Repair process of stack-shaped/I-shaped preset solder terminal connector

A terminal connector and preset technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as difficulty in ensuring product reliability, welding, and increased rework costs, so as to avoid short-circuit tinning, reduce the risk of deformation, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

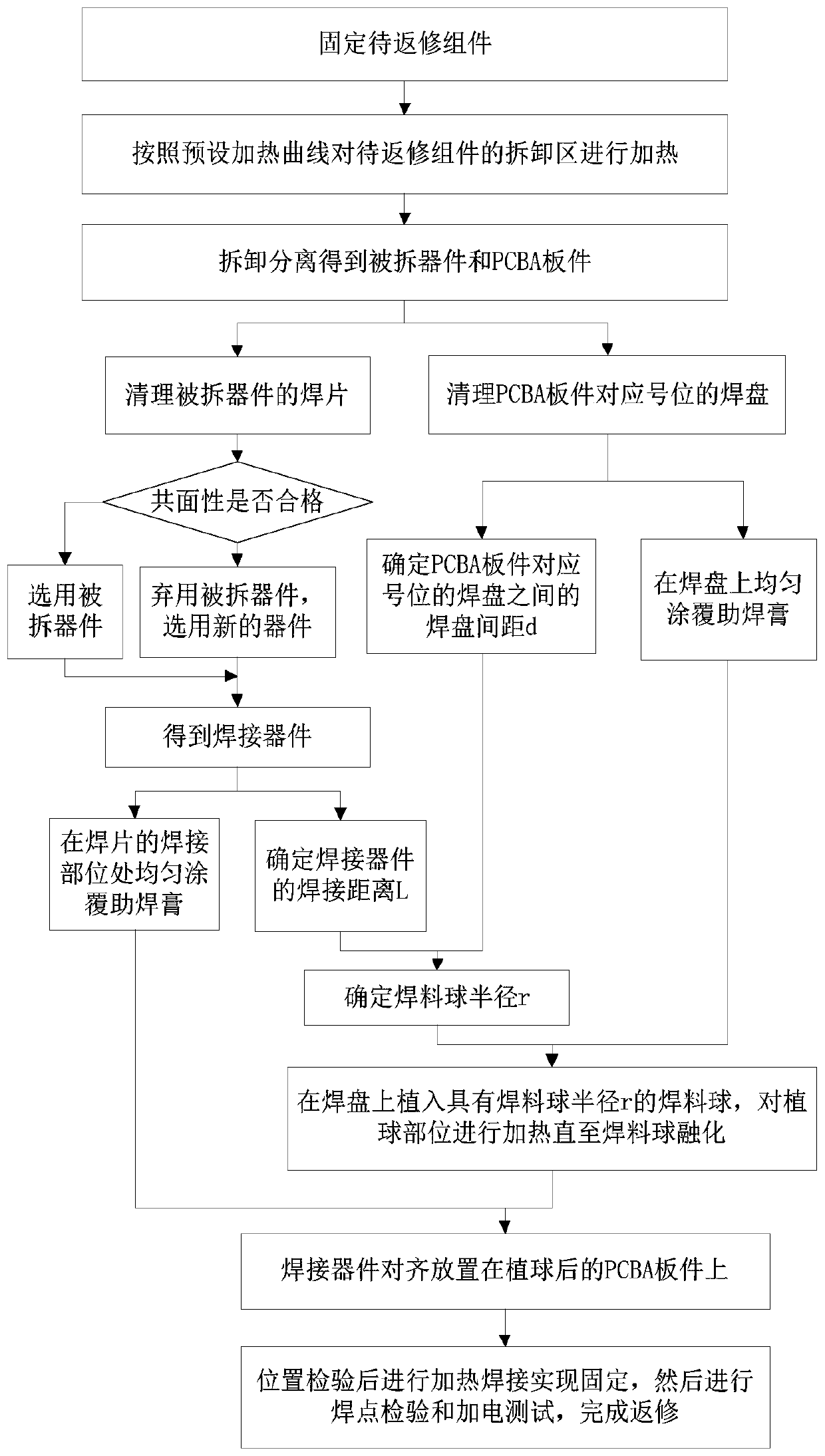

[0033] This application discloses a rework process for stacked / I-shaped pre-set solder terminal connectors, please refer to figure 1 As shown in the flowchart, the rework process includes:

[0034] 1. Fix the component to be repaired on the rework and desoldering station, fix the four corners of the component to be repaired, and when the length of the component to be repaired exceeds 200mm and / or the width exceeds 150mm, add a thimble to the middle of the component to be repaired to fix. This step can prevent the component to be reworked from being deformed due to thermal stress during the heating process of the rework station.

[0035] 2. Heating the device disassembly area of the component to be repaired. In this application, heating is not performed at a constant temperature, but according to a preset heating curve. The entire heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com