Patents

Literature

83results about How to "Accelerates the infiltration process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery positive electrode slurry, preparation method thereof and lithium ion battery

PendingCN110797536AGood dispersionLarge specific surface areaCell electrodesSecondary cellsPhysical chemistryLithium-ion battery

The invention relates to lithium ion battery positive electrode slurry, a preparation method thereof and a lithium ion battery. The positive electrode slurry comprises a positive electrode active substance, a solvent, a composite binder, a composite conductive agent and a dispersing agent, wherein the composite conductive agent is a mixture composed of a conductive agent A and a conductive agent B; the conductive agent A is a conductive agent capable of forming a point-to-point conductive network; the conductive agent B is a conductive agent capable of forming a point-to-line or surface-contact conductive network; and the conductive agent A and the conductive agent B respectively account for 80-90% and 10-20% of the total weight of the conductive agent. According to the method disclosed bythe invention, the positive electrode slurry is processed and modified by changing the adding sequence of different substances in the positive electrode slurry, adjusting the stirring time, the stirring speed and the proportioning ratio and using the dispersing agent, the positive electrode slurry which enables all the components to be uniformly mixed and is relatively good in dispersion, moderate in viscosity and relatively small in fineness can be prepared, and the positive electrode slurry can improve the processing performance of the lithium battery and also can keep the battery to have excellent electrochemical performance.

Owner:桑顿新能源科技(长沙)有限公司

Uncured polyurethane waterproofing coating and preparation method thereof

ActiveCN103923565AGood adhesionGrowth Intermediate ConnectivityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention discloses an uncured polyurethane waterproofing coating and a preparation method thereof, belonging to the technical field of polyurethane waterproofing coatings. The uncured polyurethane waterproofing coating is prepared from the following raw materials in percentage by weight: 13-20% of prepolymer, 30-65% of asphalt, 1.0-1.5% of latent curing agent, 3-15% of compatilizer, 2-9% of thermoplastic elastomer and 0-3% of powder stuffing, wherein prepolymer is a substance synthesized by reaction between polyether and isocyanate. The uncured polyurethane waterproofing coating mainly aims to improve the material proportion and polymerization process of polyurethane, and the problem that a hot-melted asphalt material is needed to be heated by using a machine is solved; the uncured polyurethane waterproofing coating is convenient in construction and good in flowability; the viscosity of the constructed material can be automatically enhanced, so that the constructed material can become an elastic plastic body and a favorable waterproofing layer without internal stresses; in addition, the uncured polyurethane waterproofing coating can be well bonded with a coiled material and can be compounded to be waterproof so as to form a waterproofing layer capable of overcoming tension fracture caused by basement layer cracking and preventing puncturing; the uncured polyurethane waterproofing coating is simple and convenient in process, rapid in construction, free of maintenance, high in working efficiency and capable of becoming the development direction of building waterproofing in the further.

