Patents

Literature

321results about "Particle and sedimentation analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

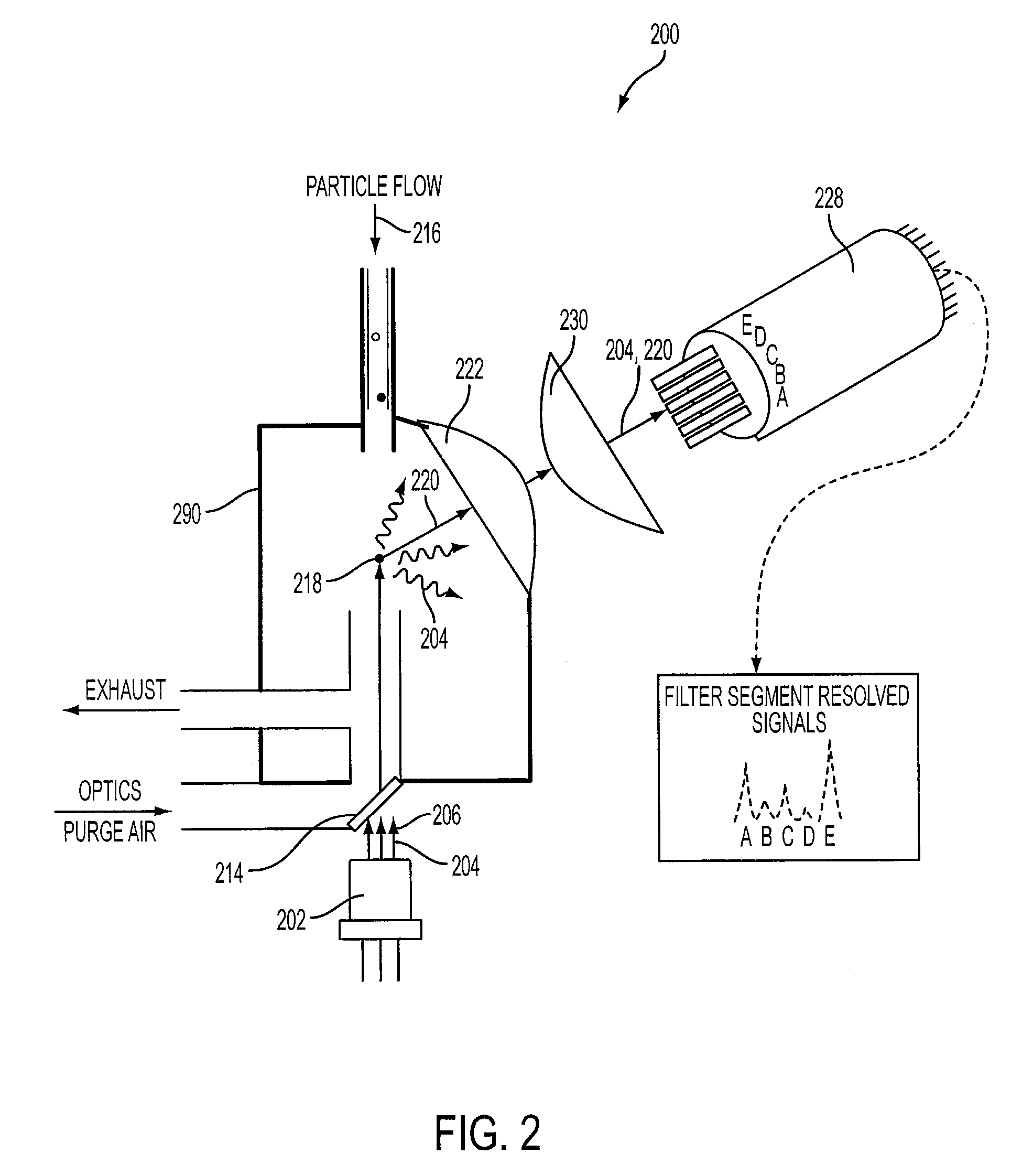

Apparatus for and method of sampling and collecting powders flowing in a gas stream

InactiveUS20060096393A1High purity samplingEnough timeCombination devicesSequential/parallel process reactionsEngineeringAirflow

A device for sampling of a mixture of ultrafine particles within a moving gas stream includes a suction generator, at least one sample collection element, and a conduit structure coupling the sample collection element with the suction generator. In some embodiments, the suction generator is configurable to separate by suction a portion of a gas stream containing a plurality of ultrafine particles, and to entrain with a motive fluid forming an output mixture. In some embodiments, a conduit is configured to accept a gas stream containing ultrafine particles and to channel it to the collection element.

