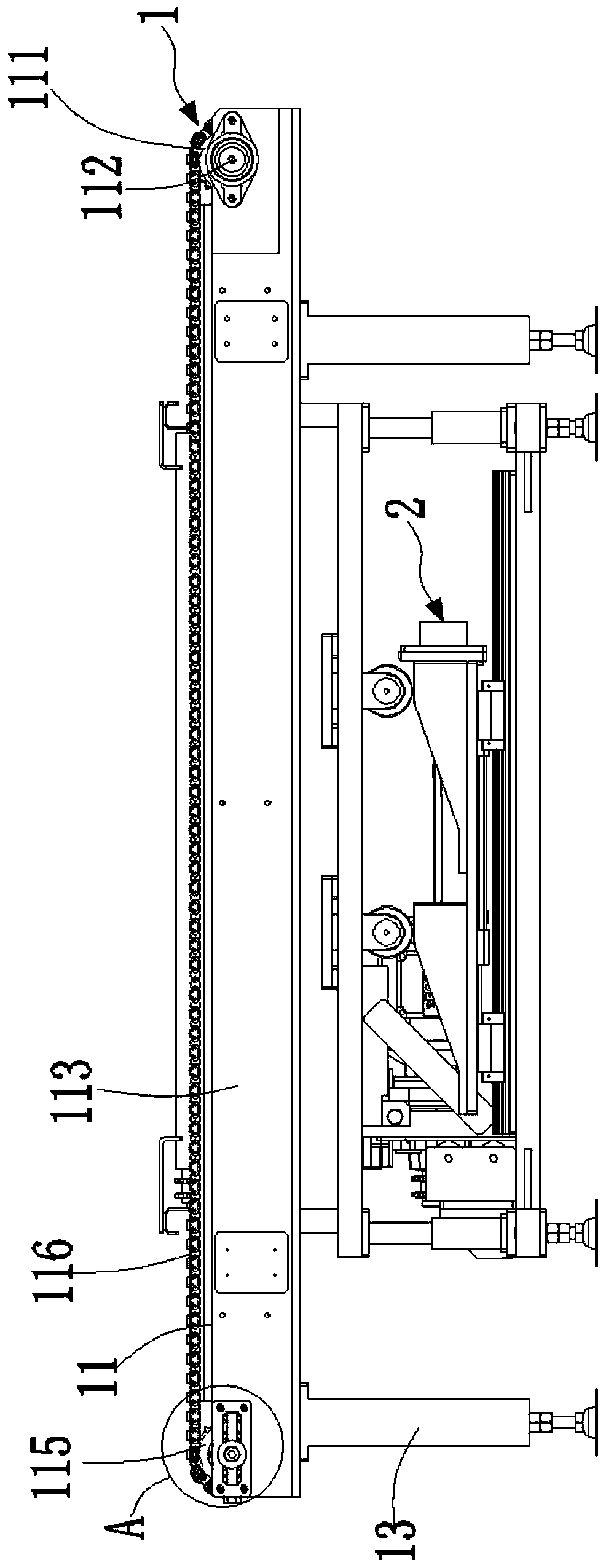

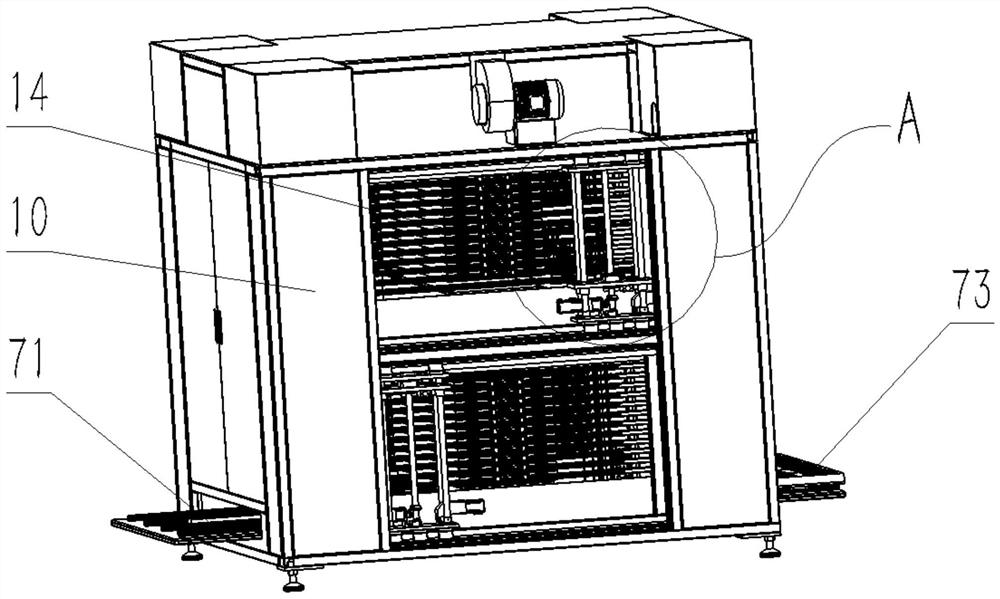

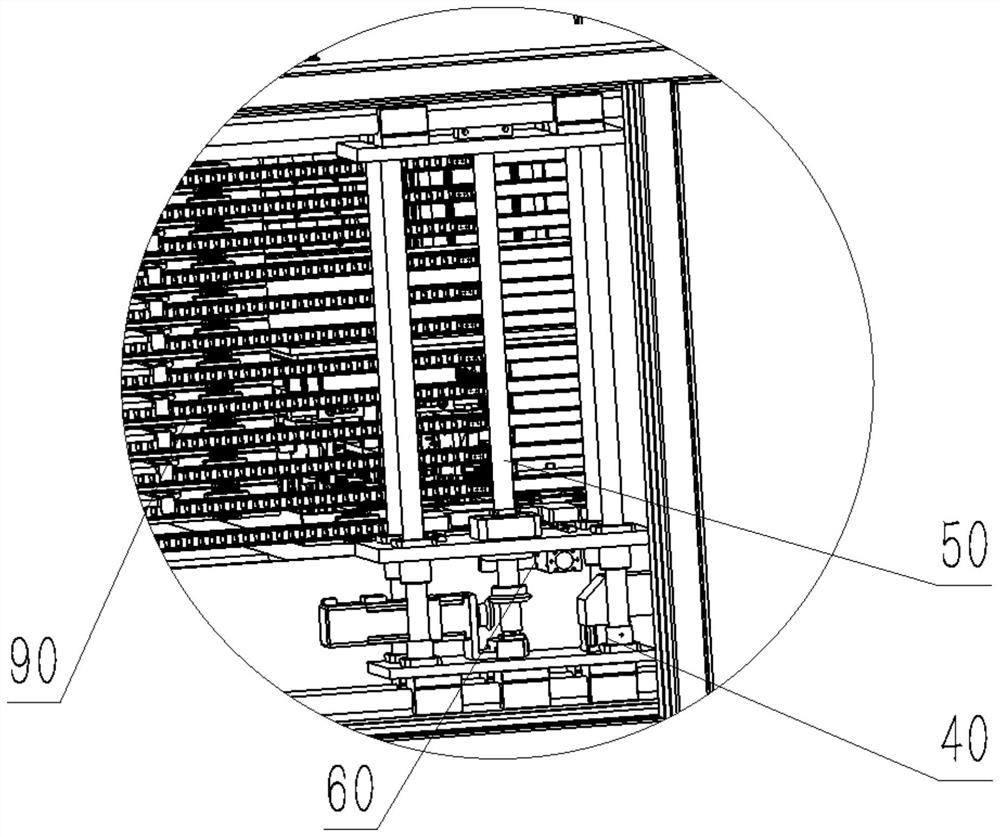

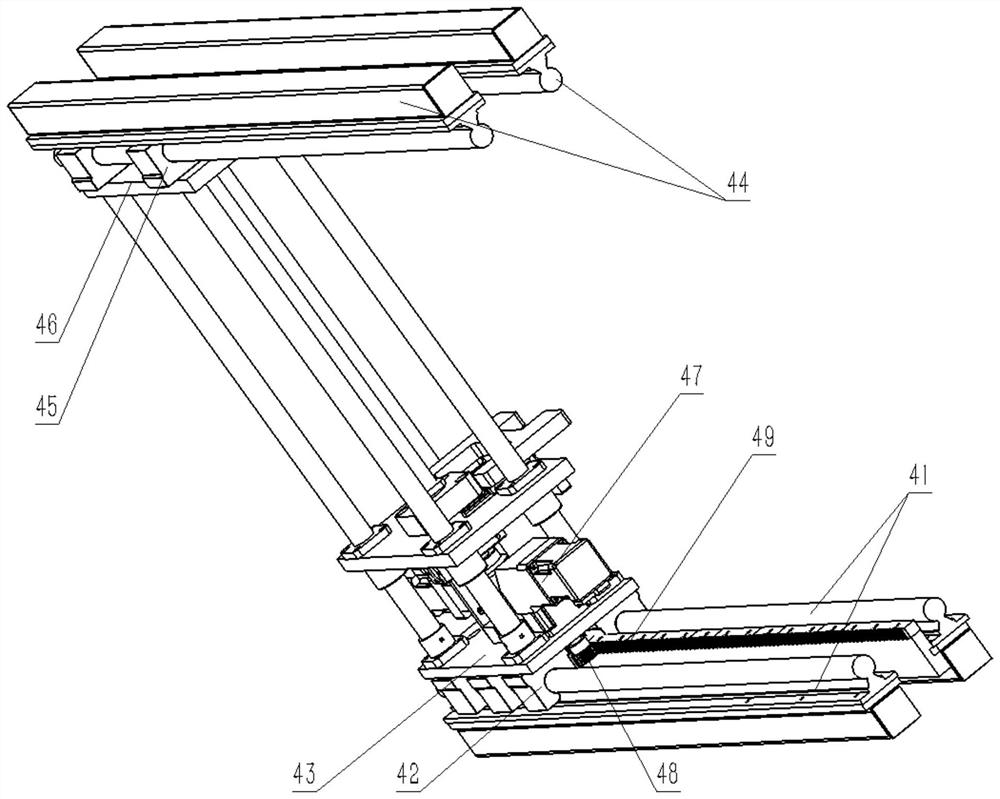

Double-layer vertical conveyor, double-layer sorting system and sorting method thereof

PendingCN110371609AIncrease flexibilityExquisite designMechanical conveyorsJunction pointEngineering

The invention discloses a double-layer vertical conveyor, a double-layer sorting system and a sorting method thereof. The double-layer vertical conveyor comprises a first annular rail and a second annular rail which are consistent in shape and area, wherein axes of the first rail and the second rail are parallel to a horizontal plane, and the axes of the first rail and the second rail are equallyin height and are arranged at an interval; at least one loading device is arranged on each of the first rail and the second rail and can move along the first rail and the second rail, and the upper surface of the loading device is kept in an upward state during moving. According to the abovementioned scheme, the double-layer vertical conveyor has the advantages that two rails which are not coaxialto each other are adopted; single-point connection and the position of a connection point of the loading device and a moving part in the rails are designed, so that the surface of the loading deviceis kept in an upward state all the time, and an object on the loading device cannot fall off in the whole moving process; a turning area and the loading device in a lower layer rail area can be fullyutilized to realize sorting, so that the sorting efficiency is improved; and meanwhile, the arrangement flexibility of a feeding line, a sorting port and other equipment can be improved.

Owner:SUZHOU GP LOGISTICS SYST

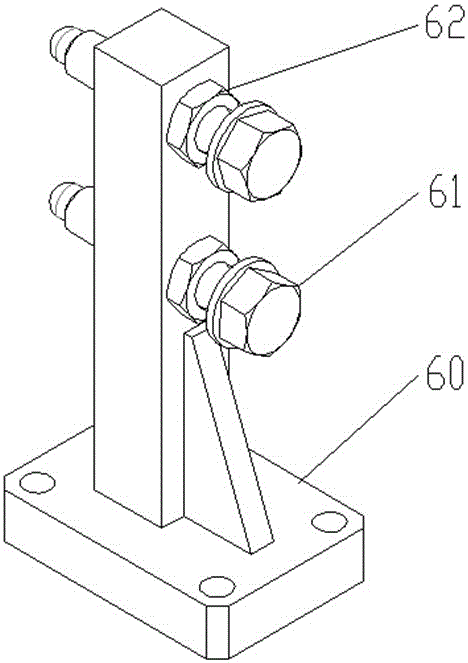

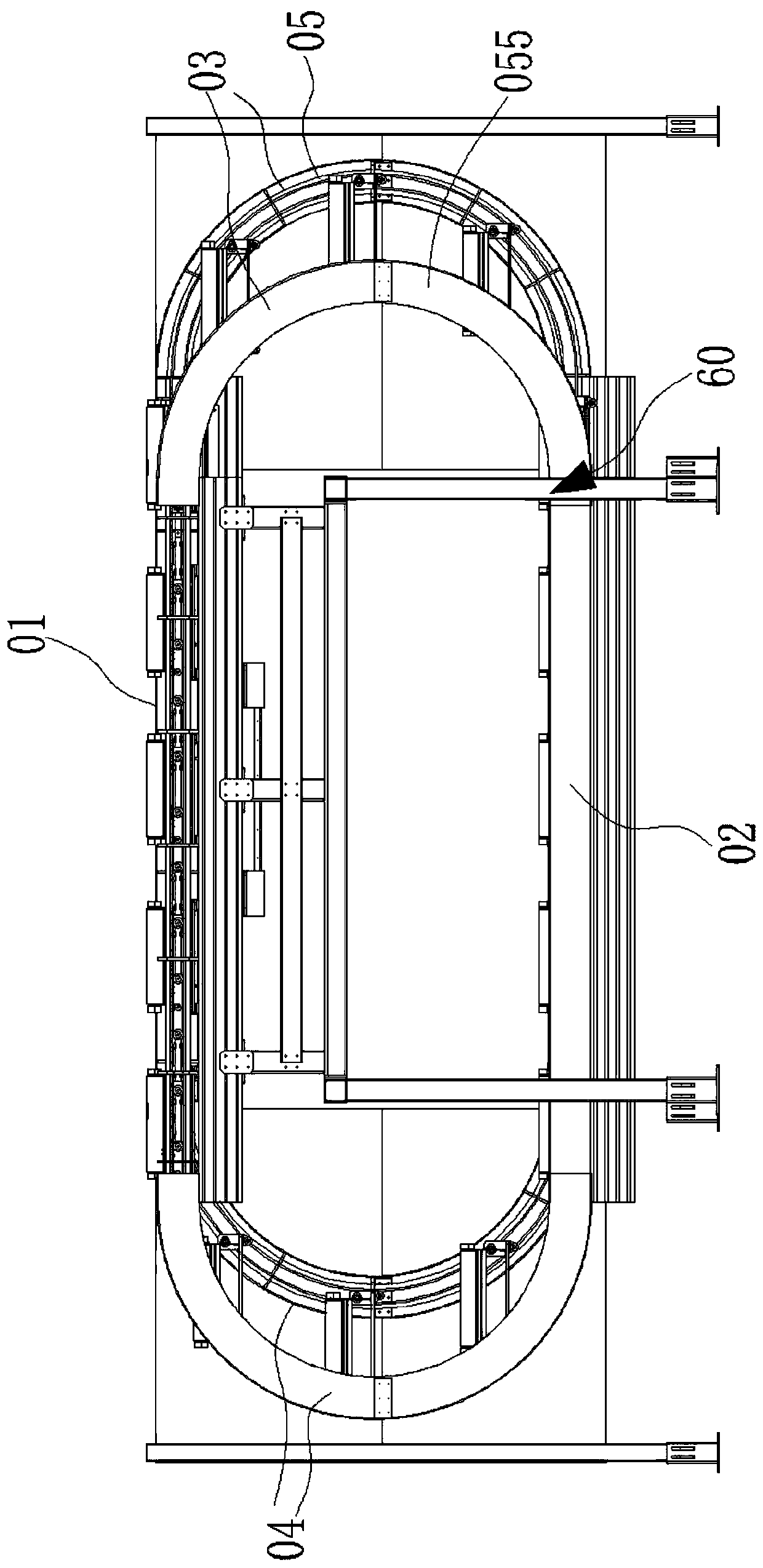

Water pressure testing method and device of ultraheavy and ultralarge compressor shell

ActiveCN105927573AReduced risk of deformationRelieve pressurePump controlNon-positive displacement fluid enginesEngineeringHigh pressure

The invention discloses a water pressure testing method and a device of a ultraheavy and ultralarge compressor shell, and belongs to the technical field of space division. The water pressure testing device of the ultraheavy and ultralarge compressor shell comprises a support mechanism contacted with a first shell, a pressure testing mechanism arranged in the first shell, a cavity separation tool flange for dividing the first shell into a low-pressure cavity and a high-pressure cavity, a thin position of the first shell located in the low-pressure cavity, a water passing mechanism connected with the first shell, and a water feeding mechanism communicated with the low-pressure cavity and the high-pressure cavity through the water passing mechanism. The water pressure testing method and the device of the ultraheavy and ultralarge compressor shell reduce the shell deformation risk, smoothly once finish the water pressure test, and save the cost, the time and the labors.

Owner:SHENYANG TURBO MASCH CORP

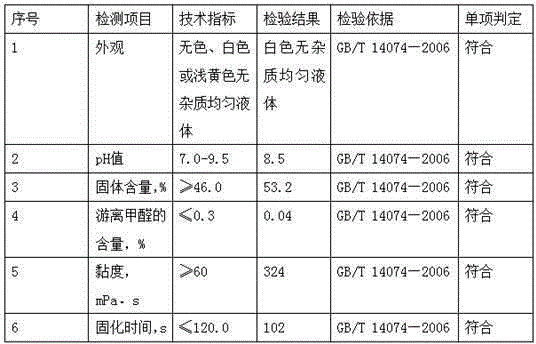

Method for manufacturing moth-proof and low-formaldehyde wardrobe plate

ActiveCN105108841AResidue reductionImprove water resistanceLaminationLamination apparatusAdhesiveMoisture resistance

The invention relates to a building material for home furnishing, in particular to a method for manufacturing a moth-proof and low-formaldehyde wardrobe plate. The method for manufacturing the moth-proof and low-formaldehyde wardrobe plate is characterized by comprising the steps of lathing a plank into pieces, conducting drying, trimming edges, applying adhesive, conducting prepressing, conducting hot-pressing, sanding cut edges, conducting moth proofing treatment, attaching abrasion resistant paper, conducting decoration veneering and sealing the edges. According to the method for manufacturing the wardrobe plate, the formaldehyde residual amount is small, an aluminum alloy frame is inlaid at the periphery of the wardrobe plate, moisture in the air can be effectively prevented from permeating the plate, the moisture resistance and water resistance of the wardrobe plate are improved, the wardrobe plate obtained through the manufacturing method has good moth prevention performance, mold prevention performance, moisture protection performance and abrasion resistant performance, the formaldehyde residual amount is small, damage to a human body is reduced, the obtained wardrobe plate is stable in quality, the dimension stability is good, the plate is not prone to being cracked, damaged or deformed, and the service life is long.