Owner:浙江鲁班建材科技股份有限公司

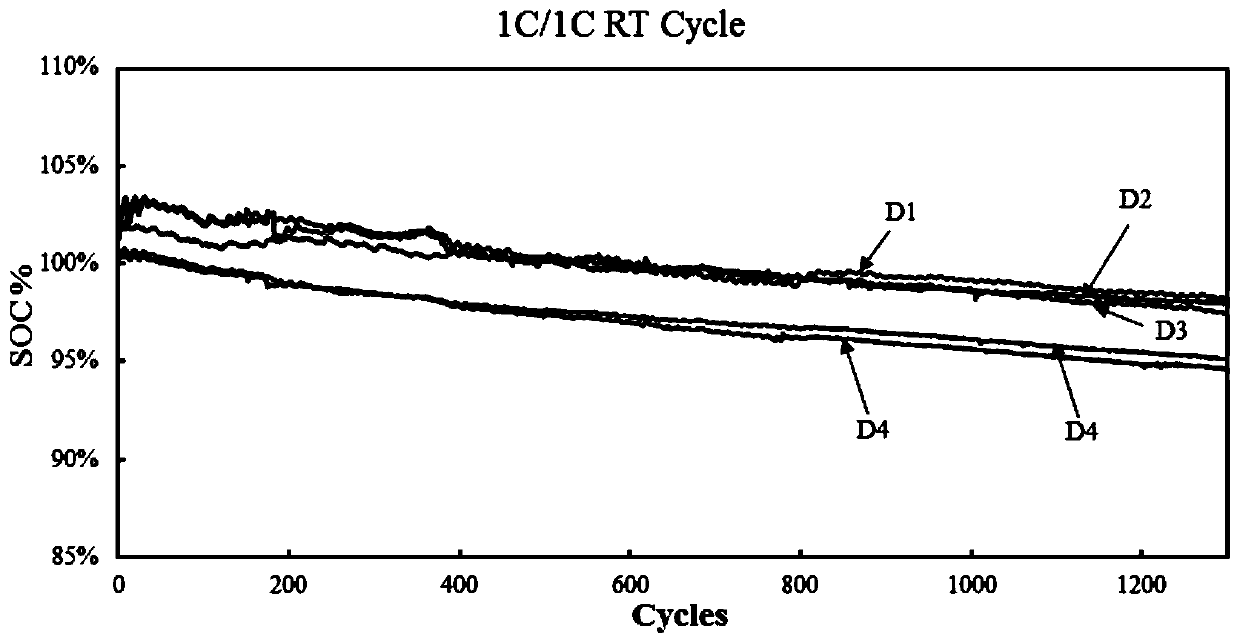

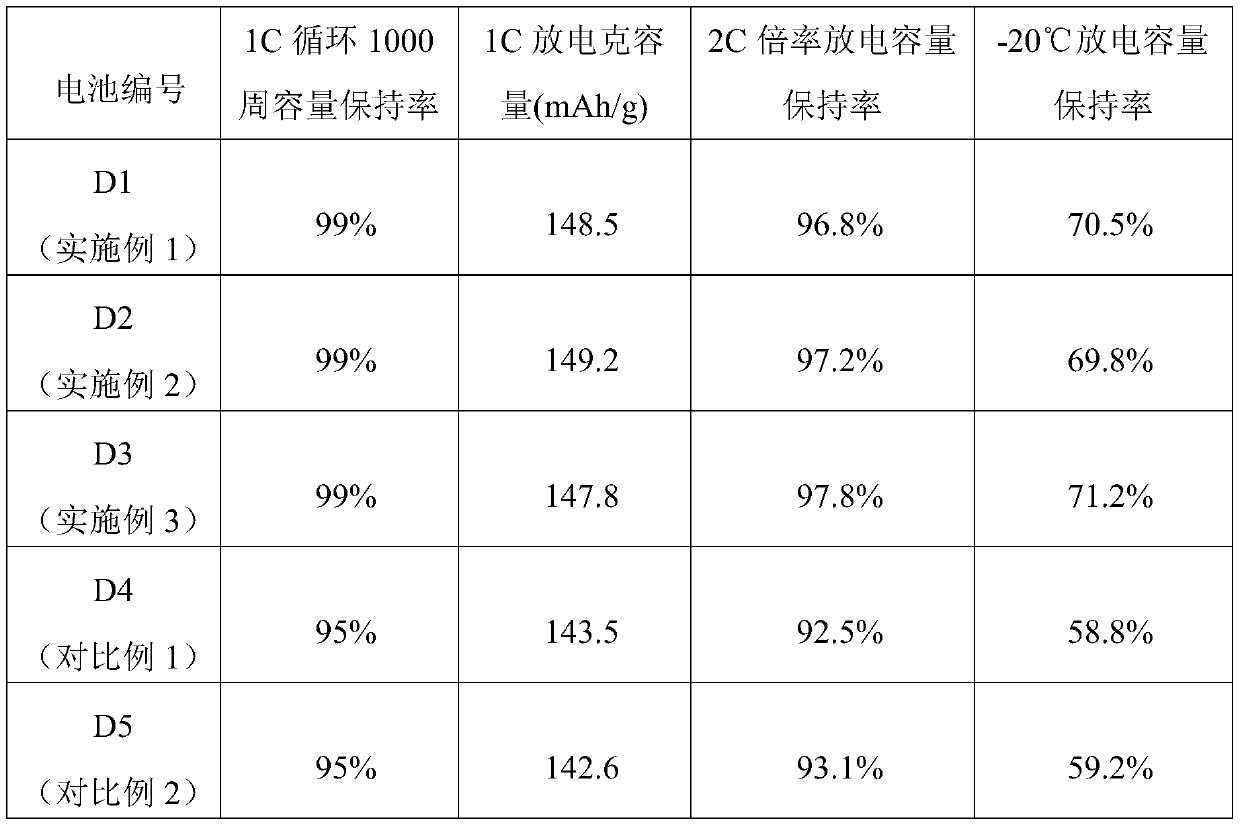

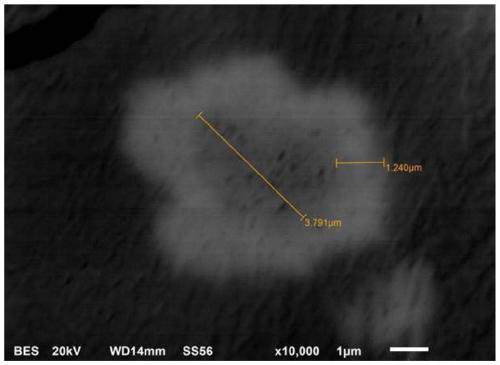

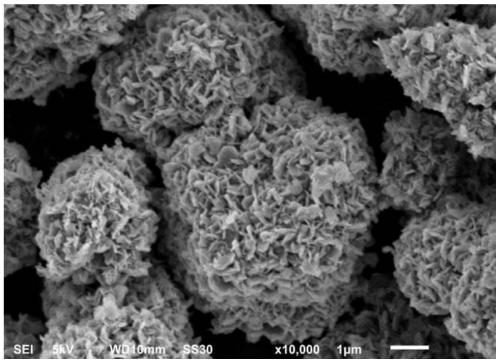

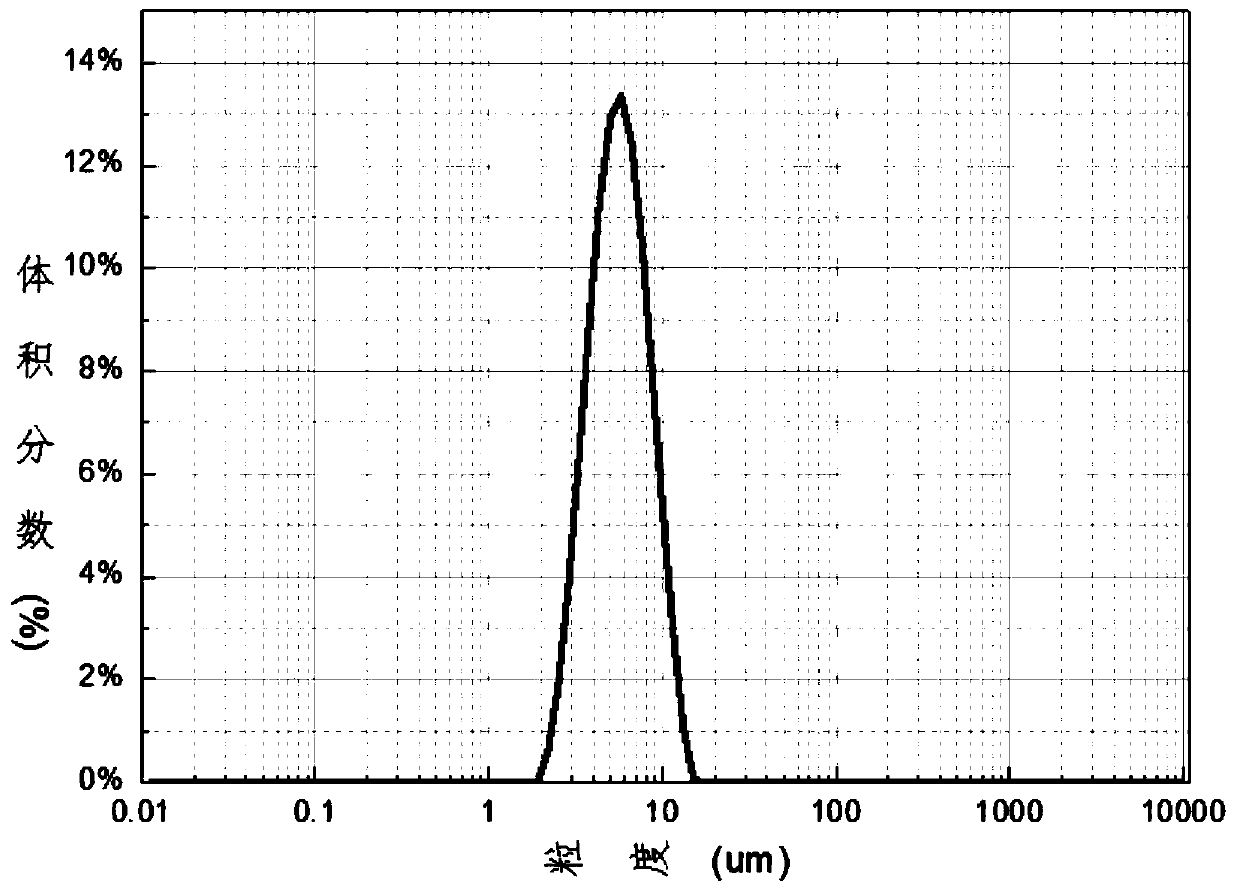

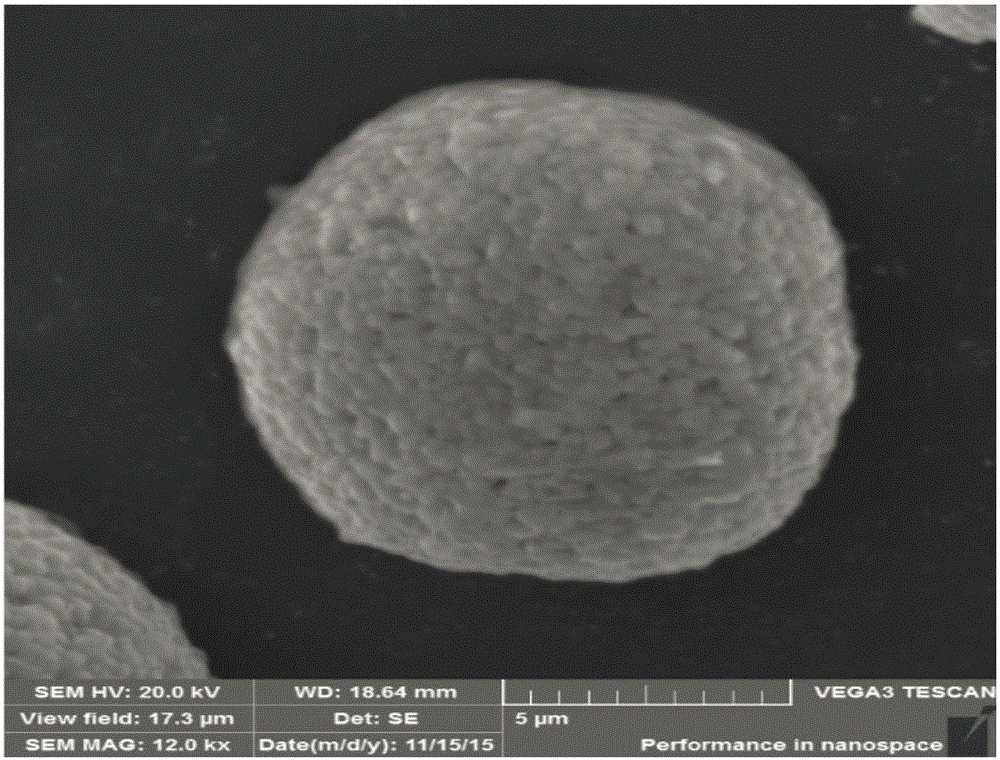

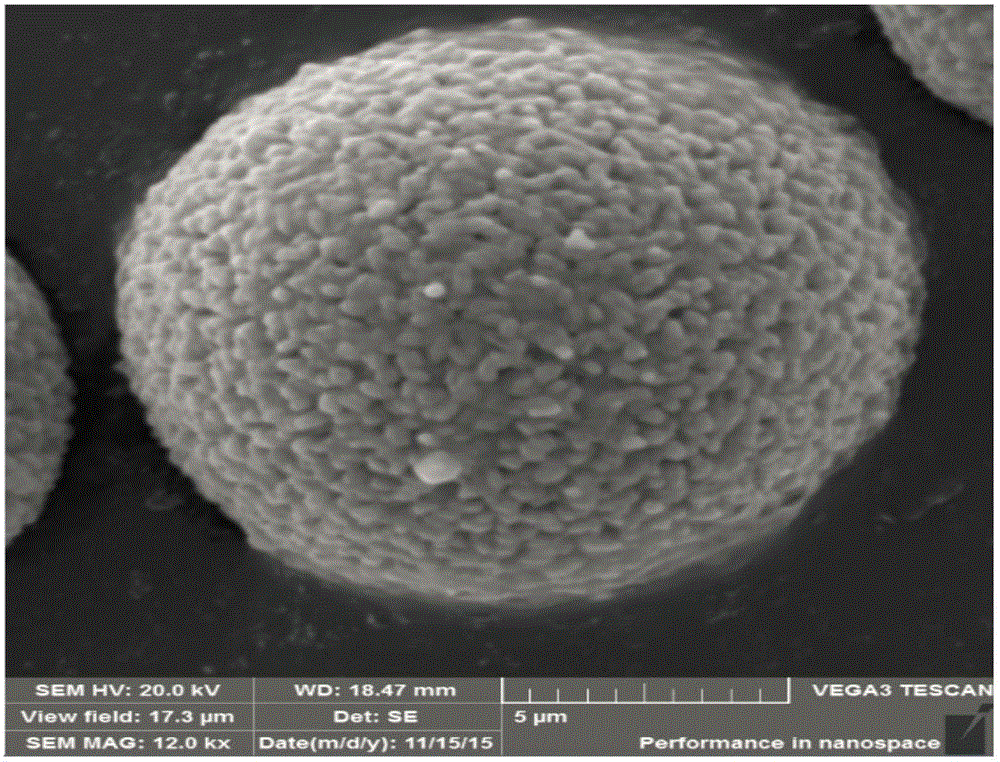

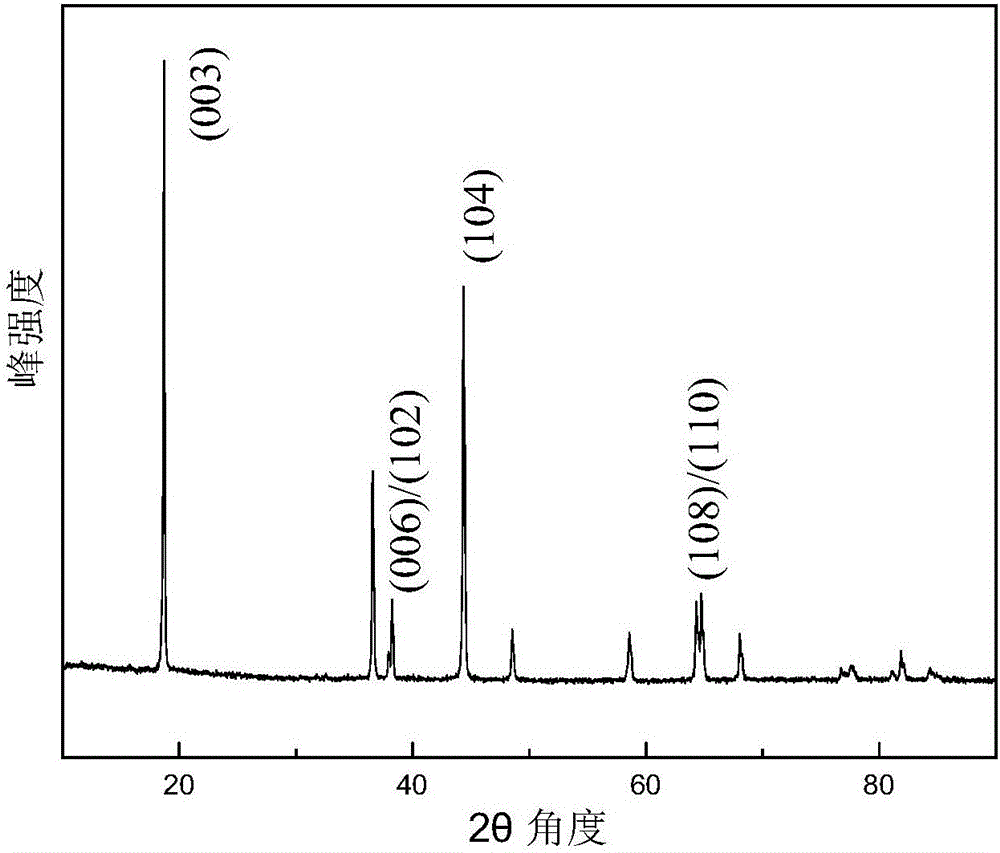

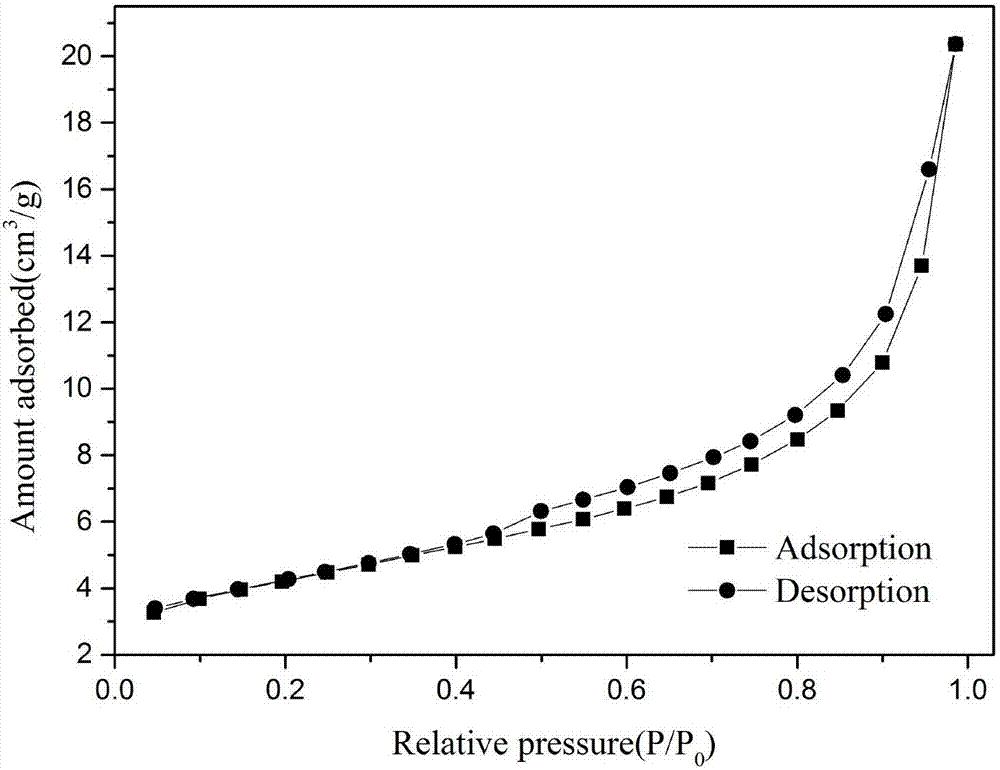

Preparation method of high-capacity monocrystalline type ternary cathode material

ActiveCN110002515AAccelerates the infiltration processEasy to storeCell electrodesSecondary cellsManganeseIncrease ph

A preparation method of a high-capacity monocrystalline type ternary cathode material comprises steps as follows: S1, a nickel cobalt manganese hydroxide precursor of a core-shell structure is prepared with a coprecipitation method, a loose and porous core is prepared by intermittently introducing a certain quantity of bicarbonate at the initial stage of core making, after core making ends, and loose flaky shells are prepared by substantially reducing the rotation speed and increasing pH; meanwhile, at the core-shell transition stage, a dispersant is added to effectively prevent agglomerationof the shells due to decrease of the rotation speed; S2, the prepared precursor and lithium salt are mixed and calcined once in the oxygen-rich atmosphere at the high temperature, and the monocrystalline type ternary cathode material is obtained. A battery is prepared from the ternary cathode material and has high capacity and good safety performance due to high lithium ion transport efficiency and reduced anisotropy in crystals. The problem of poor capacity of the material because of low lithium ion transport efficiency of monocrystalline type ternary materials is effectively solved. Besides,the monocrystalline type ternary cathode material is prepared through one-time sintering, the preparation procedure is simple, and the production cost is low.

Owner:南通金通储能动力新材料有限公司

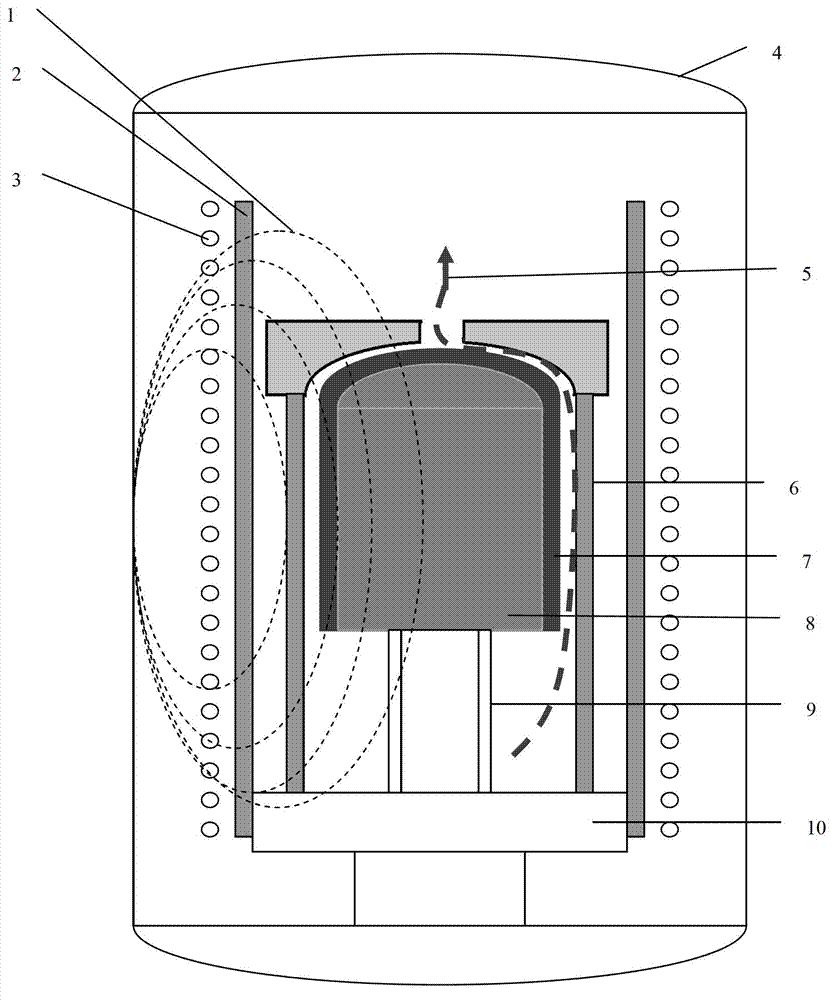

Narrow flow induction coupling chemical vapor deposition (CVD) densification method for rapidly preparing carbon/carbon composite material crucible

The invention relates to a narrow flow induction coupling chemical vapor deposition (CVD) densification method for rapidly preparing a carbon / carbon composite material crucible. The method comprises the steps of: adopting a chemical vapor deposition technology, under the synergistic effect of narrow slit airflow and inductive coupling, leading mixed gas of small-molecule hydrocarbon and N2 gas to a high-temperature reaction chamber, adsorbing the small-molecule hydrocarbon at the surface of an inner hole of a carbon fiber crucible precast body or a low-density carbon / carbon composite material crucible billet body, and releasing pyrolytic carbon at a high temperature, depositing the pyrolytic carbon at the surface of a hot carbon fiber, continuously improving the density of the billet body, and rapidly obtaining the compact carbon / carbon composite material crucible. By adopting the method disclosed by the invention, the crusting phenomenon of the surface is effectively restrained under the synergistic effect of narrow slit airflow and inductive coupling measures; high deposition temperature and reaction gas furnace pressure are permitted; inner and outer balanced densification is more rapidly carried out; the quality is improved; the cycle is shortened; and the cost is also reduced.

Owner:山东道普安制动材料有限公司

Lithium ion battery anode material with surface hydrophobicity and preparation method of lithium ion battery anode material

InactiveCN106299299APrevent delithiationNot corrodedCell electrodesSecondary cellsOrganic solventTwo temperature

The invention discloses a lithium ion battery anode material with surface hydrophobicity and a preparation method of the lithium ion battery anode material, relates to a lithium ion battery anode material prepared according to a surface modification technology and a preparation method thereof, and aims to solve the problems that the conventional anode material is poor in recycling performance, storage performance and compatibility with an electrolyte. The lithium ion battery anode material with the surface hydrophobicity has an organic hydrophobic layer on the surface, wherein the hydrophobic layer has the thickness of 0.5-20nm and the mass content of 0.1-10%; the preparation method of the lithium ion battery anode material with the surface hydrophobicity comprises the following steps: uniformly mixing an organic matter with hydrophobicity and an organic solvent, stirring together with an anode material at 30-80 DEG C, carrying out a reaction to obtain a mixture, filtering the mixture to obtain a solid filter cake, and treating the solid filter cake according to two temperature gradients to obtain the lithium ion battery anode material with the surface hydrophobicity. The lithium ion battery anode material with the surface hydrophobicity, prepared by the preparation method provided by the invention, is applied to a lithium ion battery.