Owner:UMICORE AG & CO KG +1

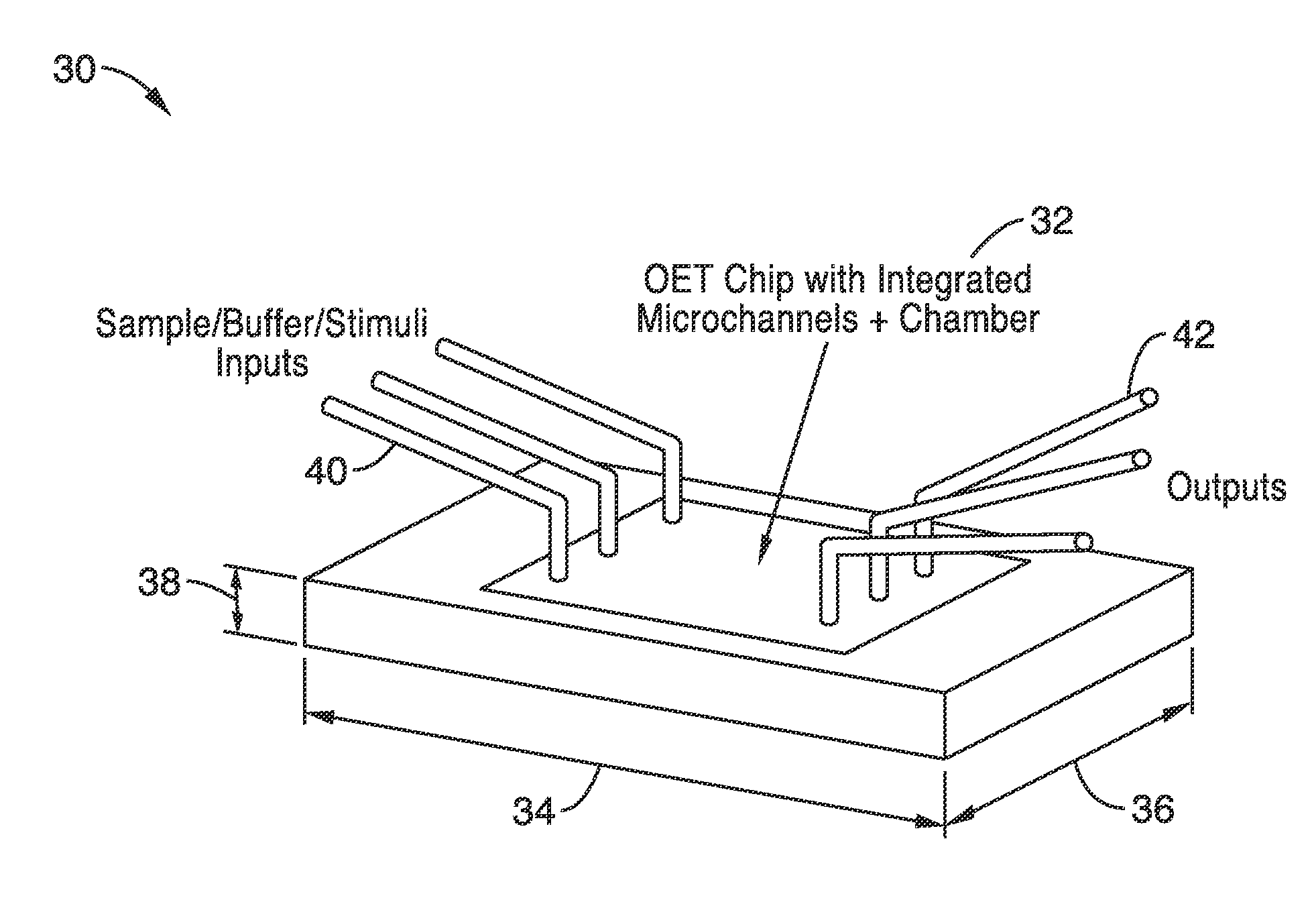

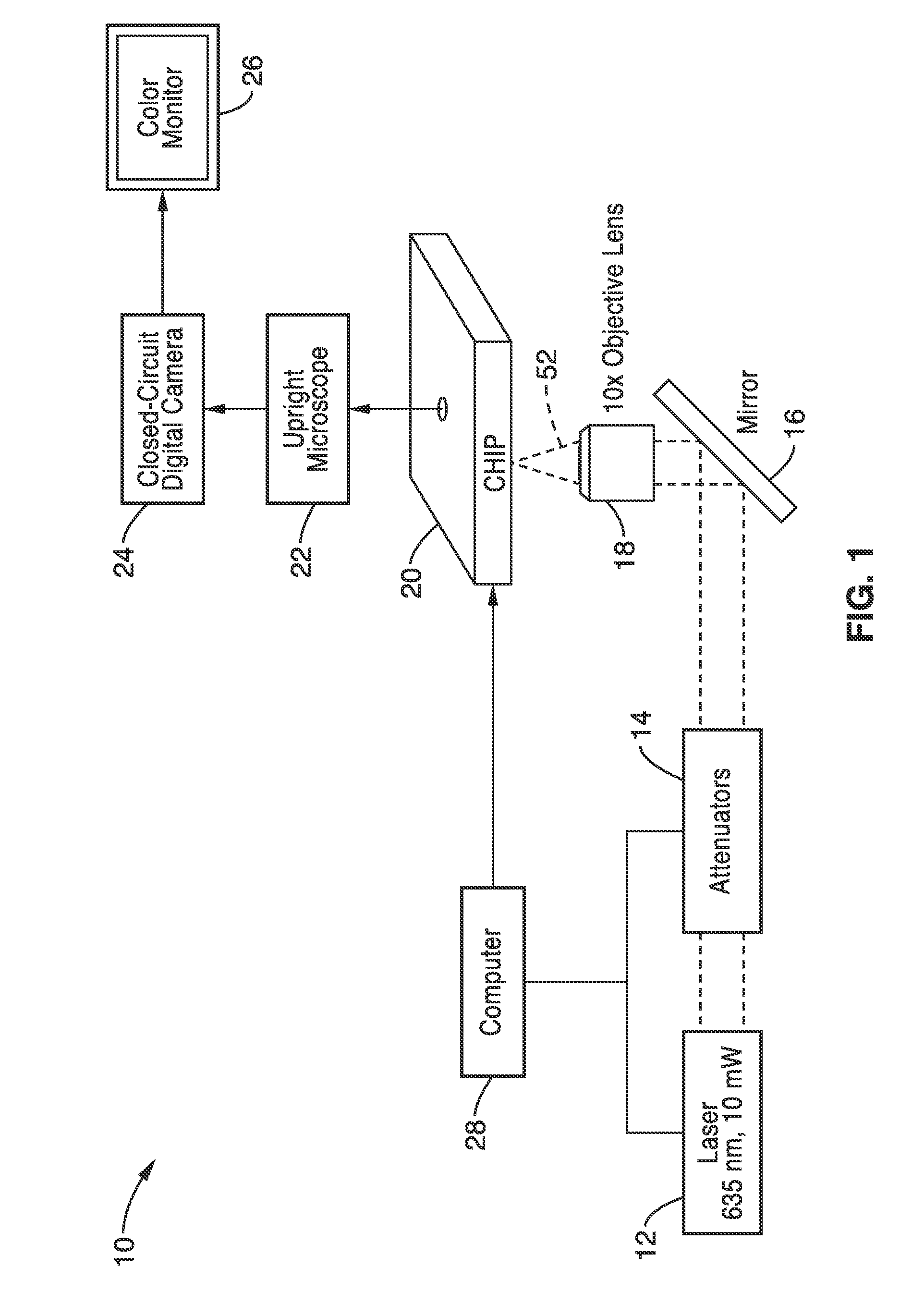

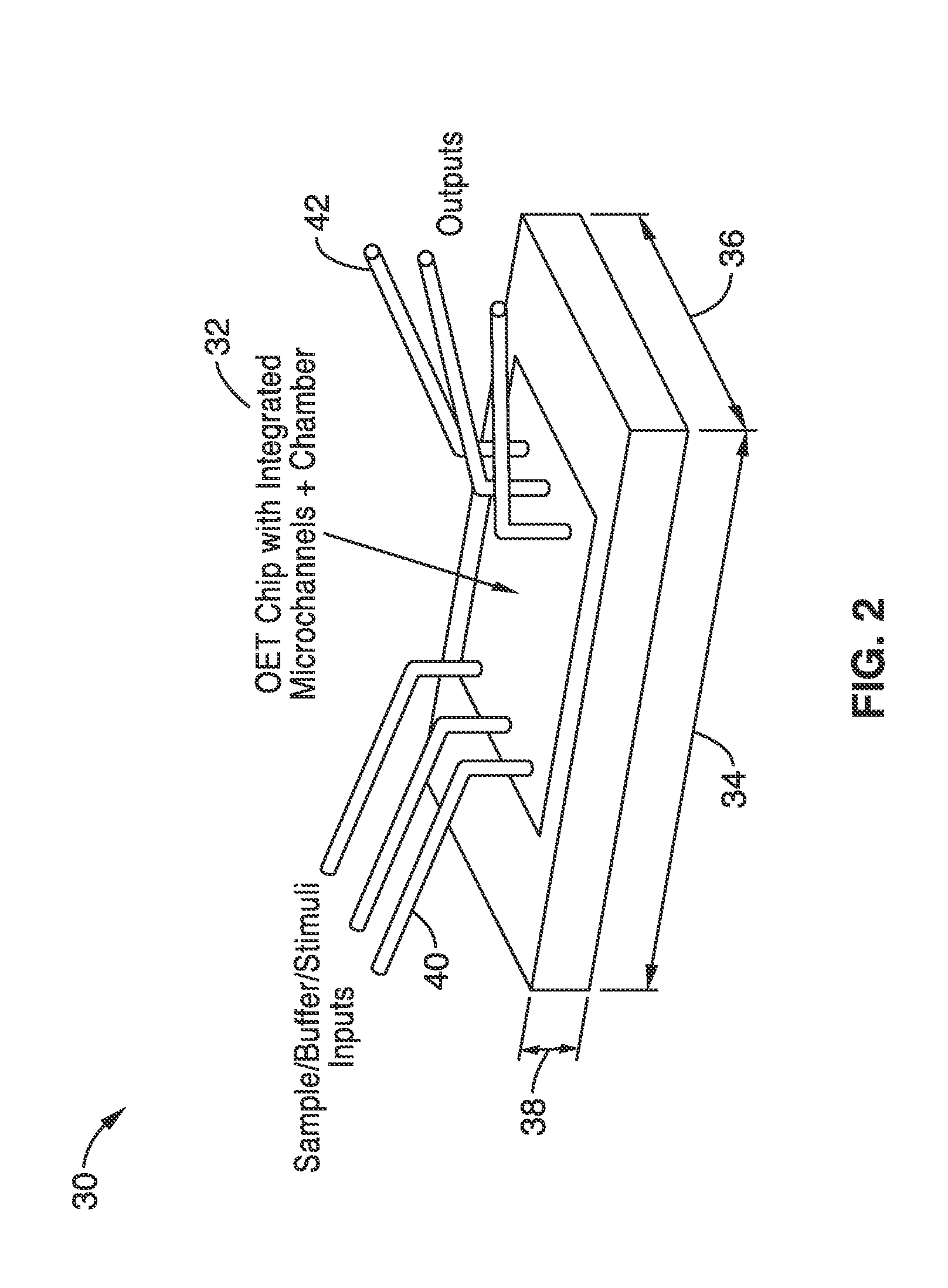

Methods and devices for sorting cells and other biological particulates

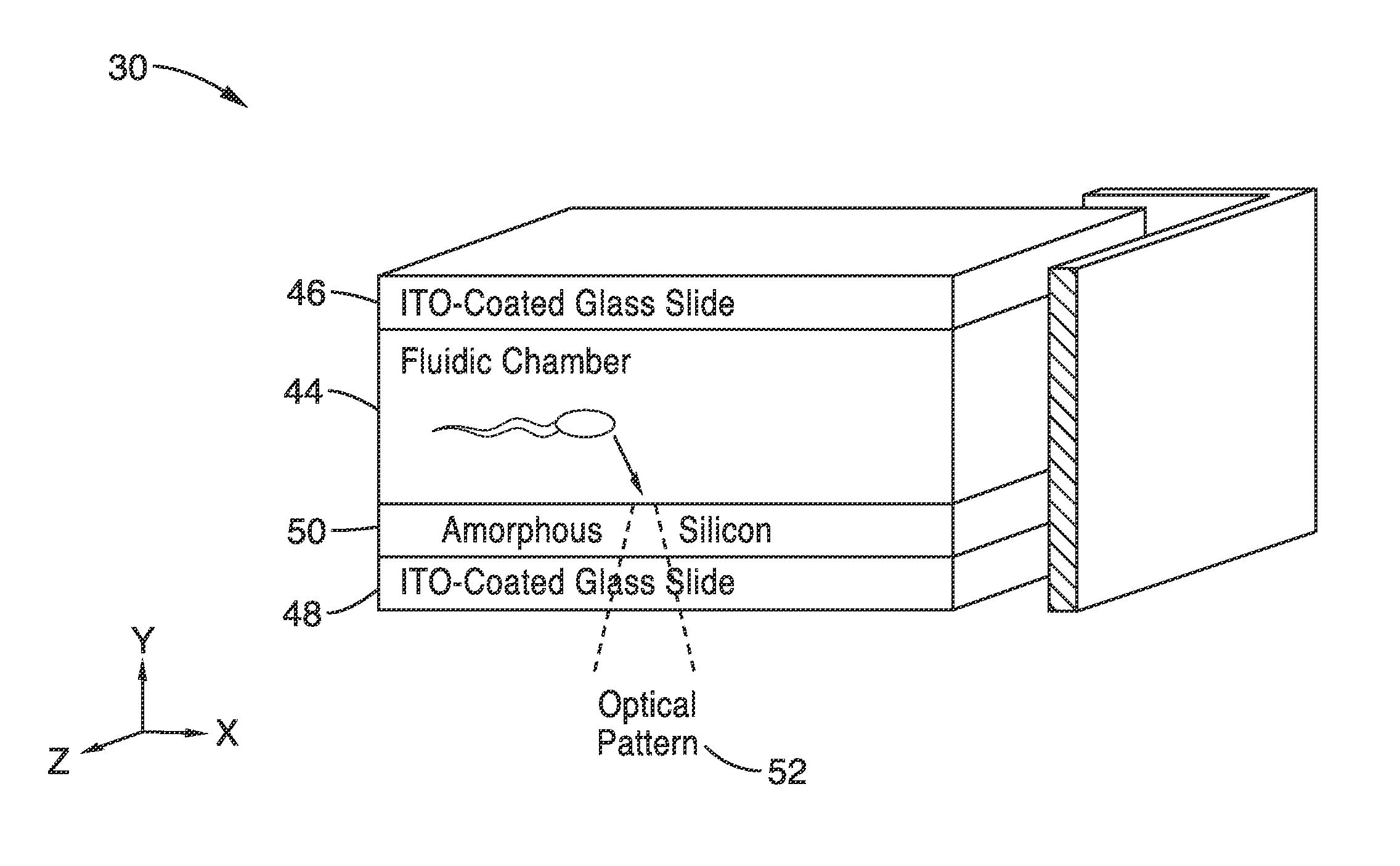

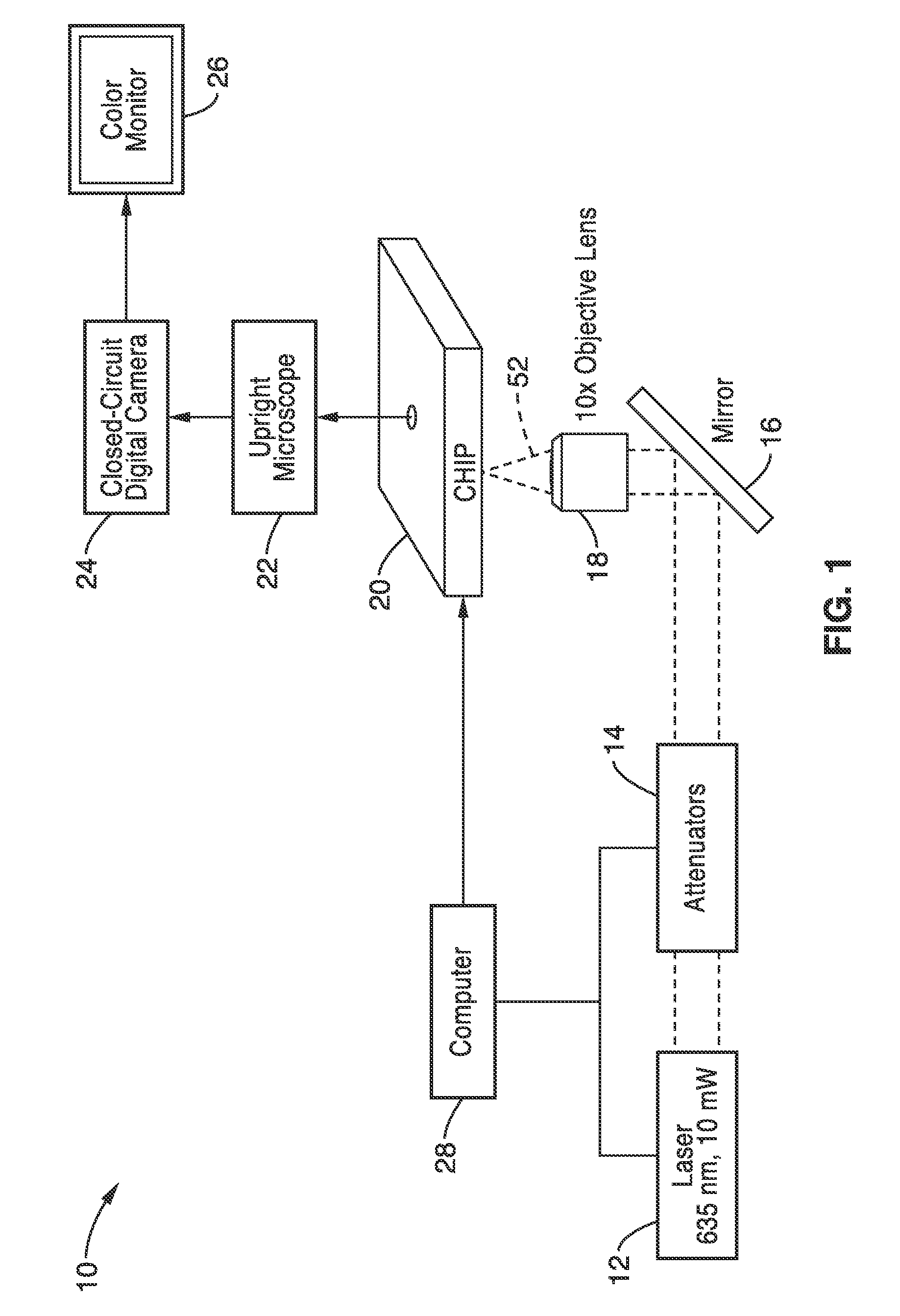

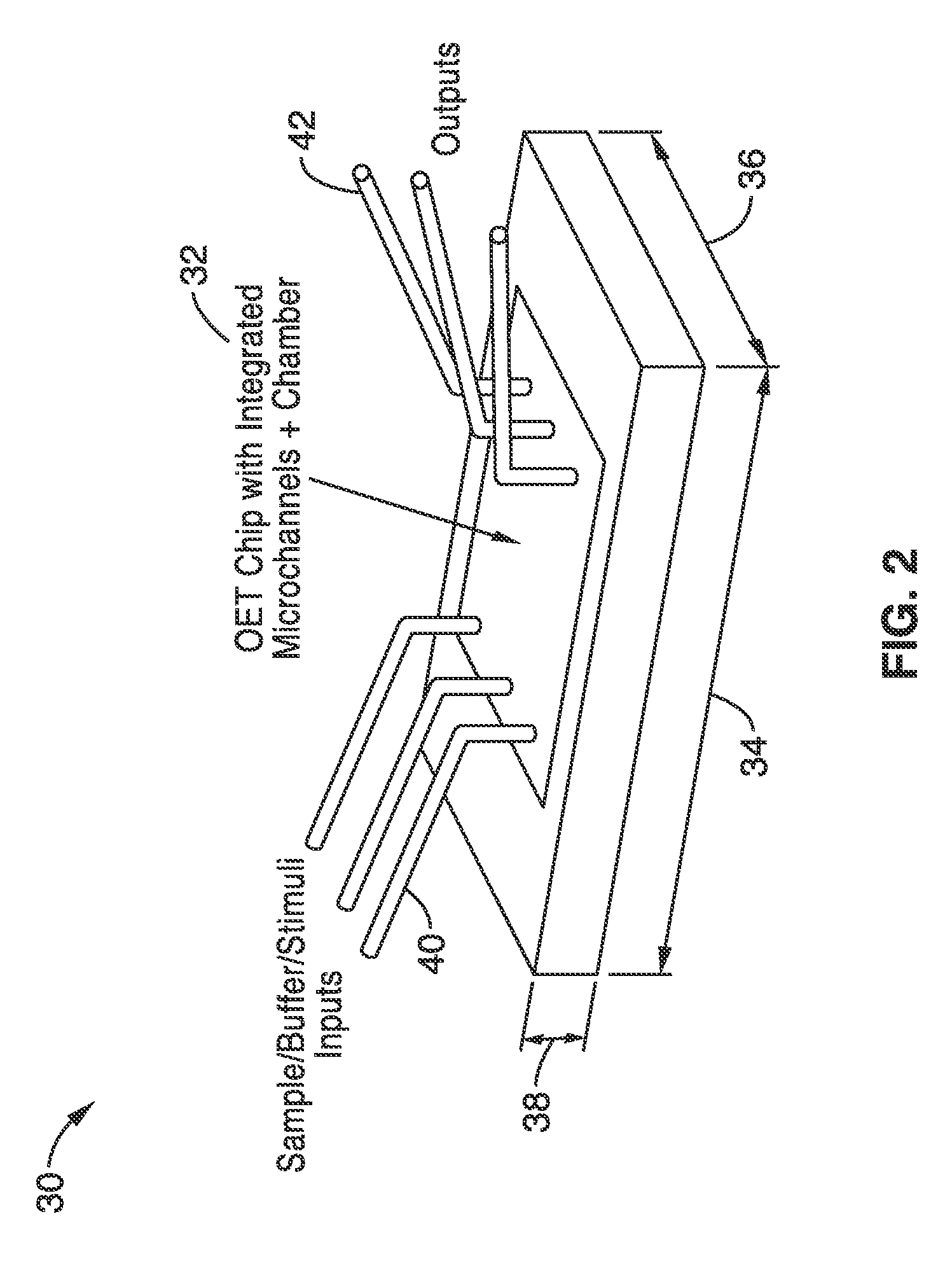

ActiveUS20120118740A1Accurately and systematically assessAccurate identificationDielectrophoresisElectrostatic separatorsParticulatesEmbryo

An optical pattern-driven light induced dielectrophoresis (DEP) apparatus and separation methods are described which provide for the manipulation of particles or cells and selection based on traits correlated with the DEP response. Embodiments of the apparatus use DEP electric field patterns in combination with microfluidic laminar flows to measure response, separate, segregate and extract particles from heterogeneous mixtures according to the relative response of the particles to one or more DEP fields without damaging living cells. The methods are particularly suited for selecting and extracting the best sperm and embryo candidates based on fitness for use with existing artificial reproduction procedures and excluding defective or non-viable gametes.