Owner:广州市艾依格家居制品有限公司

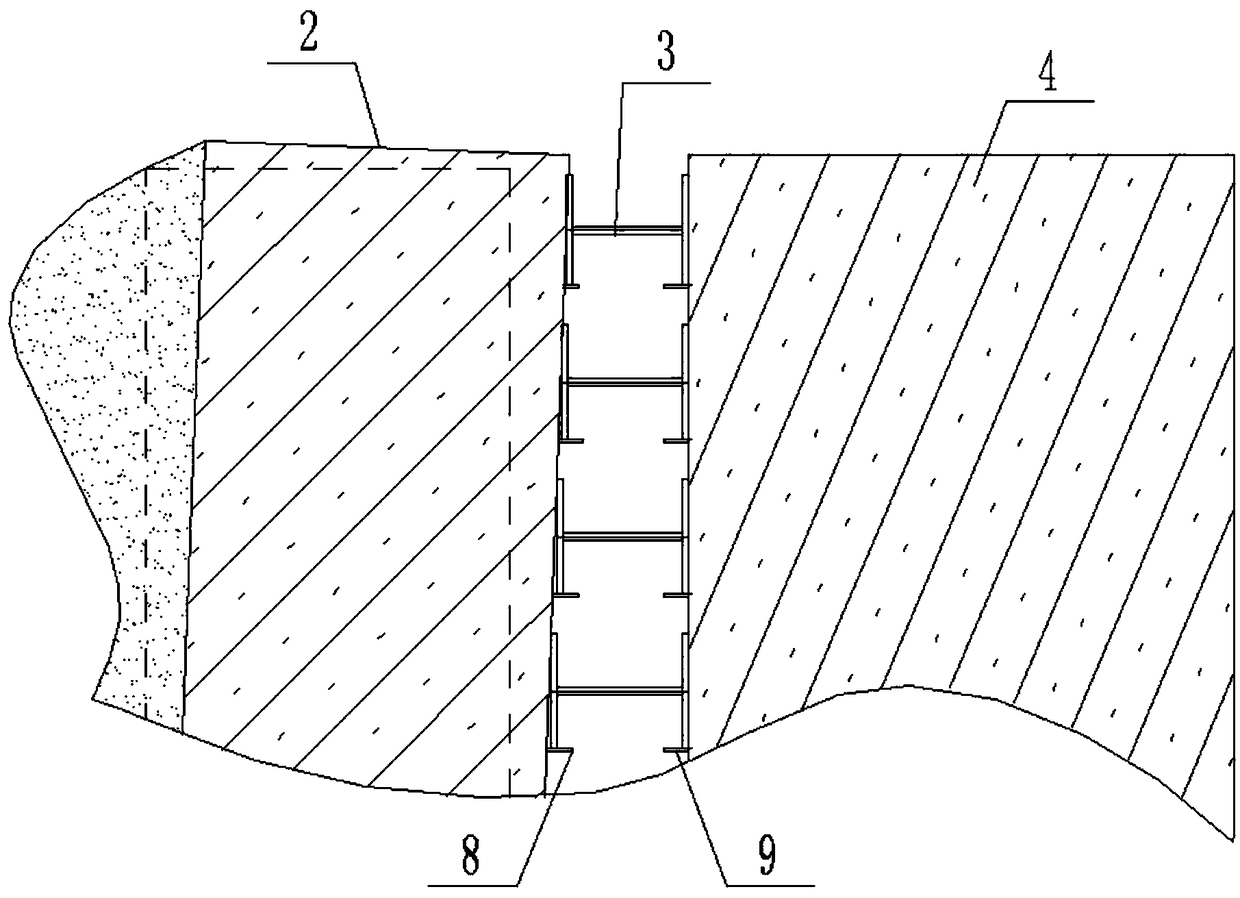

Steel plate pile surrounding purlin support system and foundation pit construction method adopting support system

InactiveCN109024610AImprove reliabilityGuaranteed reliabilityExcavationsBulkheads/pilesSupporting systemPurlin

The invention relates to the technical field of building projects, and particularly designs a steel plate pile surrounding purlin support system and a foundation pit construction method adopting the support system. The steel plate pile surrounding purlin support system comprises a plurality of steel plate piles. The steel plate piles are sequentially connected to form a steel plate pile wall for supporting the side wall of a foundation pit. The inner wall of the steel plate pile wall is further provided with at least one inner supporting assembly for providing support for the steel plate pilewall in the horizontal direction. According to the steel plate pile surrounding purlin support system, the multiple steel plate piles are connected to form the steel plate pile wall for supporting theside wall of the foundation pit, meanwhile, the inner wall of the steel plate pile wall is further provided with the inner supporting assembly for providing support for the steel plate pile wall in the horizontal direction, accordingly, the reliability of supporting of the side wall of the foundation pit through the steel plate pile wall is greatly improved, so that even when the steel plate piles penetrate through a plurality of soil layers, the reliable support can still be provided.

Owner:THE FIFTH ENG CO LTD OF CHINA RAILWAY NO 10 ENG GRP +1

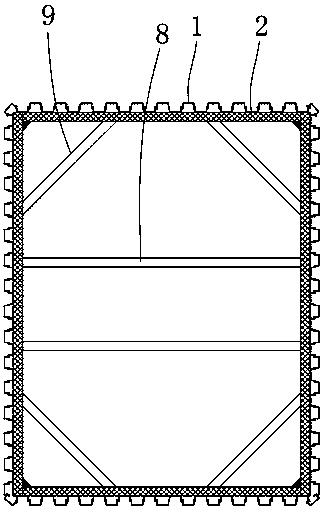

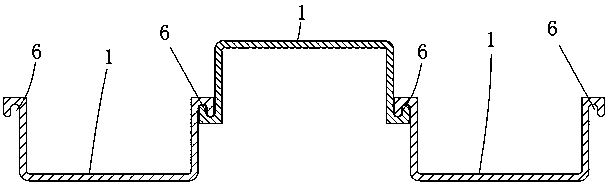

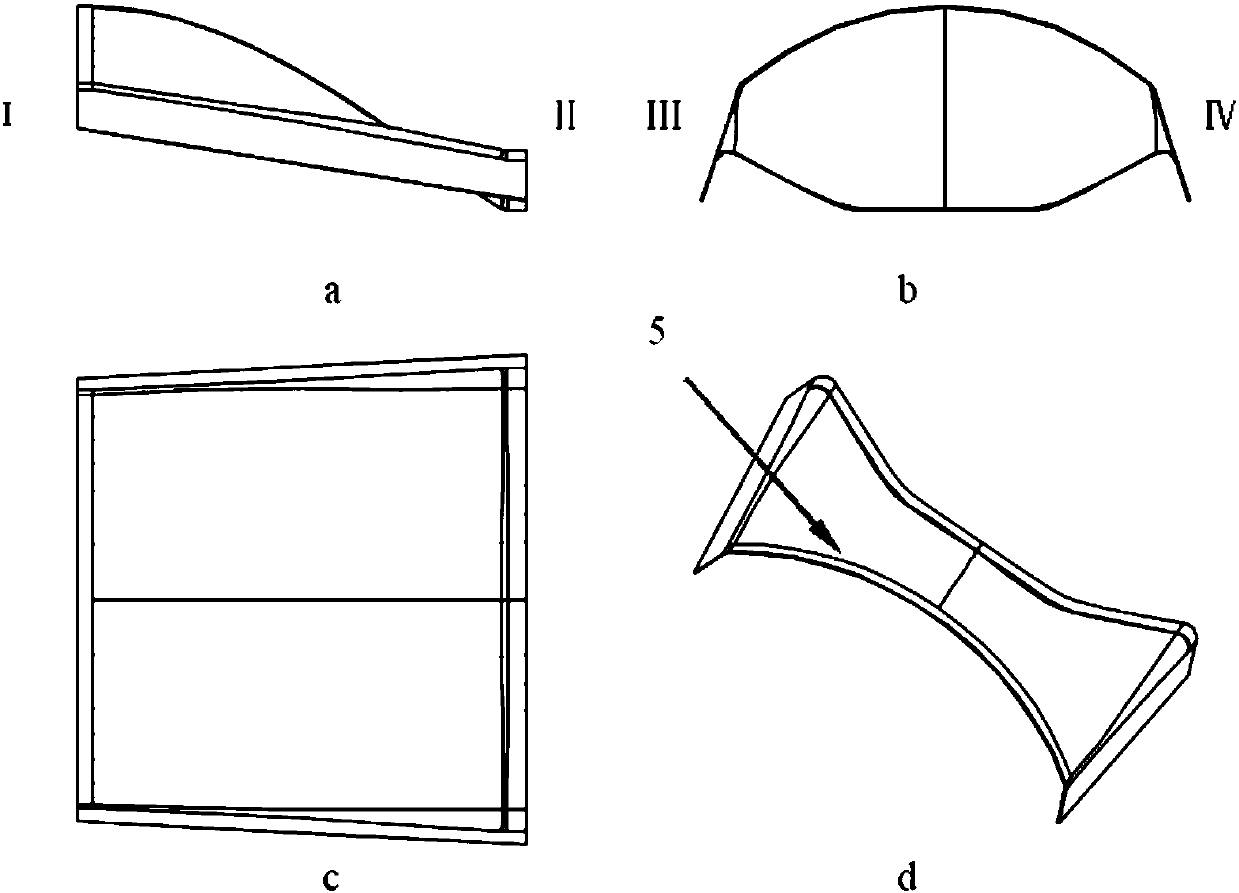

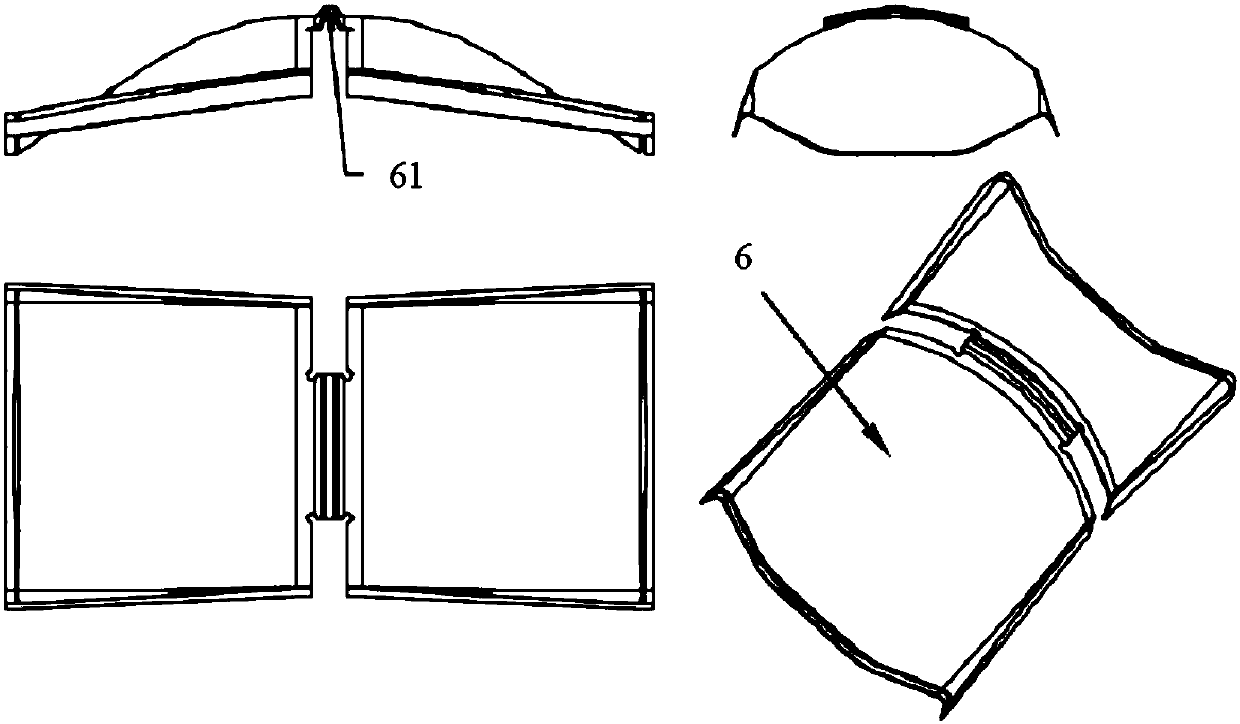

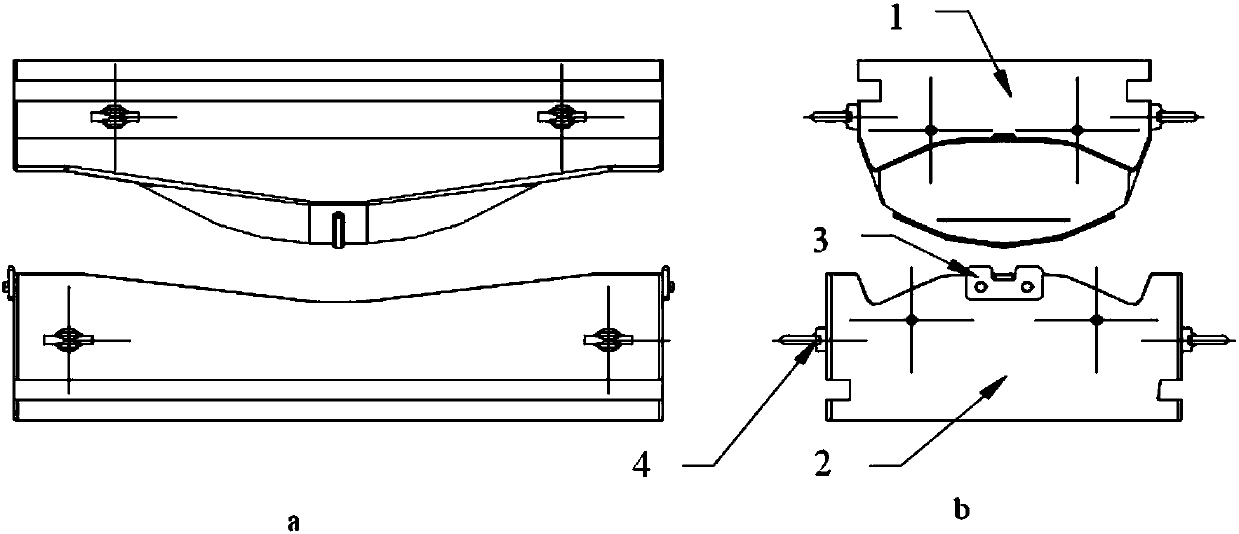

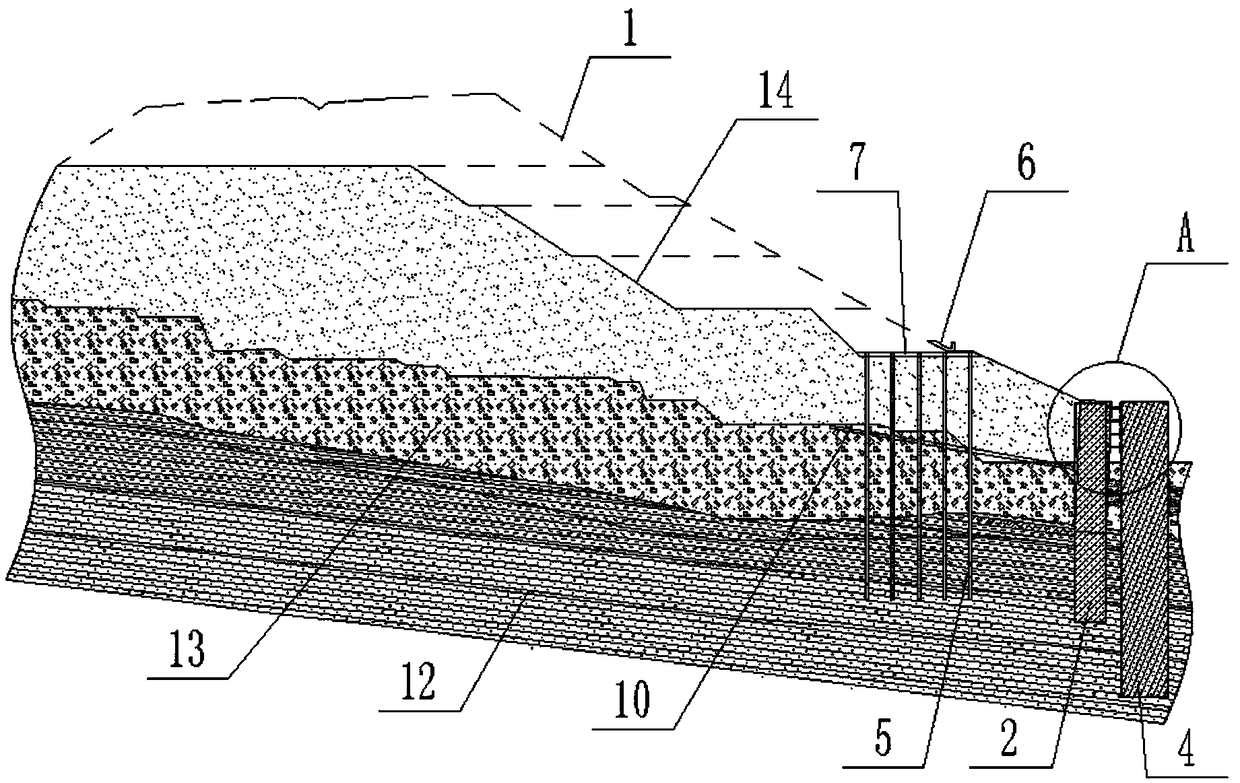

Lightweight hot forming die of special-shaped curved aluminum alloy thin-wall part and design method thereof