Owner:HARBIN INST OF TECH

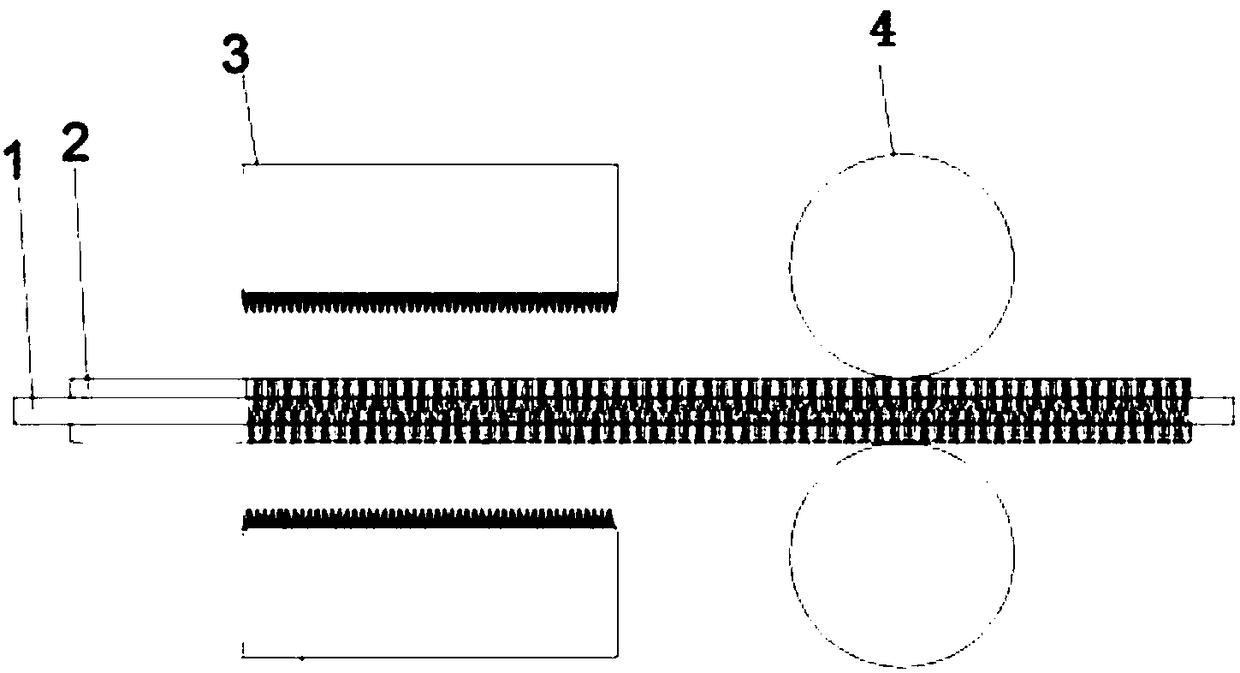

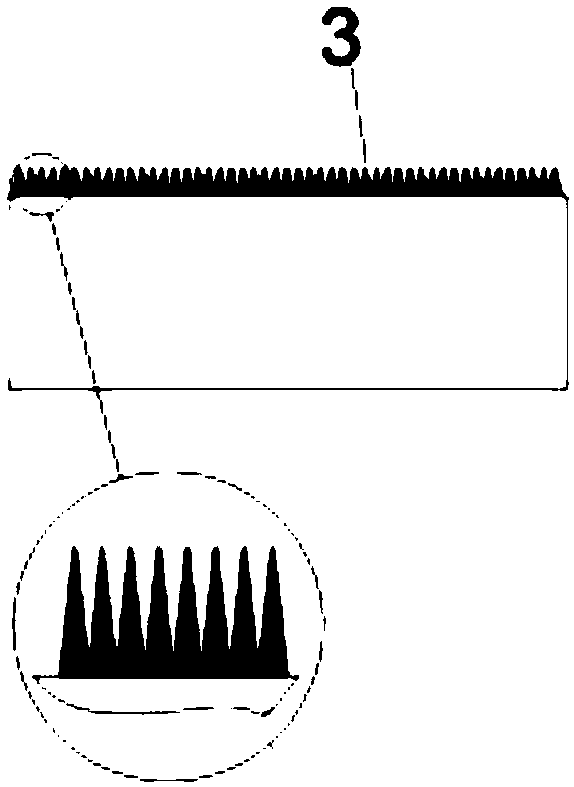

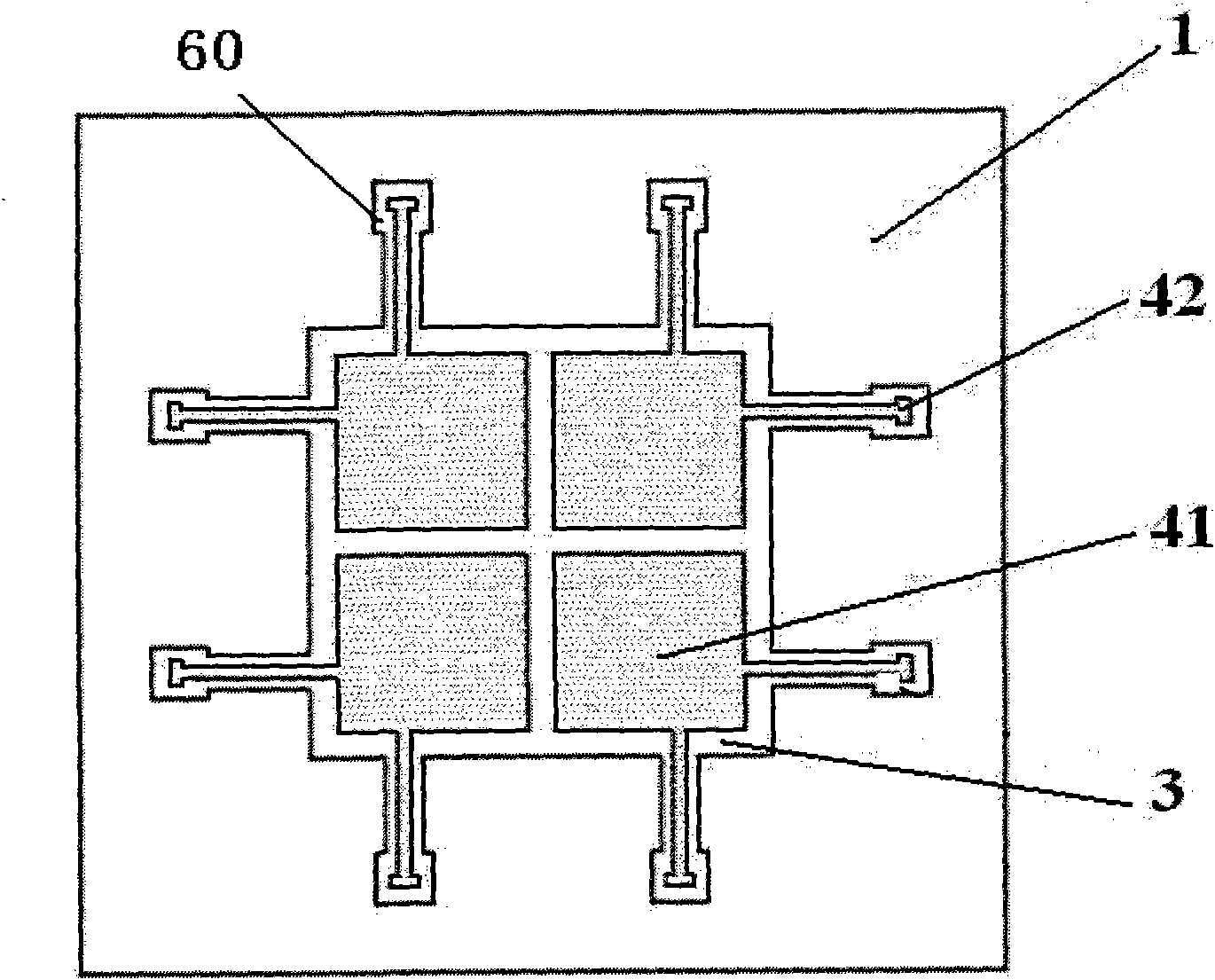

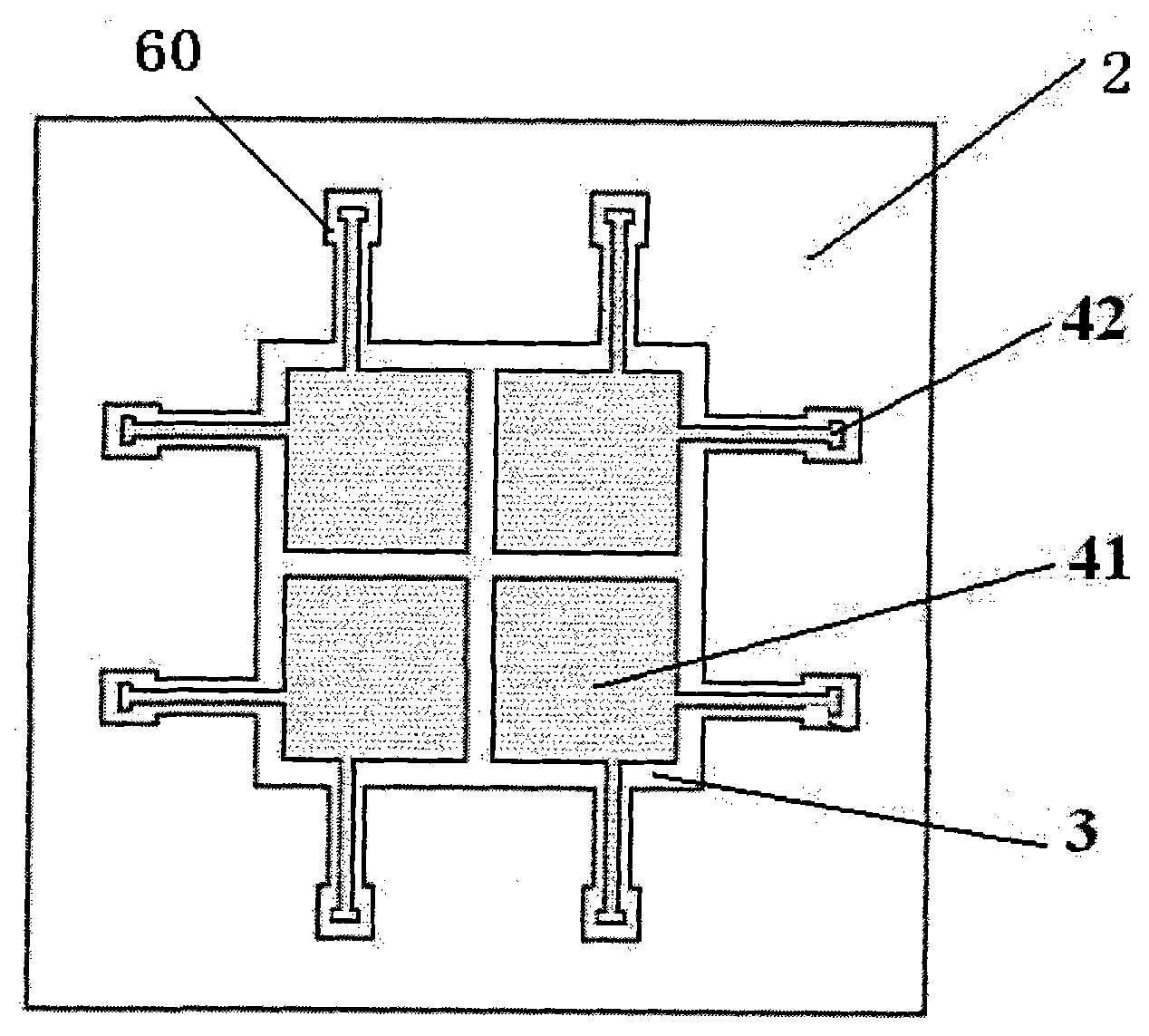

Perforated positive plate of lithium ion battery, and preparation method thereof

ActiveCN108400284AImproved magnification performanceImprove wettabilityElectrode collector coatingElectrical batteryEngineering

The invention discloses a perforated positive plate of a lithium ion battery. The perforated positive plate comprises a current collector coated with a lithium-iron oxide layer, and active substance layers arranged on upper and lower surfaces of the current collector, wherein uniform diffusion through holes are formed on the active substance layers and the current collector. The preparation methodcomprises the following steps: firstly coating a layer of Li5FeO4 on the aluminum foil surface to provide redundant lithium source for the battery, thereby retarding the lithium ion with the negativepole first effect to form irreversible SEI film consumption and enhancing long circulation performance; secondly, increasing the energy density of the battery by using the positive electrode with high compaction and high surface density; and finally forming a perforated pole plate, wherein the electrolyte can sufficiently enter the internal of the active substance to increase the infiltration ofthe electrolyte and retarding the expansion of the active substance, and the perforated positive plate can be applied in the battery industrialization in large scale. The conventional perforated aluminum foil is obtained by coating after perforating, and the perforated positive plate is obtained by perforating after coating, so that the surface density of the active substance is higher, and the energy density of the battery is 30% higher in relative to the conventional perforated pole plate.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

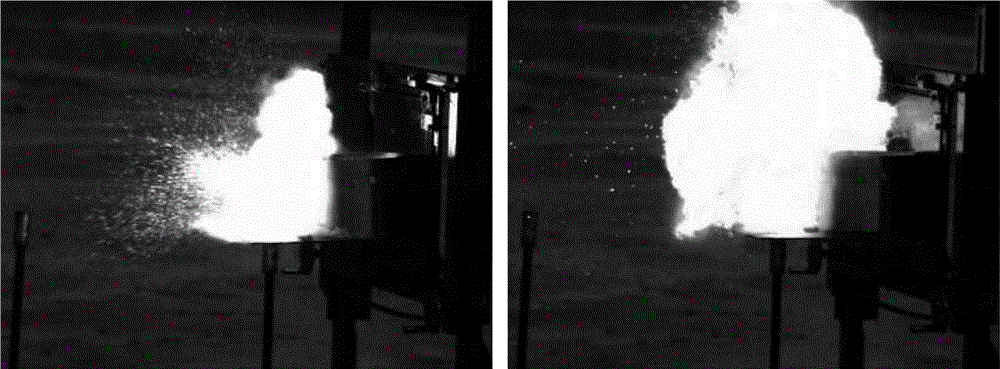

Energy-containing fragment on basis of nanometer Al/M<x>O<y>/oxidizing agents

InactiveCN105753616AHigh mechanical strengthGuaranteed penetration effectExplosivesChemical reactionFerrocene

The invention relates to an energy-containing fragment with nanometer Al / M<x>O<y> / oxidizing agents.The energy-containing fragment comprises, by weight, 10-30% of nanometer aluminum powder, 30-60% of transition metal oxide (the M<x>O<y>), 10-40% of the oxidizing agents, 1-5% of ferrocene, 1-7% of high explosive and 3-8% of mixed binders.The energy-containing fragment has the advantages that the energy-containing fragment is high in energy density and fire setting capacity, good in safety performance and easy to ignite, immediate reaction can be prevented when the energy-containing fragment is driven by explosive, but violent chemical reaction can be carried out in penetration procedures, extremely high-temperature heat can be released, and high-temperature hot reaction products with flowability can be generated.

Owner:ZHONGBEI UNIV

Preparation method of carbon/carbon nanotube coated lithium iron phosphate composite material by in situ synthesis

ActiveCN106876705AHigh carbon coverageImprove electrochemical performanceCell electrodesSynthesis methodsPhosphate

The invention provides a preparation method of a carbon / carbon nanotube coated lithium iron phosphate composite material by in situ synthesis, and relates to the technical field of battery materials. The preparation method provided by the invention comprises the steps of weighing raw materials of a lithium source, iron powder, a phosphate and a carbon source; first performing ball-milling on the iron powder and the phosphate and adding hydrogen peroxide; and then adding the lithium source and the carbon source to obtain a slurry, drying and sintering under the protection of reducing / inert gas to obtain the composite material. According to the preparation method provided by the invention, the carbon / carbon nanotube coated lithium iron phosphate composite material is prepared by employing an in-situ synthesis method, so the heat treatment time is short; the composite material has relatively high carbon coating rate, stable electrochemical property and relatively good consistency, the cycle performance and the rate performance are greatly improved, the whole preparation process is simple, and the preparation method has the advantages of safety, high efficiency, low cost and environmental protection, etc.