Owner:RGT UNIV OF CALIFORNIA

High throughput discovery of materials through vapor phase synthesis

InactiveUS20050233380A1Good repeatabilitySequential/parallel process reactionsElectric discharge tubesGas phaseProcess engineering

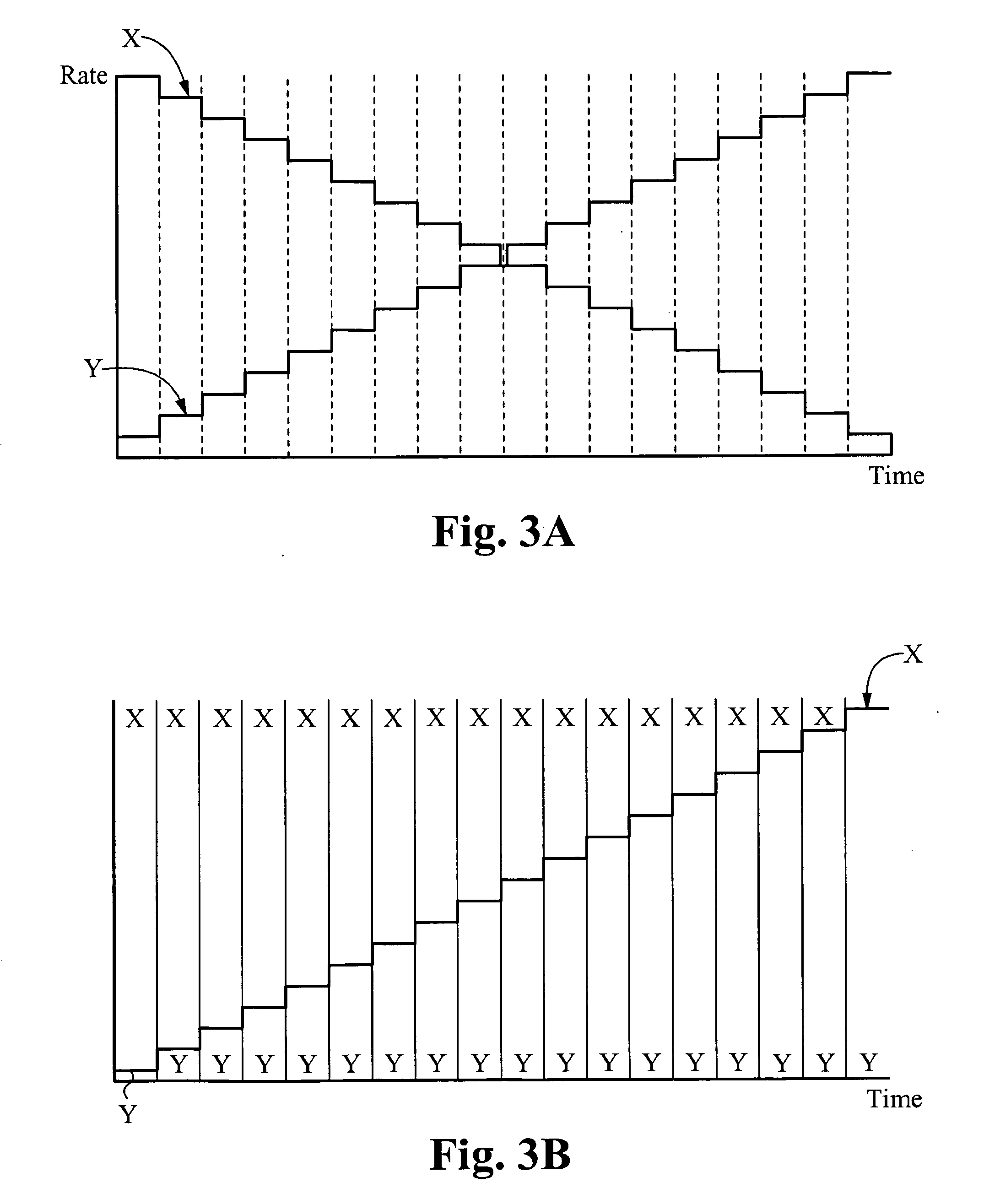

A method of and apparatus for producing a plurality of powder compositions, both stoichiometric and non-stoichiometric, is disclosed. The method includes the steps of introducing a plurality of materials into a particle production system under a first set of operating parameters, introducing the plurality of materials into the particle production system under a second set of operating parameters wherein at least one operating parameter of the first set is changed to form the second set, and sampling at least a portion of an output mixture representative of each of the first set of operating conditions and the second set of operating conditions. The apparatus includes a reactor, dispensing devices for supplying materials to the reactor, and other structures. The apparatus is preferably configurable via modification of operating parameters to produce a range of possible compositions for a given plurality of input materials.

Owner:SDC MATERIALS

Coal dust concentration dynamic detection system and coal dust concentration dynamic monitoring method of mine

InactiveCN106855492AAccurate concentration distribution imageImprove accuracyParticle suspension analysisParticle and sedimentation analysisShielded cableVoltage pulse

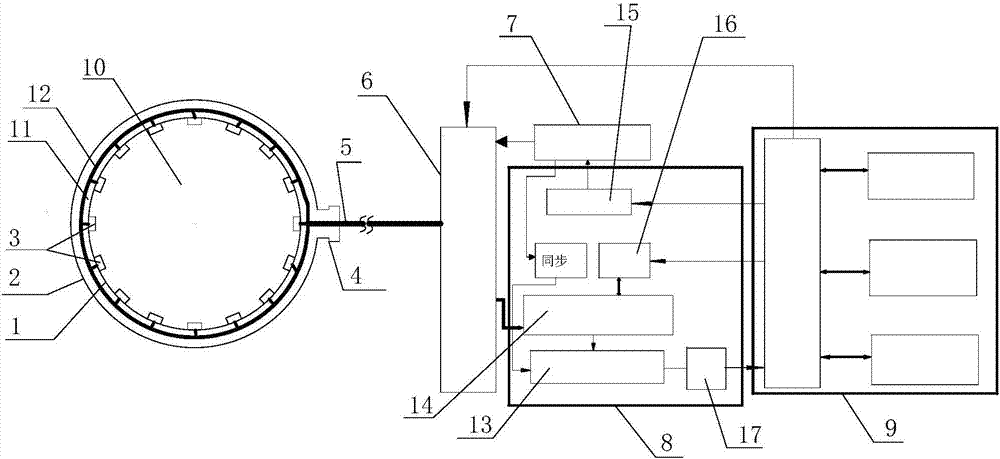

The invention discloses an ultrasonic wave-based coal dust concentration dynamic detection system and coal dust concentration dynamic monitoring method of mine. Sixteen ultrasonic sensors are fixed on the inner wall of an inner ring in a uniform angle manner, and every ultrasonic sensor simultaneously has ultrasonic wave emitting and receiving functions; all signal wires are commonly connected to a multi-core plug on an outer ring, the multi-core plug is connected with a programmed multipath toggle switch through a shielded multi-core cable, the programmed multipath toggle switch is respectively connected with a voltage pulse generator and an ultrasonic data acquisition device through wires, the voltage pulse generator is connected with the ultrasonic data acquisition device through a wire, and the ultrasonic data acquisition device is connected with a data processing center through a wire. An existing single-emitting and single-receiving detection mode is improved to a cycle single-emitting multi-receiving CT detection mode, and an ultrasonic wave speed CT image and an absorption coefficient CT image are adopted to reflect the coal dust concentration distribution, so the detection accuracy is improved.

Owner:SHANDONG UNIV OF SCI & TECH

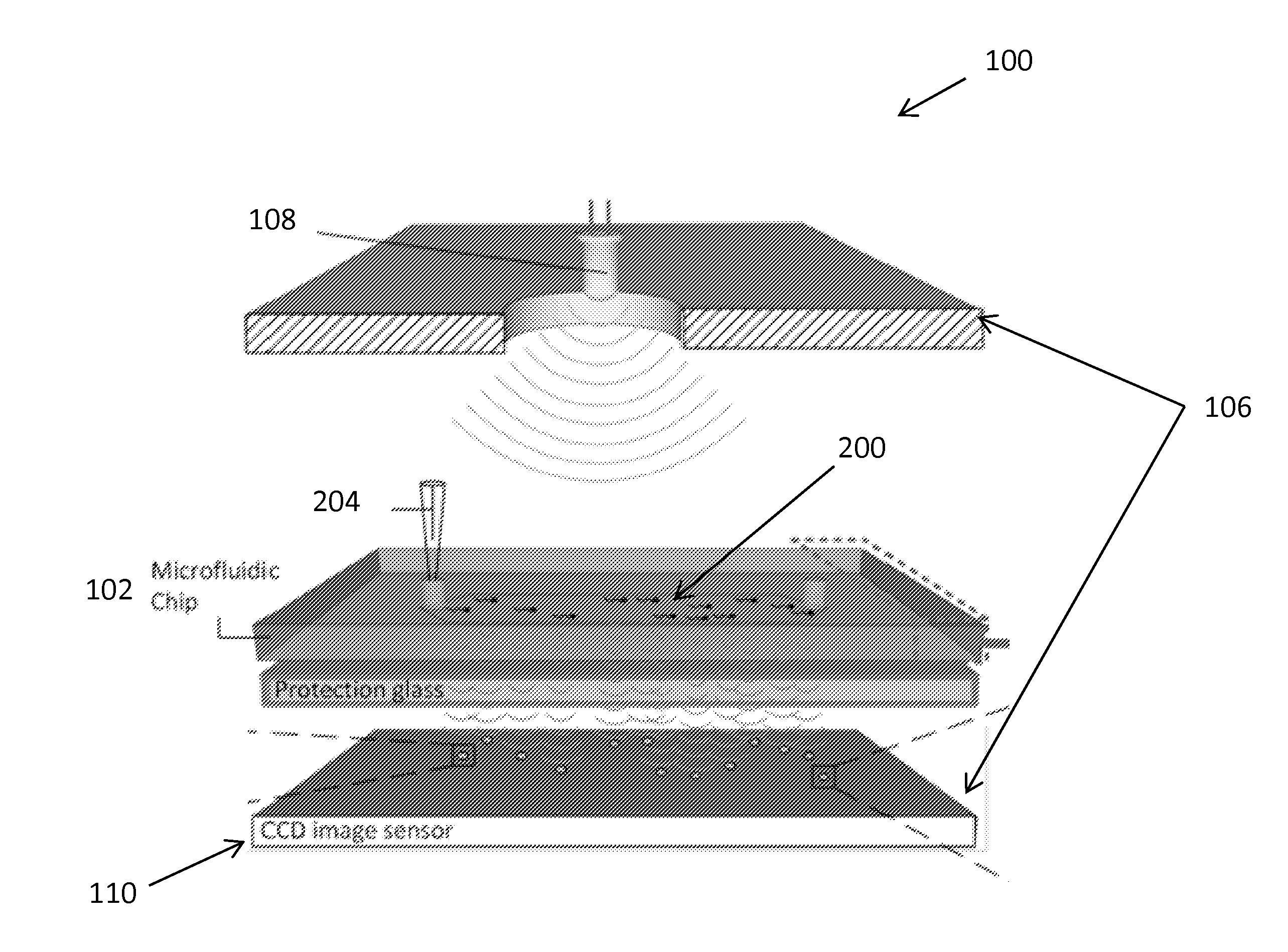

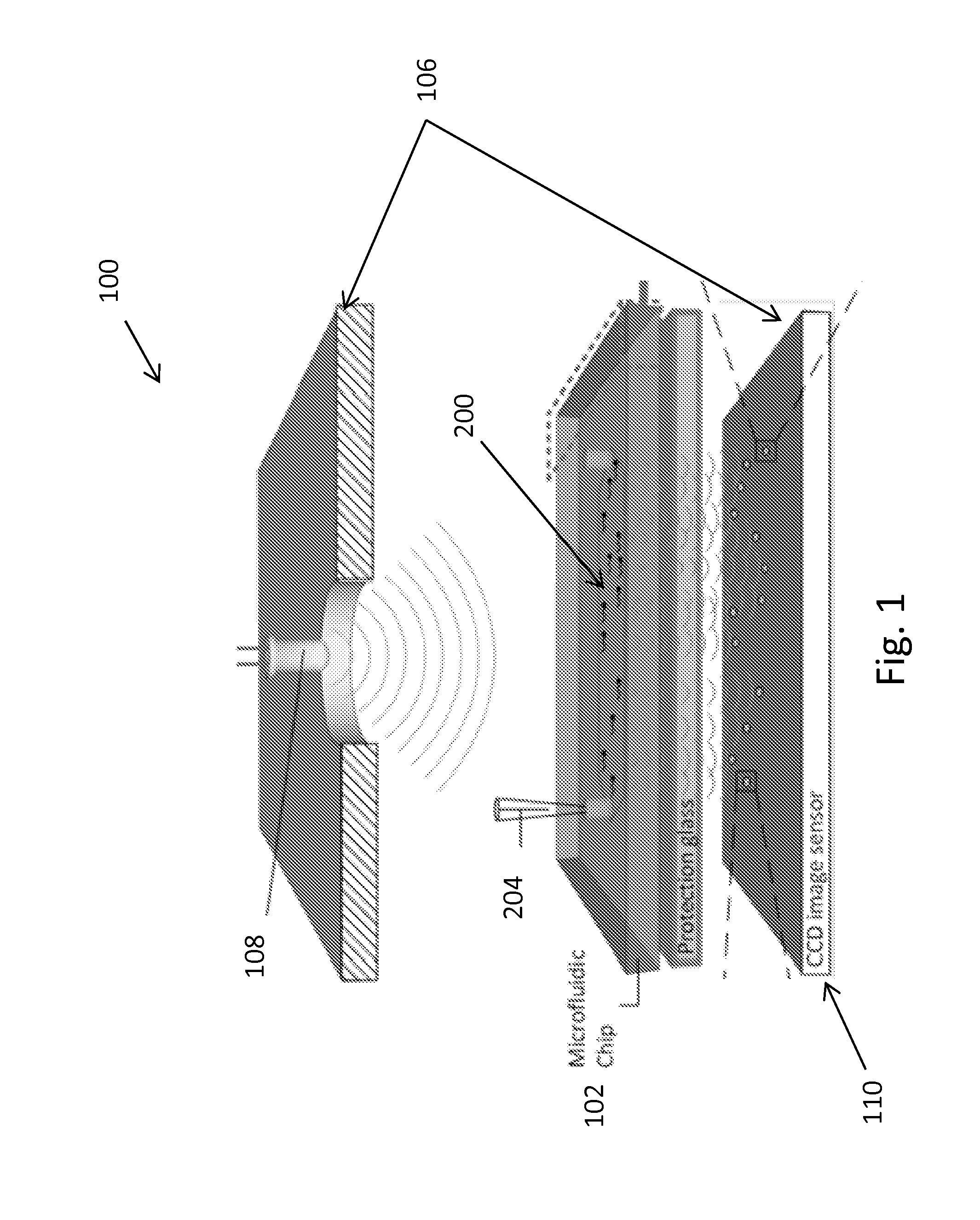

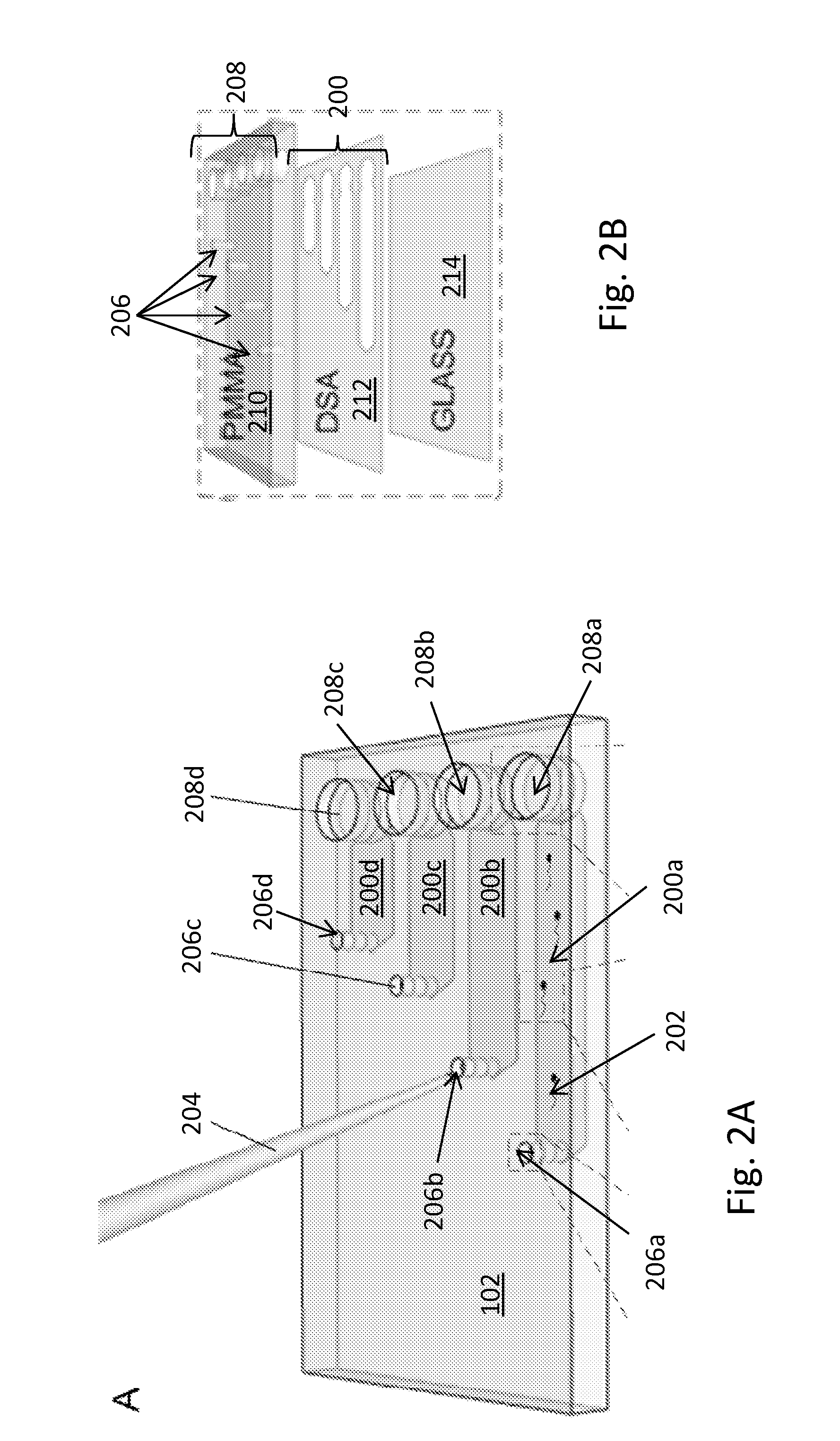

High-efficiency separation and manipulation of particles and cells in microfluidic device using surface acoustic waves at an oblique angle

