A fully automatic preheating furnace

A preheating furnace, fully automatic technology, used in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of inability to remove dust from the heating plate, deformation of the heating plate at the bottom, insufficient negative pressure, etc., to reduce cable breakage. Risk, stress reduction, effect of reducing temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific drawings and embodiments.

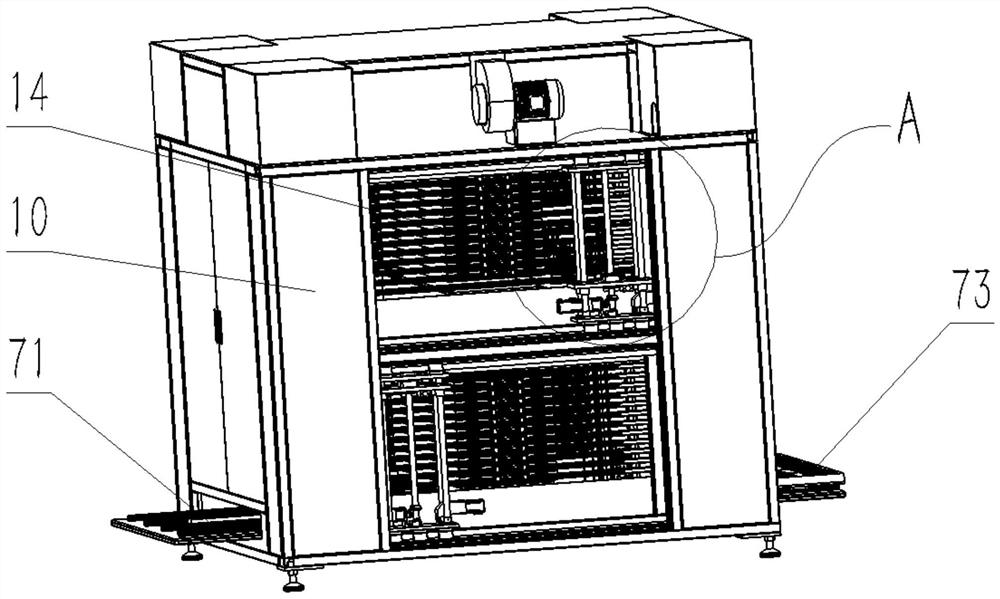

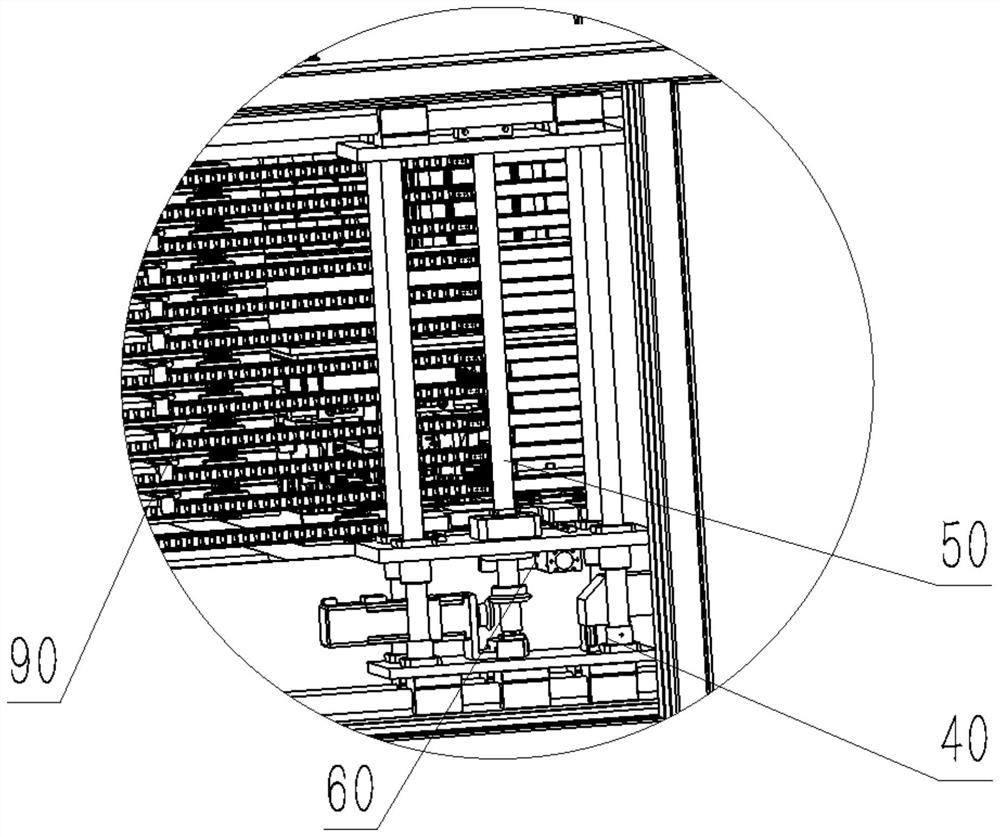

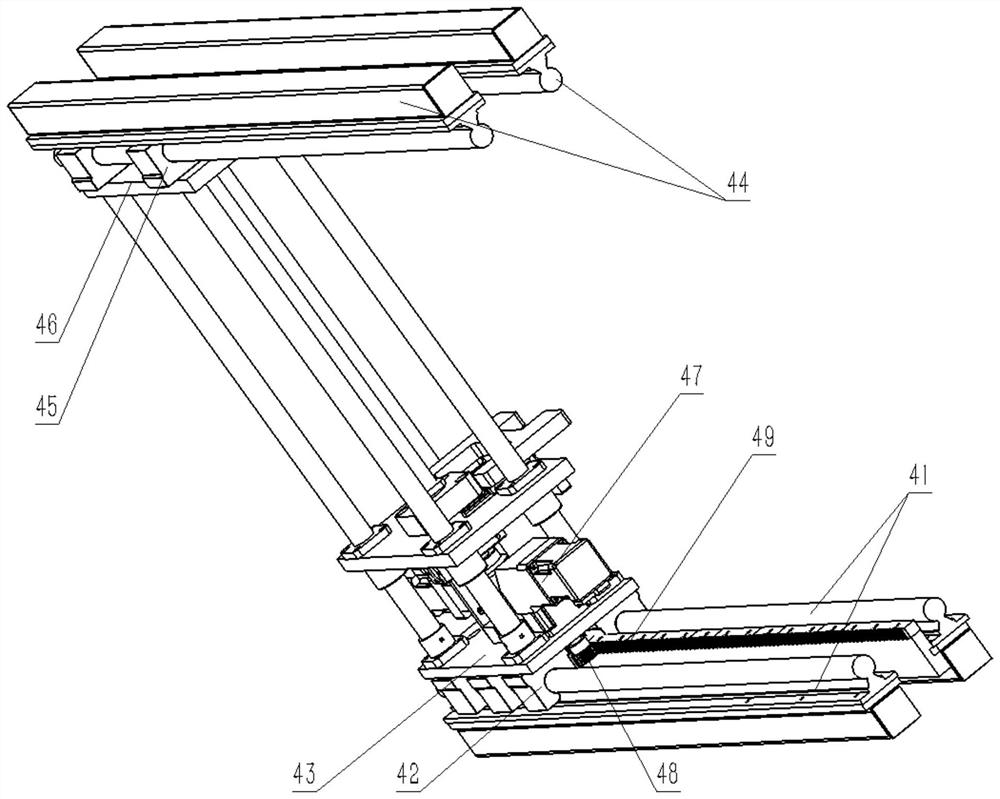

[0041] combine Figure 1-16 , the present invention provides a fully automatic preheating furnace, comprising a furnace body frame 10, a battery loading station 11, a battery heating station 12 and a battery unloading station 13, a heating chamber 14 is provided in the furnace body, and a battery heating station 12 is located in the heating chamber 14, the battery loading station 11 is located in the front of the battery heating station 12, the battery unloading station 13 is located in the rear of the battery heating station 12, and several layers of trays are arranged in the heating chamber 14. The heating plate 20, the tray-type heating plate 20 is horizontally movable and fixed in the furnace body frame 10 through the heating plate guide assembly 30, and it also includes pushing the tray-type heating plate 20 to move back and forth to the battery feeding st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com