The invention relates to a lightweight hot forming die of a special-shaped curved aluminum alloy thin-wall part and a design method thereof. The die comprises a male die (1), a female die (2), positioning plates (3) and lifting lugs (4), wherein the bottom surface of the male die (1) is a forming molded surface which protrudes outwards, and the amplification coefficient of the forming molded surface on the basis of the molded surface of a workblank is determined according to the hot forming temperature requirement; a forming groove is formed in the top surface of the female die (2), and the amplification coefficient of the profile of the forming groove on the basis of the molded surface of the workblank is determined according to the hot forming temperature requirement; the positioning plates (3) are located in the middle of the both sides of the female die (2); and the lifting lugs (4) are respectively distributed on the side surfaces of the male die (1) and the female die (2). According to the lightweight hot forming die, precise hot forming of the special-shaped curved aluminum alloy thin-wall part can be effectively guaranteed, and the special-shaped curved aluminum alloy thin-wall part formed by the die has the advantages of stable quality, high dimensional accuracy, profile accuracy and surface quality, short forming cycle and high production efficiency.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

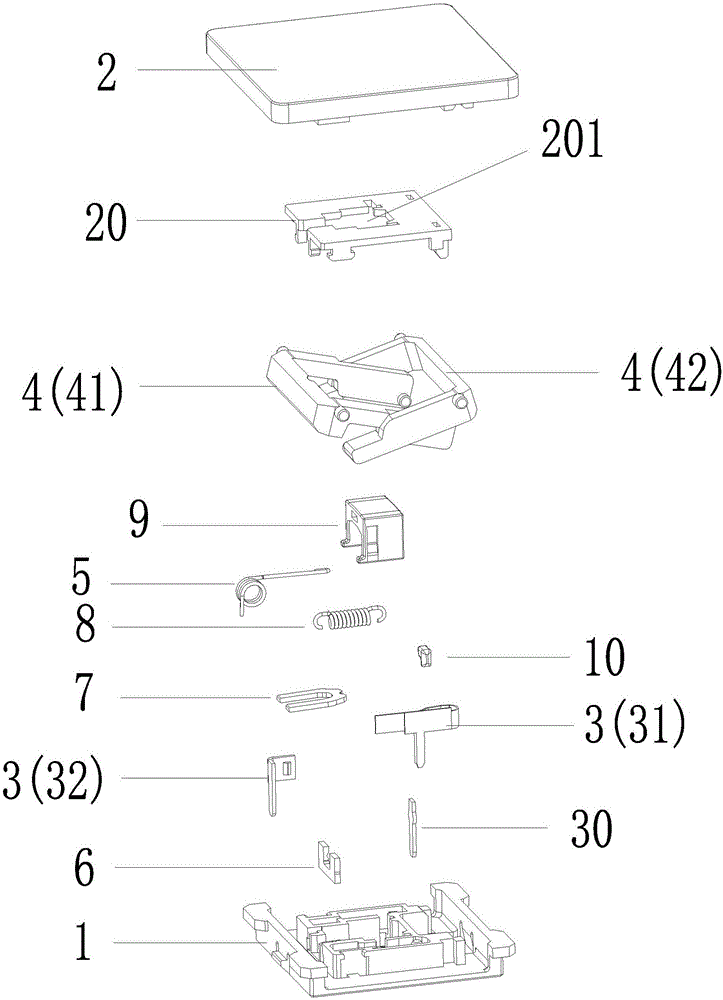

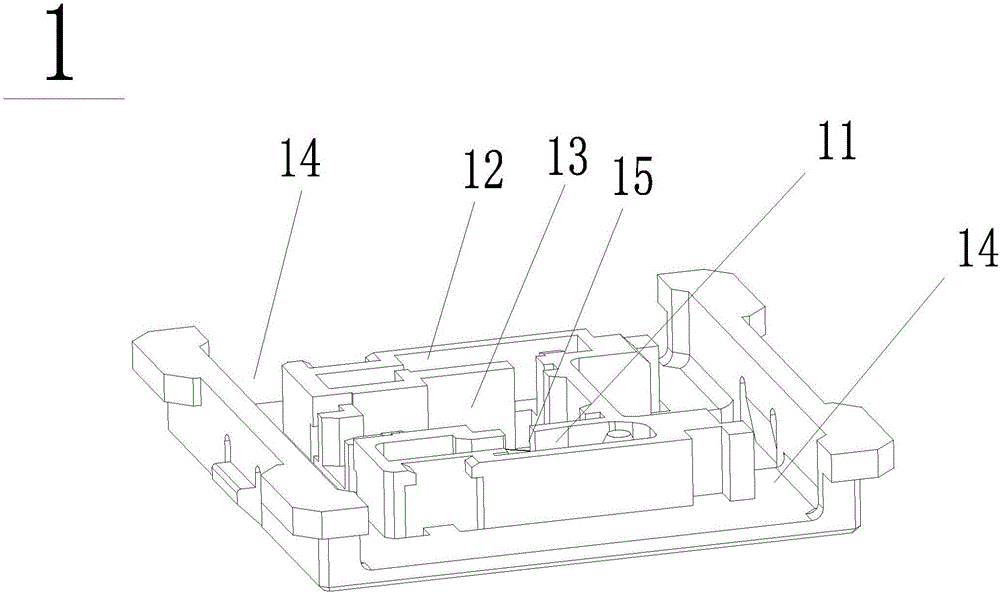

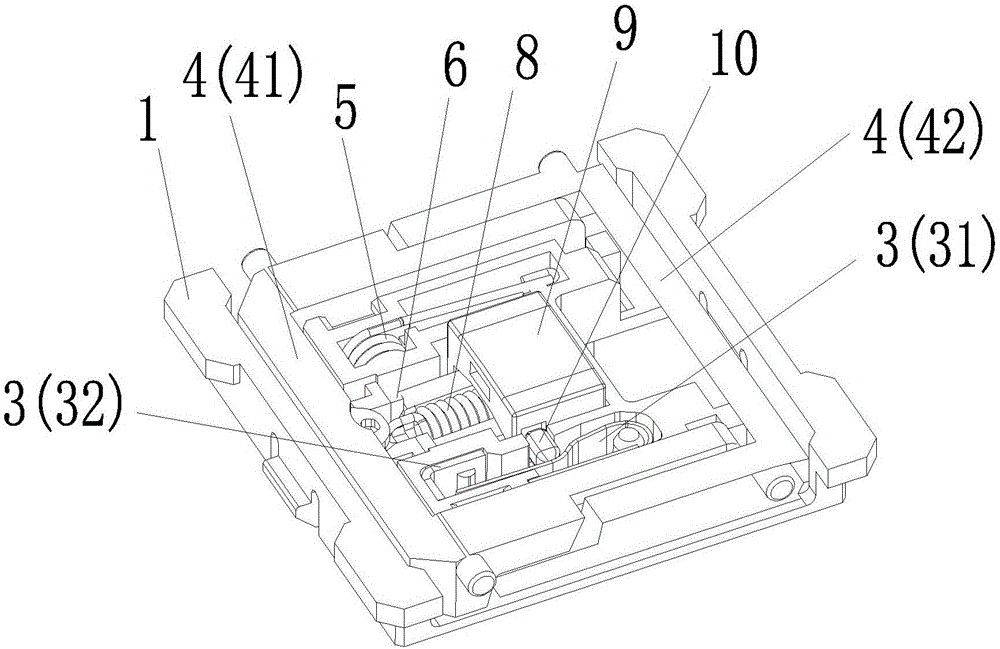

Thin-type mechanical keyboard switch

ActiveCN106356233AImprove balanceStable structural designDigital data processing detailsContact operating partsBiochemical engineeringPiston

The invention discloses a thin-type mechanical keyboard switch. The thin-type mechanical keyboard switch comprises a base and a keycap arranged on the base, wherein a first lateral containing groove is formed in the base; a conducting assembly is arranged on the first lateral containing groove; a second lateral containing groove, a middle containing groove located between the first lateral containing groove and the second lateral containing groove, and a surrounding groove formed around an upper end edge of the base are further formed in the base, wherein the surrounding groove is internally provided with a balance frame and a torsional spring is arranged in the second lateral containing groove; the middle containing groove is internally provided with a separation sheet, a hanging sheet, a tension spring and a guide core; one end of the tension spring is clamped into the guide core and is connected with the hanging sheet and the other end of the tension spring is connected with the balance frame; a through groove is formed between the first lateral containing groove and the middle containing groove; the middle containing groove is internally provided with a piston; the piston is located between the guide core and the conducting assembly. By adopting the thin type mechanical keyboard switch, the stability is improved and the thin type mechanical keyboard switch has a good touch feeling in a pressing process; sounds can be made in the pressing process and user experience is improved.

Owner:DONGGUAN CITY KAIHUA ELECTRONICS

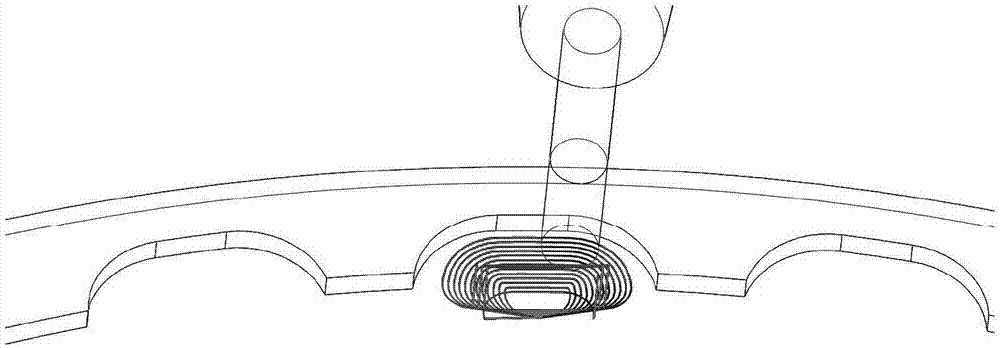

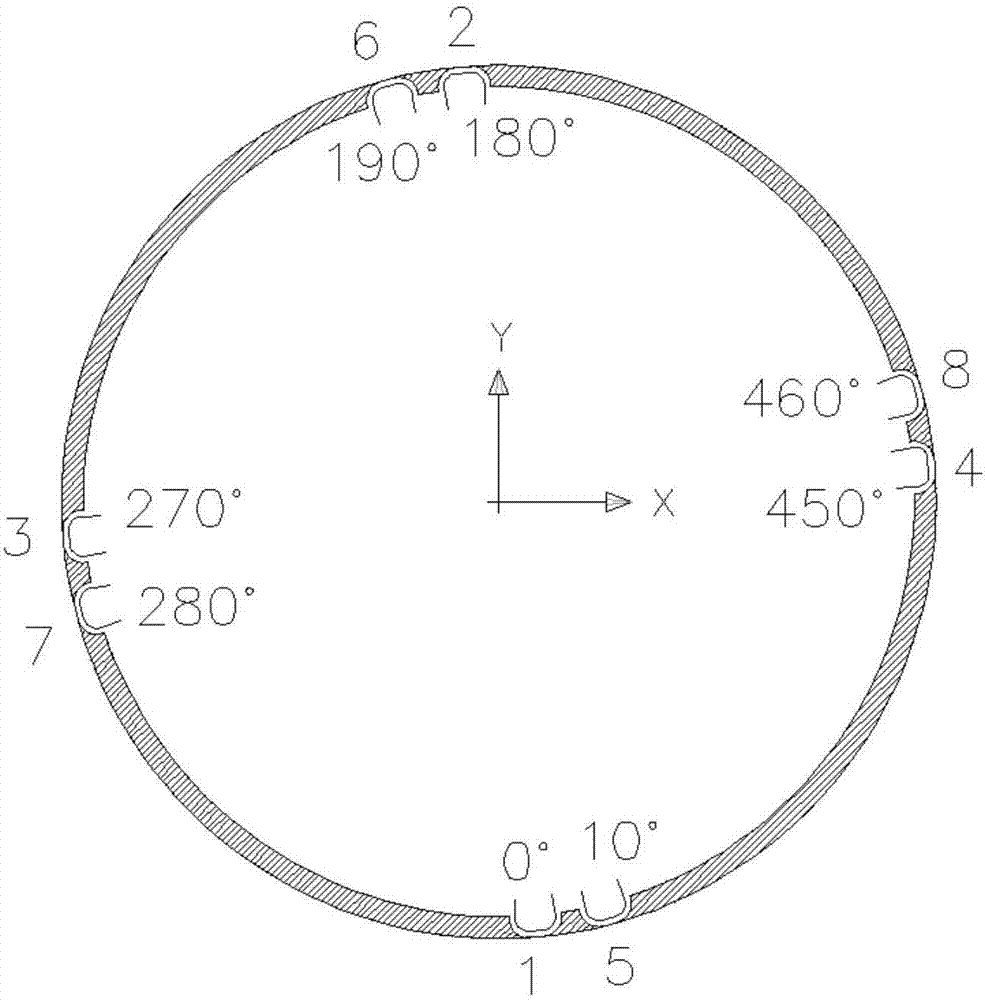

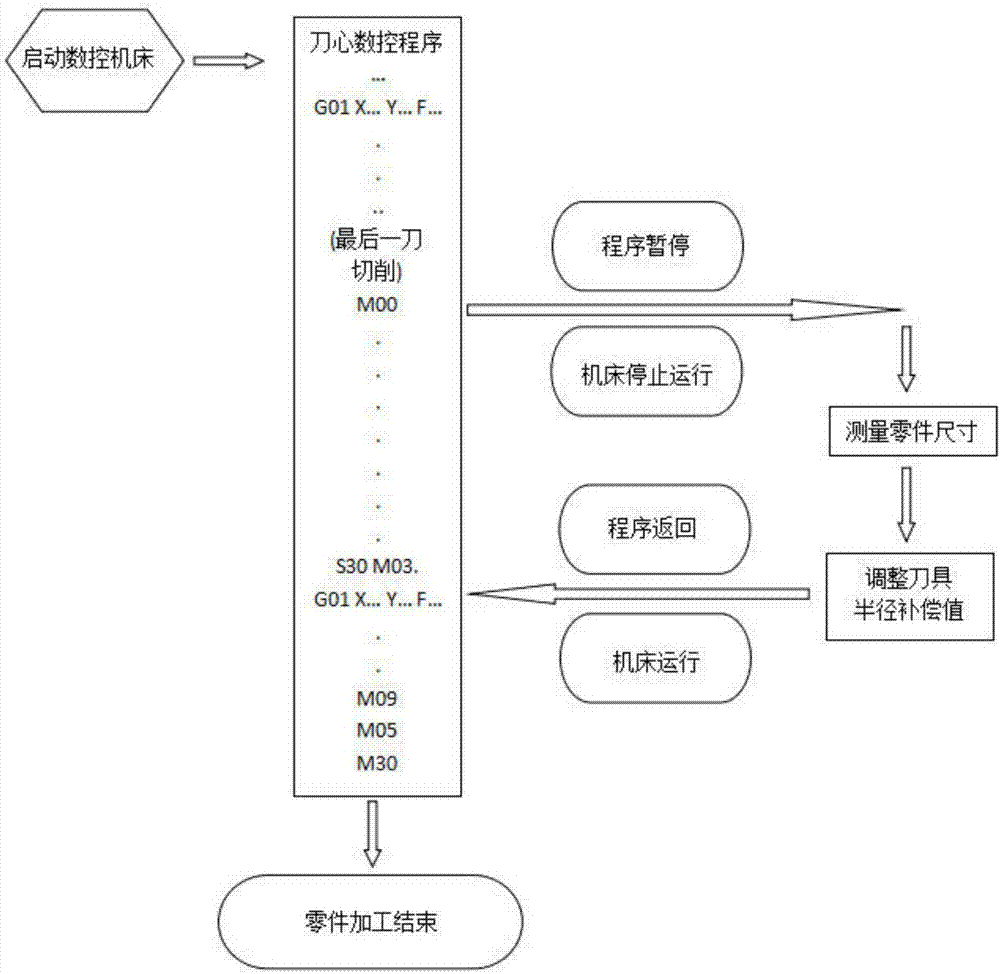

Machining method for circumferential efficient milling deformation control

ActiveCN107971534ALess interventionReduced risk of deformationMilling equipment detailsNumerical controlCutting forceDeformation control

The invention discloses a machining method for circumferential efficient milling deformation control. The machining method adopts a layered milling mode for machining. In the machining process, the cutter center numerically-controlling process comprises the following steps that (1) a numerically-controlled machine tool is started, and a cutter center numerically-controlling main procedure is operated; (2) a rough machining procedure is called, after the rough machining procedure completes last cut of machining cutting, the procedure is suspended, and the machine tool stops operating; (3) the sizes of parts are measured, and the cutter radius compensation value is adjusted according to the measured result; (4) the procedures are executed again, the machine tool operates, and a fine machining procedure is called; and (5) part machining is finished. According to the machining method for circumferential efficient milling deformation control, the intervention degree of an operator is reduced, layered milling is adopted, cutting force is reduced, the part deformation risk is reduced, free change of the cutter length makes abrasion of a cutter be uniform, and the precision of the profiletolerance is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

