Water pressure testing method and device of ultraheavy and ultralarge compressor shell

A hydraulic test and test method technology, applied in the direction of machine/engine, mechanical equipment, pump control, etc., can solve problems such as scrapping, casing product deformation, casing deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

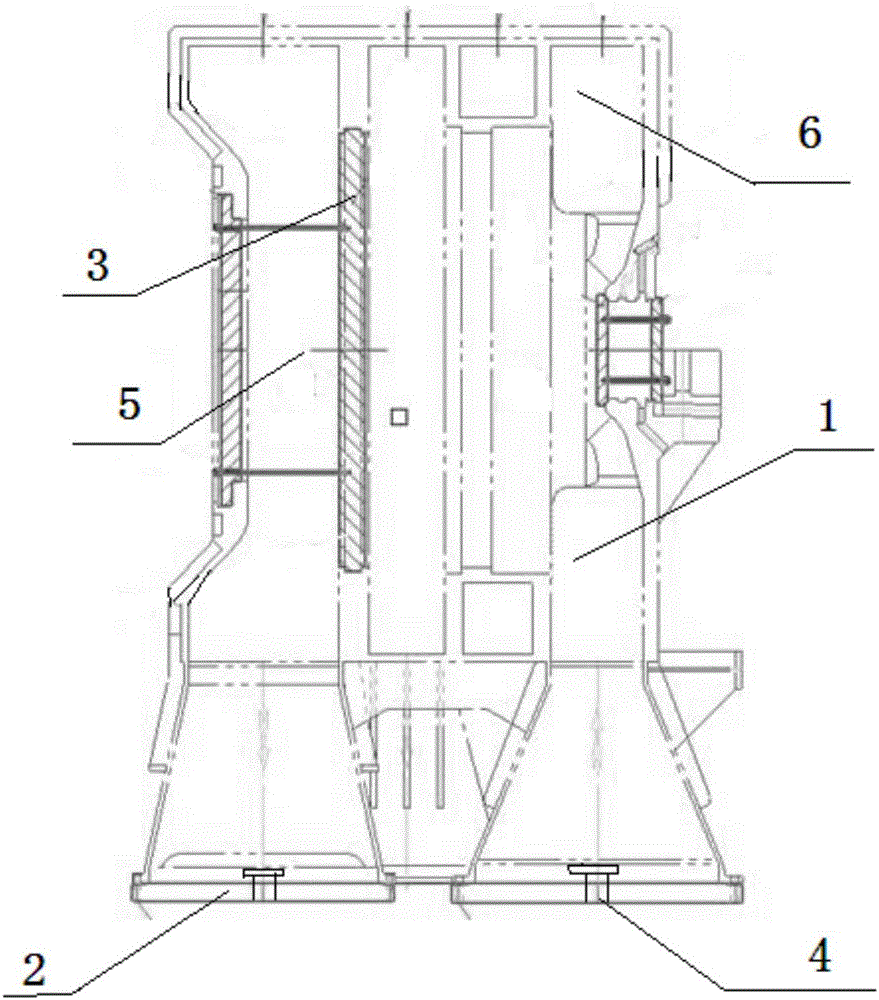

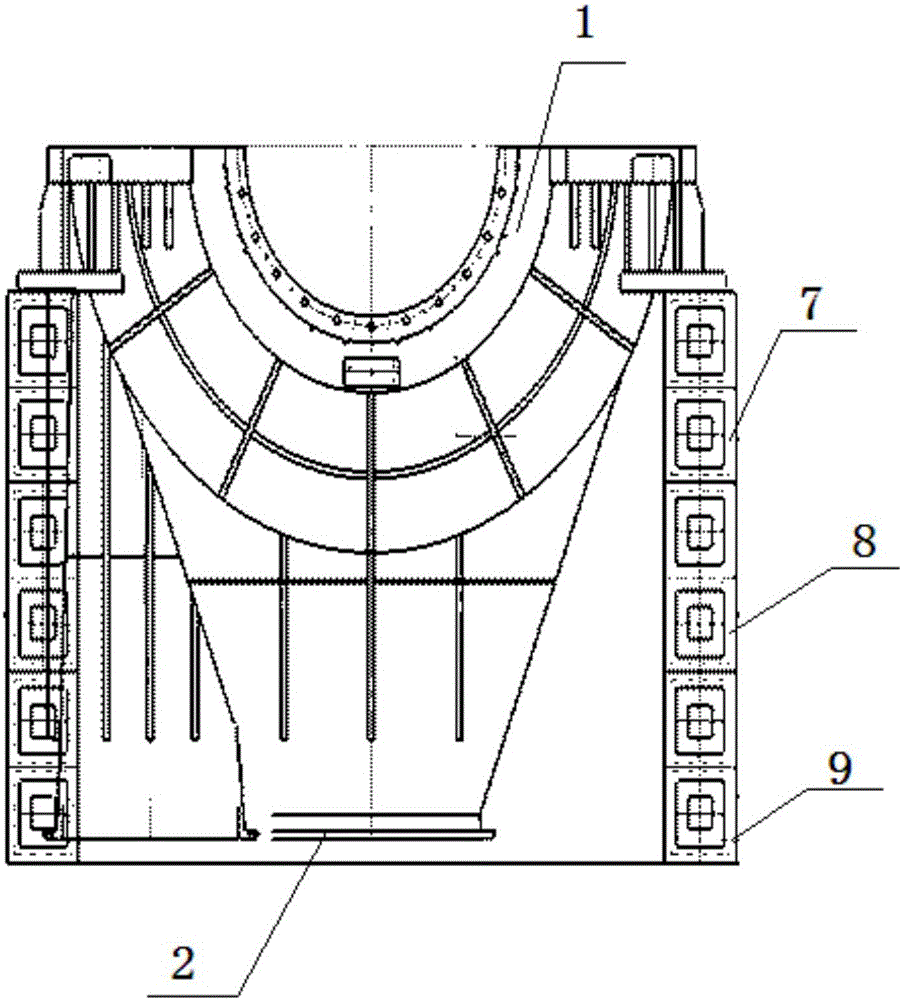

[0016] see Figure 1-2 , the embodiment of the present invention provides a hydraulic test method for an overweight and super-large compressor casing. The centrifugal section of the air separation compressor includes a first casing 1 and a second casing. The test method includes the following steps :

[0017] Step 1, setting a support mechanism according to the size of the legs of the first casing 1, and the support mechanism props up the first casing 1;

[0018] Step 2, turning over the first casing 1 so that the middle part of the first casing faces upward, and the support mechanism supports the first casing 1;

[0019] Step 3, installing a pressure testing mechanism in the first casing 1, the pressure testing mechanism divides the first casing 1 into a low-pressure chamber 5 and a high-pressure chamber 6, and the weak position of the first casing is at The low-pressure chamber 5;

[0020] Step 4, filling the low-pressure chamber 5 and the high-pressure chamber 6 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com