Lithium ion battery anode material with surface hydrophobicity and preparation method of lithium ion battery anode material

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle performance and storage performance electrolyte compatibility, and achieve improved cycle stability, consistency and reliability. The effect of performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

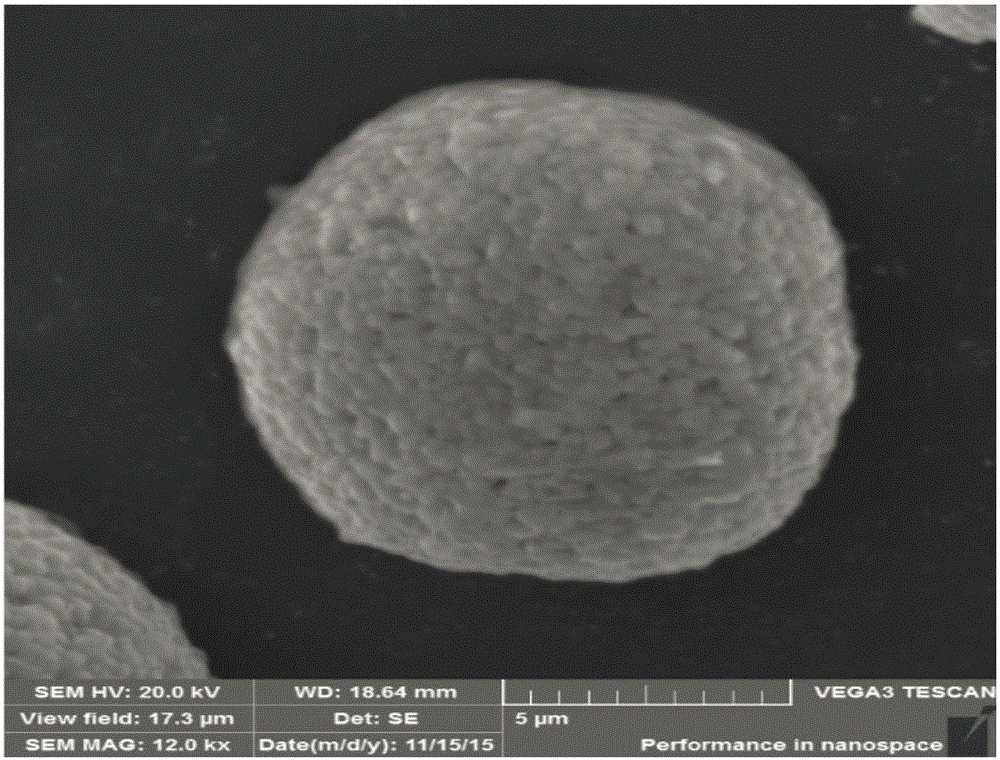

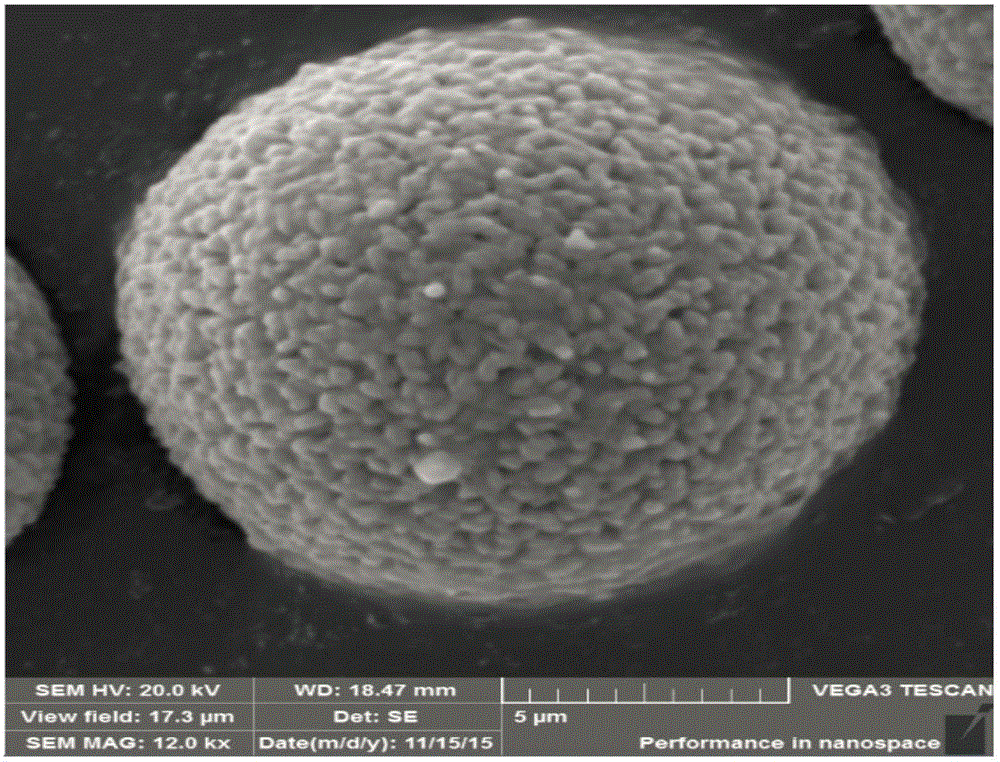

[0033] Specific embodiment 1: The surface of the positive electrode material of the lithium-ion battery with surface hydrophobicity in this embodiment has a layer of organic hydrophobic layer, the thickness of the hydrophobic layer is 0.5nm-20nm, and the mass content of the hydrophobic layer is 0.1%-10%; The positive electrode material is one or a combination of layered structure or spinel structure lithium ion battery positive electrode materials.