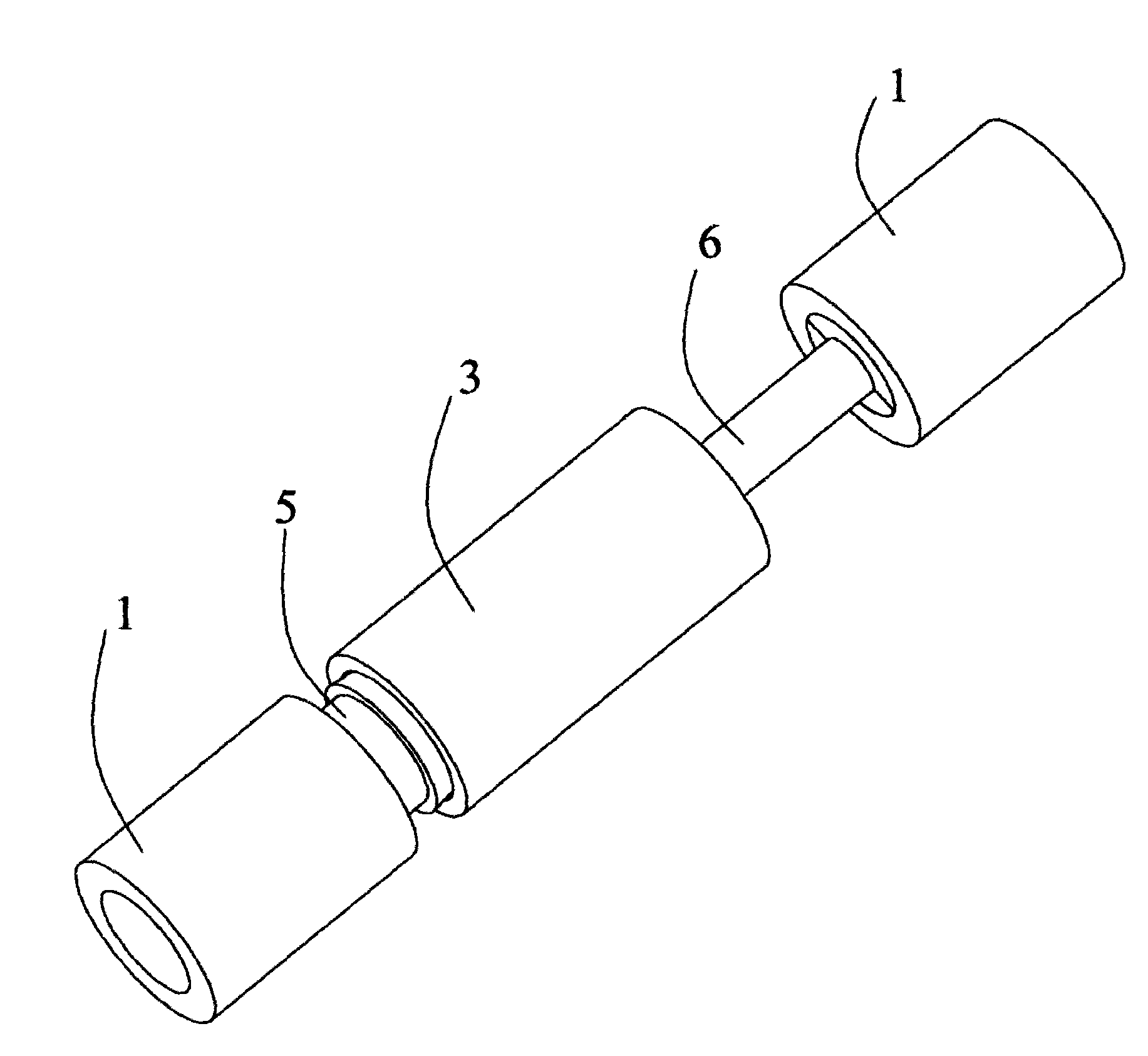

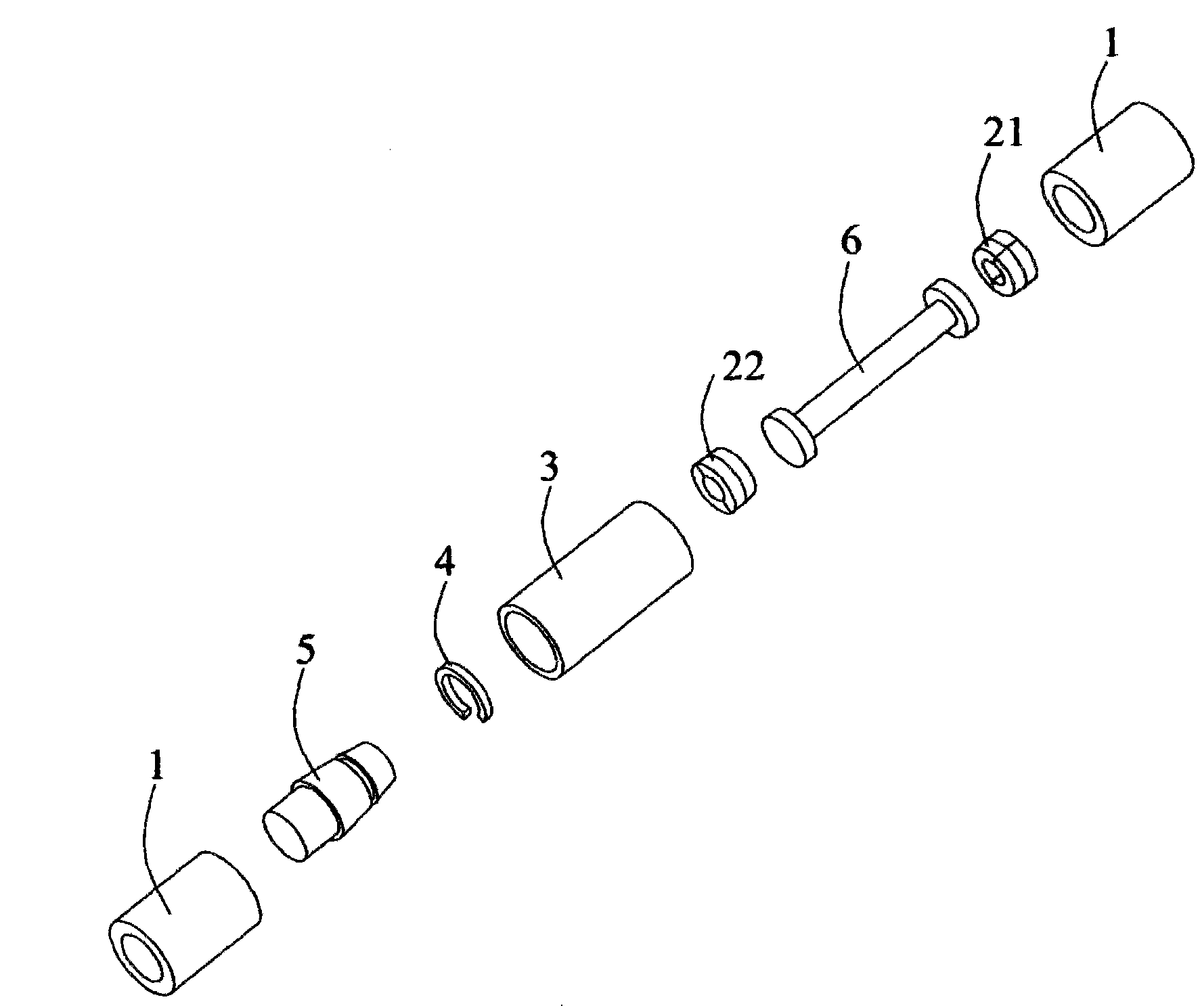

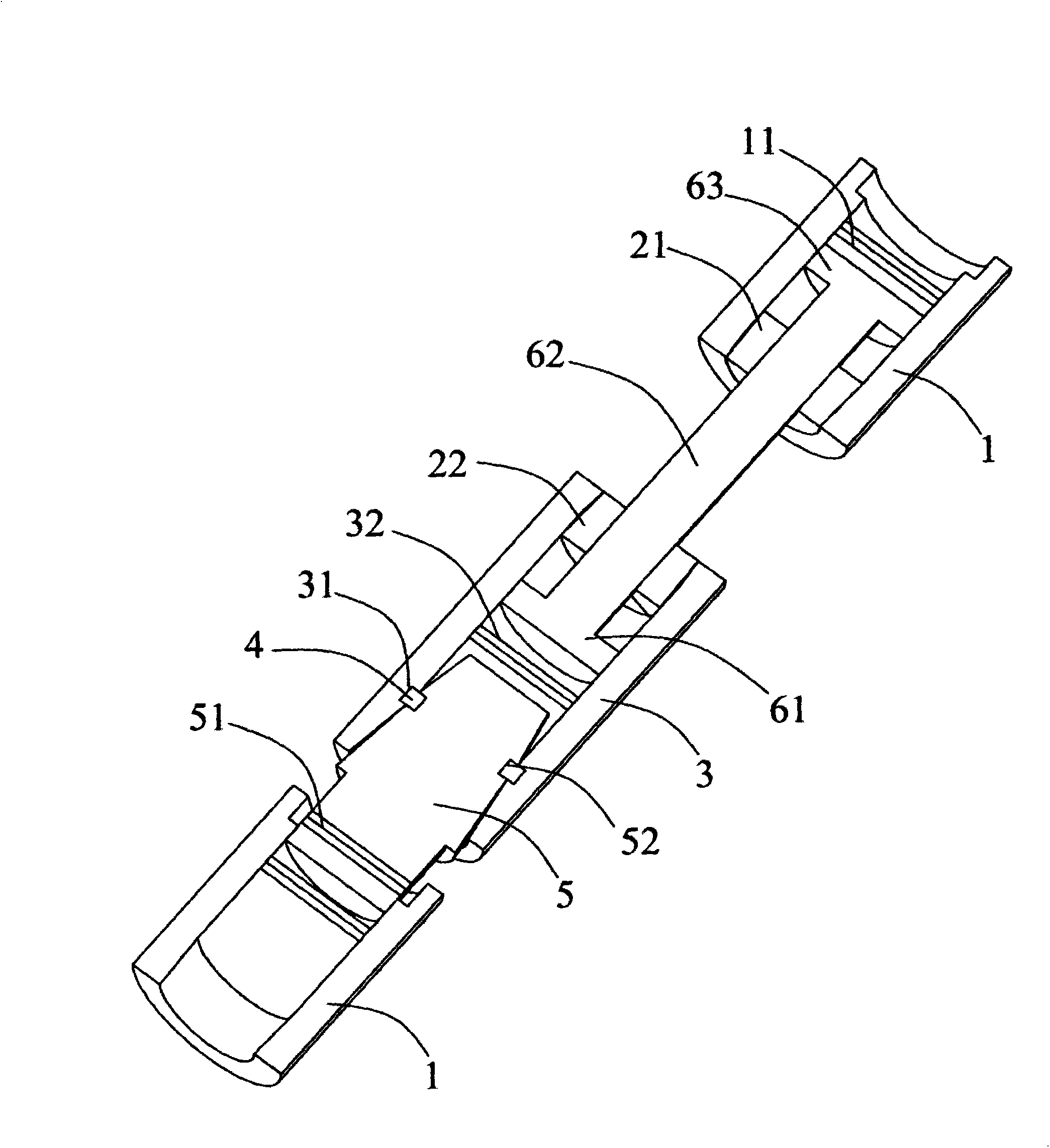

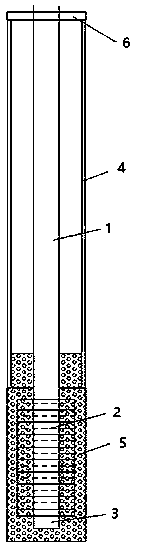

Tubular pile end-plate-free and pulling resistant functional assembly

InactiveCN103882863ALess steel consumptionReduce manual labor intensityBulkheads/pilesHollow cylinderEngineering

The invention discloses a tubular pile end-plate-free and pulling resistant functional assembly. The tubular pile end-plate-free and pulling resistant functional assembly comprises short nuts, locking clamps, a long nut, a snap spring and a connecting bolt. The locking clamps include the first locking clamp and the second locking clamp. Each locking clamp is a cylinder provided with a cylindrical face with the inclination taper. Each short nut is a hollow cylinder. First internal threads are arranged at the large-opening end of each short nut, and the taper matched with the first locking clamp is arranged at the small-opening end of the short nut. The long nut is also a hollow cylinder. A first snap spring groove is formed in the large-opening end of the long nut, and the taper matched with the second locking clamp is arranged at the small-opening end of the long nut. Second internal threads matched with a tension screw are arranged in the middle of the long nut. One end of the connecting bolt is provided with bolt threads matched with the first internal threads, and the other end of the connecting bolt is provided with a second snap spring groove. The snap spring is arranged between the first snap spring groove and the second snap spring groove. The tubular pile end-plate-free and pulling resistant functional assembly is low in production cost.

Owner:姚瑜

Binder used for 3D printing materials

InactiveCN109251455AGood adhesionAccelerates the infiltration processAdditive manufacturing apparatusPolyvinyl alcoholPotassium carbonate

The invention discloses a binder used for 3D printing materials. The binder is composed of a component A and a component B at a mass ratio of 2-3:1; the component A comprises, by mass, 50 to 60 partsof acrylic emulsion, 30 to 40 parts of polyvinyl alcohol, 10 to 13 parts of polyvinyl acetate emulsion, 8 to 15 parts of non-ionic polyacrylamide, 20 to 40 parts of soybean protein glue, 2 to 3 partsof sodium hypochlorite, 7 to 12 parts of sodium dodecyl benzene sulfonate, 15 to 20 parts of inorganic gel, 5 to 8 parts of hydroxypropyl methyl cellulose ether, 3 to 6 parts of a stabilizing agent, and 3 to 5 parts of a thickening agent; and the component B comprises, by mass, 35 to 45 parts of polylactic acid, 15 to 20 parts of aerosil, 30 to 40 parts of wax maize starch, 10 to 15 parts of ethylene glycol diacetate, 20 to 35 parts of alumina sol, 8 to 13 parts of allyl methacrylate, 15 to 22 parts of absolute ethyl alcohol, 5 to 8 parts of anhydrous potassium carbonate, 15 to 25 parts of anhydrous magnesium sulfate, 2 to 4 parts of glycol, 5 to 9 parts of nanometer manganous oxide, 3 to 5 parts of a composite initiator, 3 to 6 parts of a curing agent, and 6 to 11 parts of an activator.