Owner:合肥国轩科宏新能源科技有限公司

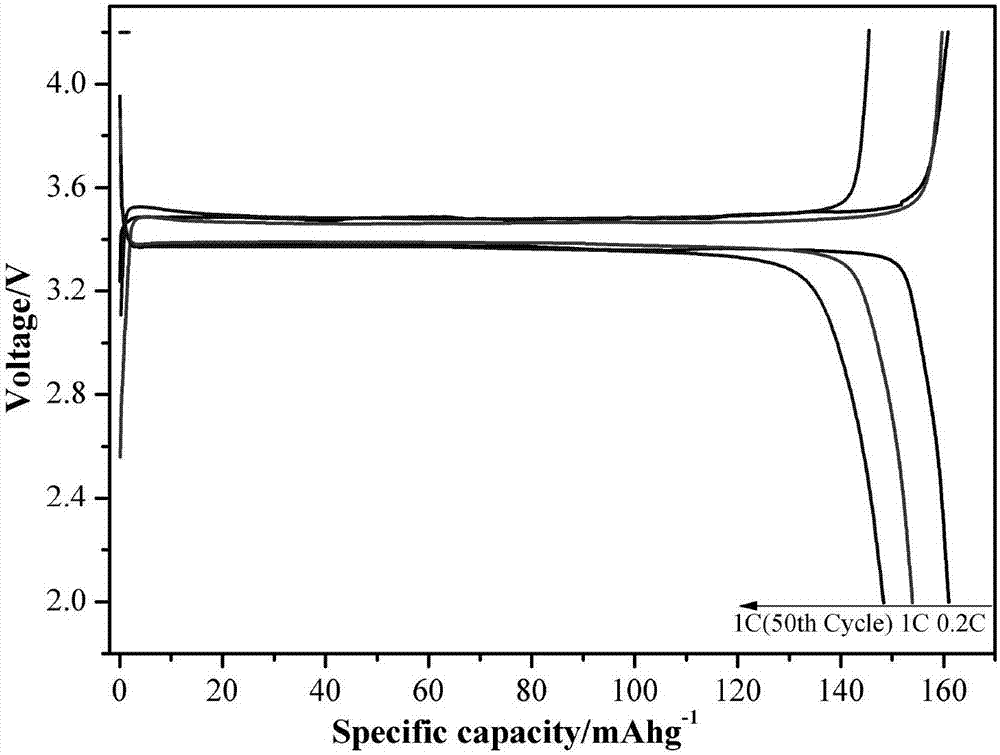

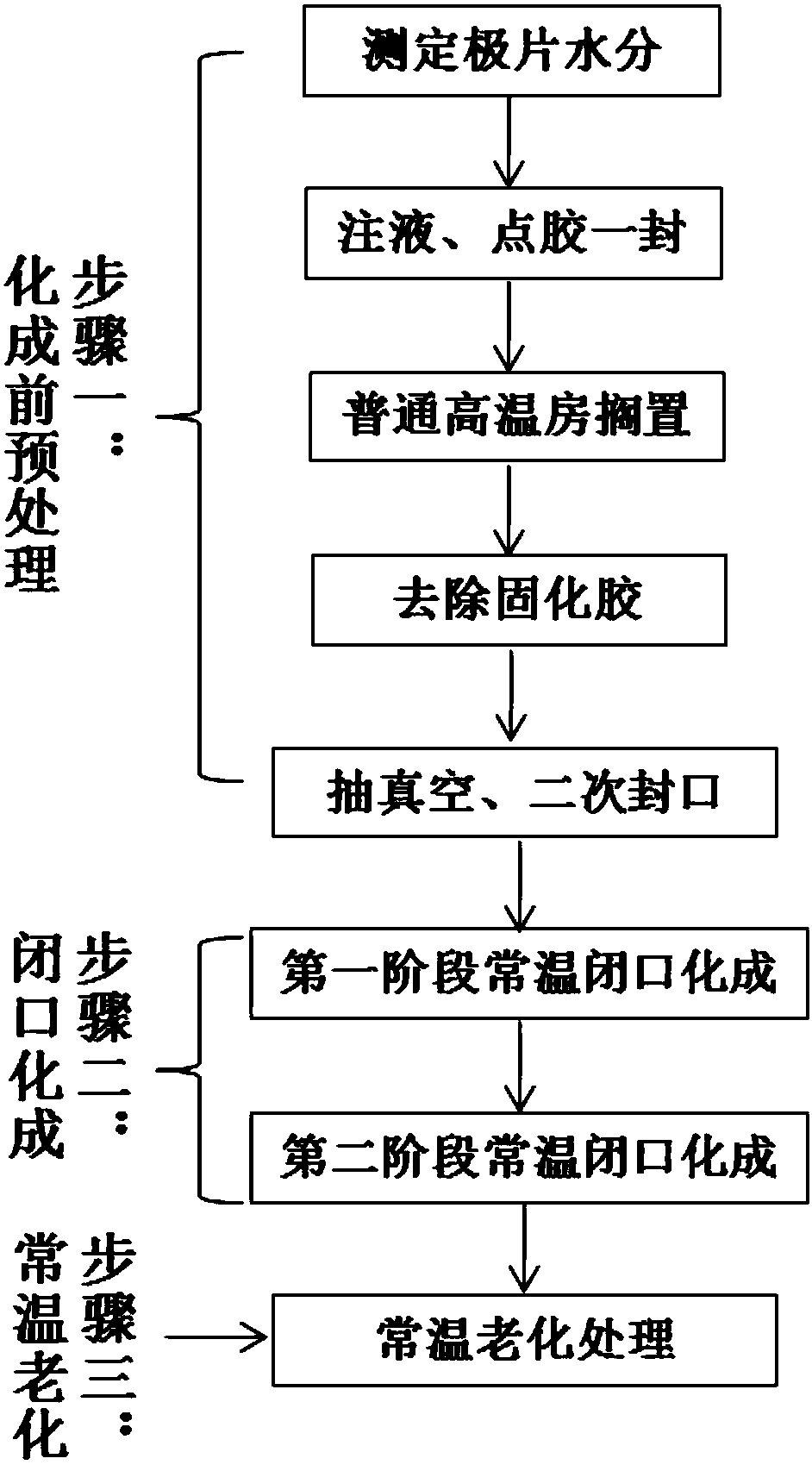

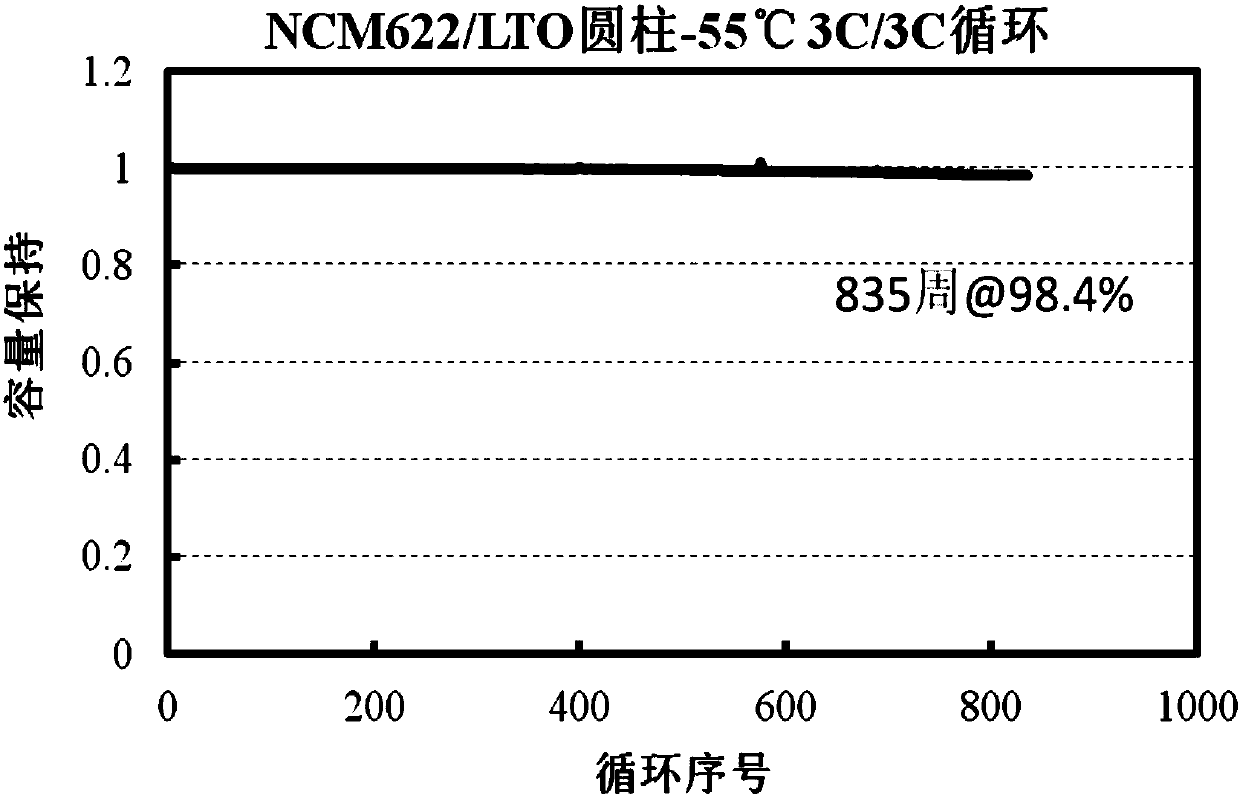

Closed formation method of cylindrical lithium titanate battery

ActiveCN107732311AAccelerates the infiltration processImprove stabilityFinal product manufactureCylindrical casing cells/batteryPower flowElectrical battery

The invention discloses a closed formation method of a cylindrical lithium titanate battery. The closed formation method is applicable to a cylindrical lithium titanate battery with a negative electrode material being a lithium titanate material. The closed formation method comprises the steps of measuring moisture content of a roll core pole plate of the cylindrical lithium titanate battery, placing the dispensed and pre-packaged cylindrical lithium titanate battery in a high-temperature room to stand after liquid injection, removing sealing glue after the pole plate is fully immersed and stabilized, vacuumizing and discharging air, sealing a steel ball, and performing secondary dispensing and sealing; placing the lithium titanate battery on a formation cabinet for battery formation processing, wherein the formation process is divided into two stages under a normal-temperature environment, constant-current charging is performed with an I1 current in the first stage until a voltage reaches V1, constant-current and constant-voltage charging is performed with a small current I2 in the second stage, a cutoff voltage is V2, and a cutoff current is I3; and placing the lithium titanate battery in a normal-temperature environment condition for aging. By the method, the closed formation of the cylindrical lithium titanate battery is achieved, gas generation during the formation processand the circulation process of the lithium titanate battery is prevented, and industrial production on a large scale is easy to achieve.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

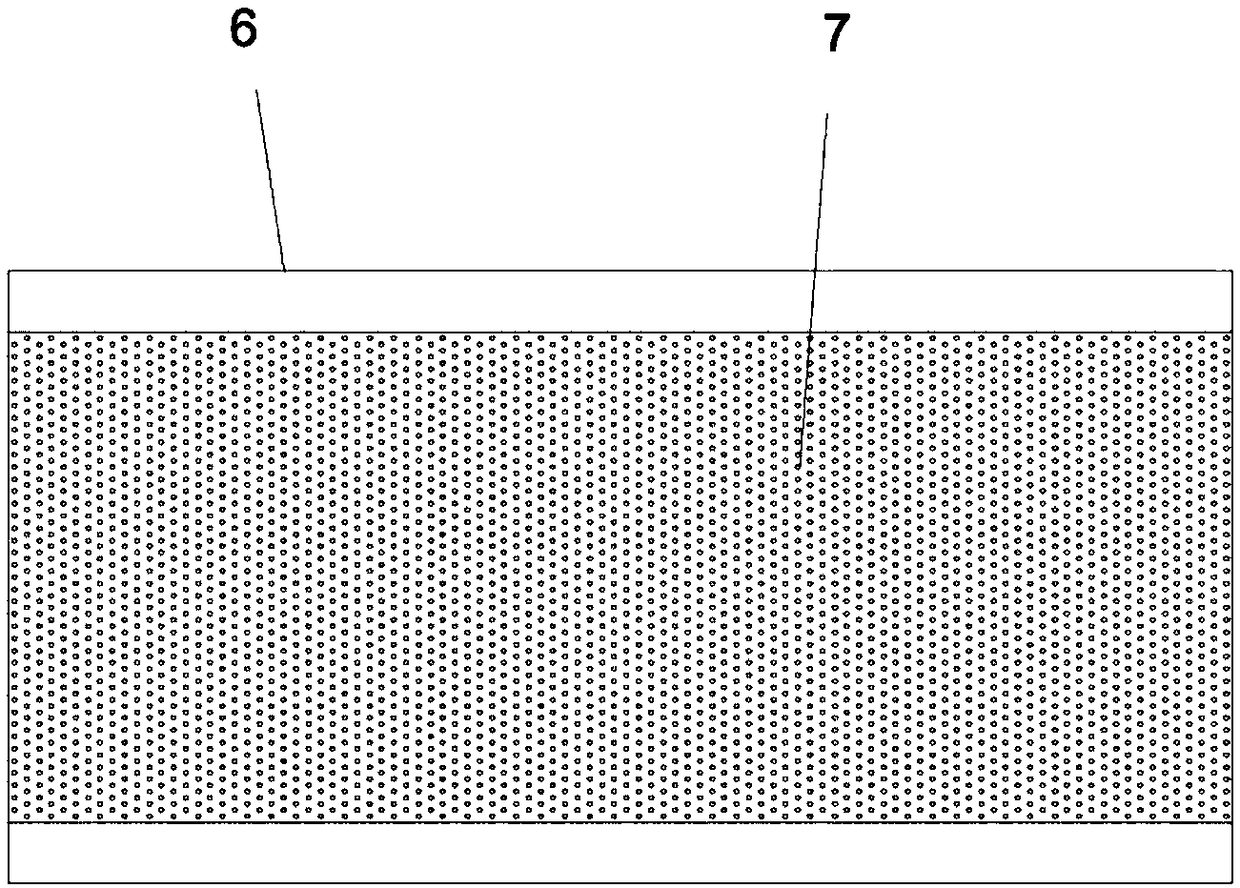

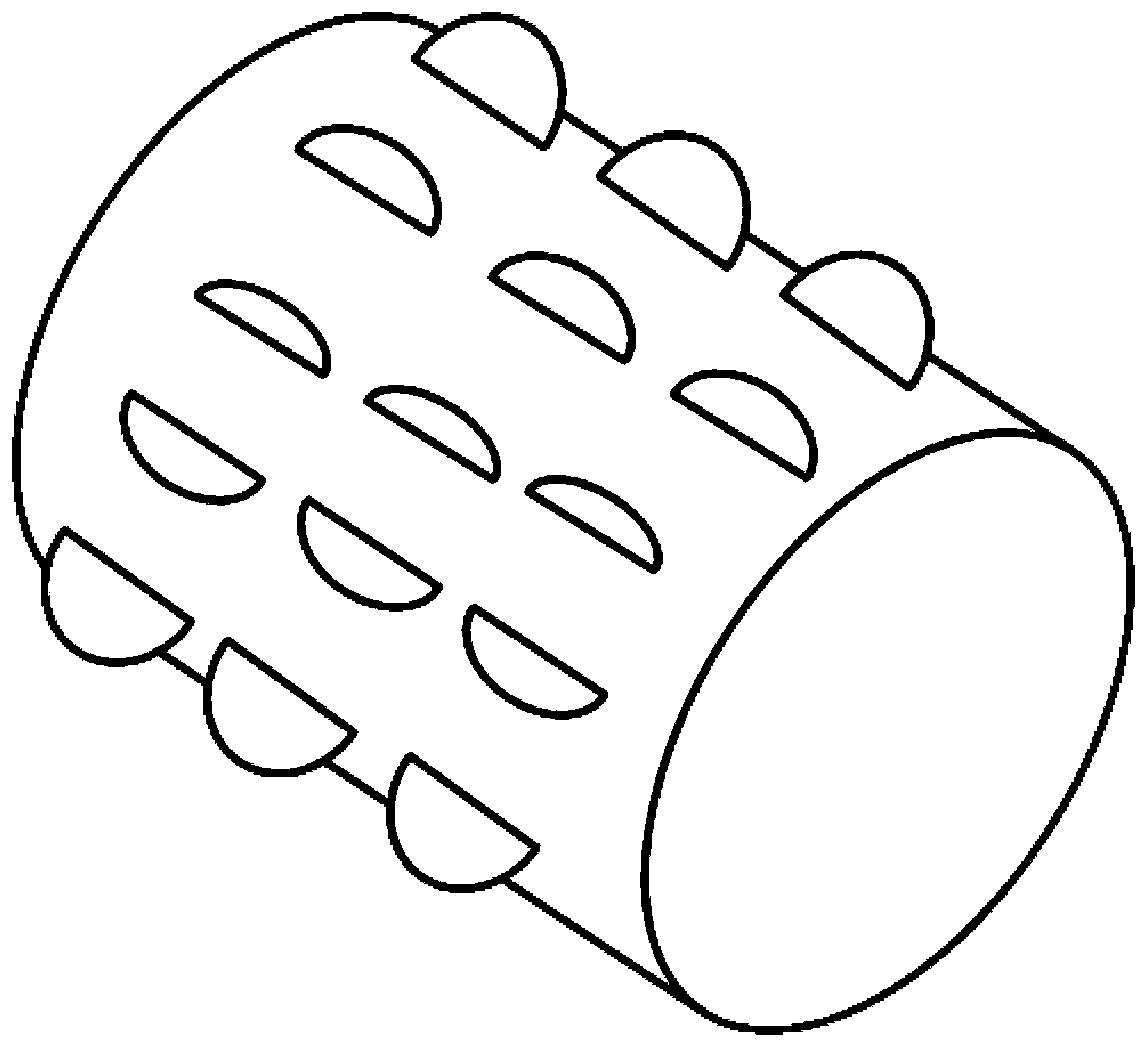

Pole piece, preparation method thereof and lithium ion battery

PendingCN110752345AImprove rolling effectImprove wetting and absorptionElectrode rolling/calenderingSecondary cellsPhysicsElectron transmission

The invention relates to a pole piece, a preparation method thereof and a lithium ion battery. According to the invention, the positive / negative pole piece is subjected to shape-setting cold pressingby adopting a pressing roller with a specific shape, the pressing roller is provided with hemispherical or football-shaped bumps so as to enable the pressed material to have pits which are continuously and uniformly distributed; a pore-forming agent is applied to the surface of the cold-pressed pole piece by means of transfer coating for pore forming so as to obtain the pole piece with a gradientporosity structure. The preparation method of the pole piece with the gradient porosity structure has the advantages that the operation is simple, feasible and efficient, and a solution is provided for the problem of thick pole pieces in the development process of high-specific-energy batteries. According to the pole piece with the gradient porosity structure, the infiltration and absorption effects of an electrolyte can be improved, the specific surface area of the material is increased, the ion / electron transmission rate is increased, the resistivity is reduced, the high energy density of the designed material is achieved, and then the requirements of a new energy automobile for a power battery are met.

Owner:EVE ENERGY CO LTD

Technical method using low resin content prepreg for preparation of composite material

The invention belongs to the technical field of low-cost manufacturing of high performance composite materials, and relates to a technical method using a low resin content fiber-reinforced prepreg for preparation of a composite material. First of all, resin content in the prepreg can be regulated by precise control of the concentration of a resin solution in a wet-method prepreg preparing process, and under the premises of ensuring structural integrity and technical operability of the prepreg, fiber tows are partly wetted with resin to obtain the low resin content prepreg; then by combination with a mold-closing RTM (resin transfer molding) technology and in dependence on injection and flowing of low viscosity RTM resin, the reinforced fiber can be finally and completely wetted to obtain the high performance composite material which has good paving technical properties and high fiber collimation degree and fiber volume fraction of both the prepreg and the composite material and can combine manufacturing flexibility of the RTM technology.

