Negative electrode material and preparation method and application thereof

A technology of negative electrode material and carbon material, applied in the field of negative electrode material and its preparation, can solve the problems of affecting the stability and integrity of the SEI film on the surface of the negative electrode, deteriorating the long-term service life and capacity retention of the battery cell, removing the film and removing powder, etc. Reliability, improve cycle performance and storage performance, improve the effect of cell expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

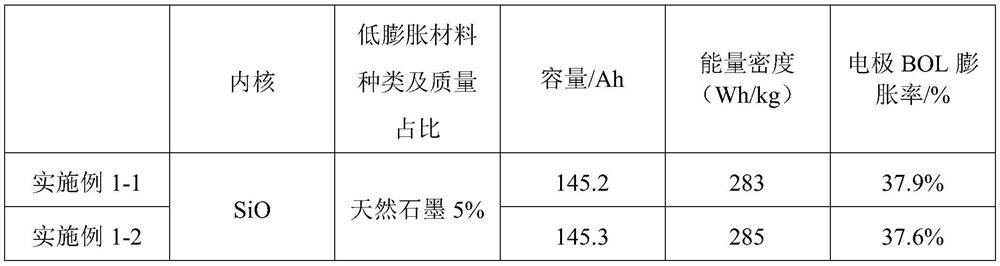

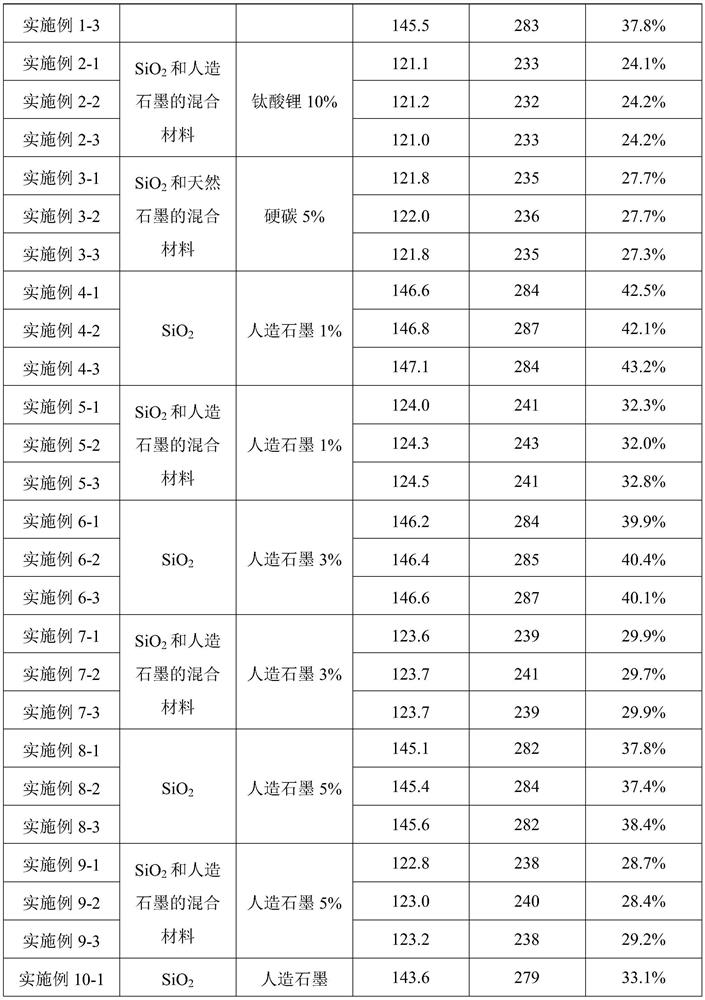

Embodiment 1

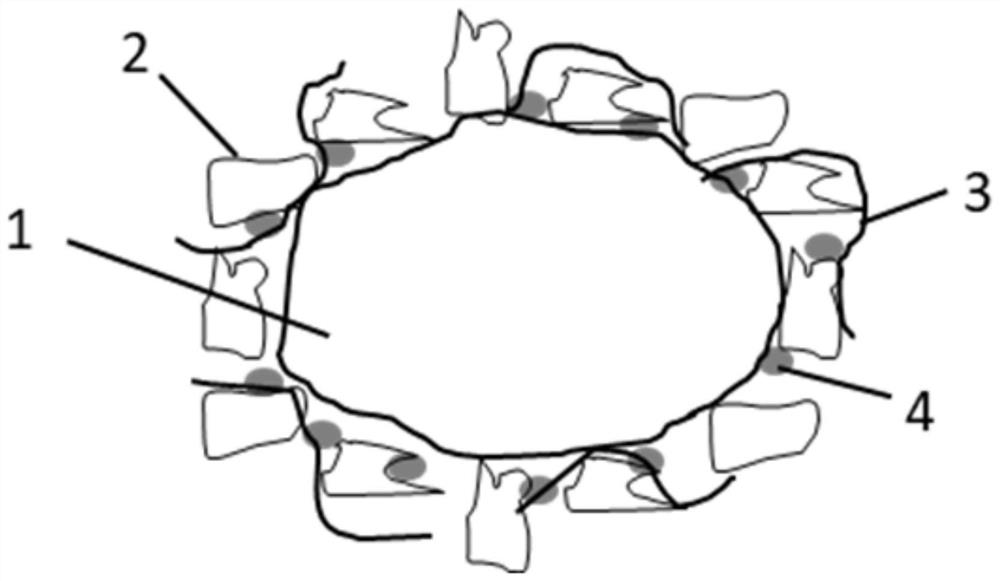

[0047] This embodiment provides a negative electrode material, such as figure 1 As shown, the negative electrode material includes an inner core 1 and a buffer layer coated on the surface of the inner core, the inner core 1 is SiO with a median particle size of 10 μm, and the buffer layer contains a low expansion material 2 and a conductive agent 3 And binding agent 4, described low-expansion material 2 is the natural graphite that median diameter is 2 μm, and described conductive agent 3 is the carbon nanotube that the aspect ratio of diameter is 200nm is 13, and described binding agent 4 is Styrene-butadiene rubber; the mass proportion of the natural graphite is 5%.

[0048] The preparation method of the negative electrode material is as follows:

[0049] SiO, natural graphite, carbon nanotube, styrene-butadiene rubber are stirred 40min with the mass ratio of 93:5:1:1 and water with the stirring linear speed of 70m / min, obtain the mixed slurry that solid content is 50%, at ...

Embodiment 2