Owner:江苏天泽教育咨询有限公司

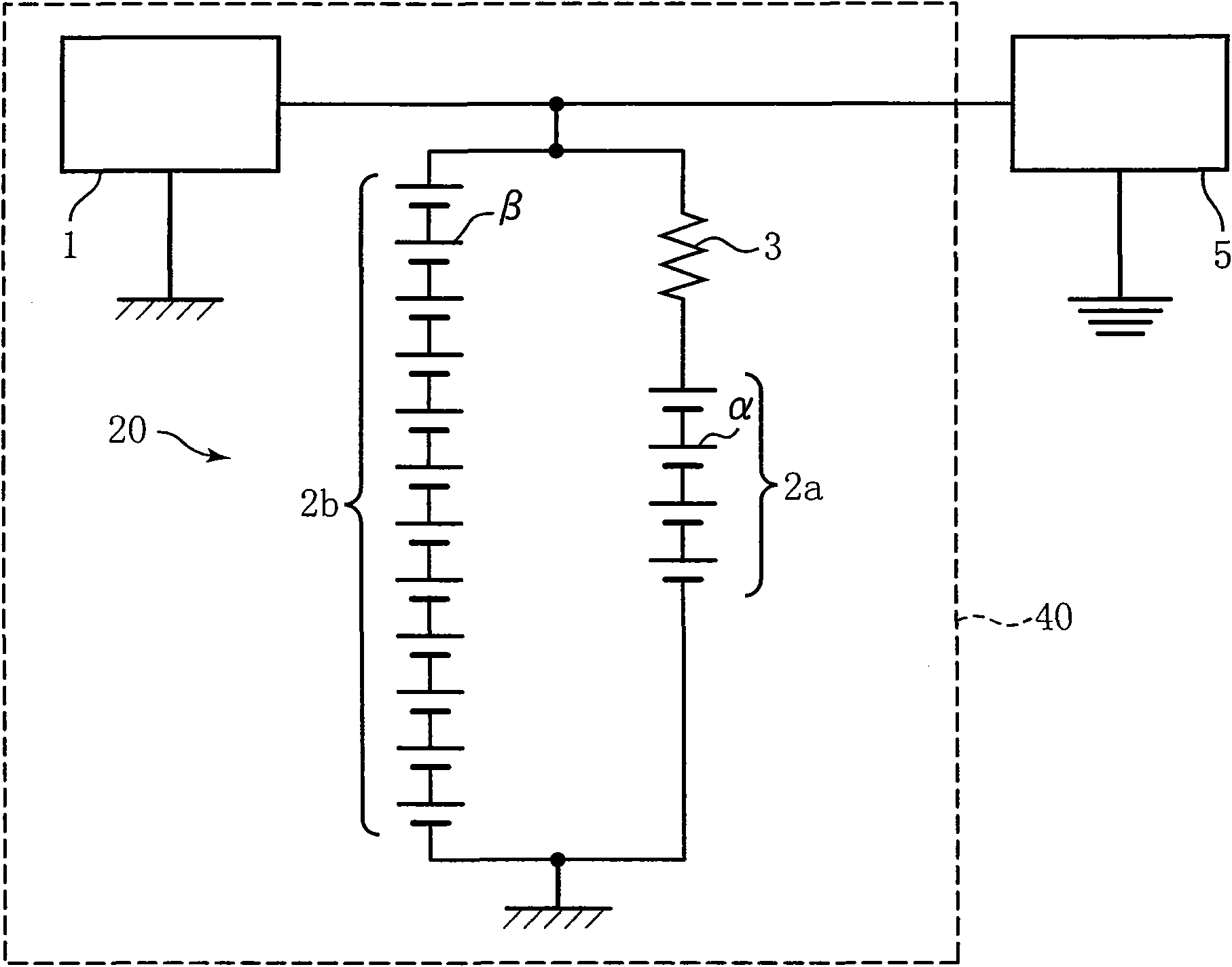

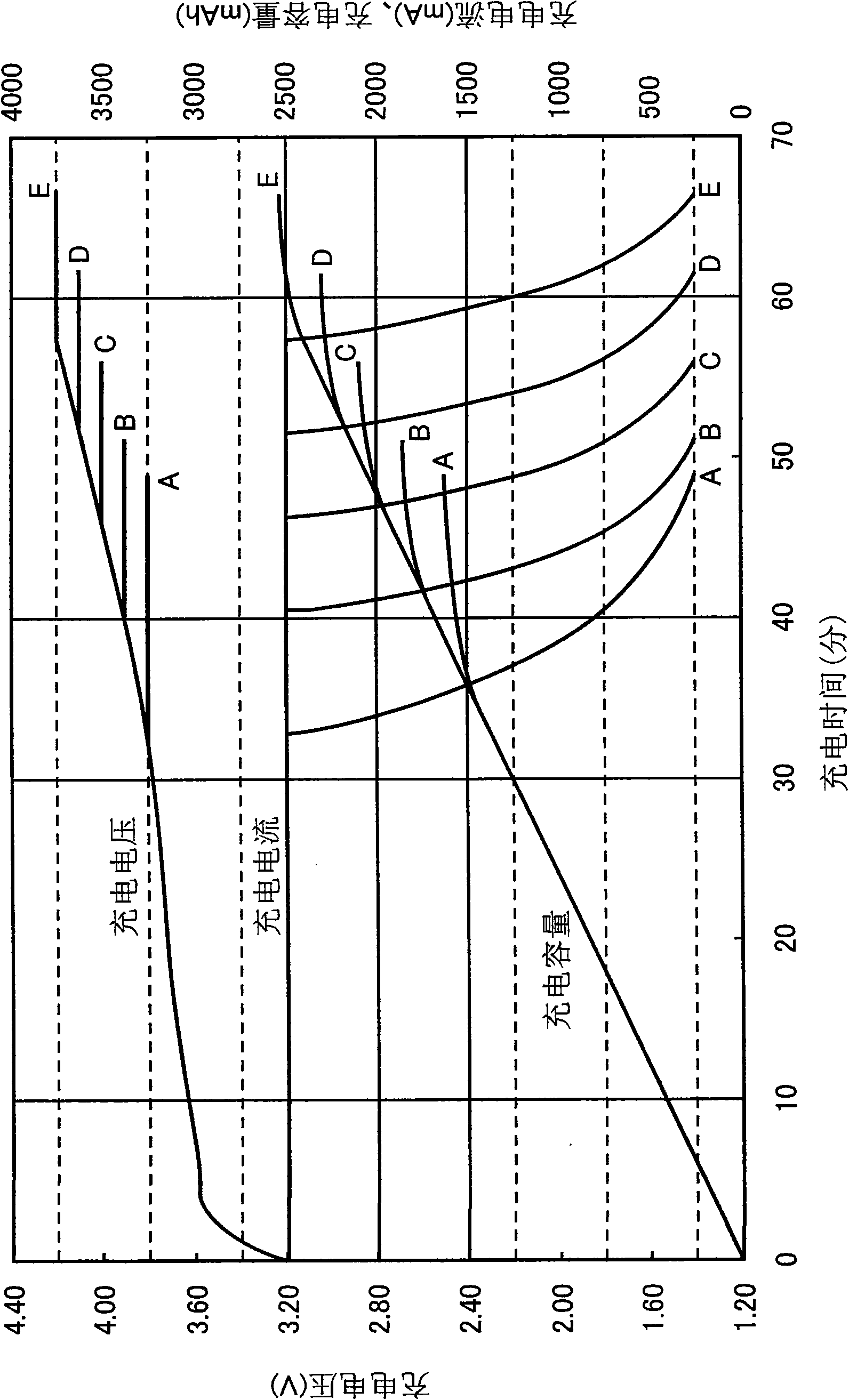

Power supply system

InactiveCN101816082AReduced risk of deformationCell electrodesCharging managementCapacitanceTerminal voltage

A power supply system includes: a cell assembly formed by a first cell set having a plurality of first element cells connected in series and a second cell set having a plurality of second element cells connected in series; and a generator for charging the cell assembly. The cell assembly is set so that an average voltage V1 as a terminal voltage when the charge capacitance of the first cell set is half of a full charge capacitance is smaller than an average voltage V2 as a terminal voltage when the charge capacitance of the second cell set is half of a full charge capacitance. The first cell set is connected to a resistor in series.

Owner:PANASONIC CORP

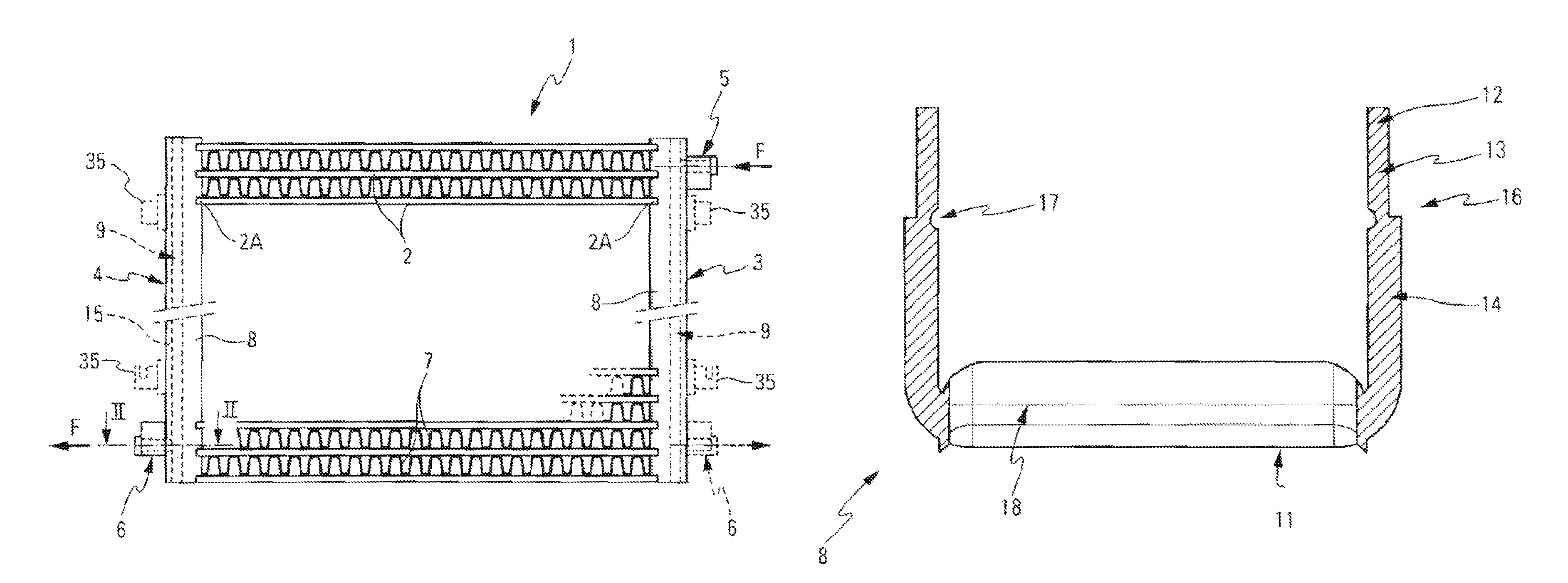

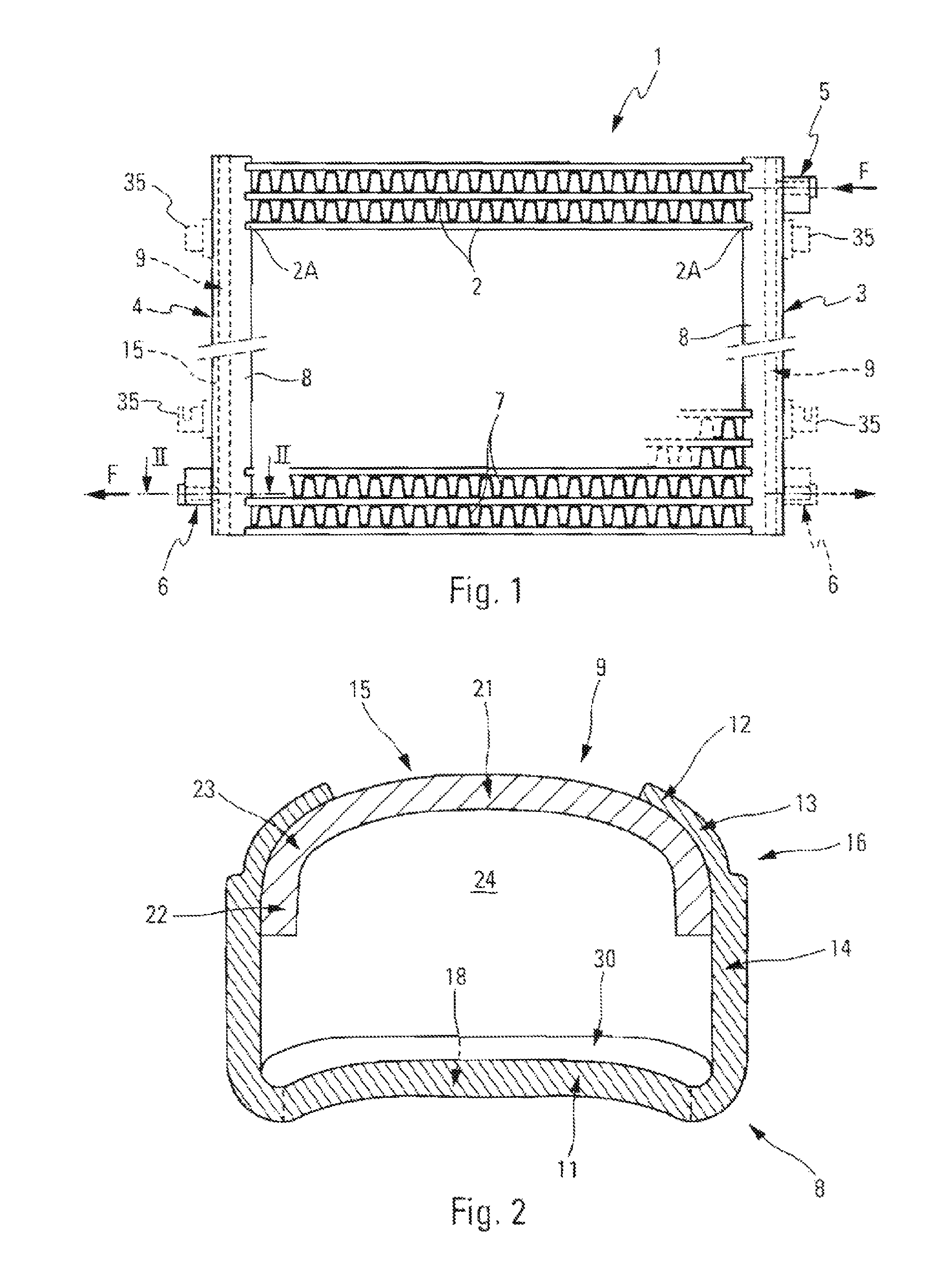

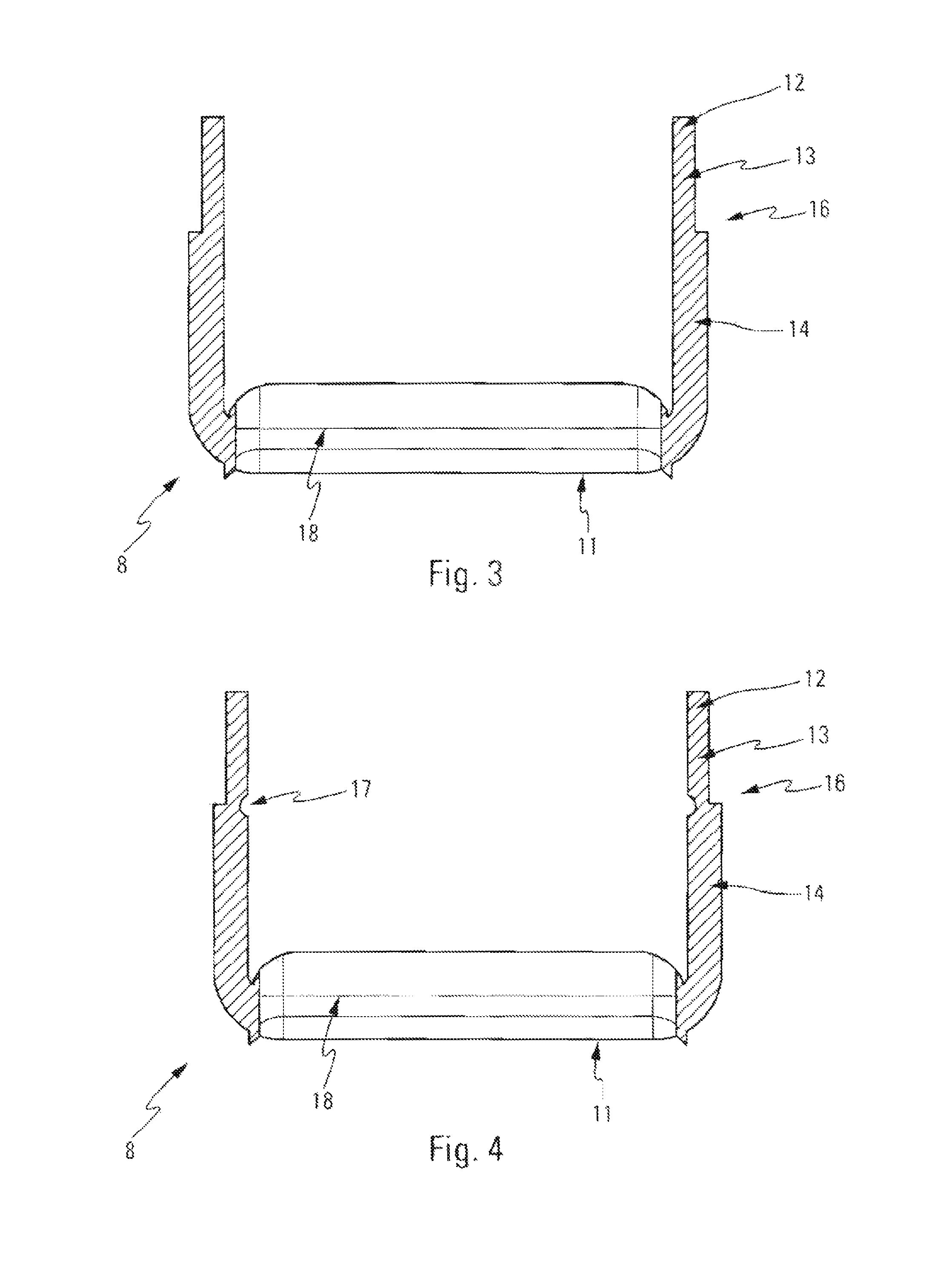

Assembly of two parts crimped one over the other

ActiveUS9546828B2Easy to foldReduced risk of deformationStationary conduit assembliesHeat exchanger casingsEngineeringMechanical engineering

The invention relates to an assembly of two parts crimped together by folding at least one portion of peripheral edge (12) of one so-called first part (8) over the other so-called second part (9). Said first part (8) has a hinge-forming region facilitating the folding of said portion of peripheral edge (12). The invention also relates to a manifold comprising said assembly and a heat exchanger comprising said manifold.

