Machining method for circumferential efficient milling deformation control

A deformation control and processing method technology, applied in the direction of digital control, manufacturing tools, metal processing equipment, etc., can solve the problems of large machining allowance, low processing efficiency, serious tool wear, etc., and achieve uniform processing stress distribution and uniform tool wear , the effect of reducing the degree of intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

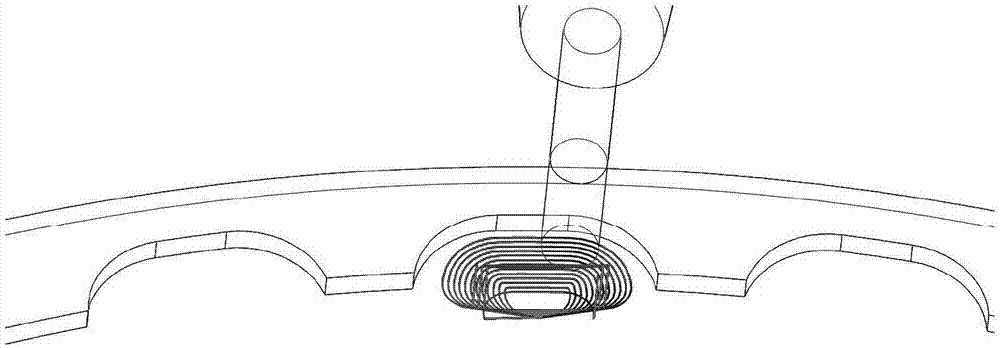

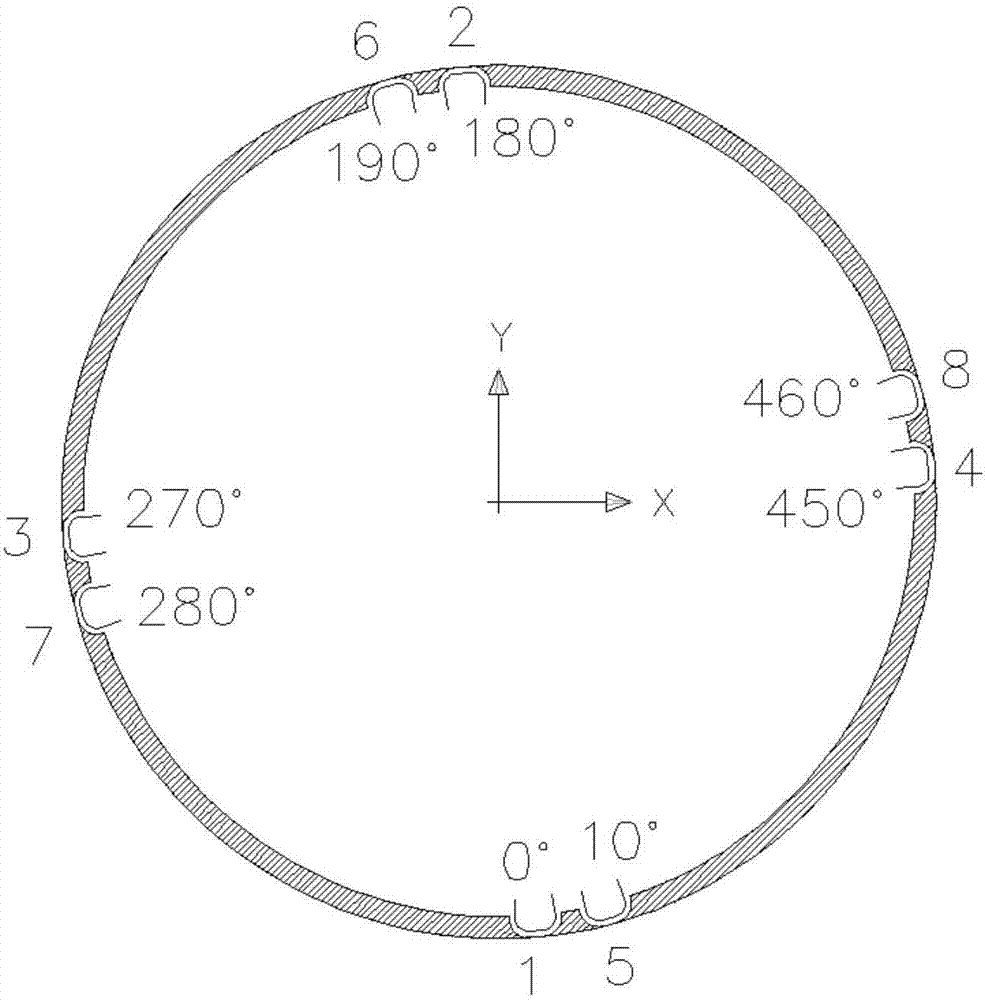

[0014] refer to Figure 1-4 The embodiments of the present invention are further described.