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the organic hydrophobic layer is RSiX 3 , wherein R is one or more of oxygen, mercapto, amino, vinyl, ethoxy, epoxy, amido, methacryloxy, aminopropyl, ureido, isocyanate organic functional groups , X is one or more of hydrolyzable halogen, alkoxy, and acyloxy. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

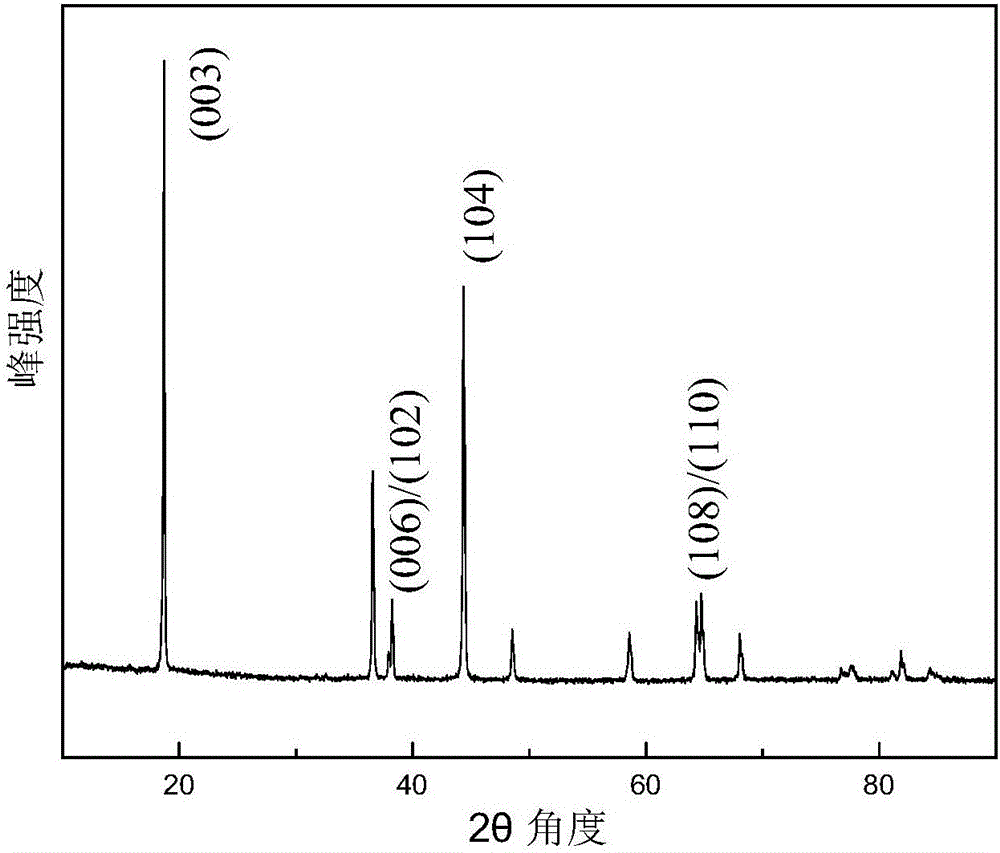

[0035] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the anode material of the layered structure is LiNi x co y mn z m 1‐x‐y‐z o 2 , where 0≤x≤1, 0≤y≤1, 0≤z≤1, M is Zr, Fe, Sm, Pr, Nb, Ga, Zn, Y, Mg, Al, Cr, Ca, Na, Ti, One or more of Cu, K, Sr, Mo, Ba, Ce, Sn, Sb, La, Bi. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com