Owner:VALEO SYST THERMIQUES

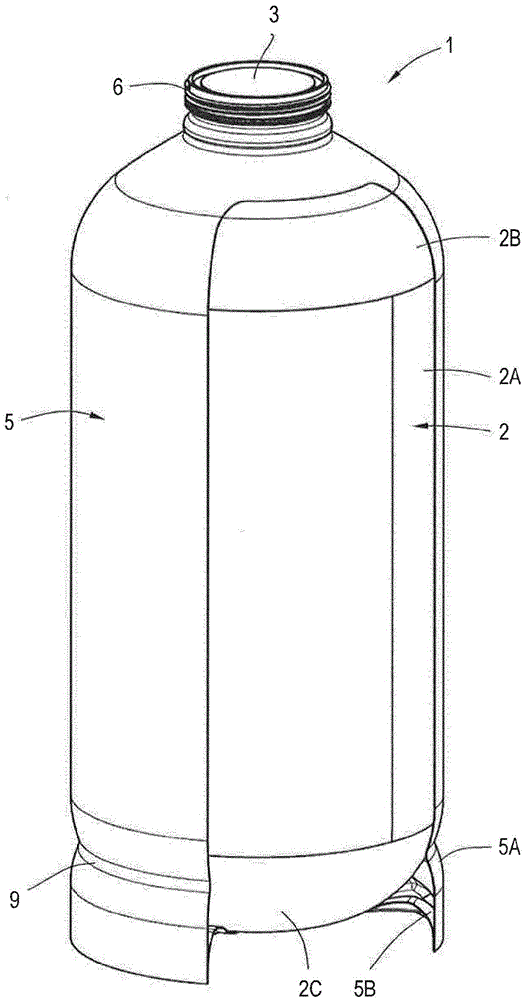

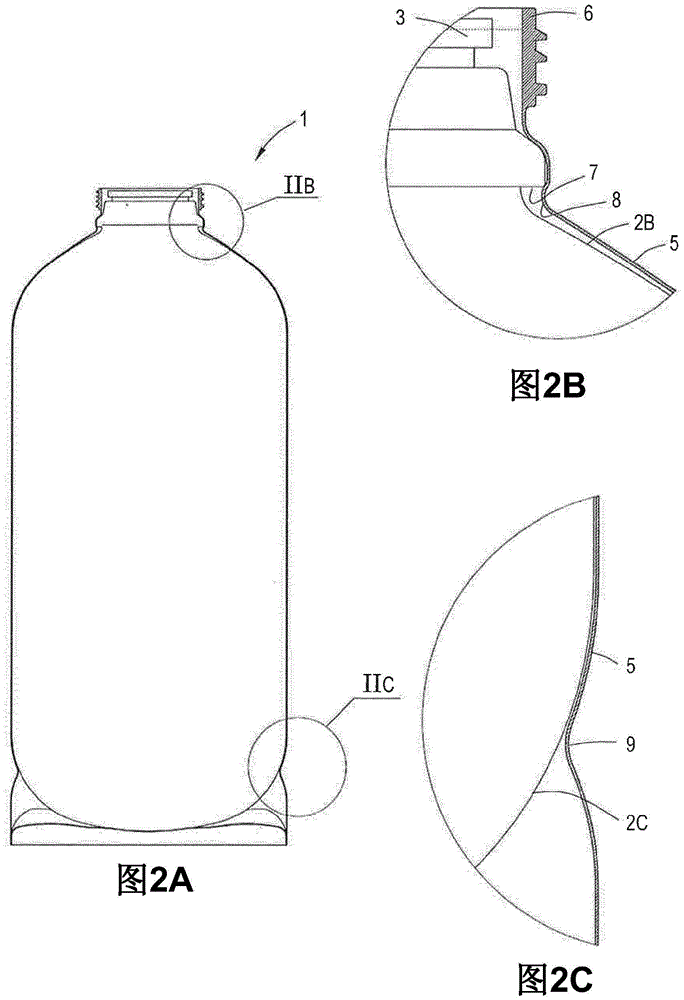

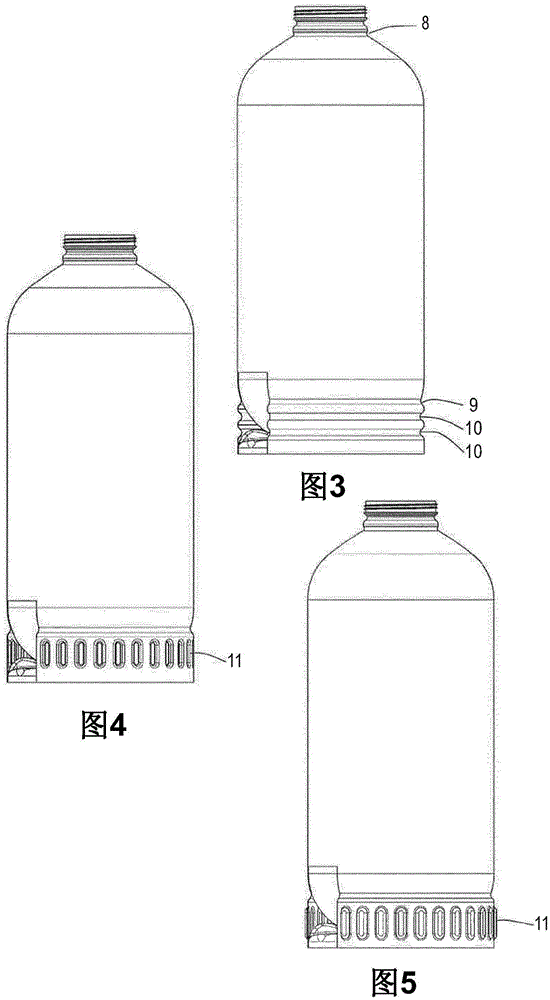

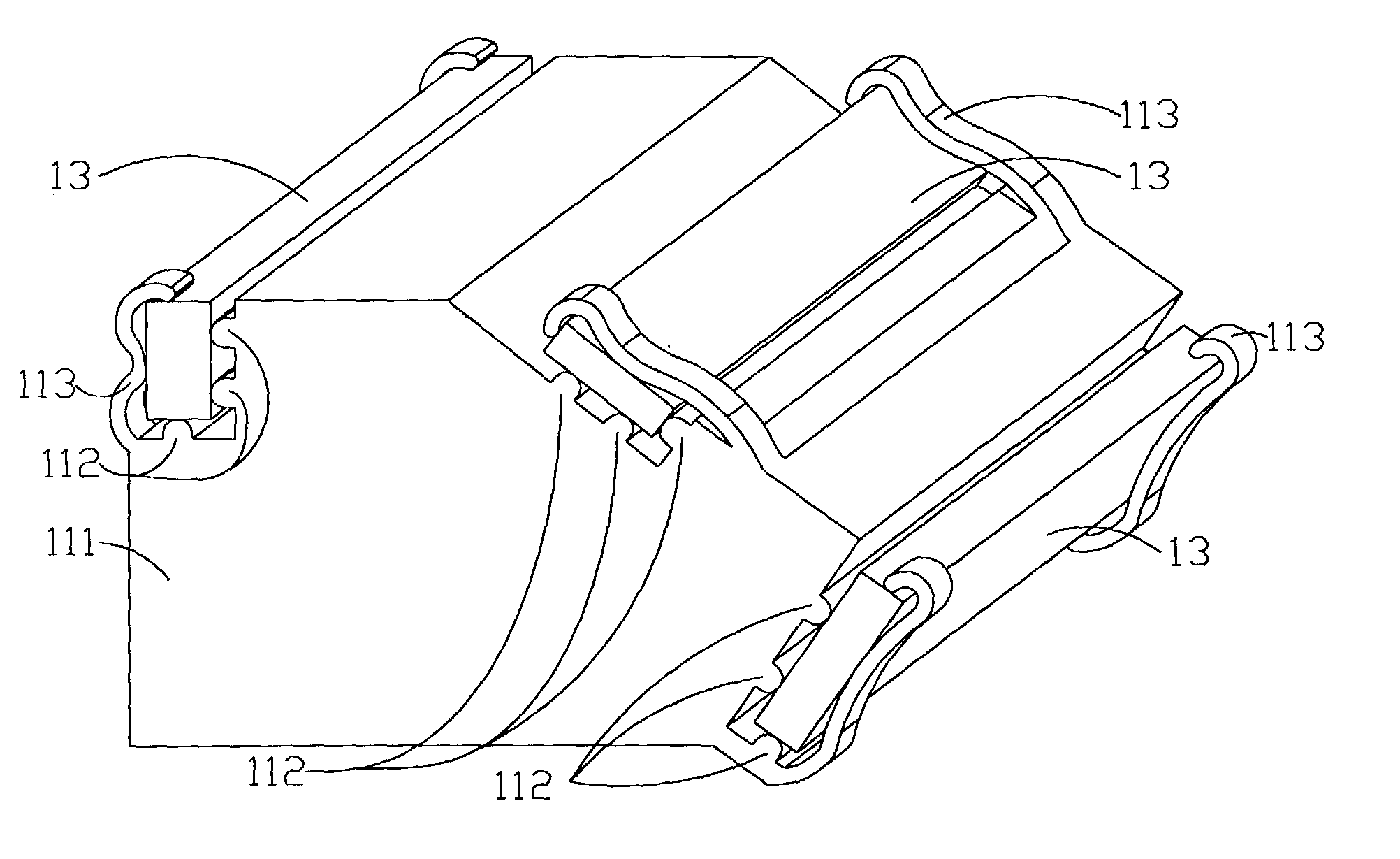

Container for liquids

InactiveCN105555673APrevent or reduce misalignmentReduced risk of deformationLiquid transferring devicesCans/barrels/drumsEngineeringMechanical engineering

Owner:EUROKEG BV

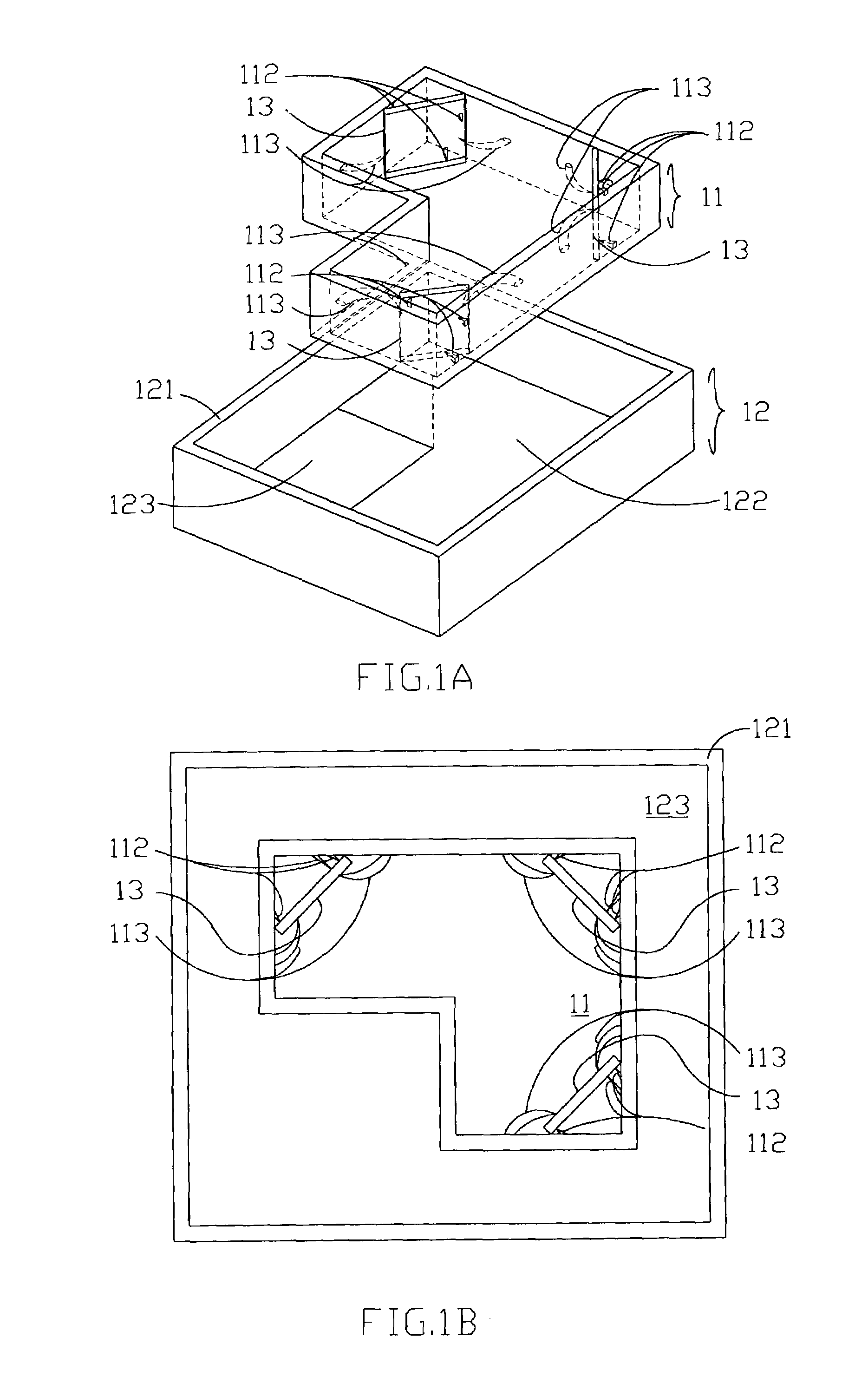

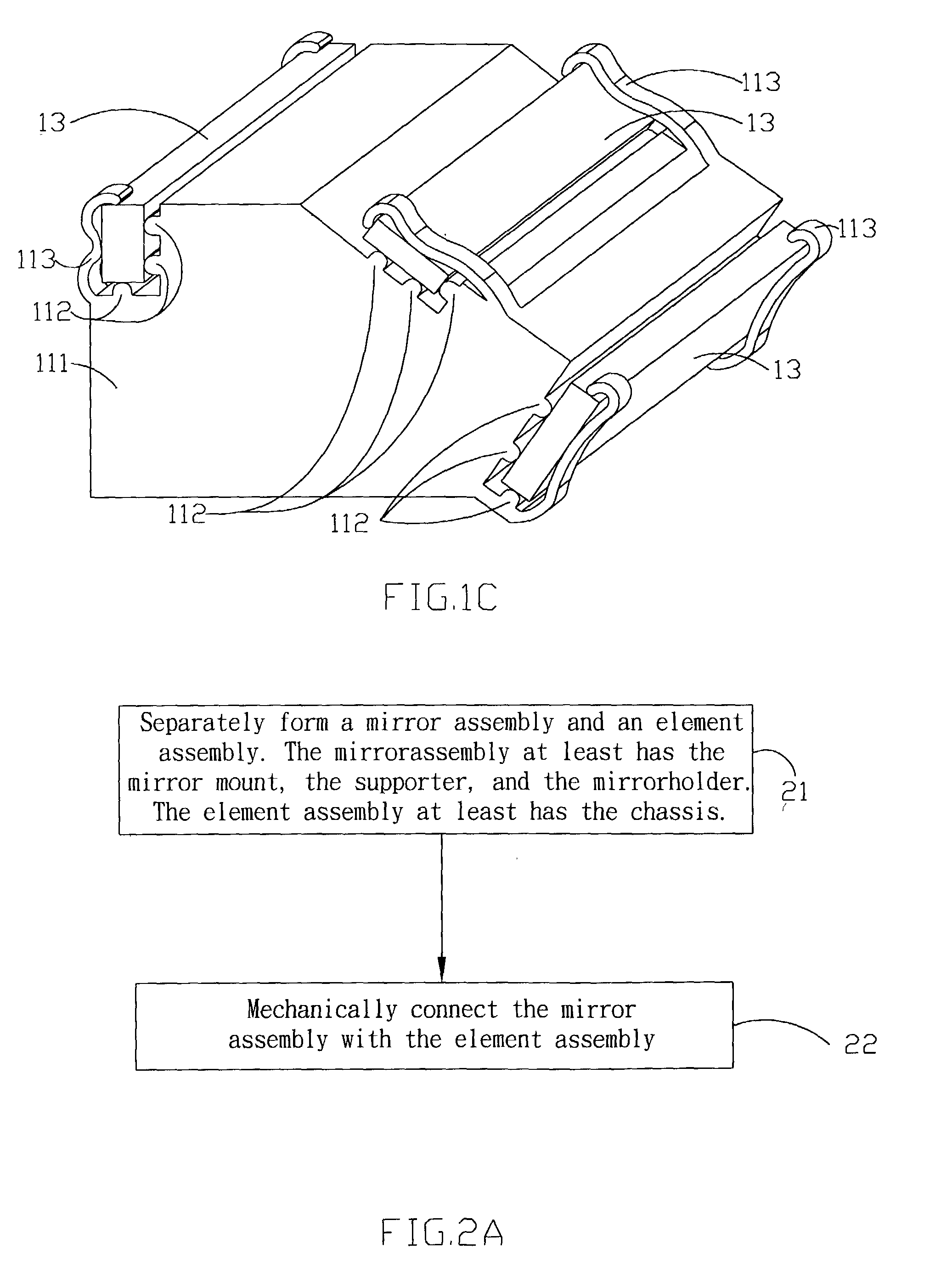

Optical carriage of scanner and method for the same

InactiveUS7133164B2Reduce riskLow costSolid-state devicesMaterial analysis by optical meansBiomedical engineeringMirror mount

An optical carriage of scanner has a mirror assembly and a device assembly, the mirror assembly has a mirror mount, some mirror holder, and some supporters, and the device assembly has a chassis. In this invention, the mirror assembly and the device assembly are mechanically connected after separately formation. Further, to ensure correct shape of these mirror holders and these supporters, they could be formed by metal punch, plastic ejection, or plastic process.