Owner:AVIC COMPOSITES

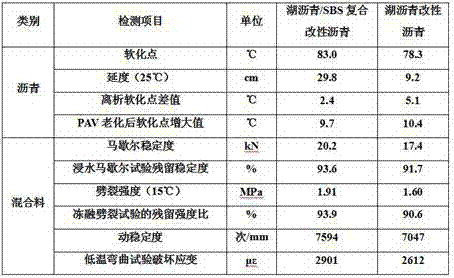

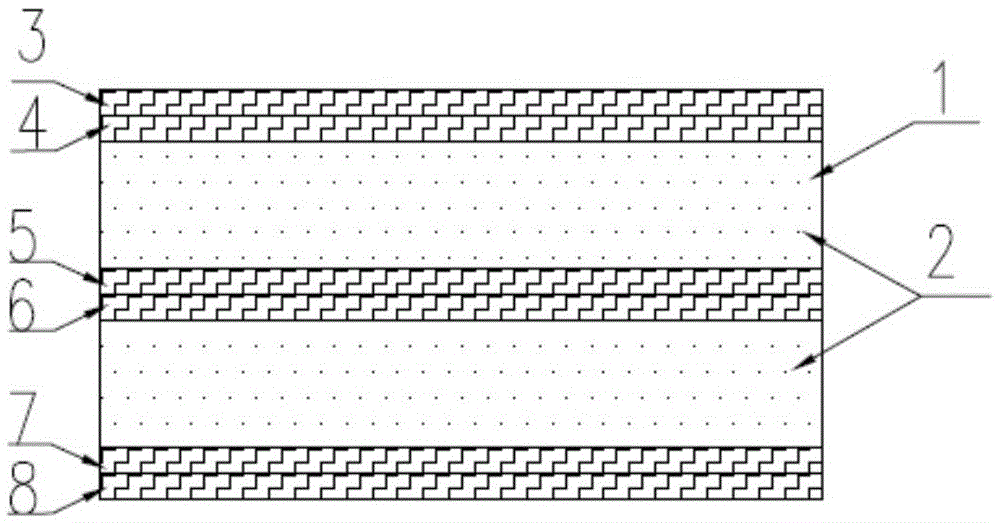

Lake asphalt/SBS compound modifier and preparation method and application thereof

InactiveCN106928731AImproves resistance to water damageImprove low temperature cracking resistanceBuilding insulationsCrack resistanceRoad surface

The invention relates to a lake asphalt / SBS compound modifier and a preparation method and application thereof. The lake asphalt / SBS compound modifier is a pre-dispersant which is prepared by the fusion and blending of lake asphalt, polymer SBS and compatilizers, and modified asphalt can be prepared by fusing and blending the lake asphalt / SBS compound modifier with petroleum asphalt and stabilizers. The obtained lake asphalt / SBS compound modifier is the pre-dispersant which can remarkably improve the high-temperature deformation resistance capability, low-temperature cracking resistance capability and water damage resistance capability of the petroleum asphalt, and by adding the pre-dispersant into the petroleum asphalt and taking use of the advantage of good compatibility between the pre-dispersant and the petroleum asphalt, the lake asphalt / SBS compound modified asphalt is prepared, wherein the modified asphalt is uniform in dispersion, and layered segregation does not occur easily on the modified asphalt. The modified asphalt is used for the construction of heavy-loaded traffic asphalt pavements in high temperature, damp and rainy areas, asphalt pavement diseases can be significantly reduced, the maintenance cost of the pavements is reduced, and the service life of the asphalt pavements is prolonged.

Owner:FUZHOU UNIV

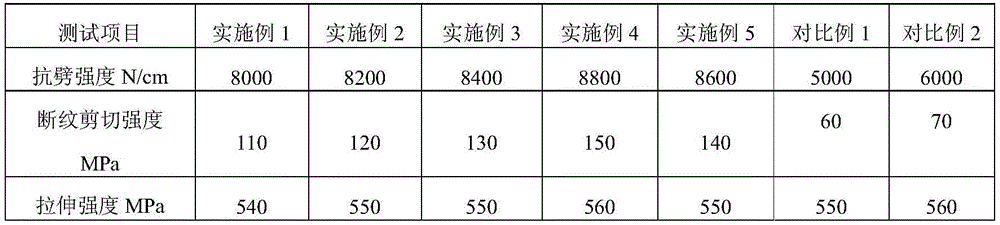

High-strength pultruded profile and preparation method thereof

ActiveCN106808762AImprove mechanical propertiesEnsure Structural IntegritySynthetic resin layered productsGlass/slag layered productsGlass fiberResin matrix

The invention relates to a high-strength pultruded profile which comprises the following components: 20-30 wt% of resin matrix, 30-40 wt% of glass fiber and 30-40 wt% of multiaxial sized raw fabric. The high-strength pultruded profile is characterized in that the glass fibers are uniformly distributed inside the resin matrix to enhance the axial strength of the pultruded profile; the multiaxial sized raw fabrics are respectively formed by previously dipping the fabric in the resin matrix and carrying out semi-curing, and respectively positioned on the surface and in the middle of the pultruded profile; the multiaxial sized raw fabric on the surface is used for protecting the surface of the pultruded profile and enhancing the transverse strength of the pultruded profile surface; and the multiaxial sized raw fabric in the middle is used for enhancing the overall transverse strength of the pultruded profile. The invention also relates to a preparation method of the high-strength pultruded profile.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

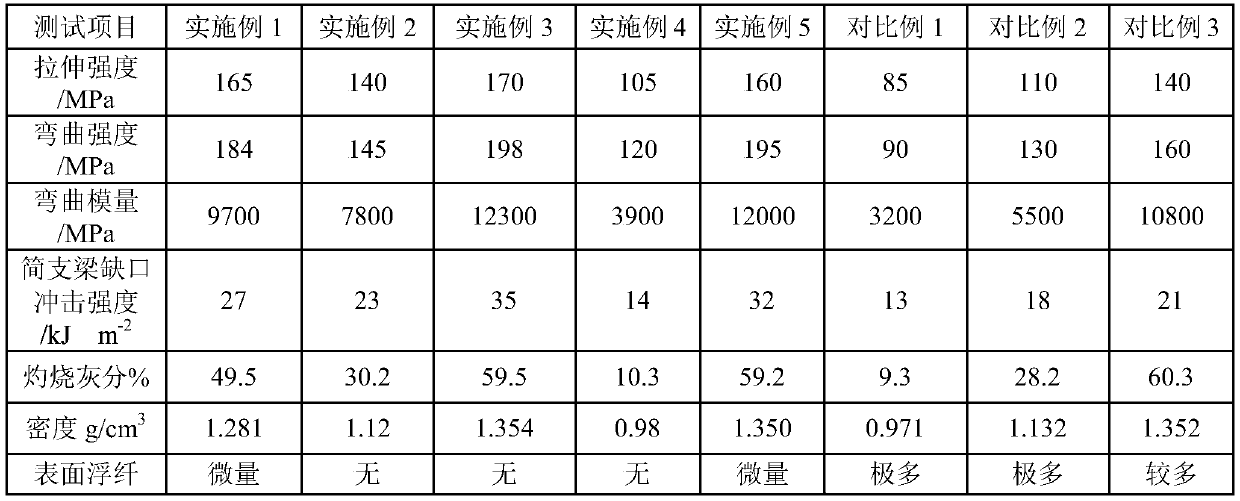

Long glass fiber enhanced polypropylene composite material and preparation method thereof

The invention relates to the technical field of polypropylene materials, and specifically relates to a long glass fiber enhanced polypropylene composite material and a preparation method thereof. Thelong glass fiber enhanced polypropylene composite material comprises a component A and a component B. The component A is prepared from following components in parts by weight: 30 to 90 parts of polypropylene resin, 10 to 60 parts of alkali-free continuous glass fibers, 0.5 to 2.0 parts of a lubricant, 0.01 to 0.1 part of peroxides, 0.5 to 3.0 parts of a silane coupling agent, and 0.2 to 0.7 part of an antioxidant. The component B is prepared from following components in parts by weight: 30 to 90 parts of polypropylene resin, 10 to 60 parts of alkali-free continuous glass fibers, 0.5 to 2.0 parts of a lubricant, 1.0 to 4.0 parts of a catalyst, 0.01 to 0.1 part of peroxides, and 0.2 to 0.7 part of an antioxidant. Peroxides decompose and functionalize polypropylene; during the infiltration process, polypropylene has high fluidity and excellent infiltration effect; after the material is moulded, the mechanical strength of the material is improved, and moreover, the prepared material has few fibers on the surface, is easy to mould, and has a high performance.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

Non-curing polyurethane waterproof coating and preparation method thereof

ActiveCN103923565BGood adhesionGrowth Intermediate ConnectivityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention relates to a non-curing polyurethane waterproof coating and a preparation method thereof, belonging to the technical field of polyurethane waterproof coating. It consists of the following raw materials in percentage by weight: prepolymer 13-20%, asphalt 30-65%, latent curing agent 1.0-1.5%, compatibilizer 3-15%, thermoplastic elastomer 2-9%, powder Sexual filler 0-30%, the prepolymer is a reaction composition of polyether and isocyanate. The core of the invention improves the material ratio and polymerization process of polyurethane, which overcomes the problems that hot-melt asphalt materials need to be heated by machines, etc. It is convenient for construction and has good fluidity. The waterproof layer without internal stress can also have good adhesion with the coiled material. It can be composited waterproof to form a waterproof layer that overcomes the cracking of the base layer and prevents puncture. The process is simple and can be quickly constructed. It needs maintenance and has fast work efficiency, which can become the development direction of building waterproofing in the future.

Owner:浙江鲁班建材科技股份有限公司

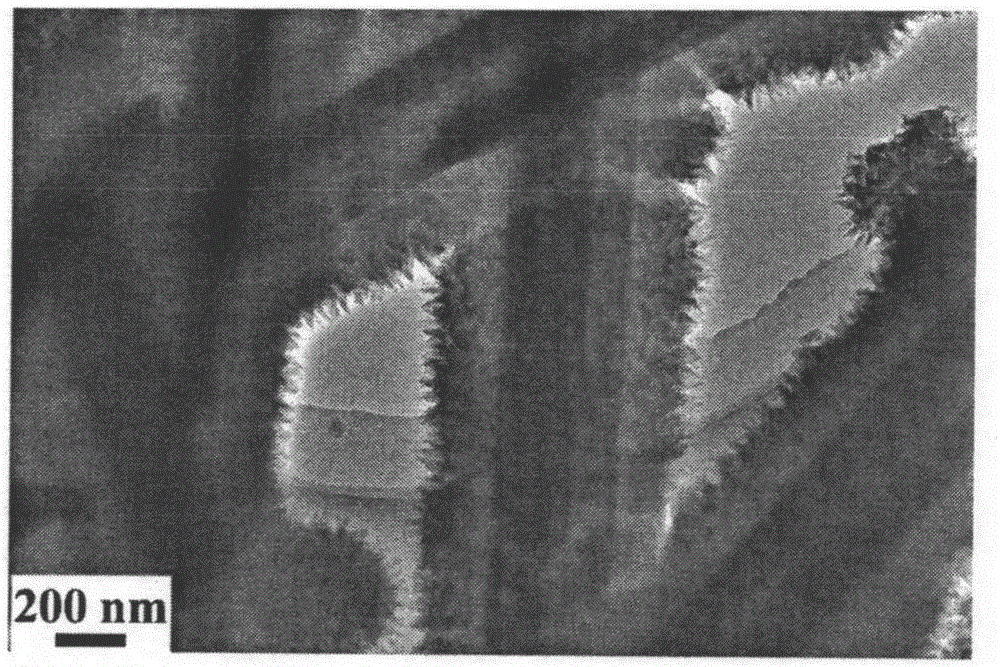

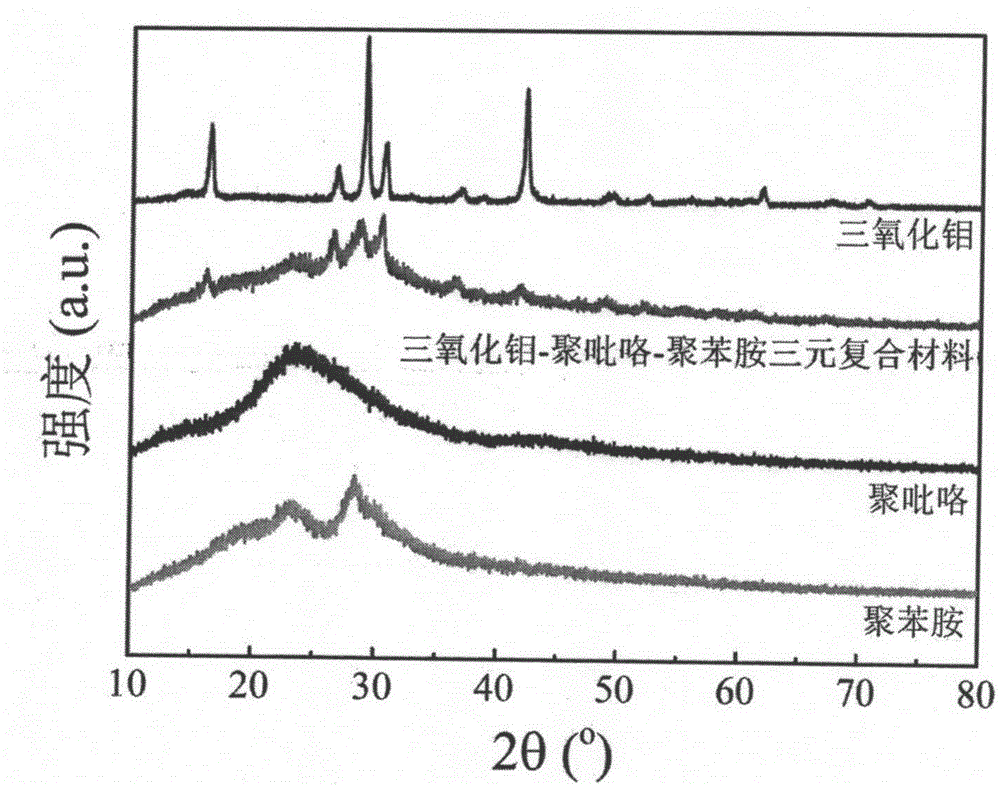

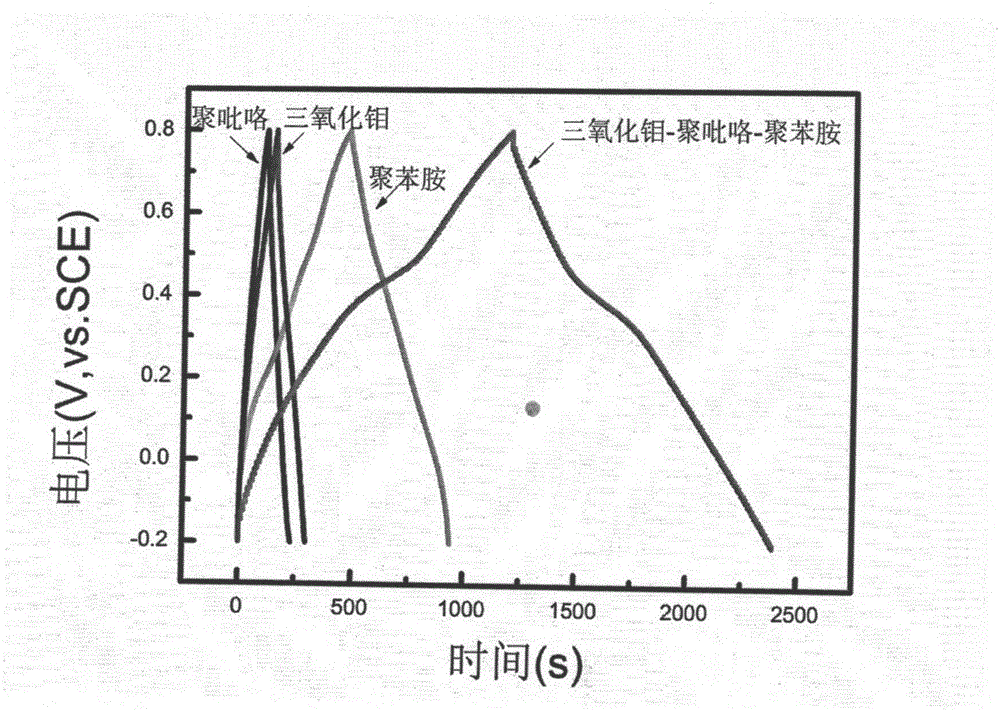

Preparation method of molybdenum trioxide-polypyrrole-polyaniline ternary composite material

InactiveCN106065180AGood aspect ratioInhibition of agglomerationCell electrodesPolypyrroleSupercapacitor

The invention provides a preparation method of a molybdenum trioxide-polypyrrole-polyaniline ternary composite material. The method comprises the following steps: 1, preparing molybdenum trioxide nanobelts through a hydrothermal technology; 2, carrying out in situ growth of polypyrrole on the molybdenum trioxide nanobelts to obtain a molybdenum trioxide-polypyrrole binary composite material; and 3, carrying out in situ growth of polyaniline on the surface of the molybdenum trioxide-polypyrrole binary composite material used as a template in order to obtain the molybdenum trioxide-polypyrrole-polyaniline ternary composite material. The molybdenum trioxide-polypyrrole-polyaniline ternary composite material prepared in the invention can be used in high-performance super capacitors, lithium ion batteries, solar batteries and other novel energies as an ideal electrode material.

