Process and method for preparing citrus fibers from pectin-extracted dregs

A process method and technology of citrus fiber, which is applied in the field of preparing citrus fiber, can solve problems such as poor water absorption and swelling effect, long delivery period, and remote production area, and achieve the effects of reducing garbage, low cost, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

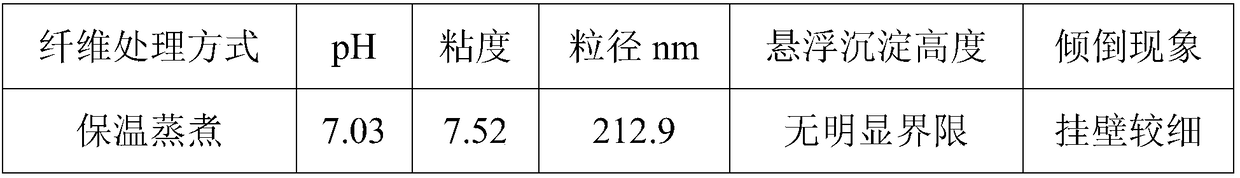

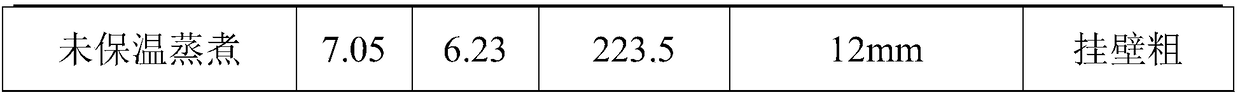

[0022] In a specific embodiment, the process of the present invention selects the dregs after extracting pectin as a raw material for the preparation of citrus fibers. The prepared citrus fibers are used in the production of peanut milk. When the dregs are in a dry state, hot water needs to be carried out first. Insulation cooking, the effect of preparing citrus fiber from the residue without heat preservation cooking is poor. In order to prove that the citrus fiber prepared by the two operations is different in the production of peanut milk, the citrus fiber processed in different ways is used to participate in peanut milk. The production process of heat preservation and cooking is as follows: Weigh the residue after extracting pectin in a dry state, add water according to the solid-to-liquid ratio of 1:15-1:25, heat at 90-100°C for 5-30min, filter, and collect the filtrate , The residue is spare. The residues produced by the dregs without heat preservation cooking and heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com