Owner:INTELLECTUAL VENTURES I LLC

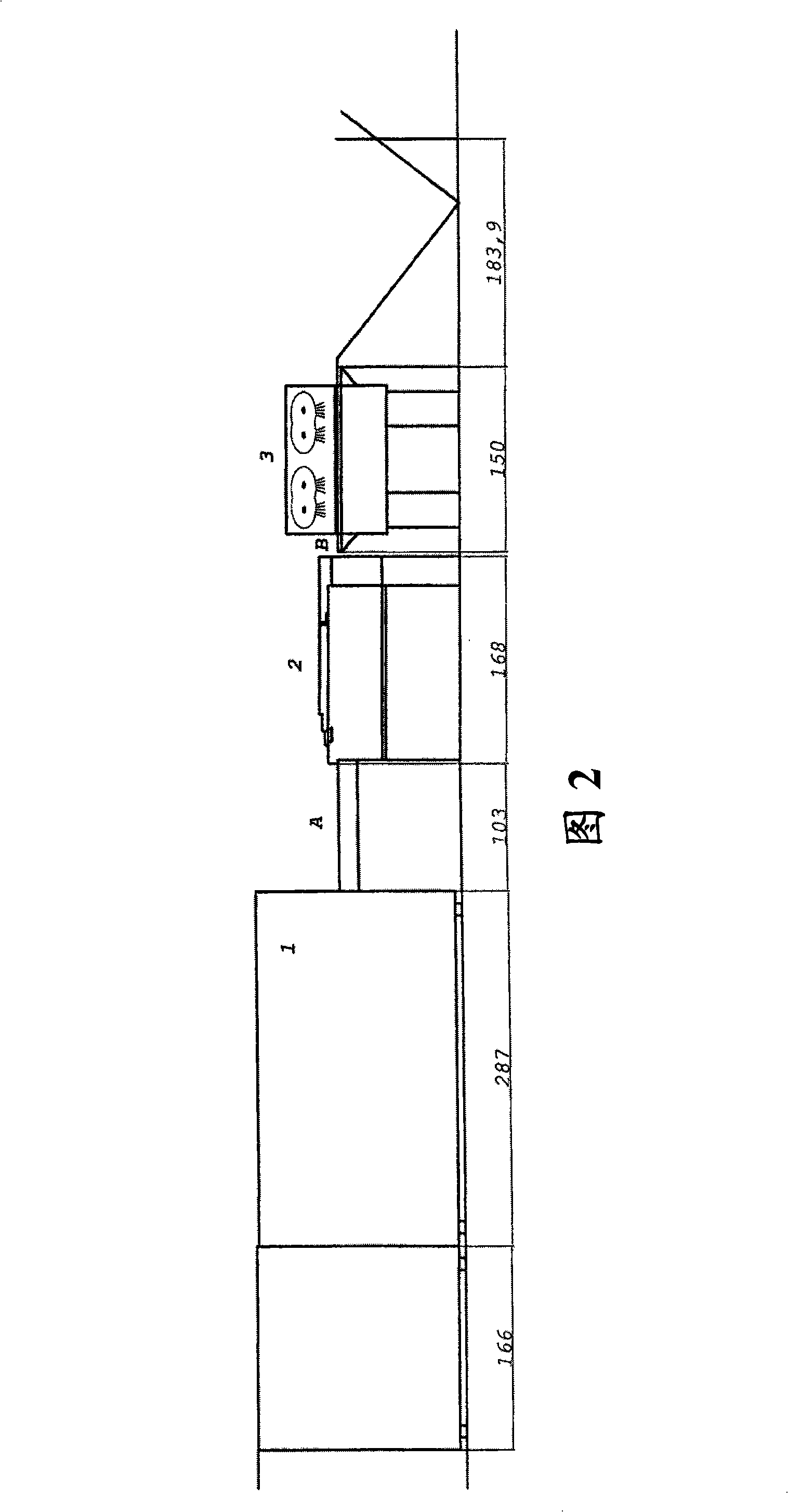

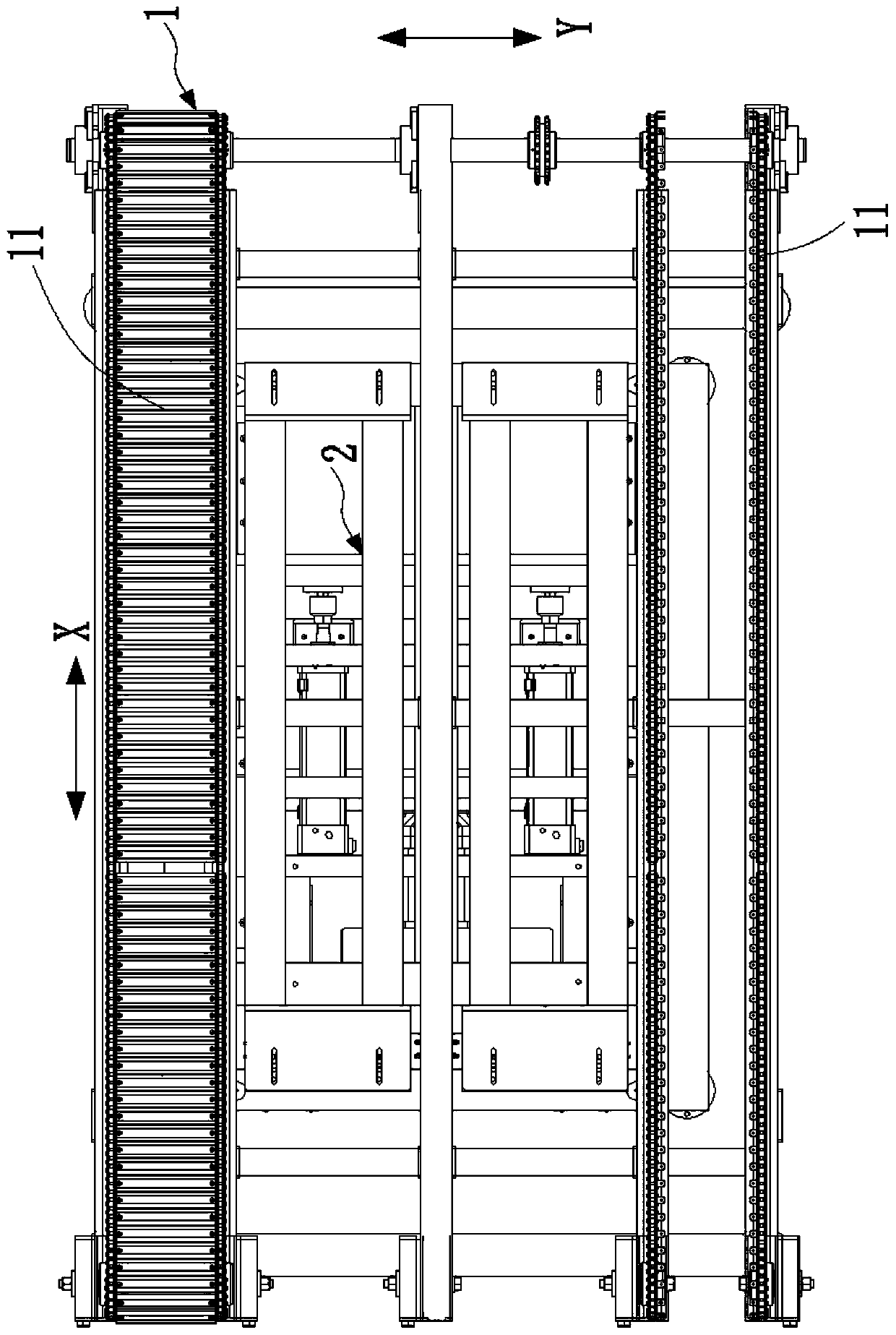

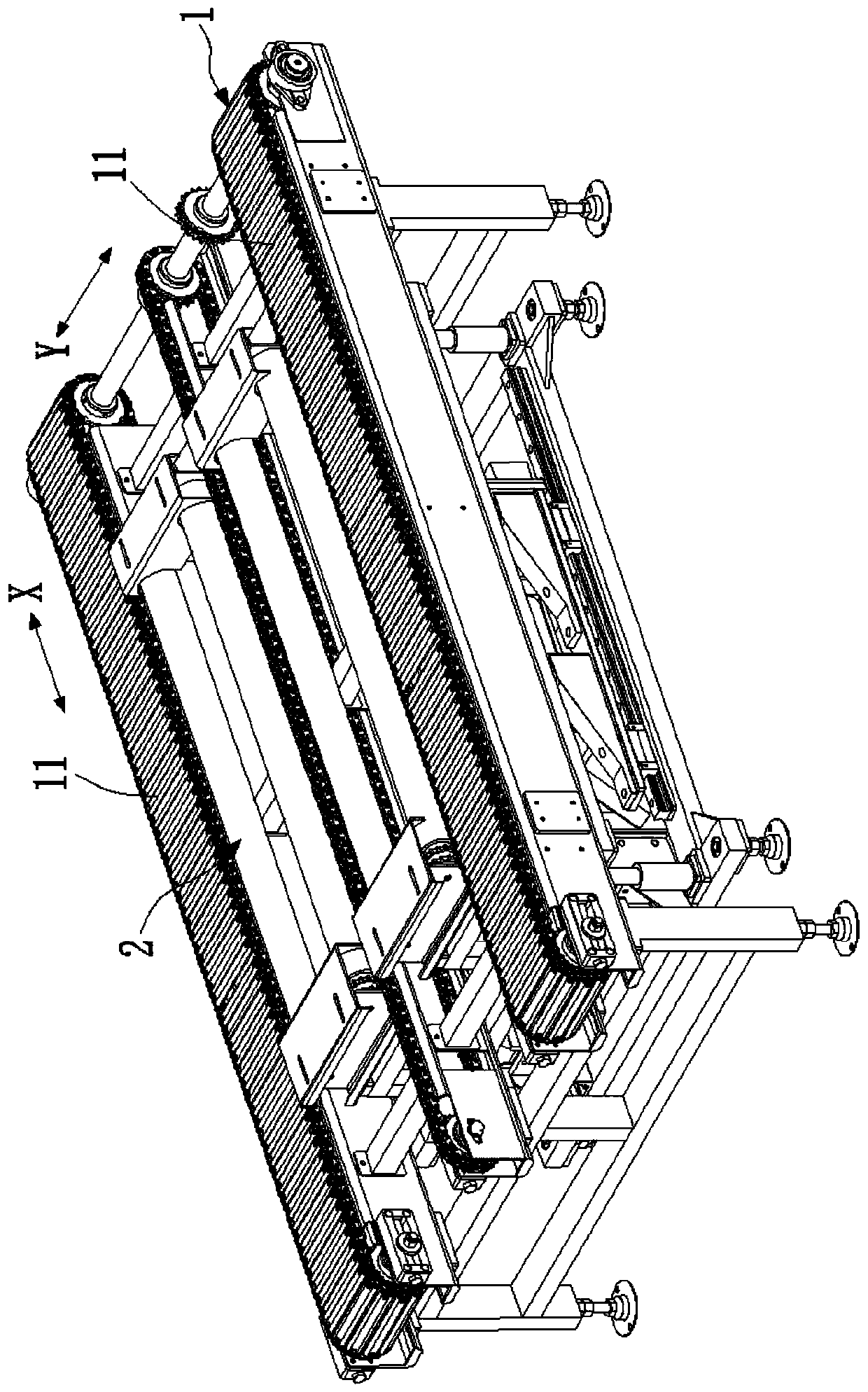

Multi-direction heavy-load conveyor and conveying method thereof

PendingCN110228696AReduced risk of deformationKeep the position fixedConveyorsConveyor partsHeight differenceEngineering

The invention discloses a multi-direction heavy-load conveyor and a conveying method thereof. The multi-direction heavy-load conveyor comprises a first conveying line and a second conveying line, wherein the first conveying line carries out conveying in a first direction, and the second conveying line carries out conveying in a second direction perpendicular to the first direction, the first conveying line comprises two chain plate conveying belts, wherein the two conveying surfaces of the two chain plate conveying belts are equal in height and are arranged at an interval, the width of the chain plate conveying belts is smaller than 1 / 4 width of the conveying surface of the first conveying line, the second conveying line is located between the two chain plate conveying belts, and the conveying surface of the second conveying line and the conveying surface of the first conveying line have a height difference. According to the scheme, the second conveying line capable of ascending and descending is additionally arranged between the two chain plate conveying belts, and the width of the chain plate conveying belts is controlled, so that the bearing capacity of the first conveying lineis effectively guaranteed, the conveying requirement of large-weight articles is met, and the deformation risk of chain plates can be reduced, and meanwhile, the two conveying lines are different in conveying direction and have two position states, so that bidirectional transfer between the two conveying lines can be effectively realized.

Owner:SUZHOU HONBEST CLEAN TECH CO LTD

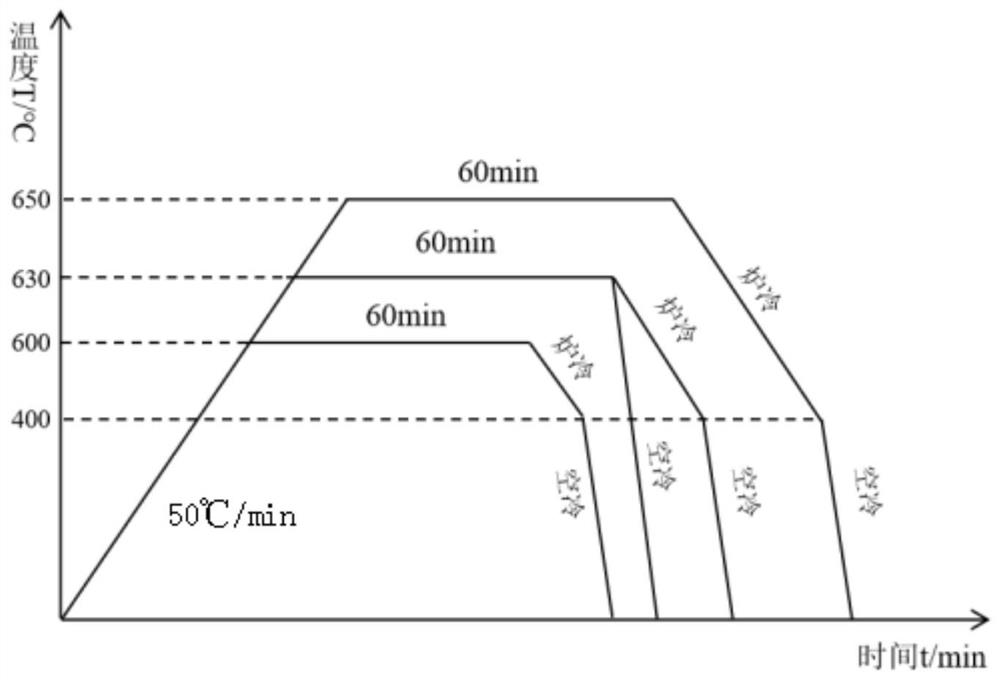

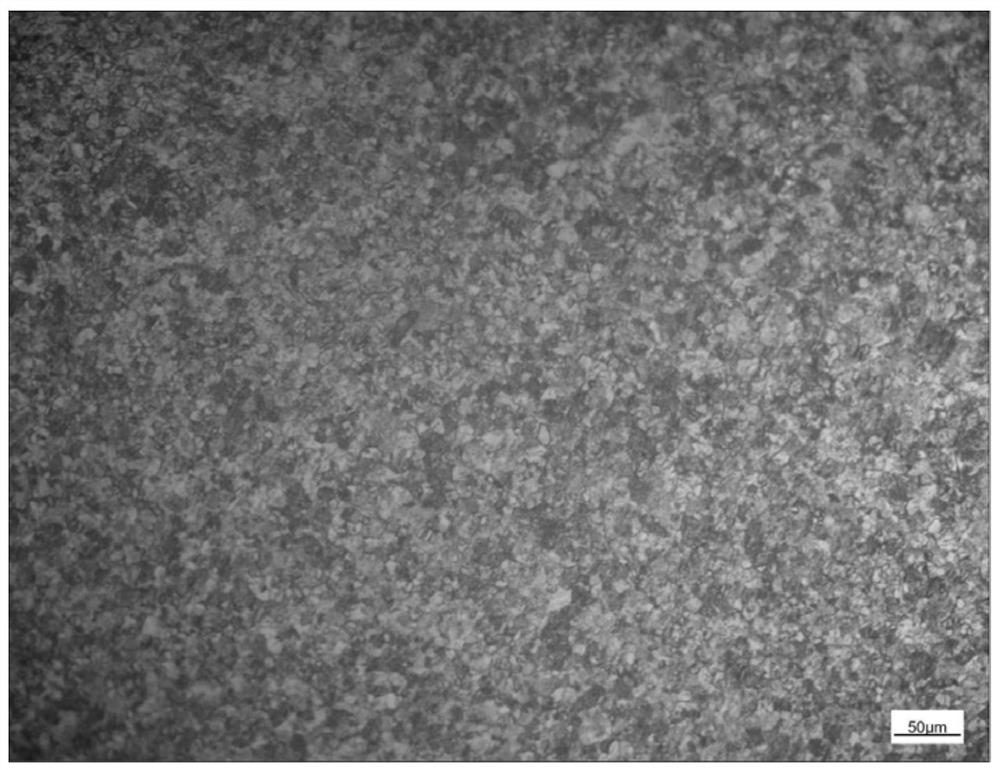

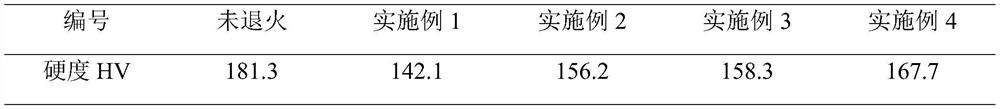

Method for eliminating residual stress of titanium part subjected to powerful spinning deformation

PendingCN112921259AEliminate residual internal stressReduced risk of deformationSpinningHeat conservation

A method for eliminating residual stress of a titanium part subjected to powerful spinning deformation comprises the following steps that 1, the titanium part subjected to spinning is placed in a heat treatment furnace, the temperature is increased to the target temperature of 530-560 DEG C at the heating speed of 10-52 DEG C / min, and the heat preservation time is 60-100 min; and 2, after heat preservation is conducted, cooling is conducted to 380-410 DEG C in a furnace cooling manner, and then discharging and air cooling are conducted to the room temperature. According to the process, the residual internal stress of the TA1 part after the powerful spinning deformation can be eliminated, so that the risk of deformation of a thin-walled cylinder part due to the release of the residual stress in the subsequent machining process is reduced, and the microstructure excellence and the use performance of the material are improved.

Owner:XIAN TAIJIN INDAL ELECTROCHEM TECH

Outside-pit rescue emergency well construction method

InactiveCN110616728AReduce the amount of backfillImprove water qualityFoundation engineeringWellheadEngineering

The invention discloses an outside-pit rescue emergency well construction method, and relates to the technical field of infrastructure construction. The technical aim of foundation pit emergency rescue can be achieved. The method comprises the steps that a protection casing is tripped in a well hole, and the protection casing is used for forming supporting on the wall of the well hole; an emergency well tube is tripped into the protection casing, the middle tube segment of the emergency well tube is a dual-layer filter tube internally containing filter materials, and the upper tube segment andthe lower tube segment are waterproof solid tubes; the filter materials are backfilled into the annular space between the emergency well tube and the protection casing, and the top face of the backfilled filter materials is higher than the middle tube segment of the emergency well tube; the protection casing is lifted to the position which is higher than the middle tube segment of the emergency well tube and lower than the top face of the backfilled filter materials; a fixing clamp is used for fixing a well opening of the emergency well tube and the protection casing; and rescue water drawingcan be implemented; after emergency rescue is finished, the emergency well tube, and the protection casing are sequentially drawn out upwards; and the backfilled clay is used for filling and levelingup the well hole. The method can achieve rapid well sinking and rapid recycling.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

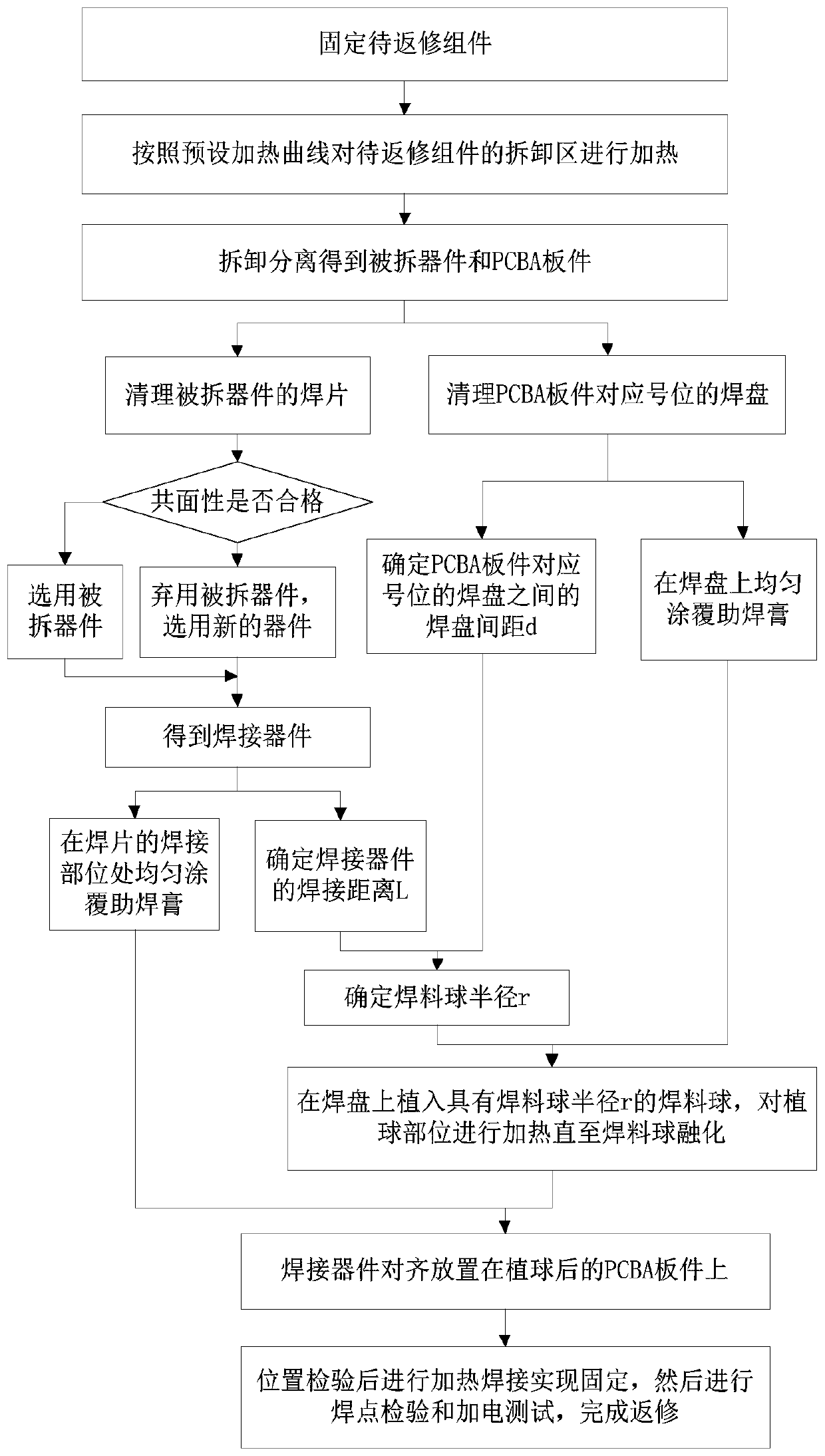

Repair process of stack-shaped/I-shaped preset solder terminal connector

The invention discloses a repair process of a stack-shaped / I-shaped preset solder terminal connector, and relates to the technical field of semiconductor processing. The method comprises the followingsteps f: firstly checking a disassembled device, and when the performance of the disassembled device is excellent, directly selecting a disassembled stack-shaped / I-shaped connector without preset welding flux as a welding device to be welded on a PCBA plate again, thereby improving the utilization rate of the device and reducing the repair cost; in the process of repair welding, proposing an innovative method for determining the size of a solder ball, so the short-circuit tin connection can be avoided while the tin soldering amount is guaranteed; performing coating of soldering paste on a soldering lug before soldering, thereby facilitating the improvement of the repair success rate and the soldering reliability of the device, and achieving high-reliability reworking of the stack-shaped / I-shaped preset solder terminal connector.