ActiveUS20140033808A1Efficient separationLow costAnalysing fluids using sonic/ultrasonic/infrasonic wavesLaboratory glasswaresSurface acoustic wave sensorOblique angle

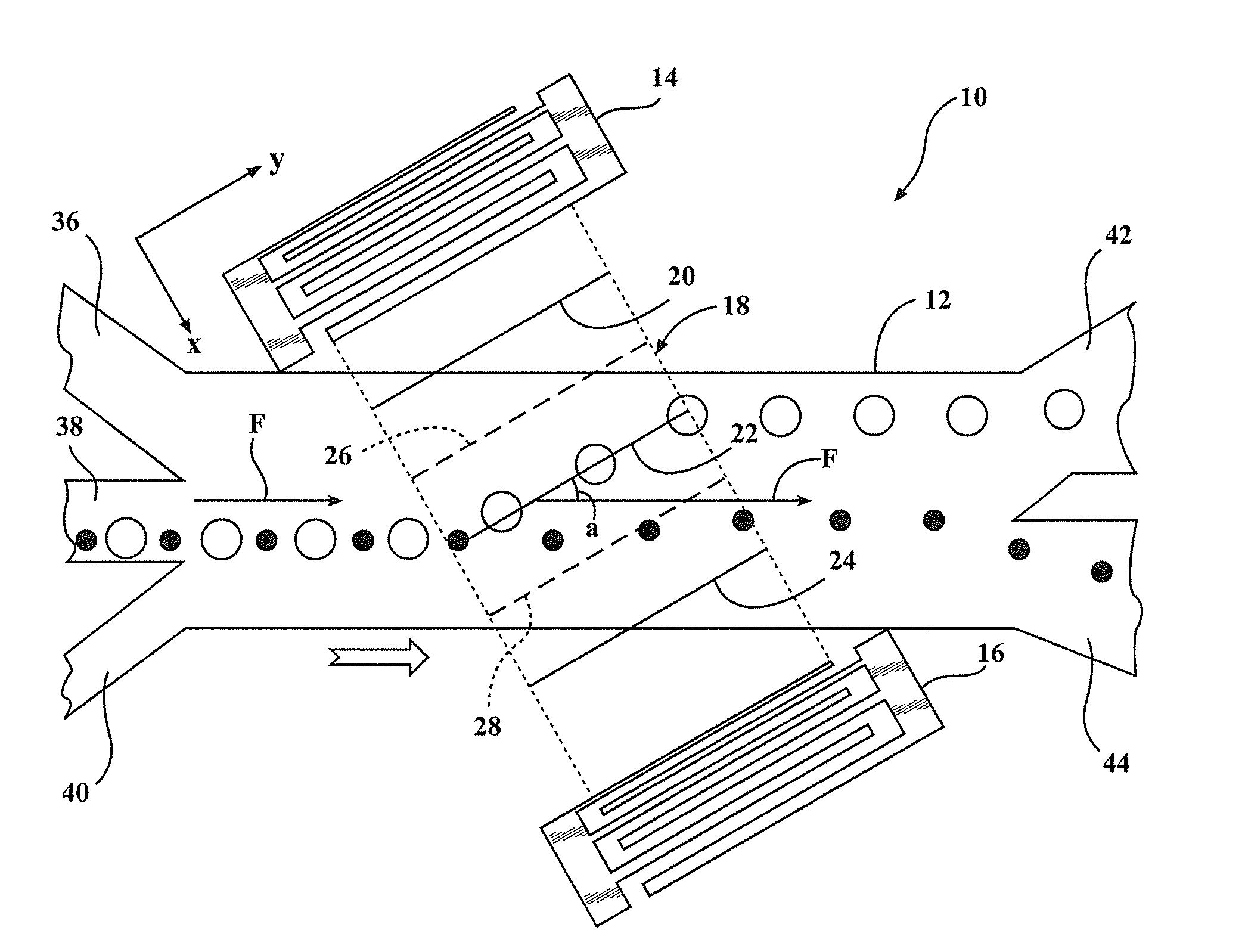

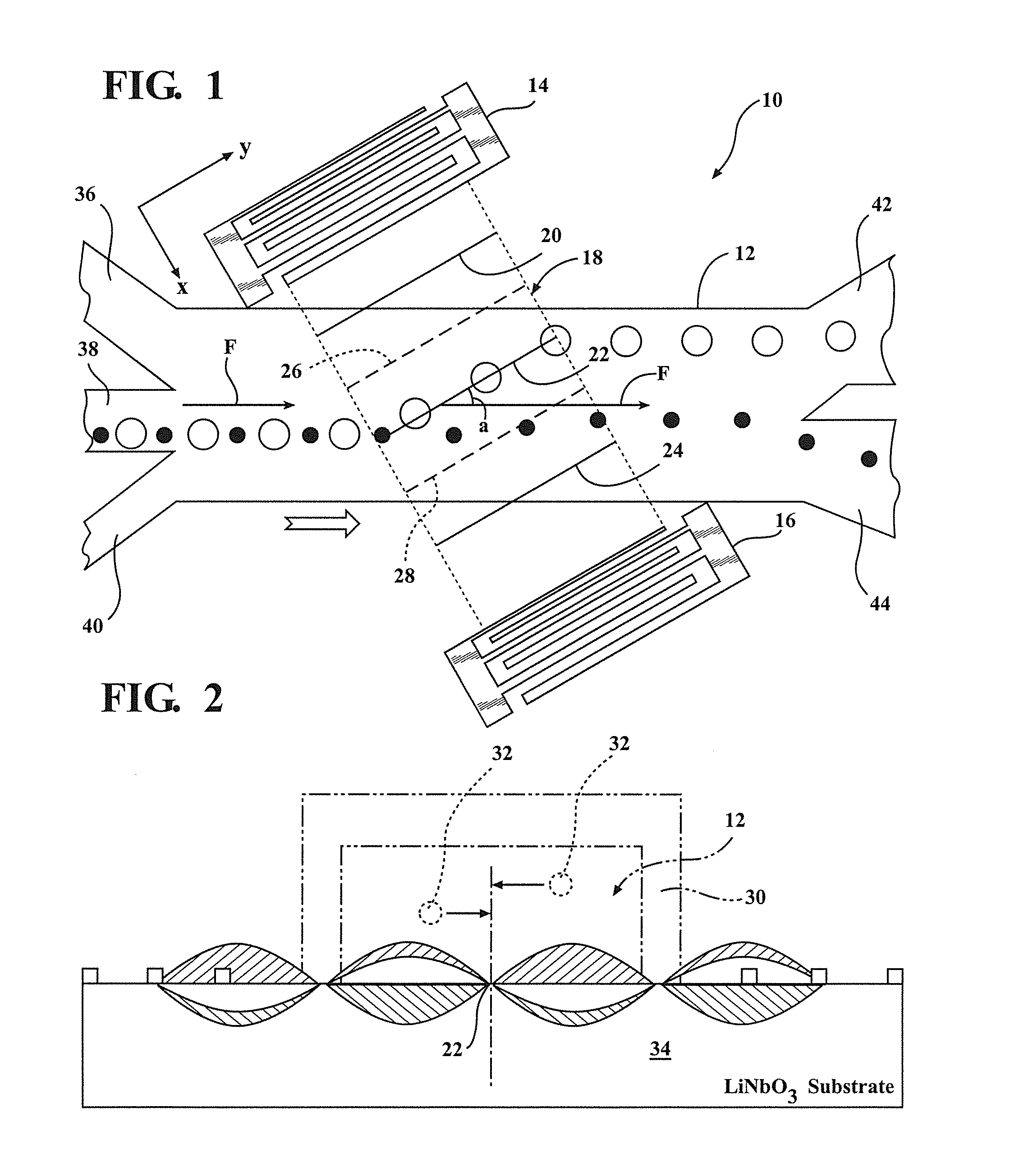

An apparatus for manipulating particles within a fluid sample includes a substrate having a substrate surface. A surface acoustic wave (SAW) generator generates a SAW within a SAW region of the substrate surface. The SAW has an SAW direction aligned with a pressure node. A channel is configured to receive the fluid sample and the fluid sample has a flow direction which is at an oblique angle to the SAW direction.

Owner:PENN STATE RES FOUND

Dust sensor and electronic product using the same

ActiveUS20160146715A1Optically investigating flaws/contaminationParticle suspension analysisAcoustic waveLength wave

A dust sensor includes a multi-wavelength light source, a receiver, and a controller. The light source emits light of different wavelengths. The receiver generates one or more acoustic wave measurement values based on acoustic waves irradiated from the light source to air particles. The controller controls at least one flickering cycle of the light source, determines the type particles based on the acoustic wave measurement values, and calculates the concentration of particles. The controller calculates the concentration of particles in proportion to an intensity of the acoustic wave measurement values, and determine the type of particles based on the acoustic wave measurement values. The acoustic waves are generated differently based on wavelengths of light emitted from the multi-wavelength light source.