Owner:DONGHUA UNIV

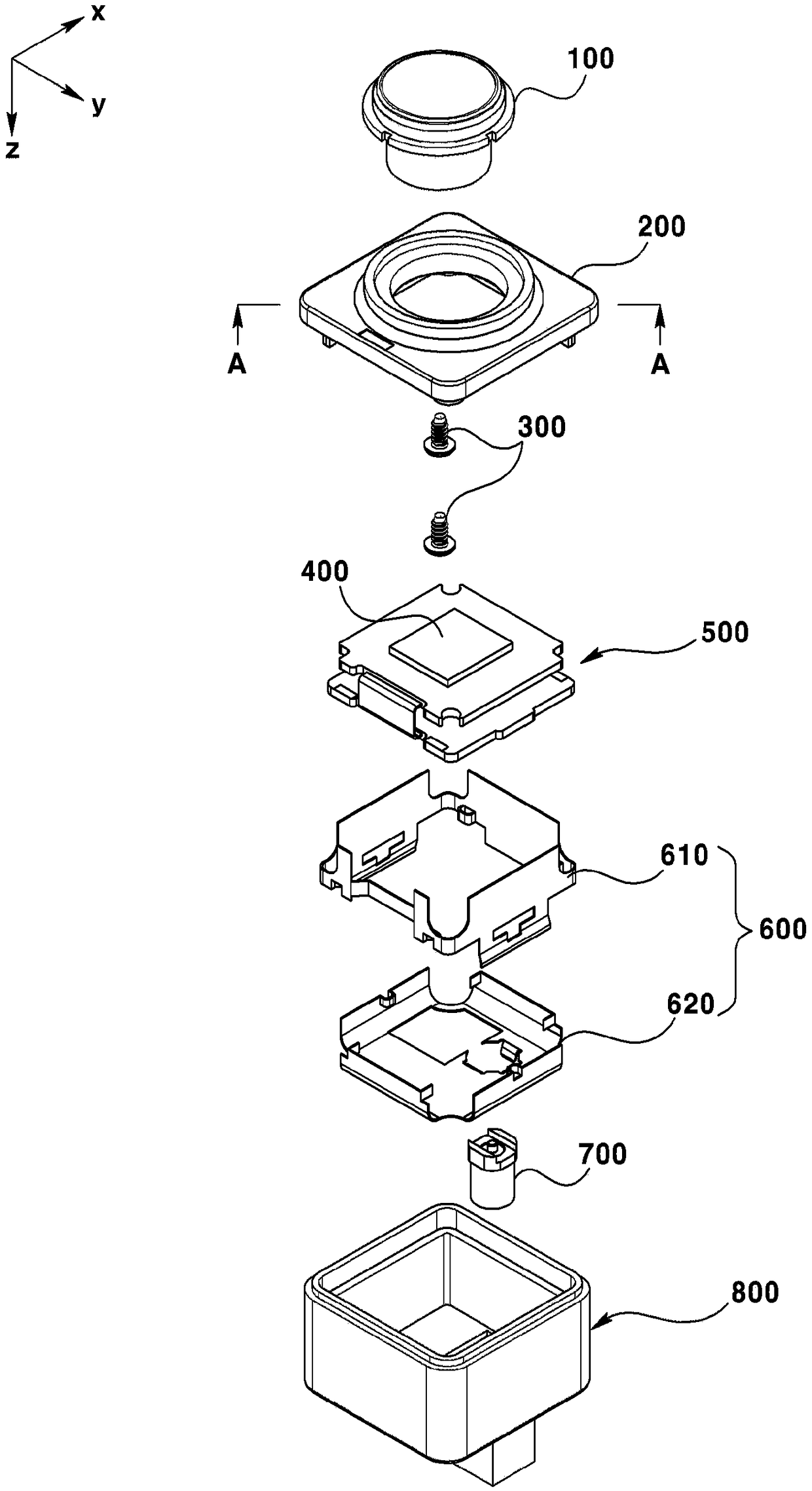

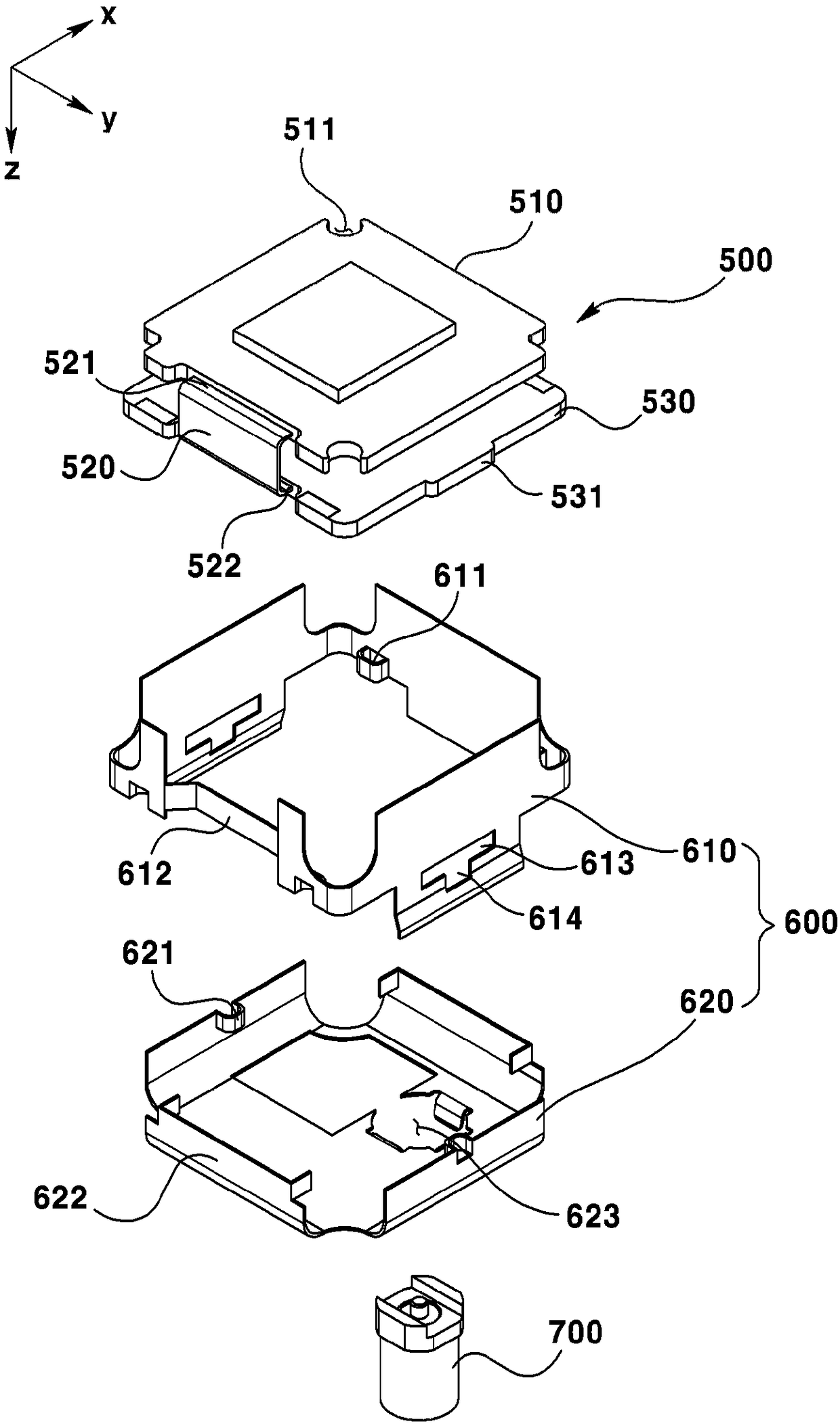

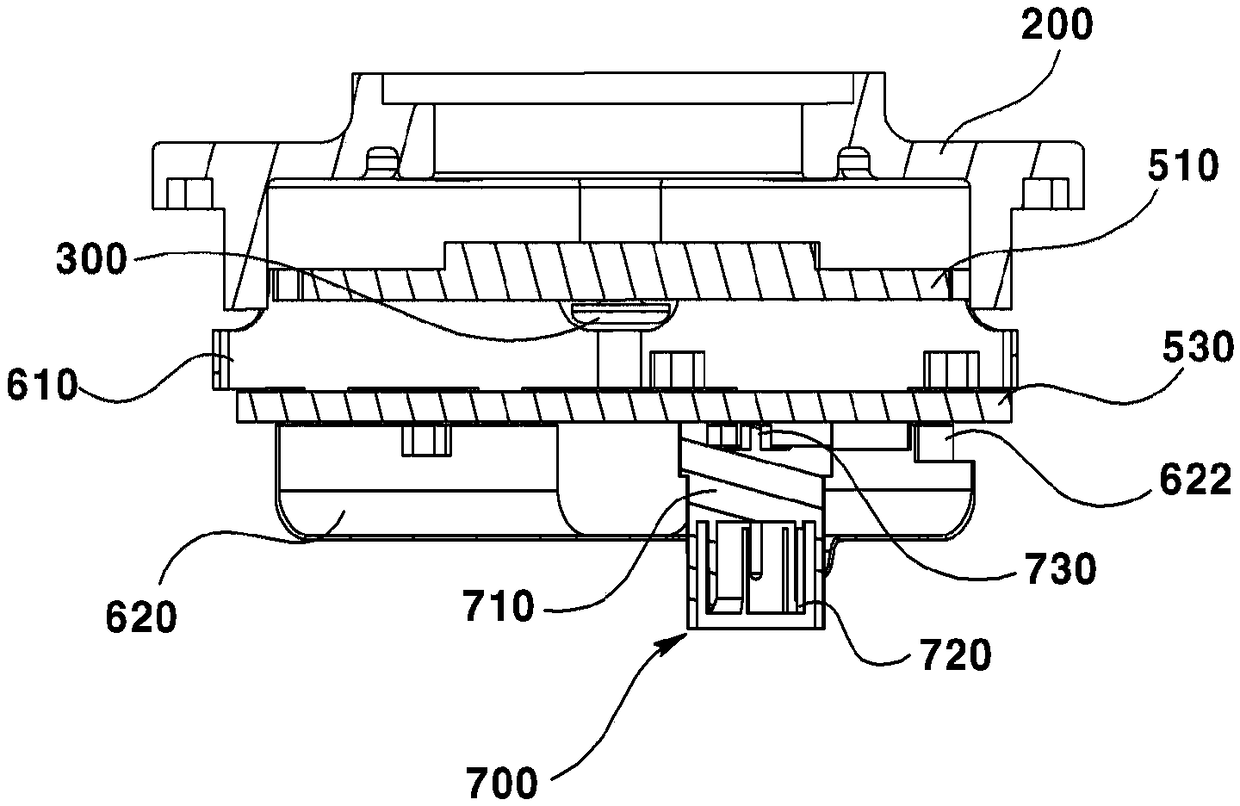

Camera module and vehicle

ActiveCN109076150AFacilitated releaseAccelerates the infiltration processTelevision system detailsColor television detailsEngineeringCamera module

The present embodiment provides a camera module and a vehicle comprising same, the camera module comprising: a lens barrel accommodating at least one lens; a front body accommodating the lens barrel;a substrate assembly which couples with the front body, is disposed so as to be spaced apart from the lens barrel, and comprises at least one substrate so as to have an image sensor and a connector mounted thereon; a shield can which couples with the substrate assembly so as to accommodate at least one portion of the substrate assembly; and a rear body which couples with the front body and accommodates the substrate assembly and the shield can. The shield can comprises: a hole formed in a position corresponding to the connector; and a connection member which is bent and extends towards the inside from the hole. The connector passes through the hole, and the connector has a ground part disposed on the outer surface thereof so that the ground part and the connection member electrically makecontact.

Owner:LG INNOTEK CO LTD

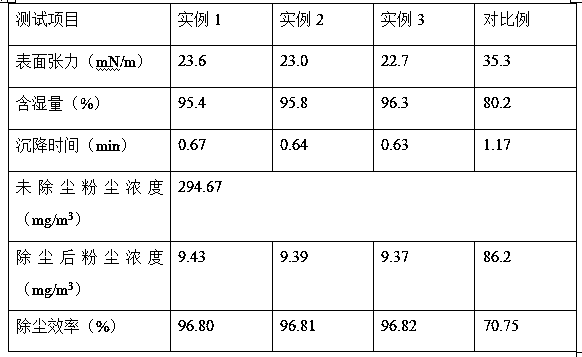

Preparation method of water-retention dust-falling agent

InactiveCN108795387AGood water swelling performanceImprove filling capacityOther chemical processesProtein isolateSide chain

The invention relates to the technical field of preparation of dust-falling agents and in particular relates to a preparation method of a water-retention dust-falling agent. According to the preparation method, corn starch is subjected to enzymolysis and then is subjected to grafted copolymerization with an acrylic monomer and acrylamide, so that oxidized dextrin has extremely good water absorption and expansion performance; hydrophilic groups including hydroxyl and the like, which are exposed by the corn oxidized dextrin, are good for water retention after water is absorbed, and a condition that excessive water is absorbed and then is leaked is avoided; calcium chloride is doped into the oxidized dextrin so that the water retention amount of the oxidized dextrin can be improved; an endonuclease effect of alpha-amylase is utilized to change the polymerization degree of linear side chains of amylose and amylopectin, so that the viscosity and concentration of the dust-falling agent can be controlled through water dilution; ammonium bicarbonate is added so that a solution surface of the dust-falling agent is foamed; after the surface area of the solution surface is enlarged, the wetting and adsorption performance on dust in the air is improved; meanwhile, protein isolate also has certain oil absorption performance and the absorption rate on oily dust can be improved, so that the dust-falling agent has a wide application prospect.

Owner:FOSHAN LINGXIE ENVIRONMENTAL PROTECTION TECH CO LTD

Lake asphalt/SBR (styrene butadiene rubber) composite modifier and preparation method and application thereof

InactiveCN106893333AGood compatibilityGood dispersionBuilding insulationsCrack resistanceRoad surface

The invention relates to a lake asphalt / SBR (styrene butadiene rubber) composite modifier and a preparation method and application thereof. The lake asphalt / SBR composite modifier is a pre-dispersed material formed by the lake asphalt, polymer SBR and a compatilizer via melt blending, and the modified asphalt can be obtained by melt blending of petroleum asphalt and a stabilizer. The lake asphalt / SBR composite modifier is the pre-dispersed material capable of remarkably improving capacities of high-temperature deformation, low-temperature cracking resistance and anti-water damage, the pre-dispersed material is then added to the petroleum asphalt, and the lake asphalt / SBR composite modified asphalt uniform in dispersion and less prone to layered segregation by the aid of the advantage of good compatibility of the pre-dispersed material and the petroleum asphalt; the modified asphalt is applied to construction of heavy traffic asphalt pavement of high-temperature, moist and rainy regions, asphalt pavement diseases can be remarkably reduced, pavement maintenance cost is lowered, and service life of the asphalt pavement is prolonged.

Owner:FUZHOU UNIV

Binder used for 3D printing materials

InactiveCN109251455AGood adhesionAccelerates the infiltration processAdditive manufacturing apparatusPolyvinyl alcoholPotassium carbonate

The invention discloses a binder used for 3D printing materials. The binder is composed of a component A and a component B at a mass ratio of 2-3:1; the component A comprises, by mass, 50 to 60 partsof acrylic emulsion, 30 to 40 parts of polyvinyl alcohol, 10 to 13 parts of polyvinyl acetate emulsion, 8 to 15 parts of non-ionic polyacrylamide, 20 to 40 parts of soybean protein glue, 2 to 3 partsof sodium hypochlorite, 7 to 12 parts of sodium dodecyl benzene sulfonate, 15 to 20 parts of inorganic gel, 5 to 8 parts of hydroxypropyl methyl cellulose ether, 3 to 6 parts of a stabilizing agent, and 3 to 5 parts of a thickening agent; and the component B comprises, by mass, 35 to 45 parts of polylactic acid, 15 to 20 parts of aerosil, 30 to 40 parts of wax maize starch, 10 to 15 parts of ethylene glycol diacetate, 20 to 35 parts of alumina sol, 8 to 13 parts of allyl methacrylate, 15 to 22 parts of absolute ethyl alcohol, 5 to 8 parts of anhydrous potassium carbonate, 15 to 25 parts of anhydrous magnesium sulfate, 2 to 4 parts of glycol, 5 to 9 parts of nanometer manganous oxide, 3 to 5 parts of a composite initiator, 3 to 6 parts of a curing agent, and 6 to 11 parts of an activator.