[0051] This embodiment provides a negative electrode material, which includes SiO with a median particle size of 8 μm 2 The inner core of the artificial graphite mixed material with a median particle size of 5 μm and a buffer layer coated on the surface of the inner core, wherein the buffer layer includes lithium titanate with a median particle size of 0.5 μm and a long diameter of 50 nm. Carbon nanotubes and polyvinylidene fluoride with a ratio of 10; the volume ratio of the artificial graphite is 30%, and the mass ratio of the lithium titanate is 10%.

[0052] The preparation method of the negative electrode material is as follows:

[0053] SiO 2 Stir the mixed material of artificial stone mill, lithium titanate, carbon fiber, polyvinylidene fluoride at a mass ratio of 87:5:5:3, and water at a stirring line speed of 60m / min for 50min to obtain a mixture with a solid content of 55%. The slurry was dried at 60° C. for 8 hours to obtain the negative electrode material.

Embodiment 3

[0055] This embodiment provides an anode material, the anode material comprising SiO with a median particle size of 20 μm 2 The inner core of the natural graphite mixed material with a median particle size of 10 μm and a buffer layer coated on the surface of the inner core, the buffer layer comprising graphene with a median particle size of 5 μm and an aspect ratio of 15 and polyacrylate; the volume ratio of the natural graphite is 50%, and the mass ratio of the hard carbon is 5%.

[0056] The preparation method of the negative electrode material is as follows:

[0057] SiO 2 Stir with the mixed material of artificial stone mill, hard carbon, graphene, polyacrylate with the mass ratio of 93.3:5:0.5:1.2 and N-methylpyrrolidone at a stirring line speed of 80m / min for 30min, and obtain a solid content of 45 % of the mixed slurry was dried at 60° C. for 8 hours to obtain the negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com