Owner:SAMSUNG DISPLAY CO LTD

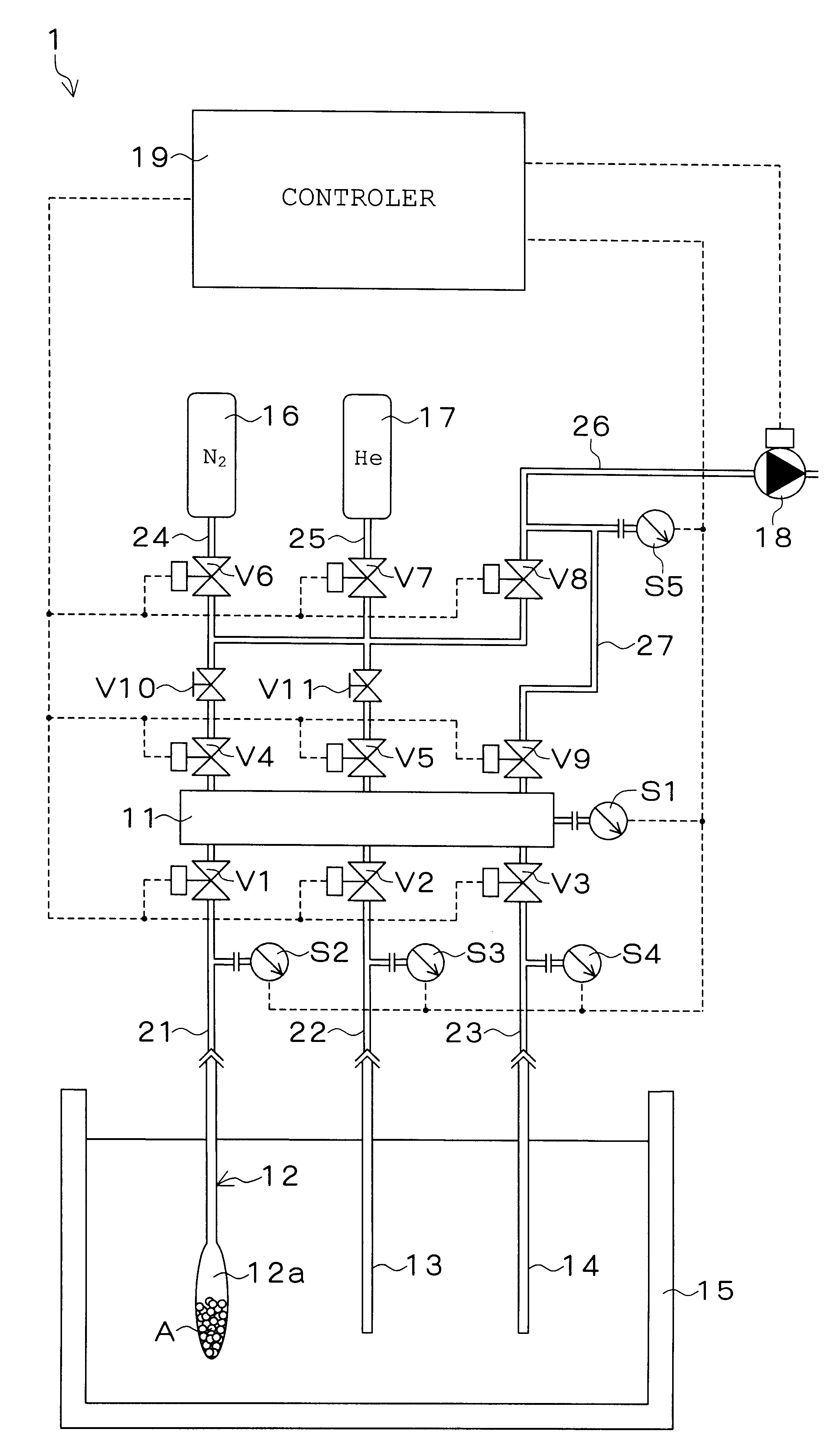

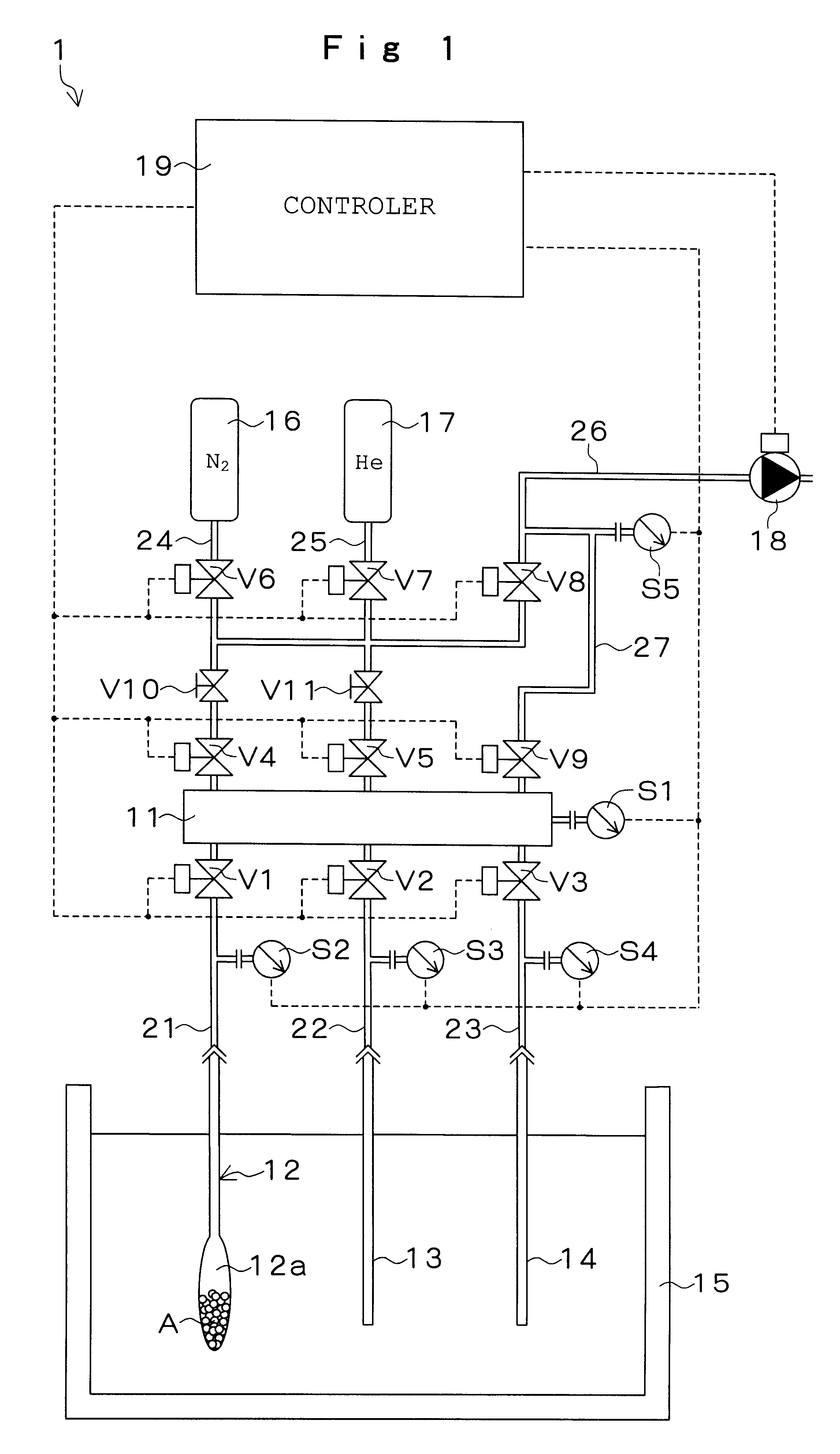

Method and apparatus for measuring amount of gas adsorption

InactiveUS6595036B1Initial dead volume of the sample cell can easily be correctedEasily and accurately determinedAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid-tightness measurement by detecting dimension changeChemical physicsDead volume

In a volumetric gas adsorption measuring method, an initial dead volume of the sample cell and an initial dead volume of a reference cell at the same time point are preliminarily determined. When the gas adsorption on the solid sample is to be measured, a change in the dead volume of the sample cell is calculated on the basis of an internal gas with the sample cell and reference cell immersed in a pressure of the reference cell measured at this time point cryogenic fluid temperature bath, the initial dead volume of the reference cell, and an initial gas pressure of the reference cell measured at a time point of the measurement of the initial dead volume of the reference cell. Then, the initial dead volume of the sample cell preliminarily measured is corrected on the basis of the change in the dead volume of the sample cell for the calculation of the amount of the gas adsorbed on the solid sample.

Owner:BEL JAPAN

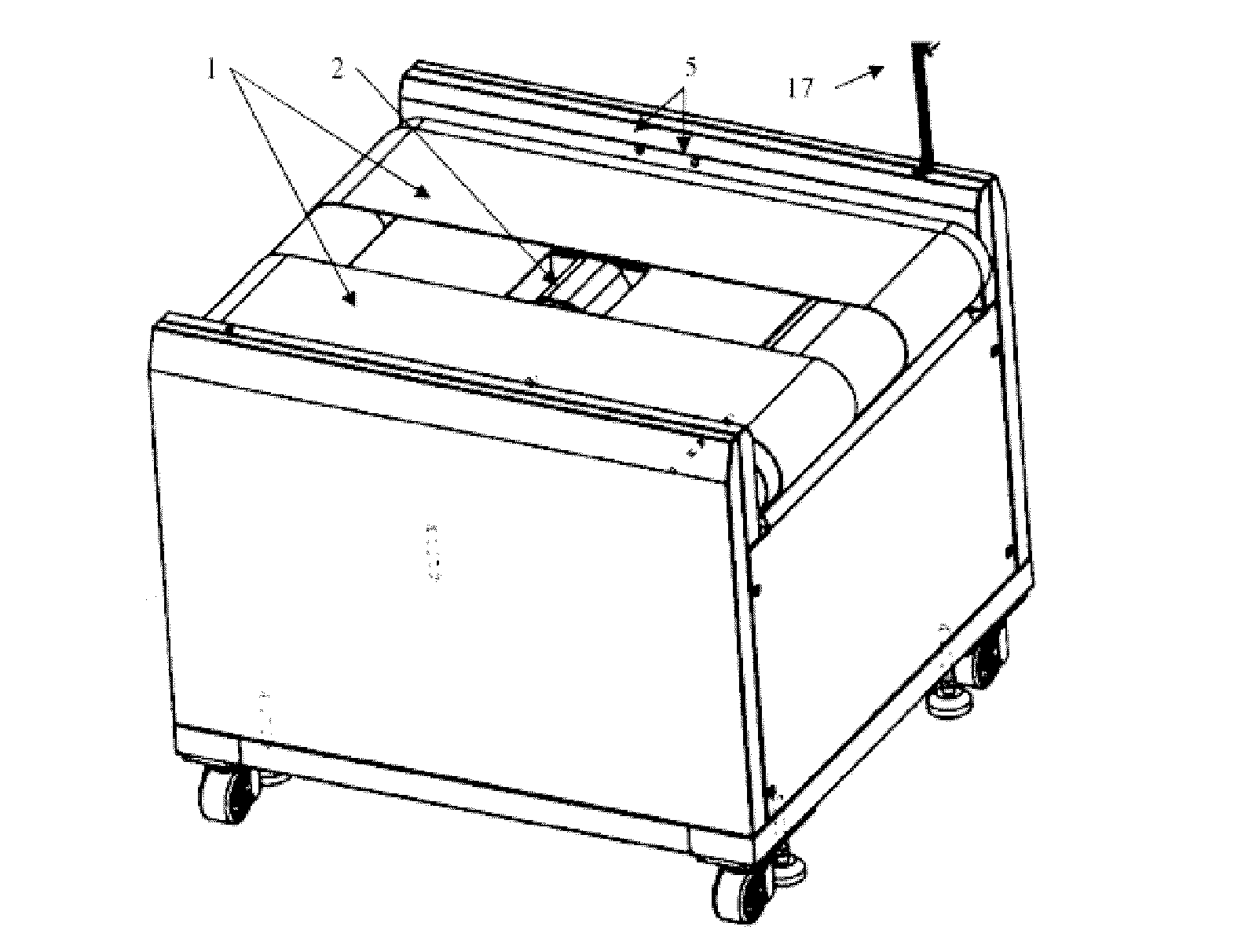

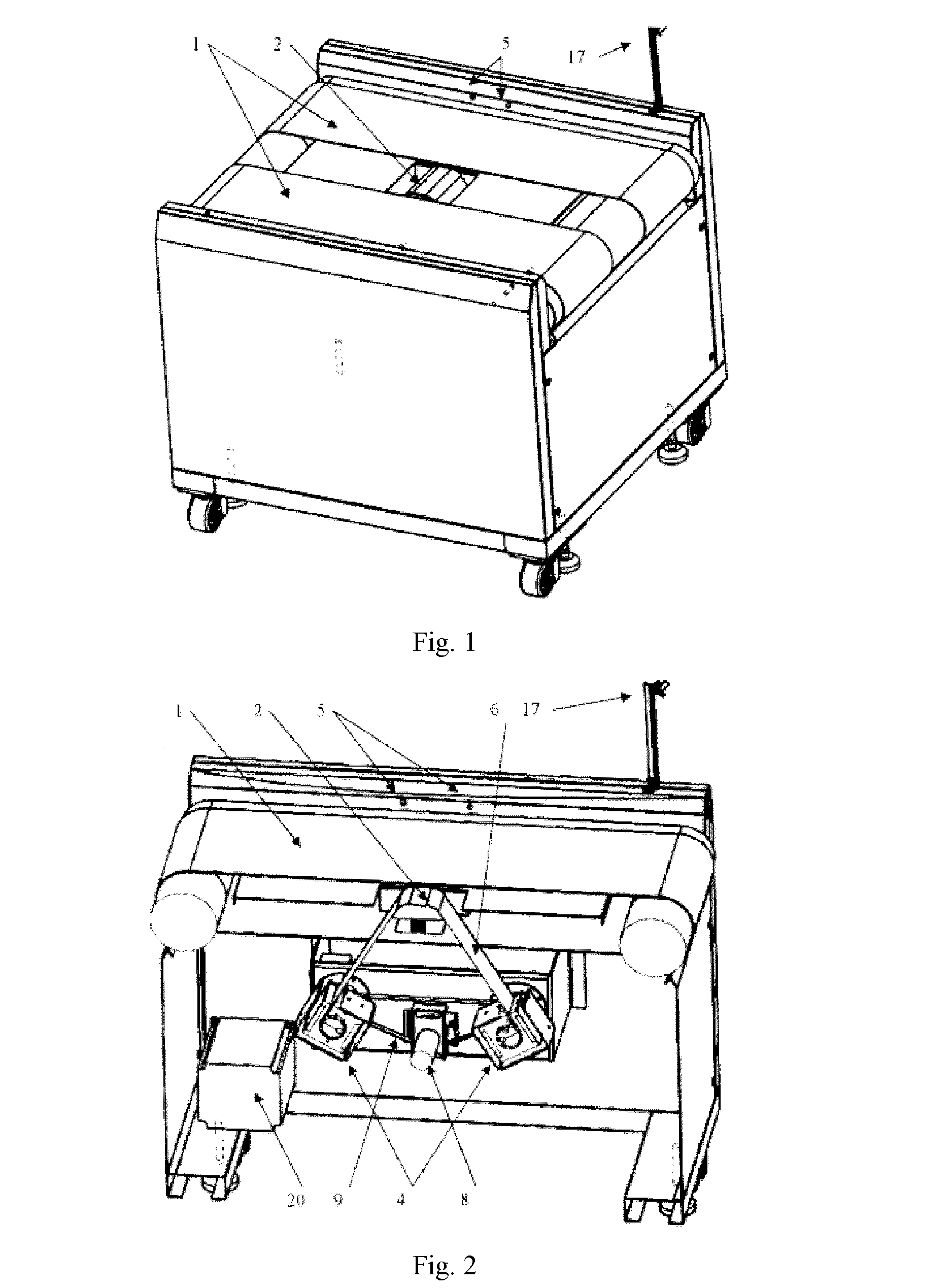

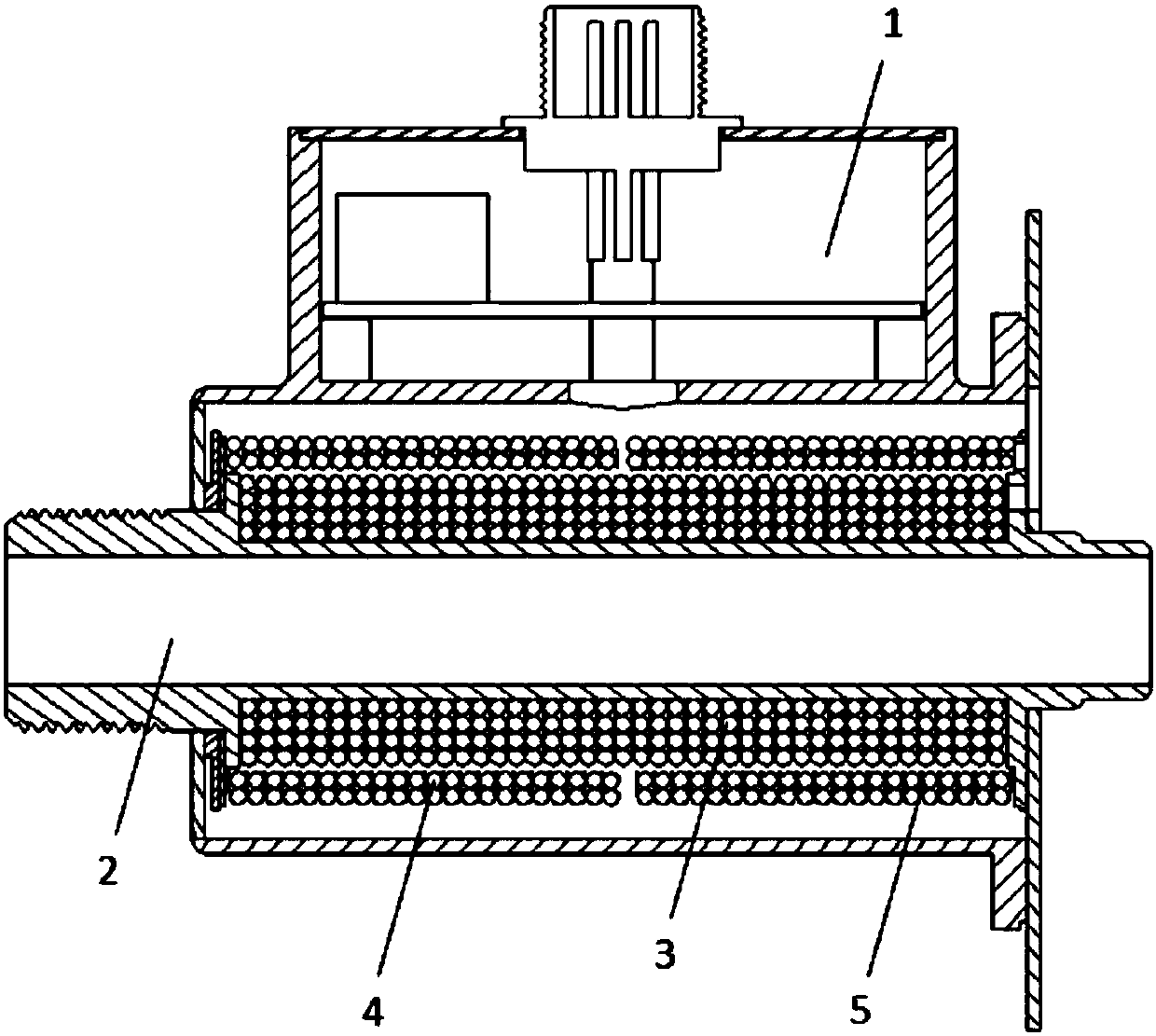

Visual online image ferrography imaging system

InactiveCN103983543ACorrect focus errorIncrease brightnessInvestigating moving fluids/granular solidsParticle and sedimentation analysisCamera lensFull field

The invention discloses a visual online image ferrography imaging system, which comprises an image acquisition device, a lens base, a focusing mechanism, an LED (Light Emitting Diode) annular reflection light source and a bicolourable ultra-thin LED backlight source; the image acquisition device is sleeved and fixed at the upper part of the focusing mechanism through the lens base; the bottom of the focusing mechanism is connected with an oil flow channel in ferrography through a thread; the LED annular reflection light source is fixedly connected with a threaded lens cone in the focusing mechanism; the bicolourable ultra-thin LED backlight source is adhered to a sedimentary slide in the oil flow channel in the ferrography. According to the invention, the object distance and the image distance are respectively adjusted through the focusing mechanism; the focal distance error of the lens is corrected; ferrography imaging with the fixed rate of 1.8 times can be realized; simultaneously, high-brightness and uniform illumination can be provided by adopting the LED annular reflection light source; the bicolourable ultra-thin LED backlight source as the transmission light source is wide in illumination range; the full-field ferrography imaging can be realized; the visual online image ferrography imaging system disclosed by the invention has the characteristics of being small in volume, high in imaging quality and easy for extracting visual abrasive particle characteristic information.

