Preparation method of water-retention dust-falling agent

A technology of dust suppressant and preparation steps, which is applied in the field of preparation of water-retaining and dust-reducing agents, which can solve the problems that dust is not easy to be infiltrated by dust-reducing agents, and the dust-reducing effect of dust-reducing agents is limited, so as to achieve the effects of improving water-retaining and water-locking performance, increasing water retention, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

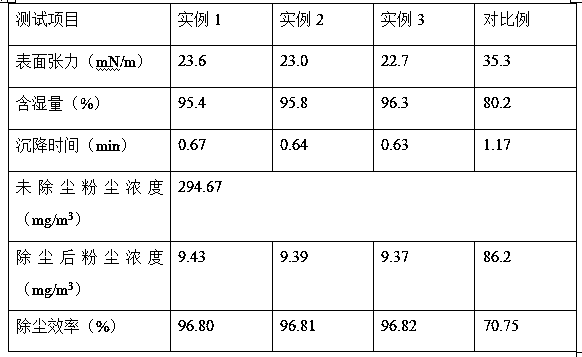

Examples

Embodiment Construction

[0023] Put 40-50g of corn flour in a conical flask, add 3-5g of α-amylase to the conical flask and add sodium dihydrogen phosphate-disodium hydrogen phosphate buffer solution with a pH value of 7, and set the volume to 100-110mL , then add 8-10mL of sodium hypochlorite solution with a mass fraction of 0.1% to the Erlenmeyer flask, place the Erlenmeyer flask in a shaker, heat it in a water bath to 42-45°C, and oscillate at a speed of 135-140r / min. After reacting for 3 to 4 days, add 10 to 12 mL of sodium hydroxide solution with a mass fraction of 40% to the Erlenmeyer flask to terminate the reaction and obtain oxidized dextrin; place the above oxidized dextrin in an oven and heat up to 60 to 70°C , after drying for 8-9 hours, put it into a three-necked flask with a thermometer and a nitrogen conduit, add 100-110mL of distilled water to the three-necked flask, heat the three-necked flask to 45-50°C, preheat for 10-15min, and add 40-50mL of calcium chloride solution with a mass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com