[0015] A processing method for the deformation control of circular high-efficiency milling,

[0016] Using layered milling to process; using layered milling means that in rough machining, the NC program automatically removes the allowance layer by layer;

[0017] During the machining process, the numerical control process of the cutter center is as follows:

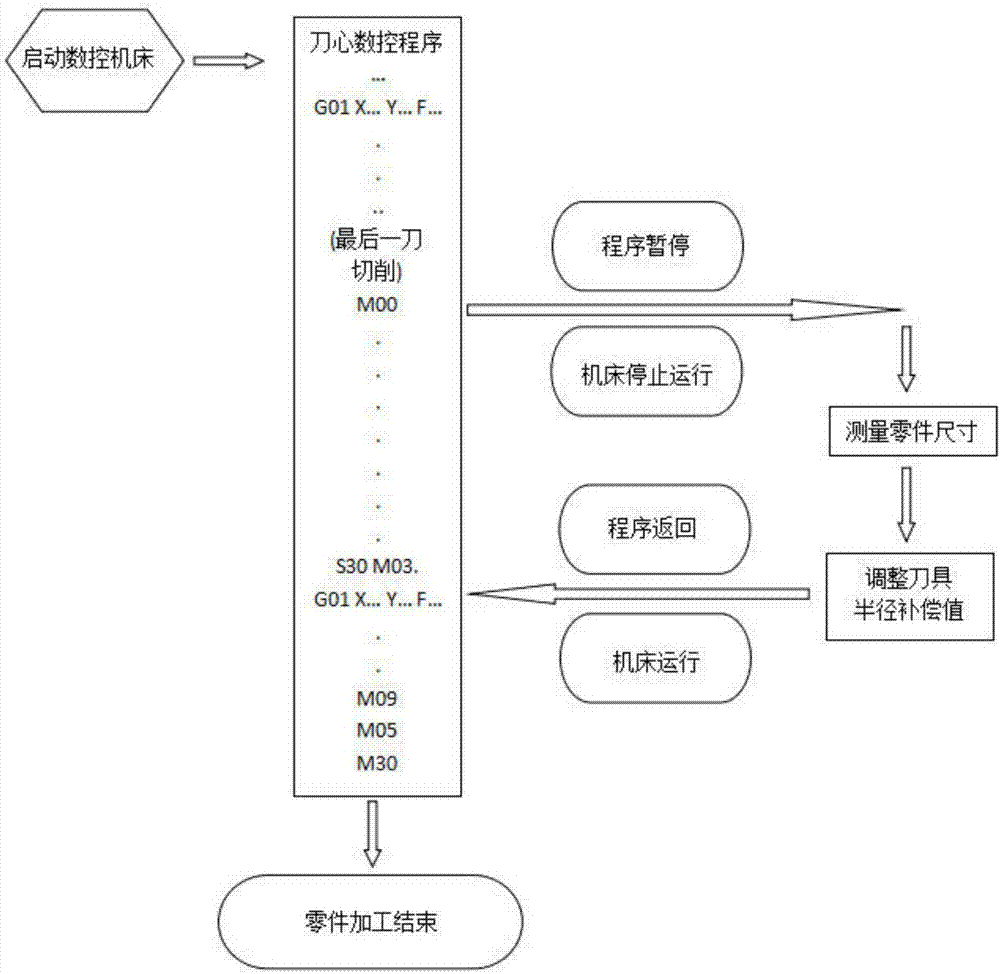

[0018] 1) Start the CNC machine tool and run the CNC main program of the knife core;

[0019] 2) Call the rough machining program, when the rough machining program completes the last cut, the program pauses and the machine tool stops running;

[0020] 3) Measure the size of the part, and adjust the tool radius compensation value according to the measurement result;

[0021] 4) The program returns, the machine tool runs, and the finishing program is called;

[0022] 5) The processing of parts is finished.

[0023] During pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com