Owner:XI AN JIAOTONG UNIV

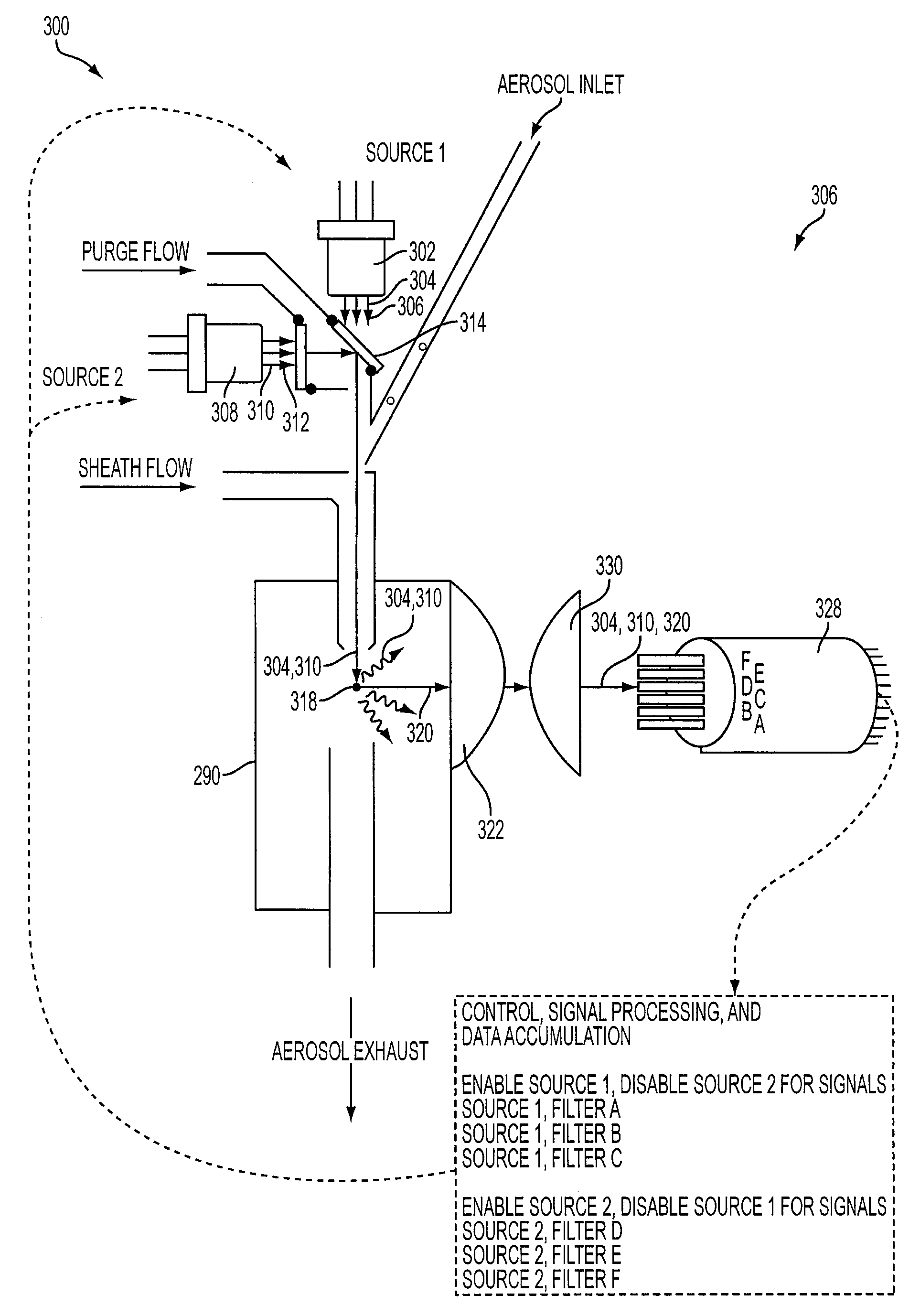

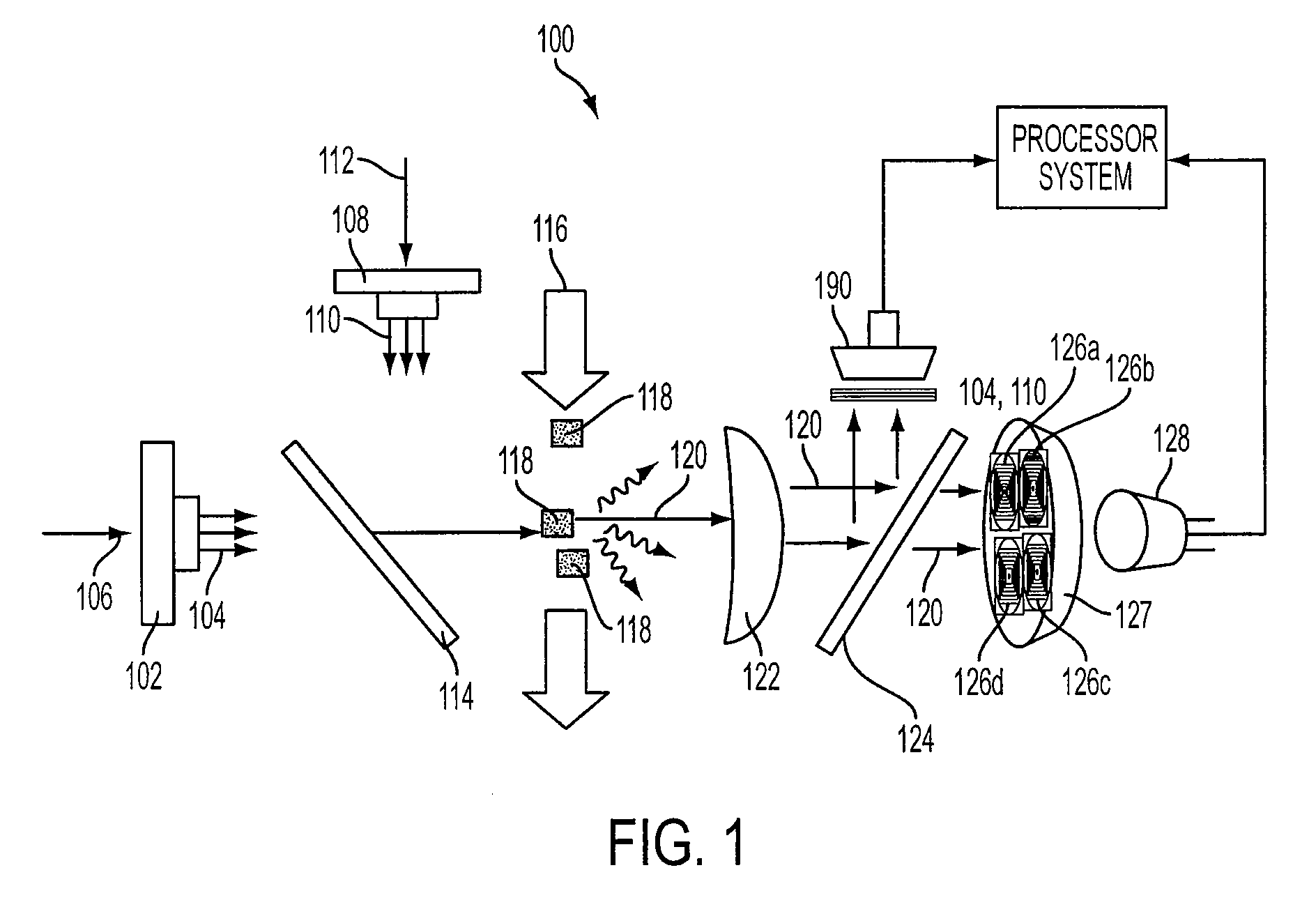

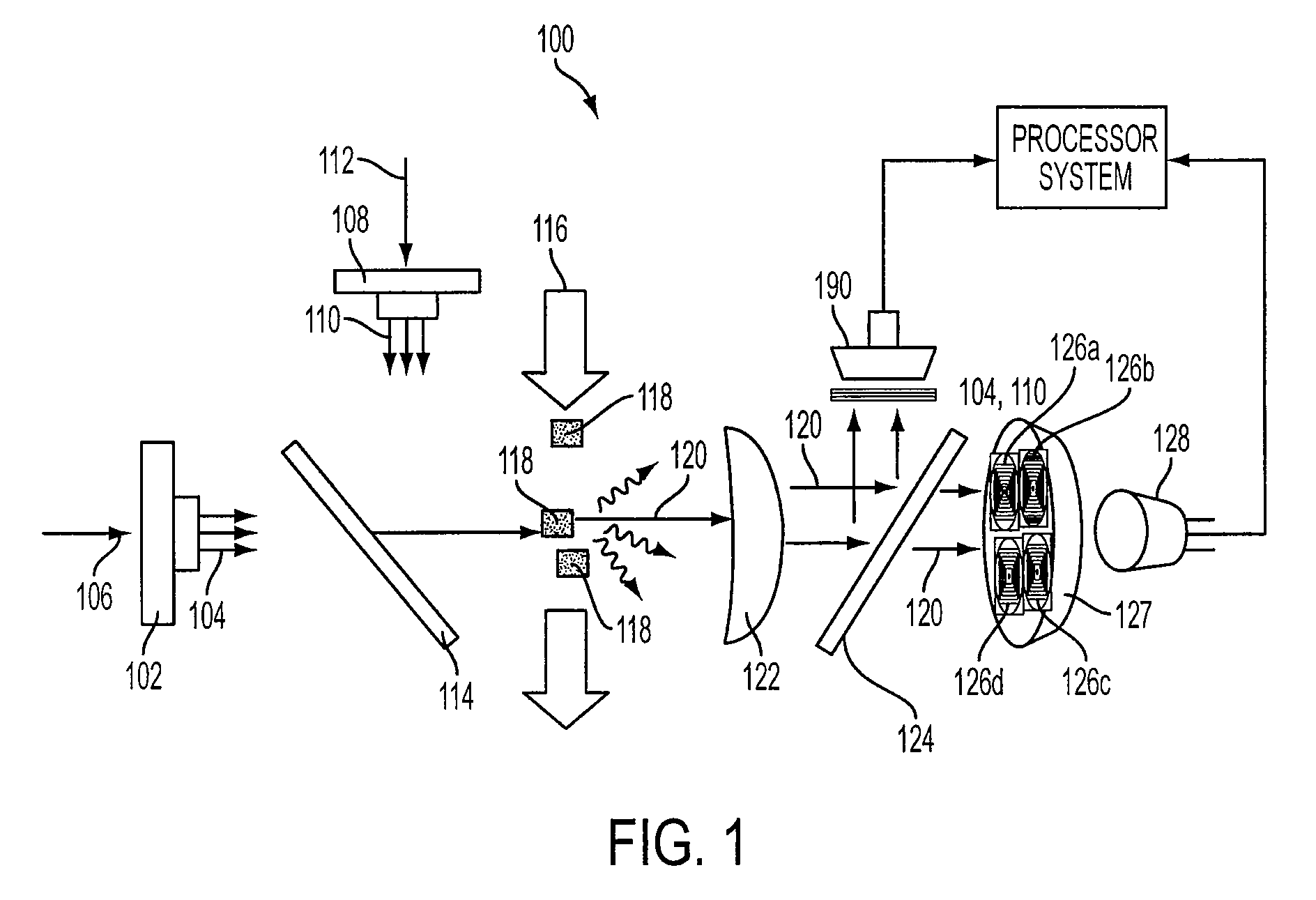

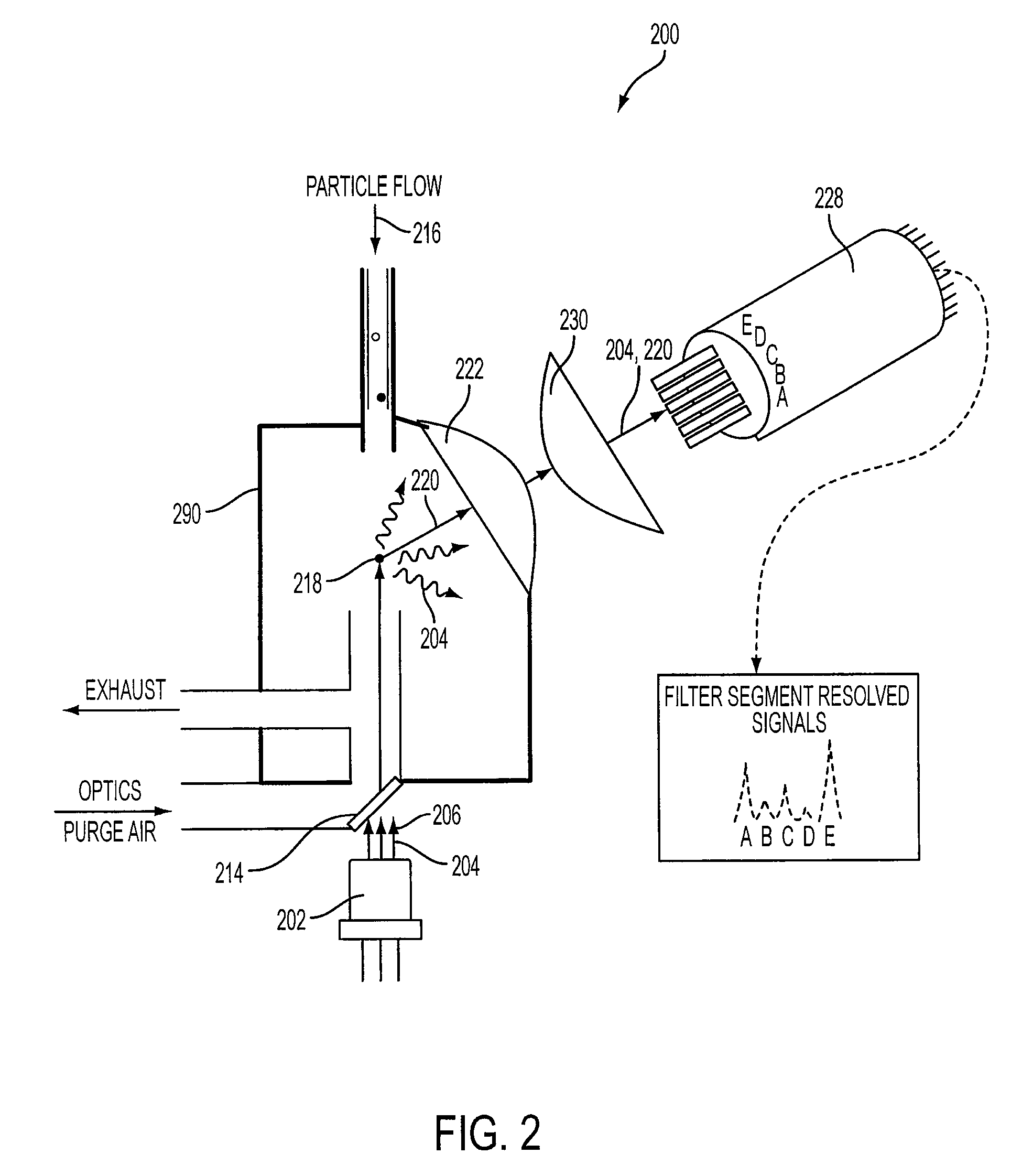

Systems and methods for use in detecting harmful aerosol particles

Owner:JANSSEN PHARMA NV +1

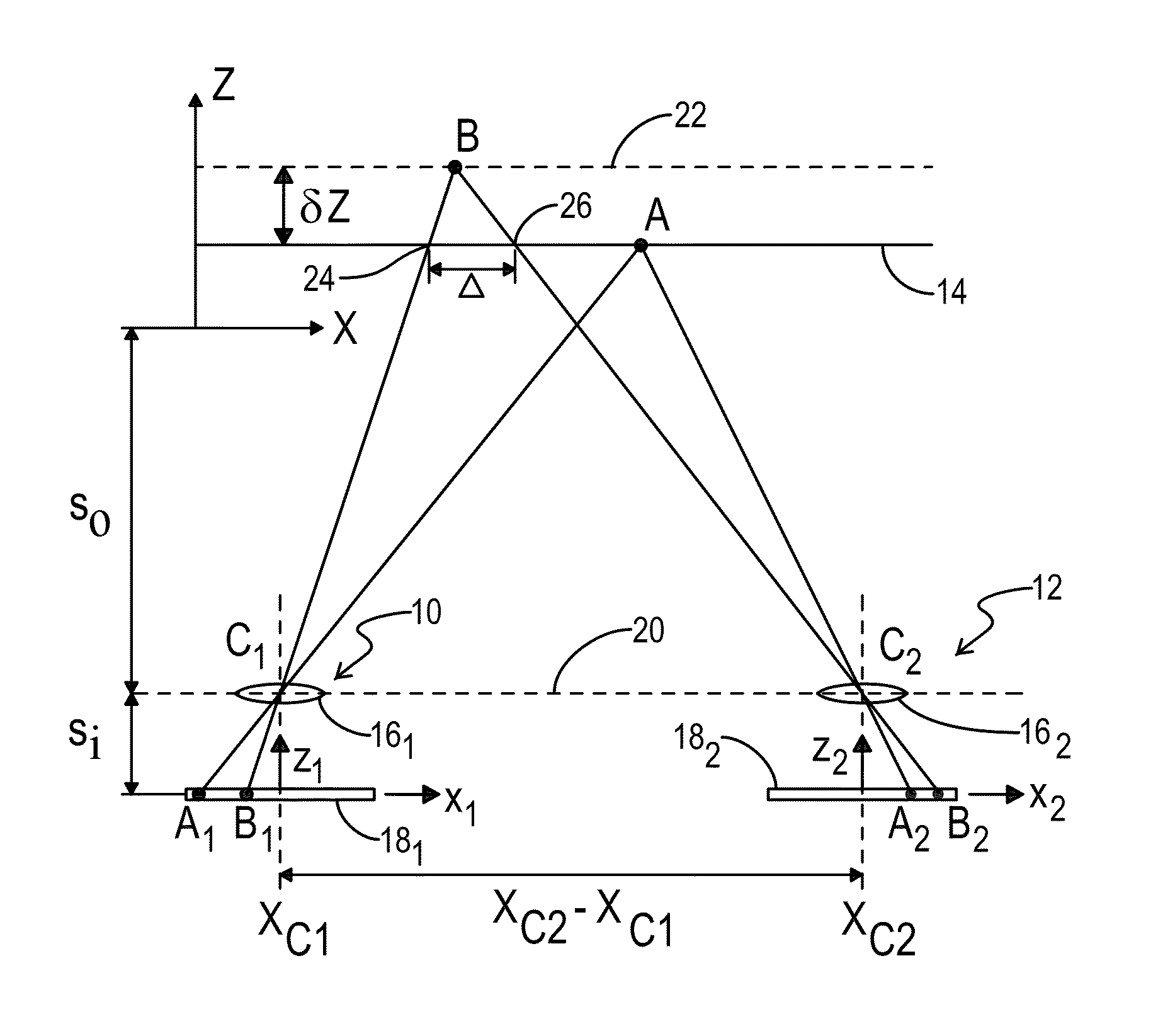