Owner:无锡市同步电子制造有限公司

Treatment method suitable for roadbed slope body collapse

ActiveCN109208619AMeet the needs of emergency managementAvoid leaningExcavationsReceptacle cultivationLand acquisitionMedicine

The present invention relates to the field of side slope or slope stabilization treatment, and discloses a treatment method suitable for roadbed slope body collapse. The method comprises the followingsteps of: S1, stepped downloading; S2, grouting of steel flower tubes; S3, addition of a reinforced slide-resistant pile; S4, surface and underground intercepting drainage; and S5, slope treatment. The treatment method suitable for roadbed slope body collapse is suitable for reinforcing treatment in a later remediation mode for the roadbed slope body which generates slippage deformation and an inclined slide-resistant pile so as to effectively avoid further deformation treatment of the high and steep road roadbed slope body, is obvious in treatment effect, does not need extra land acquisition, is less in occupation of land, reduces land acquisition cost and related removal expense and is low in treatment cost.

Owner:中铁长江交通设计集团有限公司

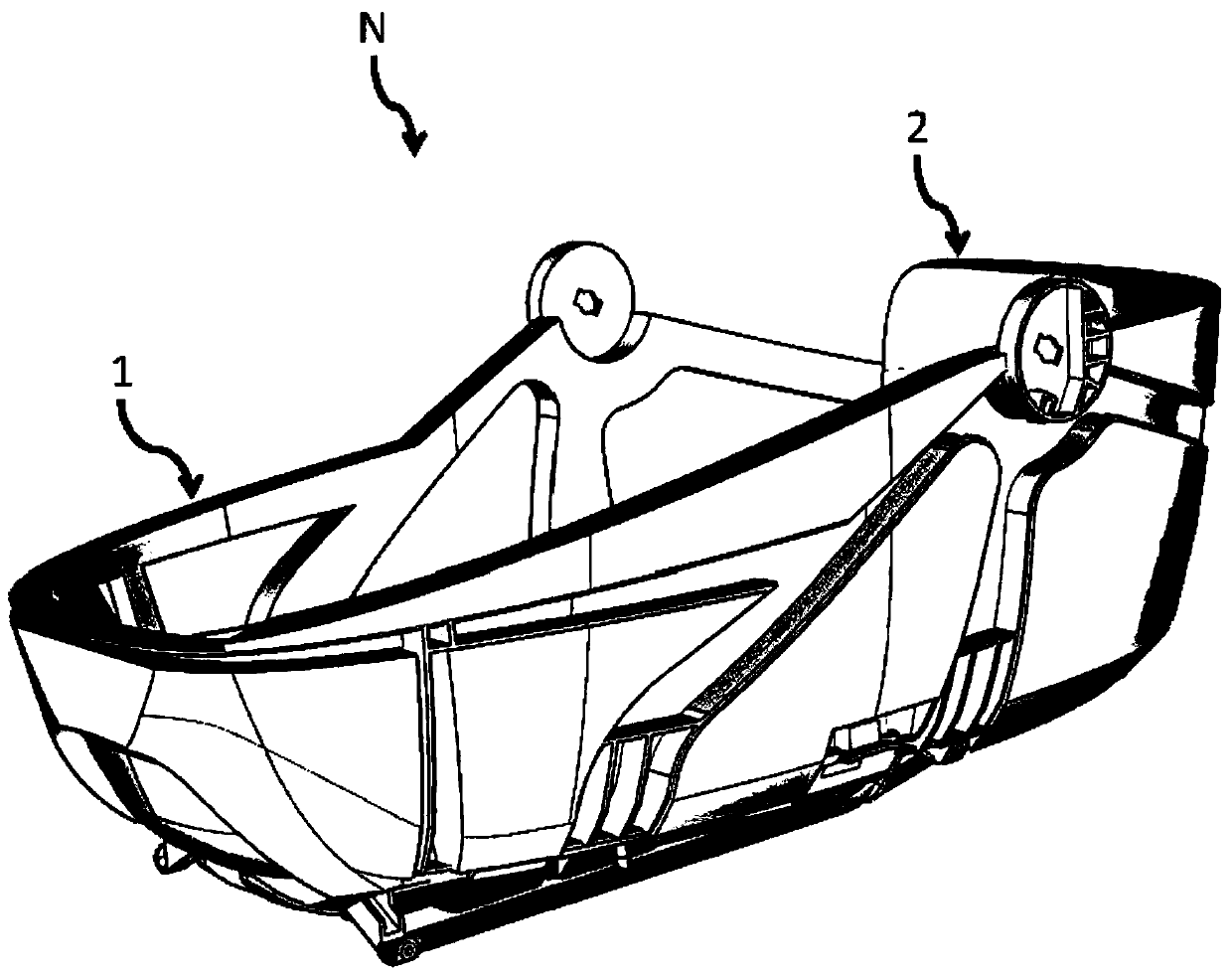

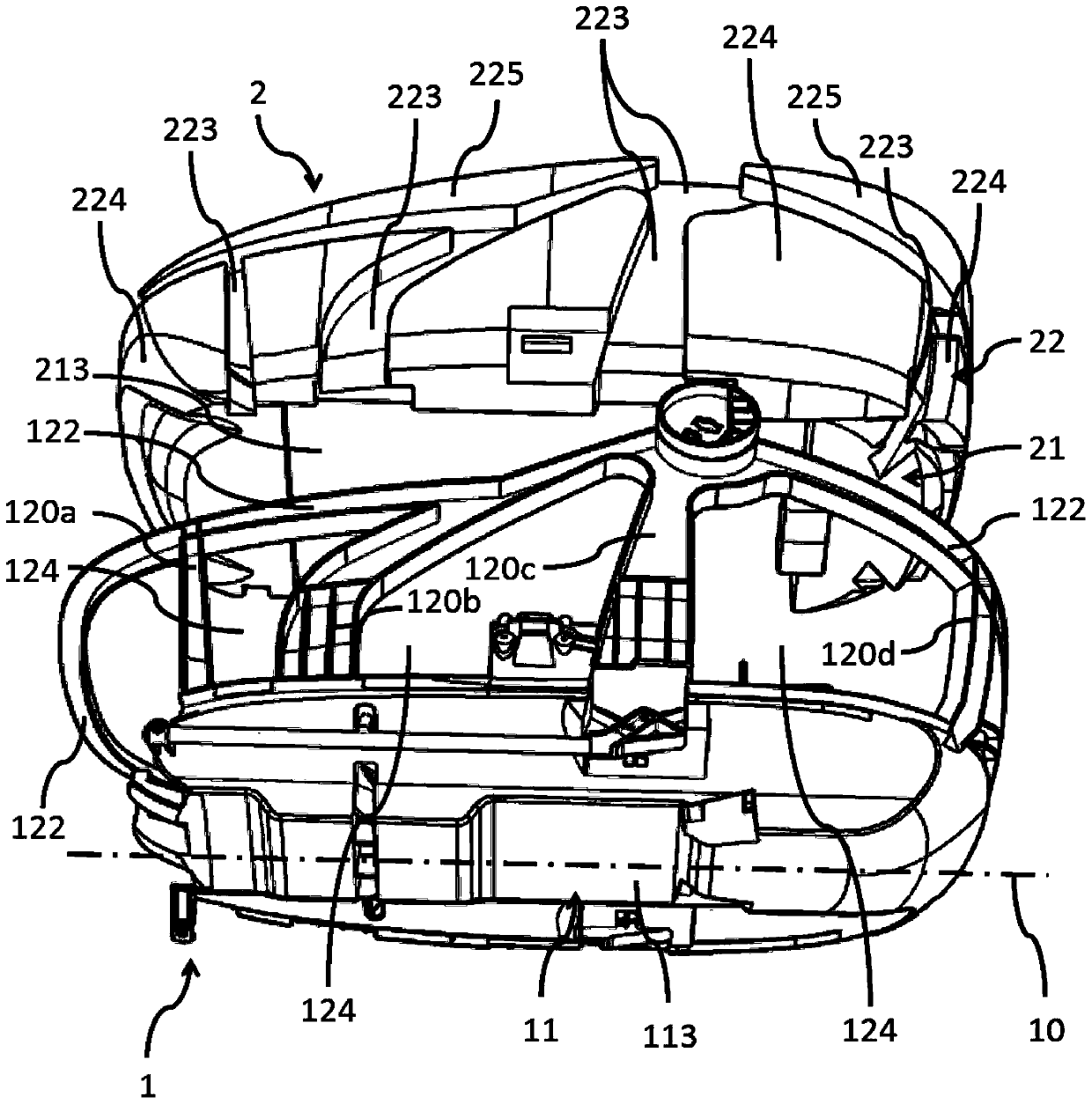

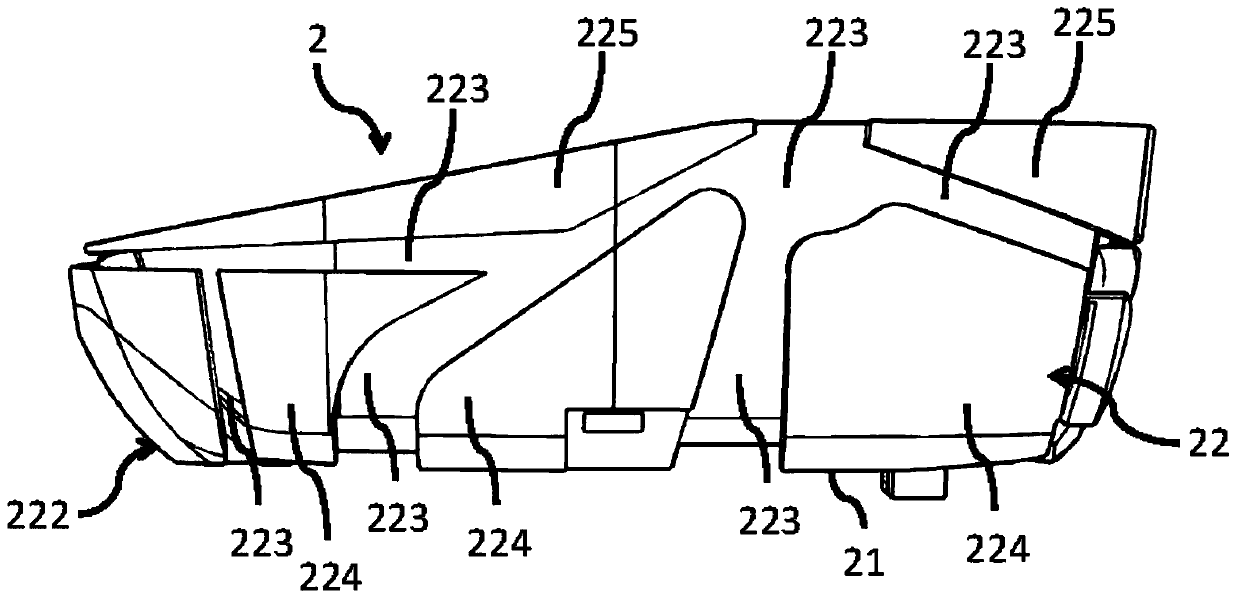

Cradle for children having a frame and a filling casing

ActiveCN109843643AControl deformationAesthetically pleasingChild seatsMobile vehicleMotorized vehicle

Owner:SHANGHAI DOREL JUVENILE CO LTD

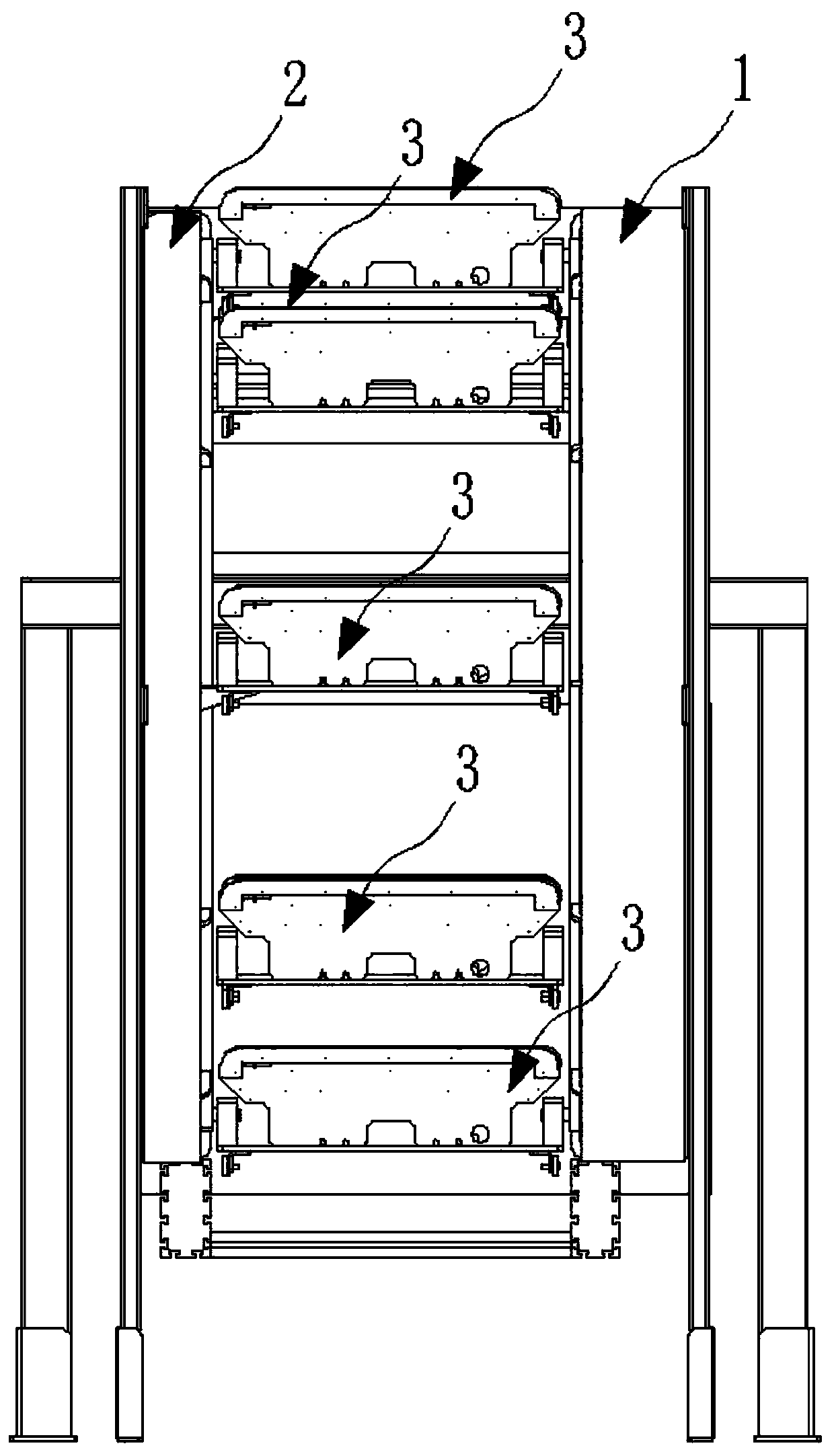

A fully automatic preheating furnace

ActiveCN109442999BReduced risk of deformationReduce stressFinal product manufactureFurnace typesThermodynamicsElectrical battery

The invention provides a fully automatic preheating furnace, comprising a furnace body frame, a battery loading station, a battery heating station and a battery unloading station, the battery heating station is located in a heating chamber of the furnace body frame, and the heating chamber Several layers of tray-type heating plates are set up and down in sequence. The tray-type heating plates can be horizontally moved and fixed in the furnace body frame through the heating plate guide assembly. It also includes pushing the tray-type heating plates to move back and forth to heat the battery at the charging station and battery. The heating plate toggle device for switching between the station and the battery unloading station. The invention adopts a tray-type heating plate that can be pushed out horizontally, which does not need to carry the gravity of the combination of heating plate groups, and reduces the deformation of the heating plate. Drag chains can be installed on both sides of the tray-type heating plate that can be pushed out horizontally to prevent cables and air pipes from moving. When breakage occurs, the tray-type heating plate is equipped with a dust removal negative pressure tube to increase the distance between the dust and the dust removal tube and increase the dust removal effect.

Owner:深圳市鹏翔运达机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com