Making method of lithium ion battery anode sheet

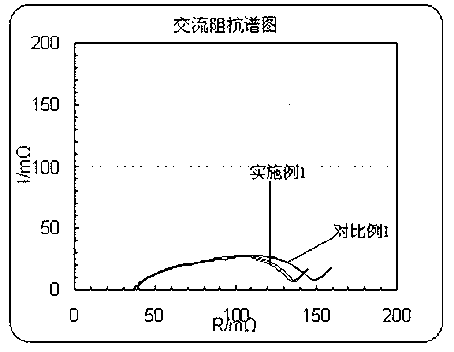

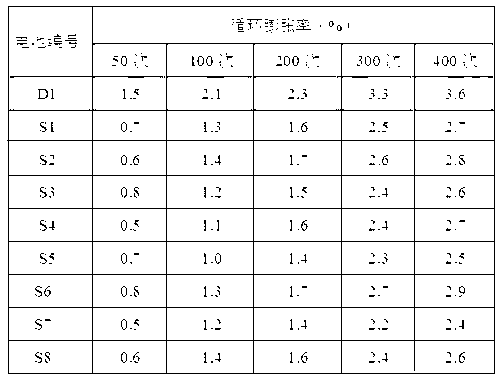

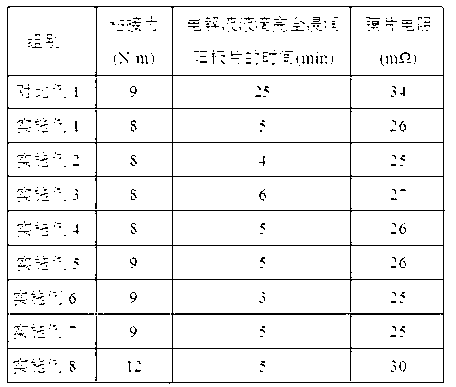

A lithium ion battery and a manufacturing method technology are applied in the field of lithium ion battery anode sheet manufacturing, which can solve the problems affecting the battery quality rate, poor low temperature performance of the lithium ion battery, easy demolding of the anode sheet, etc. The effect of reducing the number of defective films and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a method for making an anode sheet of a lithium-ion battery provided in this embodiment includes the following steps: Step 1, preparation of anode slurry: anode active material natural graphite, aqueous thickener sodium carboxymethyl cellulose , Water-based adhesive styrene-butadiene latex and superconducting carbon are added into water according to the mass ratio of 96:1:1:2, and the anode slurry is prepared after being stirred evenly.

[0026] Step 2, fabrication of anode sheet: uniformly coat the anode slurry prepared in step 1 on the anode current collector copper foil with a coating thickness of 100um, and then dry in a drying oven at 100°C to prepare an anode sheet.

[0027] Step 3, post-processing of the anode sheet: place the anode sheet prepared in step 2 in a nitrogen environment at 300°C for 30 minutes of secondary baking and softening treatment, and then complete the production of the anode sheet after cold pressing and slitting.

Embodiment 2

[0028] Embodiment 2, the manufacturing method of a kind of anode sheet of lithium ion battery provided in this embodiment, comprises the following steps: Step 1, the preparation of anode slurry: anode active material artificial graphite, aqueous thickener lithium carboxymethyl cellulose 1. Water-based adhesive pure acrylic latex and acetylene black are added into water according to the mass ratio of 92:2:5:1, and the anode slurry is obtained after stirring evenly.

[0029] Step 2, fabrication of anode sheet: uniformly coat the anode slurry prepared in step 1 on the copper foil of the anode current collector with a coating thickness of 200um, and then dry it in a drying oven at 110°C to prepare the anode sheet.

[0030] Step 3, post-processing of the anode sheet: place the anode sheet prepared in step 2 in a nitrogen environment at 250°C for 40 minutes of secondary baking and softening treatment, and then complete the production of the anode sheet after cold pressing and slittin...

Embodiment 3

[0031] Embodiment 3, a method for manufacturing an anode sheet of a lithium ion battery provided in this embodiment includes the following steps: Step 1, preparation of anode slurry: anode active material silicon-carbon alloy, water-based thickener carboxymethyl cellulose Potassium, water-based adhesive styrene-acrylic latex and carbon nanotubes are added into water according to the mass ratio of 94:1.5:3:1.5, and the anode slurry is prepared after being stirred evenly.

[0032] Step 2, fabrication of anode sheet: uniformly coat the anode slurry prepared in step 1 on the copper foil of the anode current collector with a coating thickness of 50um, and then dry it in a drying oven at 90°C to prepare the anode sheet.

[0033] Step 3, post-processing of the anode sheet: place the anode sheet prepared in step 2 in a nitrogen environment at 350°C for 50 minutes of secondary baking and softening treatment, and then complete the production of the anode sheet after cold pressing and sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com