Owner:江苏天泽教育咨询有限公司

Method for preparing suspension micro-sensitive structure based on aluminum sacrificial layer process

InactiveCN101913552AInhibit sheddingReduce performanceDecorative surface effectsChemical vapor deposition coatingEtchingSolvent

The invention discloses a method for preparing a suspension micro-sensitive structure based on an aluminum sacrificial layer process. The method comprises the following steps of: introducing a sacrificial layer into a three-layer suspension micro-sensitive structure to restrict a micro-sensitive suspension mass block during the processing, and connecting the suspension micro-sensitive structure and bulk silicon by using an aluminum light film so as to avoid influence of subsequent processing on the suspension structure; removing the sacrificial layer by wet etching; and finally replacing an etching solvent with clean water and ethanol, and drying. The method effectively ensures the integrity and mobility of the suspension micro-sensitive structure without changing the conventional process flow, does not reduce the performance of a micro-mechanical sensor because the mechanical restriction is not increased, reduces the process difficulty, improves the yield and can be widely used for processing various silicon micro-components with the suspension micro-sensitive structure.

Owner:TSINGHUA UNIV

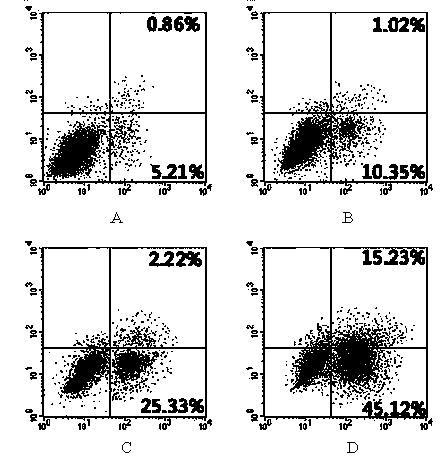

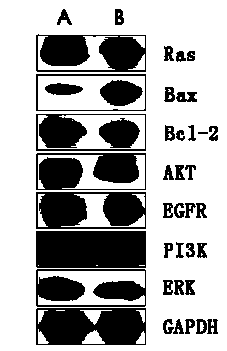

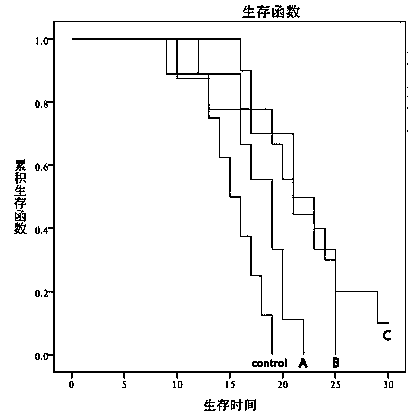

Application of aplysin in preparation of medicine for treating glioma

InactiveCN103446083AReduce weightHigh inhibition rateOrganic active ingredientsAntineoplastic agentsC6 cellsSide effect

The invention discloses application of aplysin in preparation of a medicine for treating glioma, aiming at researching the anti-tumor activity of aplysin to glioma. The MTT (Methyl Thiazolyl Tetrazolium) experiment shows that the inhibition ratio of aplysin to C6 cell is increased along with the raise of the concentration of aplysin; after the concentration is raised beyond 80mcg / m, the inhibition ratio of C6 cell does not raise obviously, namely, the most effective anti-tumor concentration of aplysin is 80mc / ml; the best effect appears in 48 hours in light of the action time; with the prolonging of the time, the cell inhibition ratio does not raise obviously. The animal experiment result shows that after the dose of aplysin is increased, the life time of a rat is prolonged, the weight of glioma is reduced, and the infiltration of lymphocyte is improved; 40mg / kg.bw is the best dose for reaching the best effect. The experiment shows that aplysin belongs to natural marine drugs and has small toxic and side effects, so that aplysin can be used as the medicine for treating glioma; aplysin is good in market application prospect.

Owner:HOSPITAL ATTACHED TO QINGDAO UNIV

Anticorrosion adhesive for rubber liner of fire hose and preparation method thereof

InactiveCN102174303AReduce polarityImprove corrosion resistanceMineral oil hydrocarbon copolymer adhesivesWax adhesivesWaxPolymer science

The invention discloses an anticorrosion adhesive for a rubber liner of a fire hose, which consists of the following components in percentage by weight: 64 to 75 percent of ethylene-acrylic acid copolymer resin, 5 to 20 percent of C5 resin, 6 to 10 percent of wax, 0.5 to 1 percent of antioxidant and 3 to 5 percent of dioctyl terephthalate (DOPT). A preparation method comprises the following steps of: preheating a reaction kettle to the temperature of between 70 and 100 DEG C, adding the DOPT and the wax in turn, adding the antioxidant after the DOPT and the wax are heated and melted in the reaction kettle, and uniformly stirring; adding the C5 resin, and uniformly stirring; and raising the temperature of the reaction kettle to be between 120 and 150 DEG C, adding the ethylene-acrylic acid copolymer resin in batches, and stirring for 15 to 30 minutes to obtain a target product. The adhesive prepared by the method has high bonding strength, stable property, corrosion resistance and high-temperature resistance, completely meets the technical specification requirement of the rubber liner of the fire hose, and also can be used for producing the rubber liner of an agricultural water delivery pipe or an industrial water pipe similar to the fire hose.

Owner:5ELEM HI TECH CORP

Heat-resistant unsaturated polyester resin

The invention discloses heat-resistant unsaturated polyester resin. The heat-resistant unsaturated polyester resin comprises the following raw materials in parts by weight: 30-40 parts of phthalic anhydride, 5-15 parts of maleic anhydride, 20-40 parts of m-phthalic acid, 2-10 parts of fumaric acid, 8-16 parts of lauric acid, 1-6 parts of benzoic acid, 12-25 parts of tung oil anhydride, 50-80 parts of diglycol, 10-30 parts of propylene glycol, 5-15 parts of styrene, 20-40 parts of alpha-methyl styrene, 1-4 parts of a stabilizer, 0.1-0.8 part of hydroquinone, 5-15 parts of epoxy resin, 1-5 parts of nano-silicon dioxide and 1-4 parts of modified sodium acrylate. The heat-resistant unsaturated polyester resin has good heat resistance and antibacterial and anti-mold effects, high mechanical strength and remarkable aging resistance.

Owner:安徽鑫力新材科技股份有限公司

White-smoke-free promotion flux for steel fastener hot dip galvanizing and application process of white-smoke-free promotion flux

PendingCN108193154AReduce pollutionImprove working environmentHot-dipping/immersion processesHexamethylenetetramineChloride

The invention relates to the technical field of steel fastener hot dip galvanizing, in particular to white-smoke-free promotion flux for steel fastener hot dip galvanizing and an application process of the white-smoke-free promotion flux. The white-smoke-free promotion flux for steel fastener hot dip galvanizing comprises the following components: 100-200g / L of zinc chloride, 10-40g / L of magnesiumchloride, 8.0-13g / L of nickel chloride, 6.0-12g / L of hydrochloric acid, 2.0-3.5g / L of hexamethylenetetramine, 2.0-10g / L of a flux additive, and the balance of water. The application process of the white-smoke-free promotion flux comprises steps of degreasing, water cleaning, rust-removing, secondary water cleaning, promotion flux adhering, drying, galvanizing and the like. The white-smoke-free promotion flux for steel fastener hot dip galvanizing disclosed by the invention does not contain ammonium chloride which generates white smoke while encountering molten metal zinc, and can greatly reduce generation of soot during hot-dip galvanizing of the steel fastener; and a hot-dip galvanizing process which uses the promotion flux is more optimized, and has the advantages of being low in production cost, stable in plating assistance quality, capable of producing steel fasteners for hot dip galvanizing on a large scale, and the like.

Owner:WENZHOU XINDE ELECTRIC FITTINGS +2

Crusher wear resisting hammerhead for high-toughness impact resisting cast-penetrated composite ore and production method thereof

InactiveCN105950963AImprove adhesionAccelerates the infiltration processFoundry mouldsFoundry coresCasting defectCrusher

The invention discloses a crusher wear resisting hammerhead for a high-toughness impact resisting cast-penetrated composite ore. The crusher hammerhead consists of a basal body, and a cast-penetrated layer on the surface of the basal body, wherein the basal body consists of the following components in percentage by weight: 0.3-0.5% of C, 1.0-1.5% of Si, 0.5-1.0% of Mn, 14-16% of Cr, 0.8-1.0% of Mo, 0.5-1% of Cu, 0.05-0.1% of B, 1-2% of Al, S not more than 0.05%, P not more than 0.05%, and the balance of Fe. The crusher hammerhead is excellent in wear resistance, toughness and impact resistance, is few in casting defects, is high in appearance quality, and is excellent in durability.

Owner:ANHUI XINHONG MACHINERY

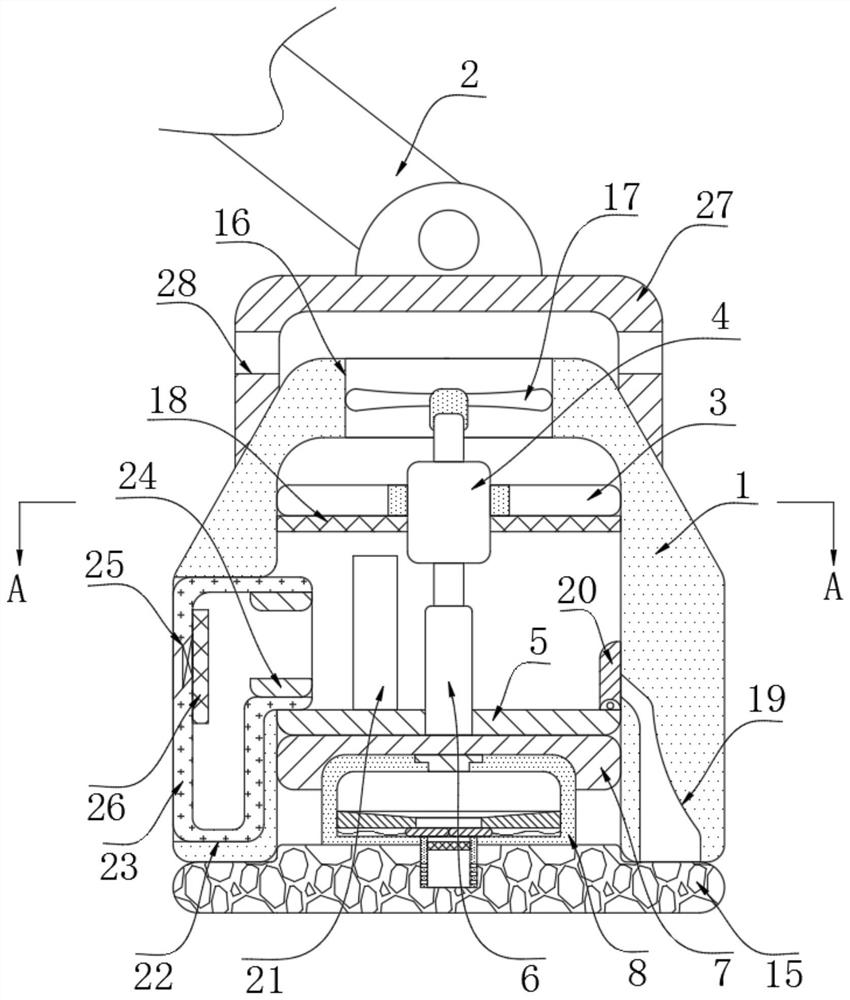

Multifunctional floor waxing machine

ActiveCN111700542AEasy to removeReduce consumptionCarpet cleanersFloor cleanersElectric machineDrive shaft

The invention discloses a multifunctional floor waxing machine. The machine includes a shell, and a protective cover is fixed at the upper end of the shell; the upper end of the protective cover is rotationally connected with a pull rod; a plurality of air holes are formed in the side wall of the protective cover, a fixing frame is installed on the inner wall of the shell, a double-head motor is fixed to the center of the fixing frame in a penetrating mode, a transmission shaft is fixed to an output shaft at the lower end of the double-head motor, a partition plate is fixed to the inner wall of the shell, and the transmission shaft penetrates through the partition plate and is rotationally connected with an installation block through a one-way bearing. The multifunctional floor waxing machine has the advantages that when the material storage box rotates, the closing plate slides under the action of centrifugal force, so that the output pipe is communicated with the interior of the material storage box, wax liquid flows out, waxing operation is achieved, when the material storage box stops rotating, the closing plate closes the output pipe under the action of elastic force of the closing spring, the wax liquid is reserved, and random flowing of the wax liquid is avoided.

Owner:台州市华滋新材料有限公司

Binder-free molten carbonate fuel cell electrolyte membrane and preparation method thereof

PendingCN112928318AImprove flexibilityImprove toughnessFused electrolyte fuel cellsElectrolytesFuel cellsMolten carbonate fuel cell

The invention discloses a binder-free molten carbonate fuel cell electrolyte membrane and a preparation method thereof, belonging to the technical field of fuel cells. The preparation method comprises the following steps: firstly, weighing a certain amount of Li2CO3 and K2CO powder, or Li2CO3 and Na2CO3 powder as electrolyte powder; mixing the weighed electrolyte powder with an organic solvent, and carrying out ball milling to obtain electrolyte slurry; carrying out vacuum pumping and tape casting on the electrolyte slurry; and finally, conducting drying and cutting to obtain the electrolyte membrane. According to the method, a binder is not added into the electrolyte membrane in cell stack assembling, and an electrolyte is directly filled with the membrane carrier after being molten, so the loss of the electrolyte under a high-temperature condition can be reduced, cell performance is improved, the service life of the cell is prolonged, and the method has good application prospects.

