Lightweight hot forming die of special-shaped curved aluminum alloy thin-wall part and design method thereof

A special-shaped curved surface and mold design technology, which is applied in the field of precision sheet metal processing, can solve problems such as large springback, wrinkle cracks, and dimensional accuracy that cannot meet the requirements, and achieve the effects of reducing part deformation, improving transfer efficiency, and avoiding wrinkle defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further details will be given below in conjunction with the accompanying drawings and embodiments.

[0032] A method for designing a light-weight thermoforming die for aluminum alloy thin-wall parts with special-shaped curved surfaces, the specific steps are as follows:

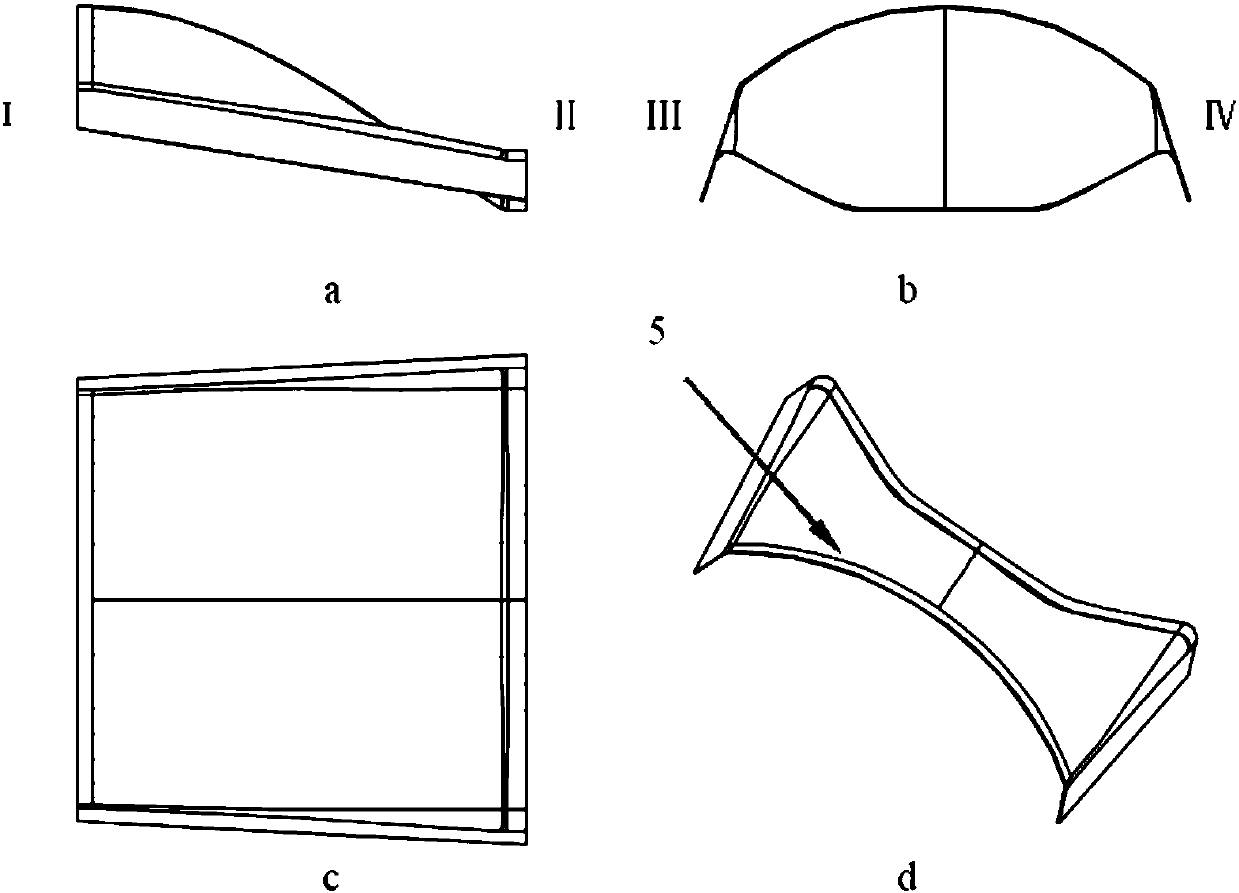

[0033] Step one, such as figure 1 a~ figure 1 d is a schematic diagram of the special-shaped curved aluminum alloy thin-walled part 5 to be processed. The shape and size characteristics of the part are analyzed. It is elastic and avoids the instability of the forming process due to asymmetric force, and adopts the form of a two-piece thermoforming mold. Part 5 is symmetrical about the plane of symmetry, and the main structure is an arc-shaped structure. From the front view, the two sides of the arc-shaped structure are long flat structures symmetrical about the plane of symmetry, forming a certain angle with the plane of symmetry, and the upper contour is about The arc is symmetrical to the symmetry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com