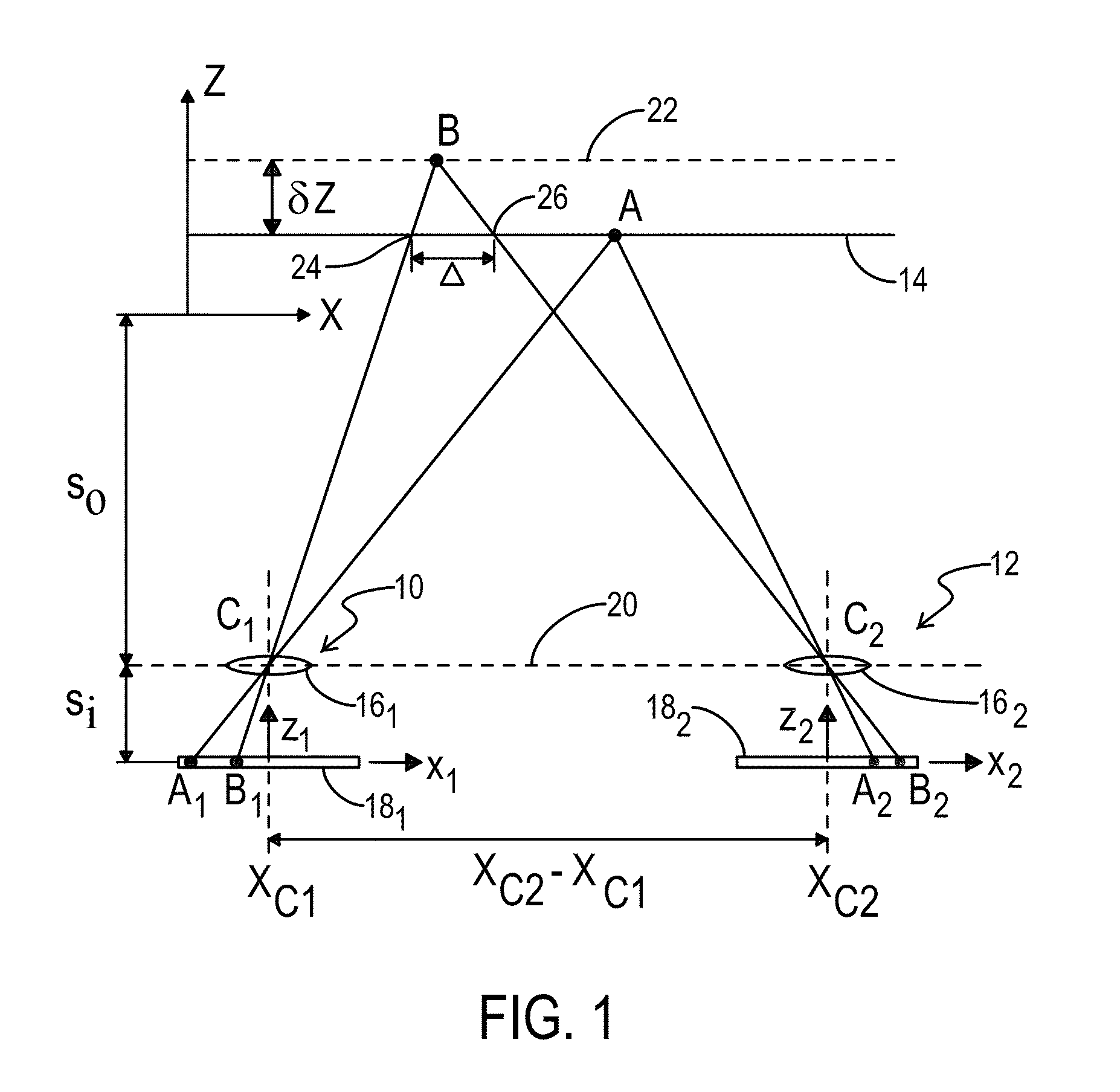

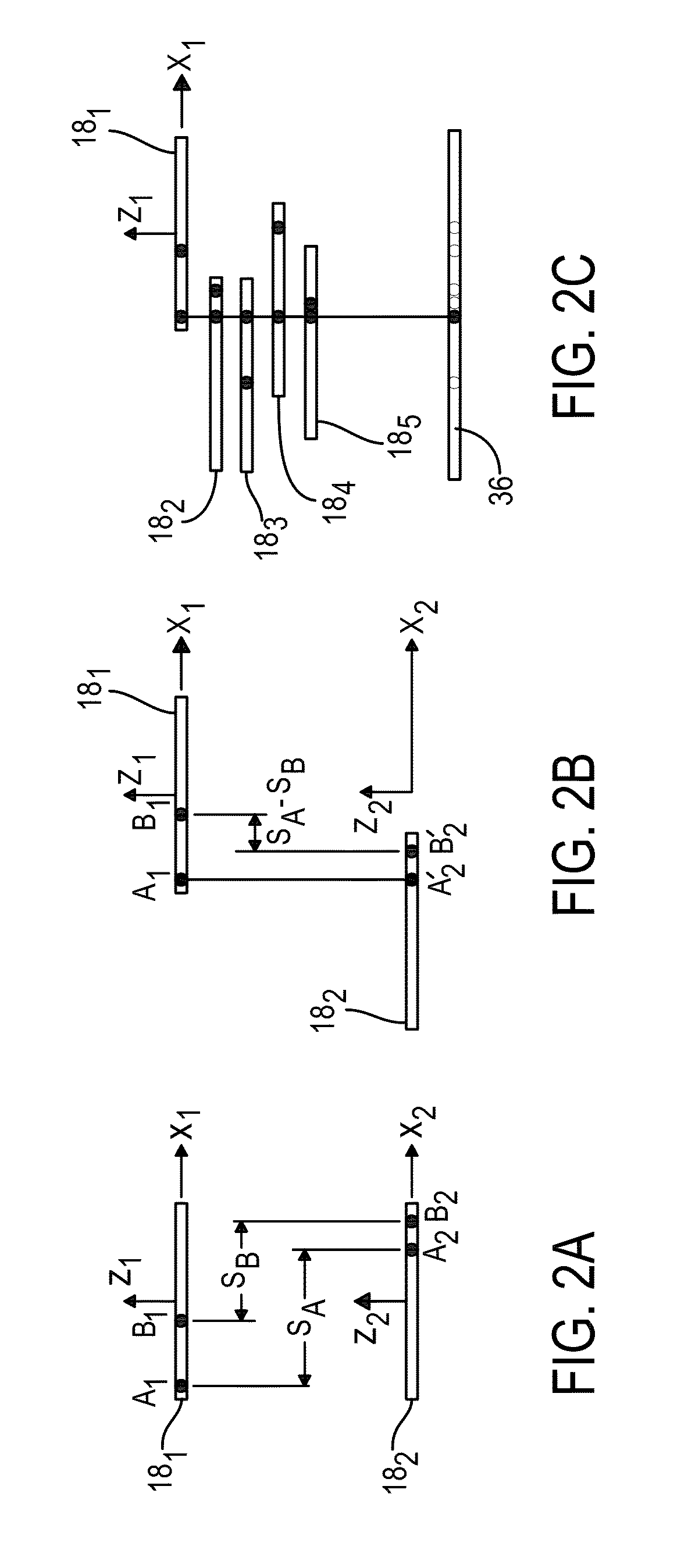

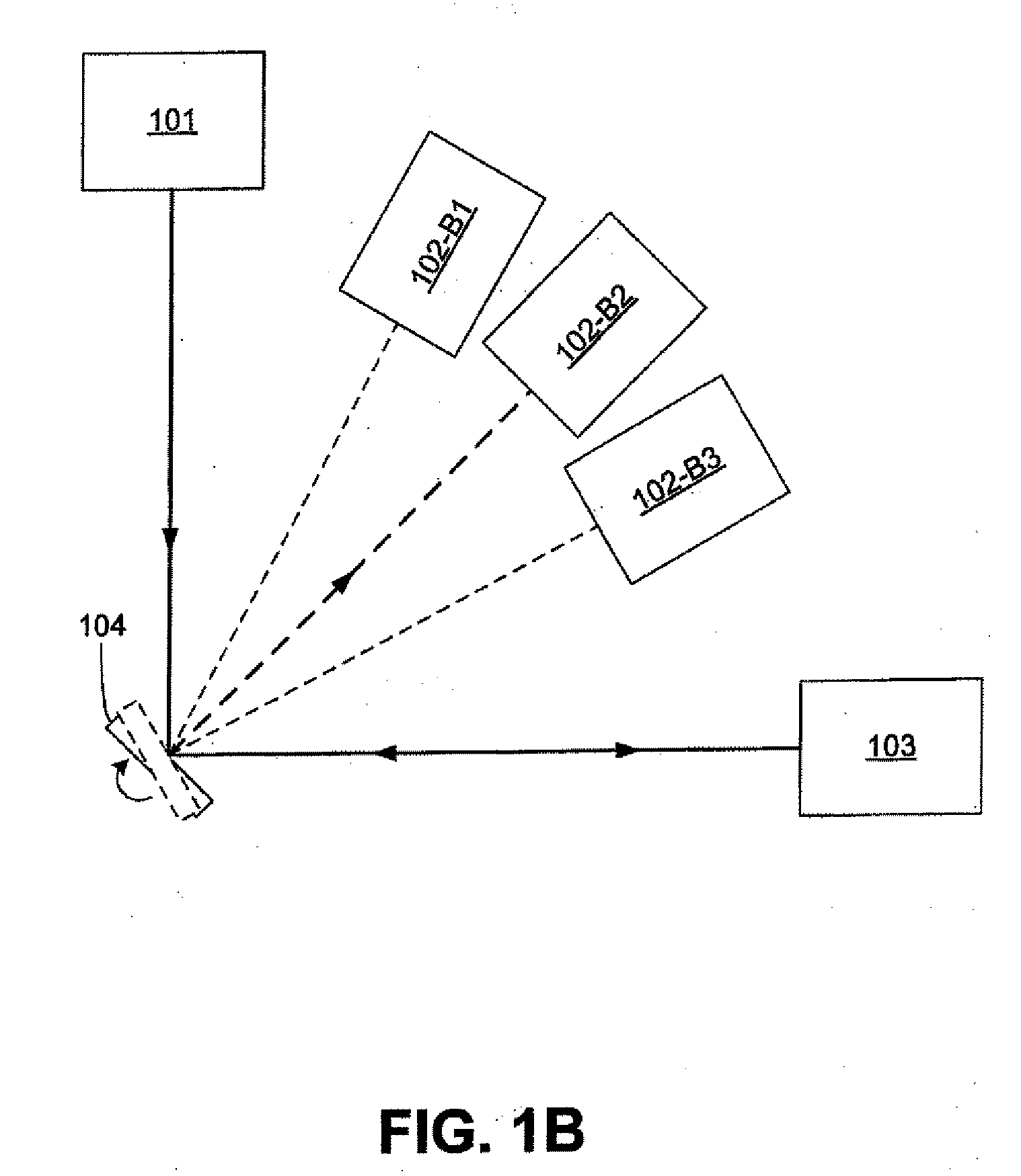

Synthetic aperture imaging for fluid flows

InactiveUS8922636B1Increase contrastColor television detailsClosed circuit television systemsSynthetic aperture sonarFluid phase