Owner:HUANENG POWER INT INC +1

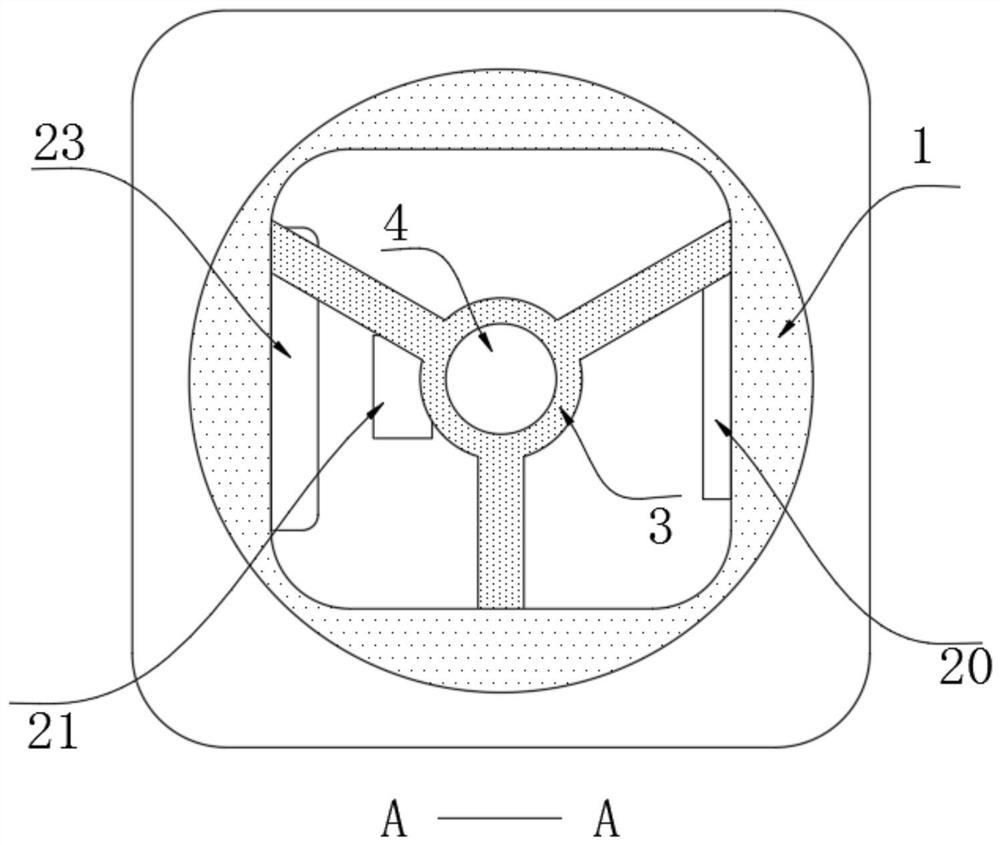

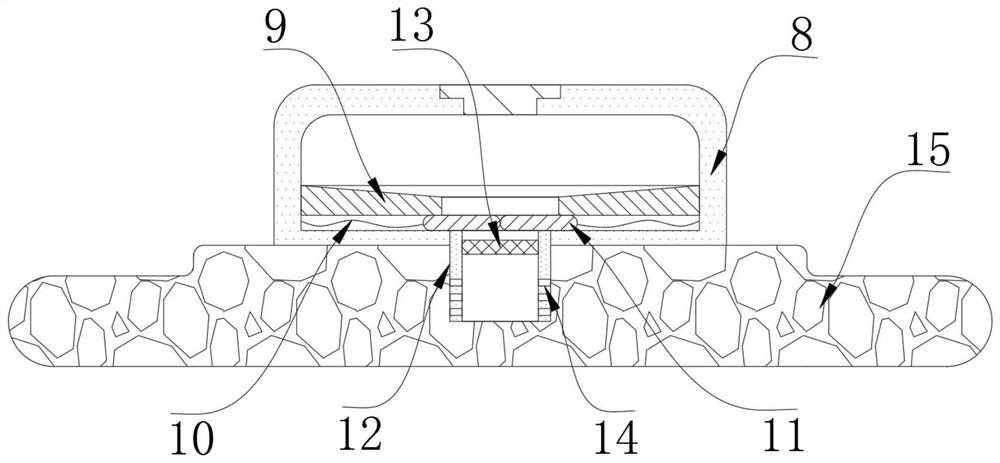

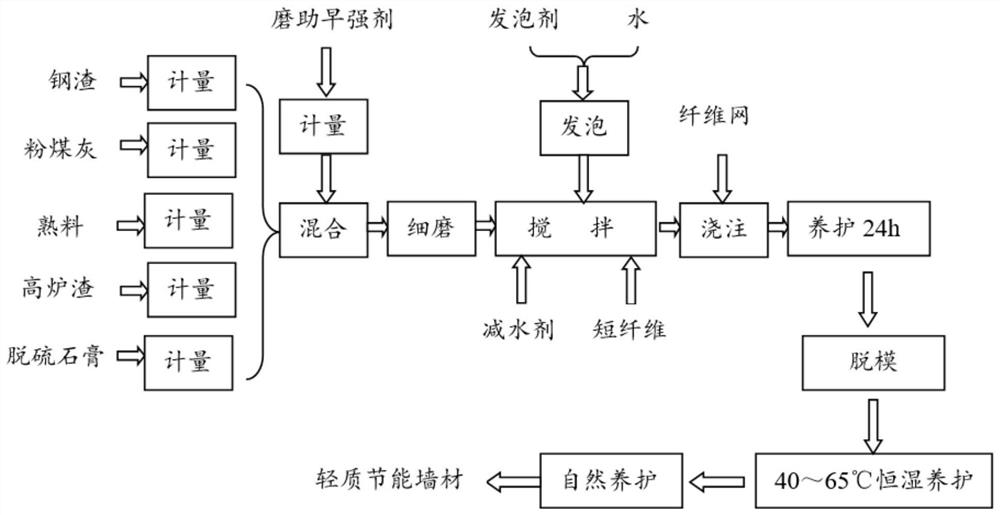

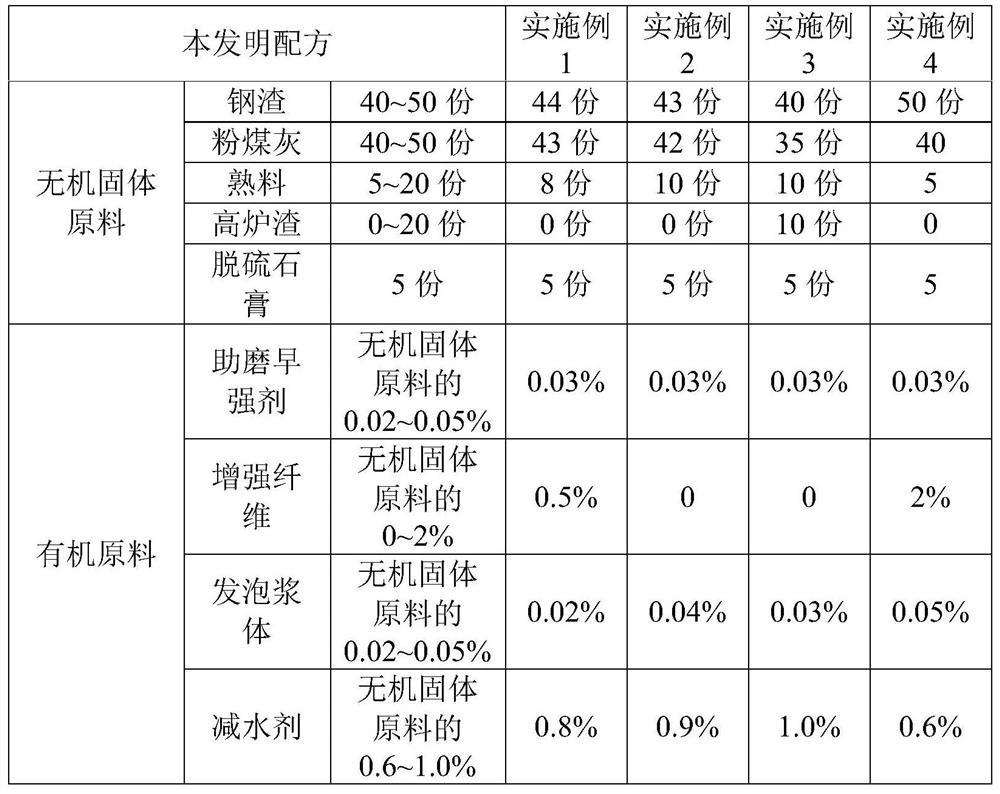

Method for preparing lightweight energy-saving building wall material from high-content steel slag

InactiveCN112919877AEliminate negative effectsImprove mechanical excitation effectSolid waste managementCeramicwareFiberSlag

The invention discloses a method for preparing a lightweight energy-saving building wall material by using high-content steel slag, and solves the problems of low utilization rate, low additional value and low consumption of the existing steel slag. The preparation method comprises the following steps: mixing 40-50 parts of steel slag, 10-20 parts of clinker, 0-20 parts of blast furnace slag, 40-50 parts of fly ash and 5 parts of desulfurized gypsum powder; performing mixing, adding 0.02-0.05% of a grinding-aid early strength agent, and performing fine grinding; adding 0-2% of reinforcing fibers into the mixture after fine grinding; mixing with foaming slurry, and adding a water reducing agent; after uniform stirring, pouring the mixture into a mold; curing the test piece for 1 day under the condition of constant humidity of 30 DEG C, performing demolding, performing curing for 3-6 days under the condition of constant humidity of 35-65 DEG C, and performing natural curing for 28 days to prepare the qualified light energy-saving wall material. The solid waste utilization rate can reach 90%, and the steel slag utilization rate can reach 42.5% or above.

Owner:安徽马钢嘉华新型建材有限公司 +1

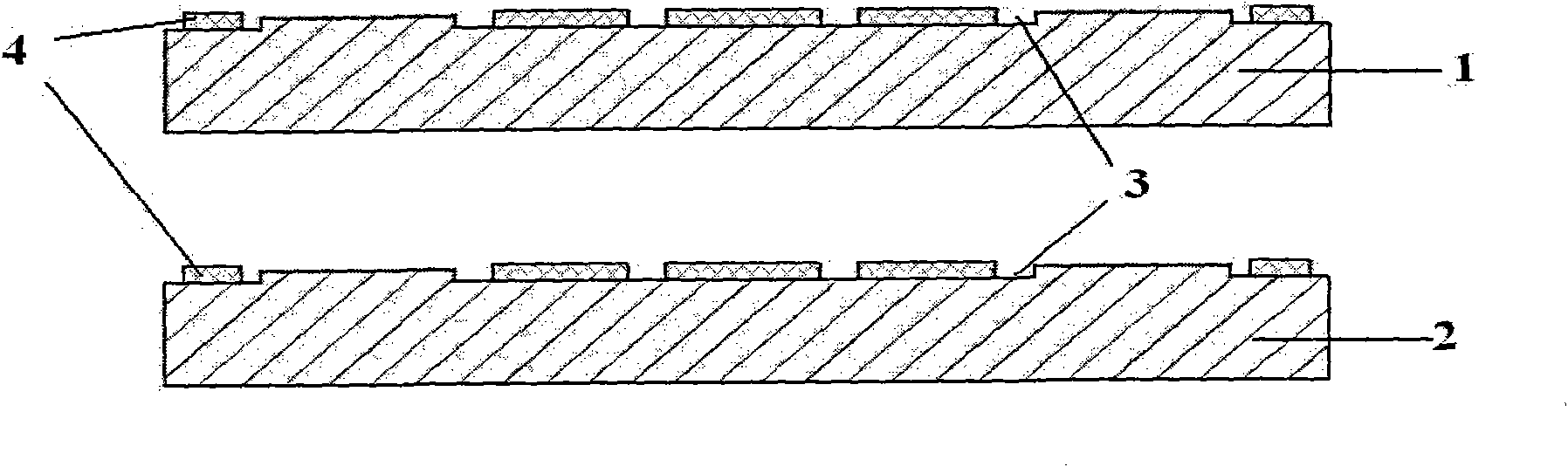

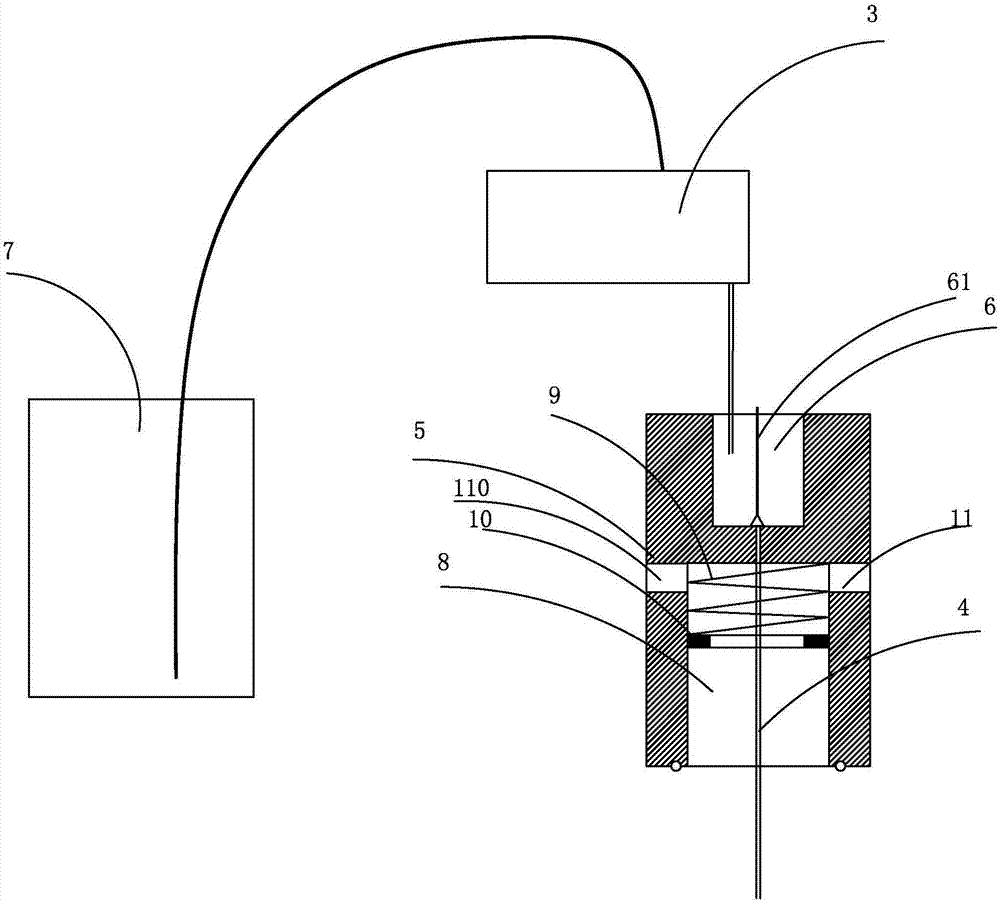

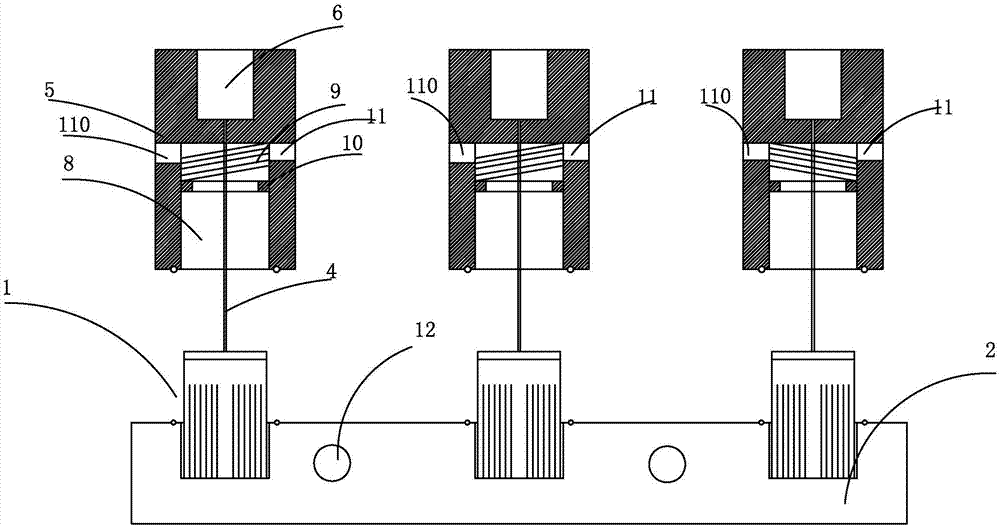

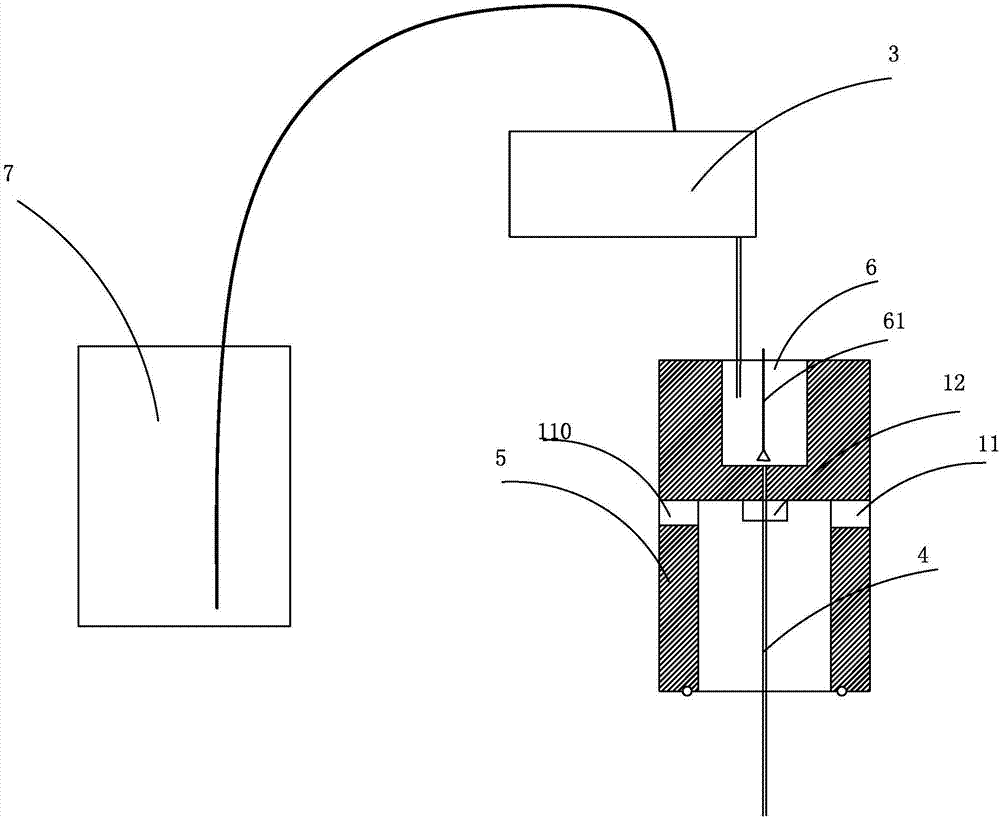

Battery electrolyte ultrasonic injection equipment and method

PendingCN107579196AMore absorption spacePromote absorptionCell component detailsInjection equipmentEngineering

The invention discloses battery electrolyte ultrasonic injection equipment and a battery electrolyte ultrasonic injection method. The battery electrolyte ultrasonic injection equipment comprises a base for placing one or more to-be-injected batteries, liquid injection devices which correspond to the corresponding to-be-injected batteries, and an ultrasonic generation device; each liquid injectiondevice comprises a metering pump and a liquid injection needle; and the ultrasonic generation device conducts ultrasonic wave into an electrolyte and an electrode coil in each battery. The battery electrolyte ultrasonic injection equipment and the battery electrolyte ultrasonic injection method have the following advantages: in the electrolyte injection process of the battery and after the batteryis vacuumized and part of or all the electrolyte is injected, ultrasonic wave is applied to the battery, so on one hand, the vacuumizing effect is improved, and on the other hand, the absorbing speedof the electrolyte between the electrodes and in the electrodes is increased; moreover, the injection quantity of the electrolyte is increased, and absorption and wetting on the electrolyte by the electrodes are improved, so that the performance of the battery is improved and the performance uniformity of the battery is improved.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com