Steel plate pile surrounding purlin support system and foundation pit construction method adopting support system

A construction method and steel sheet pile technology, applied in sheet pile wall, foundation structure engineering, excavation, etc., can solve the problems of large reliability risk and force difference of the supporting system, and improve the stability and reliability. performance, ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

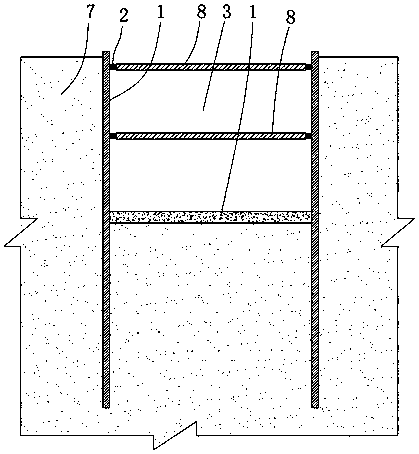

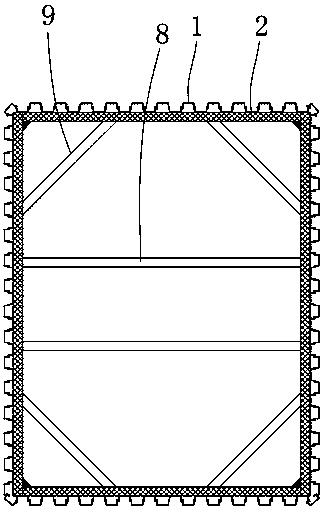

[0044] Example 1, such as Figure 1-5 Shown:

[0045] A steel sheet pile purlin support system, comprising several steel sheet piles 1, the steel sheet piles 1 are sequentially connected to form a steel sheet pile wall for supporting the side wall of the foundation pit 3, and the steel sheet pile wall At least one set of inner support components for providing support in the horizontal direction is also provided on the inner wall.

[0046] In the steel sheet pile 1 surrounding purlin 2 support system of this embodiment, a number of steel sheet piles 1 are connected to form a steel sheet pile wall supporting the side wall of the foundation pit 3, and the inner wall of the steel sheet pile wall is also provided with a The internal support component that provides support for it in the horizontal direction, thus greatly improves the reliability of the steel sheet pile wall supporting the side wall of the foundation pit 3, so that even if the steel sheet pile 1 passes through multi...

Embodiment 2

[0055] Example 2, such as Figure 1-6 as shown,

[0056] A foundation pit construction method:

[0057] Including the step of inserting the steel sheet pile 1: after the steel sheet pile 1 is hoisted to the ground above the design position, the upper end of the steel sheet pile 1 is knocked, so that the steel sheet pile 1 is inserted into the soil layer 7. During the knocking and insertion process of the steel sheet pile 1, when After beating the steel sheet pile 1 for a period of time, the steel sheet pile 1 is pulled up to a certain height, and the steel sheet pile 1 is hammered again when water seeps into the space under the steel sheet pile 1, and so on until the steel sheet pile 1 is hammered to the designed position.

[0058] In the construction method of this embodiment, in the step of inserting the steel sheet pile 1, the method of repeatedly beating, repeatedly pulling up, and repeatedly inserting is adopted. After beating for a period of time, the steel sheet pile 1...

Embodiment 3

[0072] Example 3, such as Figure 1-5 Shown by:

[0073] A foundation pit construction method: including construction preparation steps, the construction preparation steps shown are as follows:

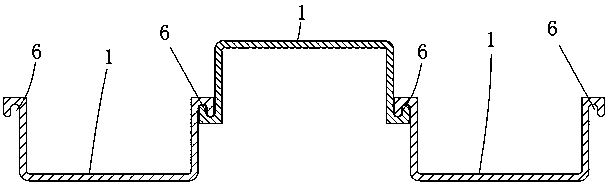

[0074] The inspection steps of the steel sheet pile 1: After the steel sheet pile 1 is transported to the construction site, it is sorted out, the debris in the lock 6 is removed, and the defective parts are repaired.

[0075] Lock 6 inspection method: Use a steel sheet pile 1 of the same type and specification about 2 meters long as a standard, and make all the same type of steel sheet pile 1 pass the inspection as lock 6. Correct the detected distortion and dead bend of the locking port 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com