Supporting system for casting concrete floor slab and beam bottom template

A technology for pouring concrete and supporting systems, applied in pillars, buildings, building structures, etc., can solve problems such as early demolition, and achieve the effect of reducing the risk of bending deformation, light weight, and good supporting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

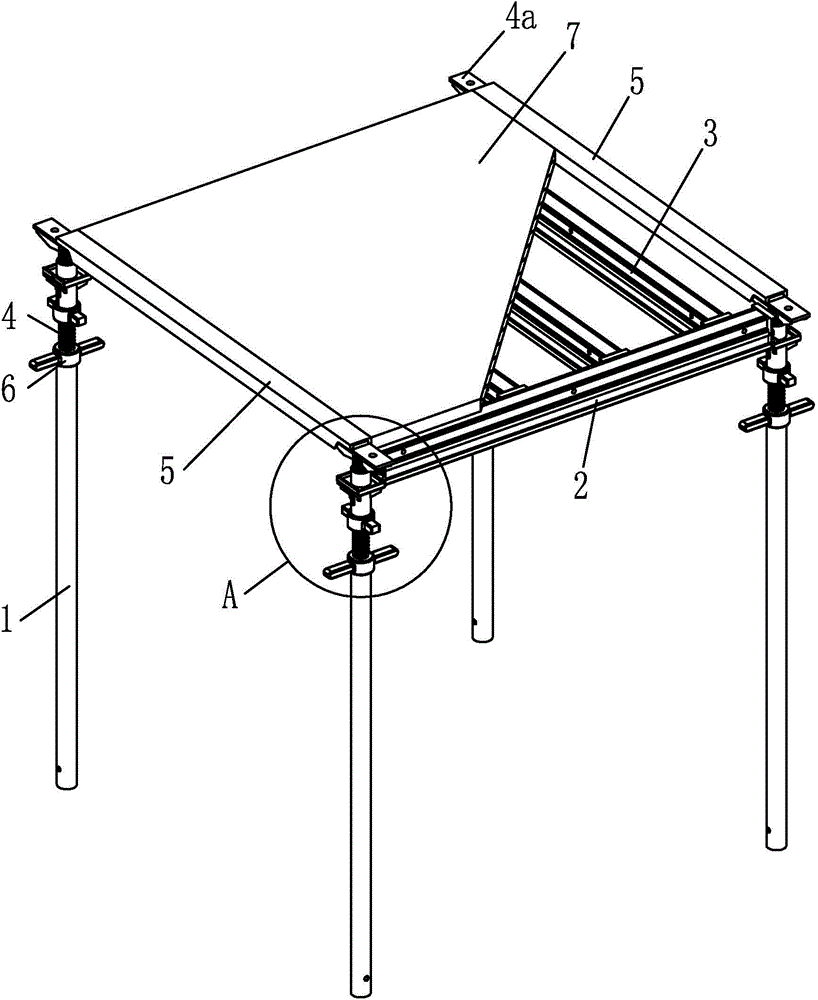

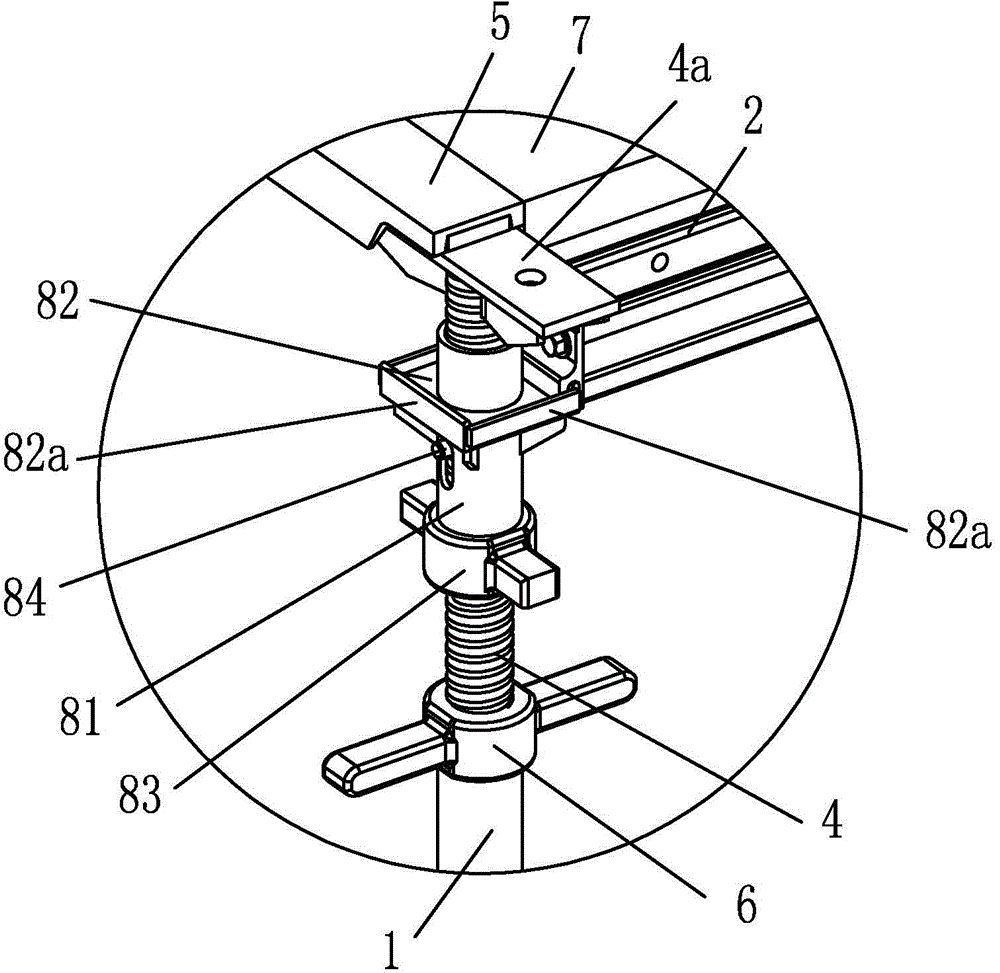

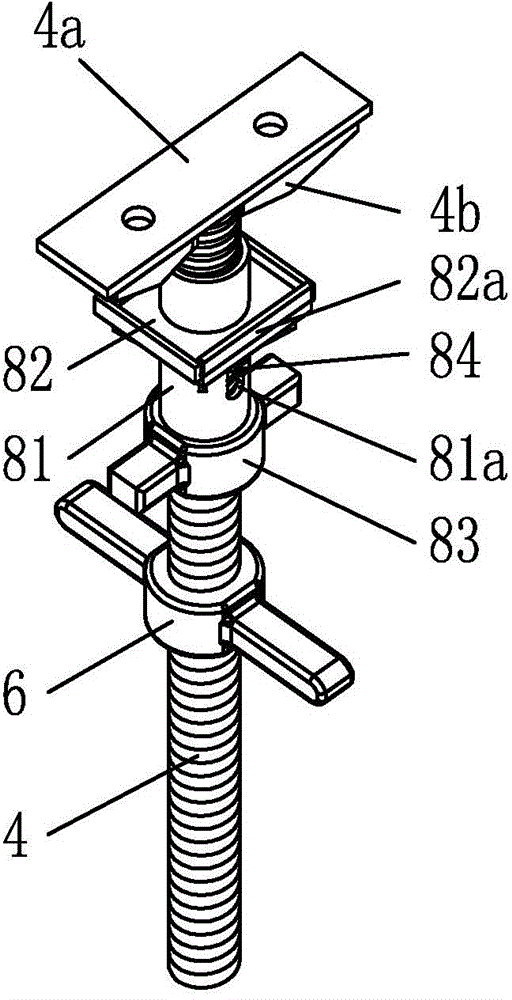

[0034] see Figure 1-16 , a pouring concrete floor and beam bottom formwork support system, comprising at least four even-numbered support columns 1, at least two main beams 2 arranged in parallel, and multiple secondary beams 3 perpendicular to the main beams 2, on which the support columns 1 There is a thread-adjustable liftable pillar 4, on which the liftable pillar 4 is screwed with a late dismantling nut 6 with a rotating arm, and the top of the liftable pillar 4 is formed with a rectangular pillar cap 4a, between the liftable pillar 4 and the rectangular pillar cap 4a There are four ribbed plates 4b distributed in the circumferential direction by welding; the main beam 2 includes a main beam body 21 and detachable beam ends 22 fixedly connected to the two ends of the main beam bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com