A synthetic aperture three-dimensional fluid flow imaging apparatus is provided. The apparatus includes a plurality of cameras. At least two of the cameras are oriented to view a volume along mutually non-parallel directions. The cameras are connected to a programmable computer. The computer captures images from the cameras to generate three dimensional intensity fields. The computer can refocus the images on at least one refocus plane to generate reconstructed three dimensional intensity fields on a plane within the volume. Intensity field cross-correlation is performed on the reconstructed three dimensional intensity fields to extract velocity fields within the volume. The velocity fields represent velocities of objects or fluid phases within the volume. These velocity fields can be recorded for later use.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Systems and methods for use in detecting harmful aerosol particles

Owner:JANSSEN PHARMA NV +1

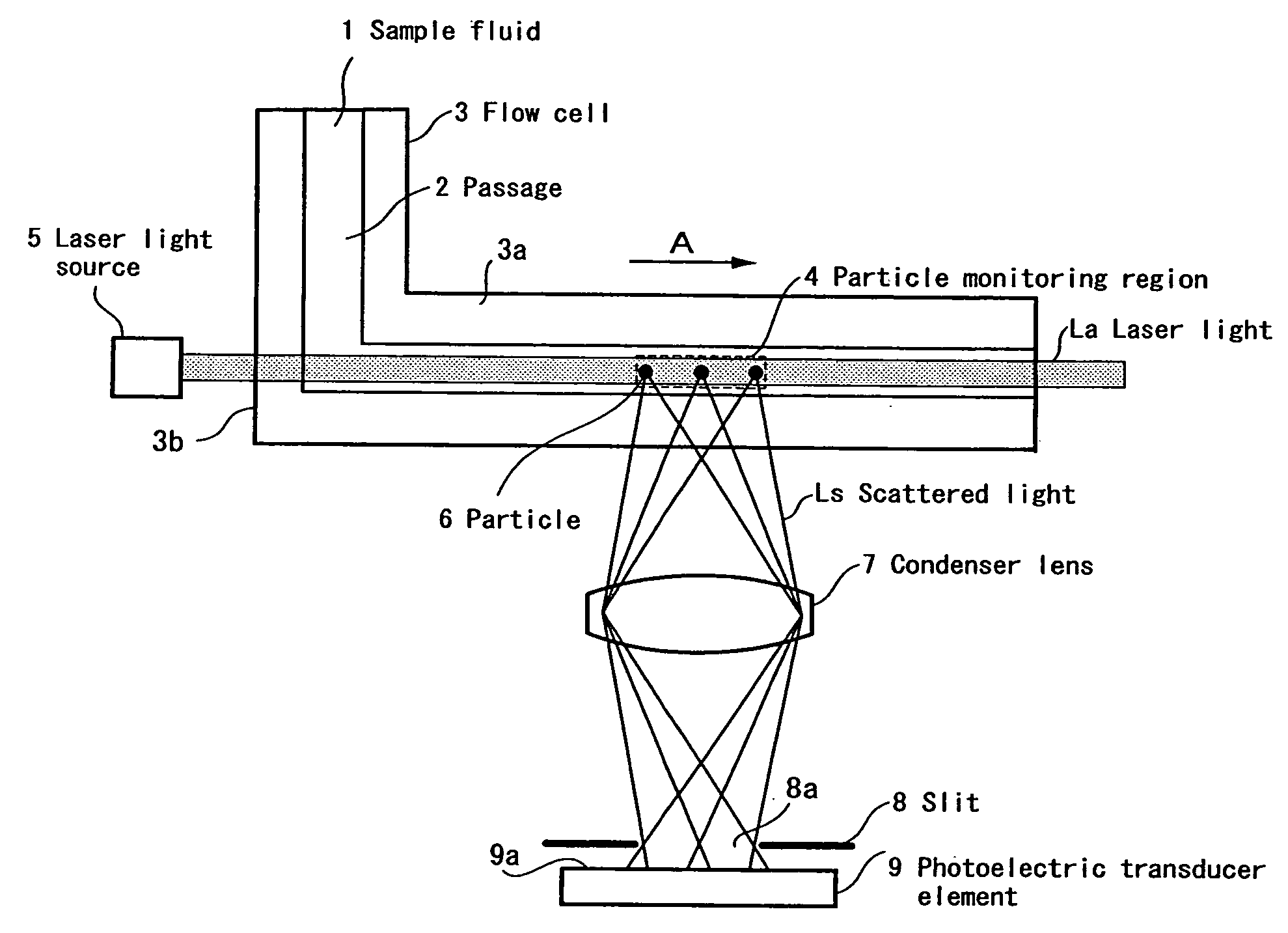

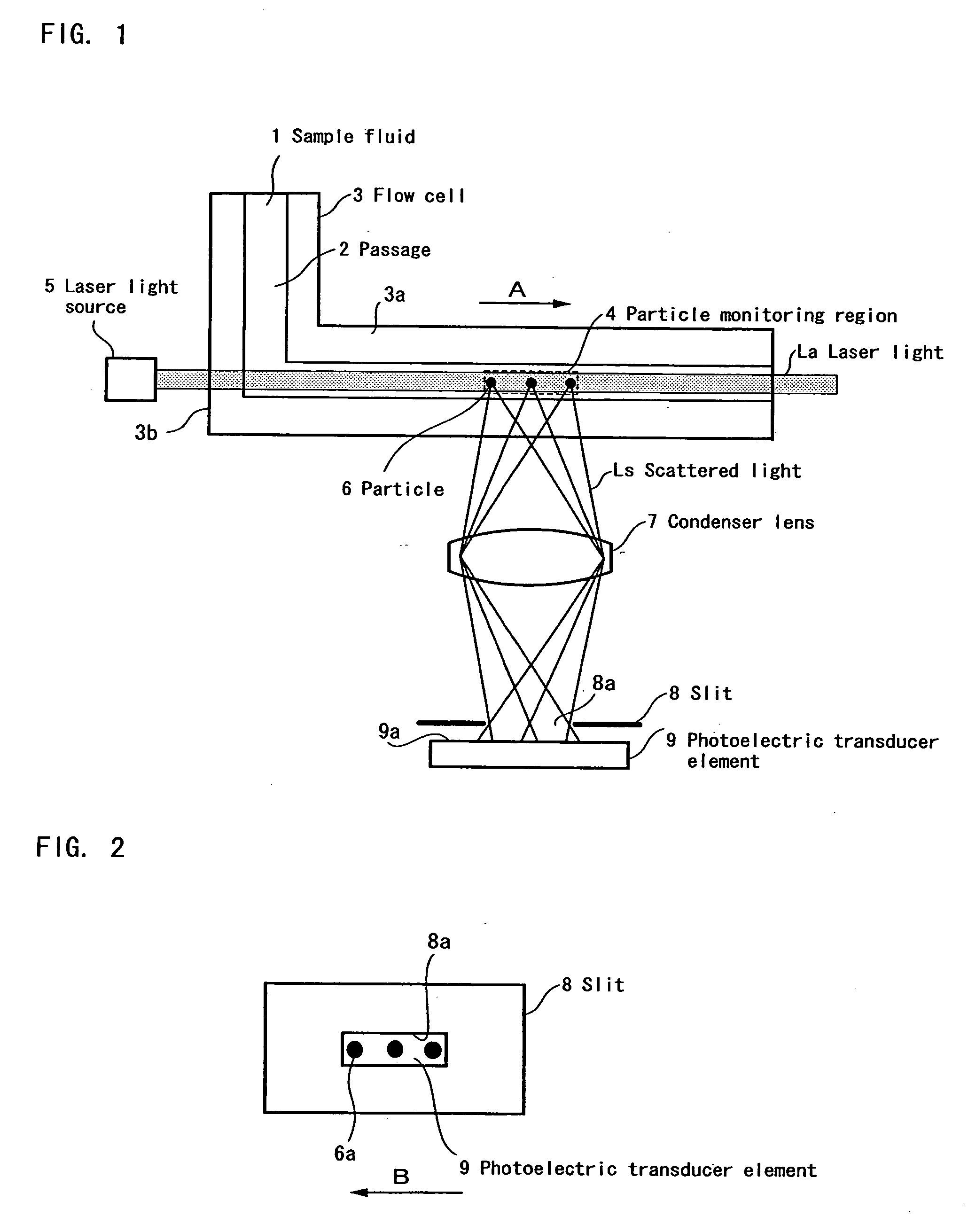

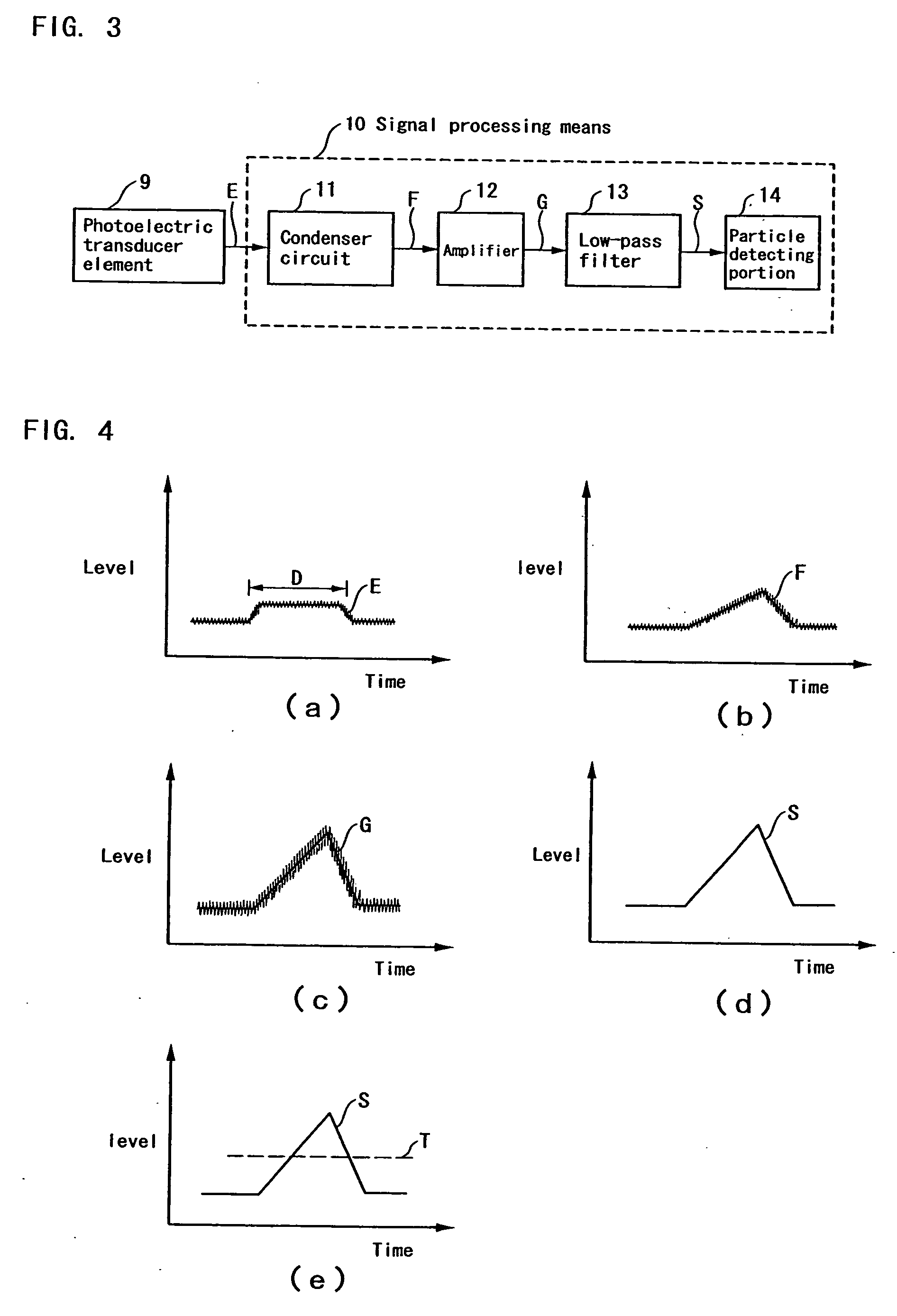

Particle detector

InactiveUS20090153857A1Scattering properties measurementsParticle and sedimentation analysisLow-pass filterTransducer

A particle detector which can detect smaller particles by increasing the pulse width of the particle signal output from a photoelectric transducer element, includes a particle monitoring region formed by irradiating sample fluid with laser light, and light scattered from particles passing through the particle monitoring region is received by a photoelectric transducer element so as to detect a particle. The direction of flow of the sample fluid and the direction of the laser light are arranged parallel to each other. The particle detector may have a condenser lens for condensing the scattered light and a slit provided at a focal point of the condenser lens and extending in a direction parallel to the sample fluid flow. Also, the particle detector may have a condenser circuit for integrating the output signal of the photoelectric transducer element, and a low-pass filter for filtering the output signal of the condenser circuit.

Owner:RION COMPANY

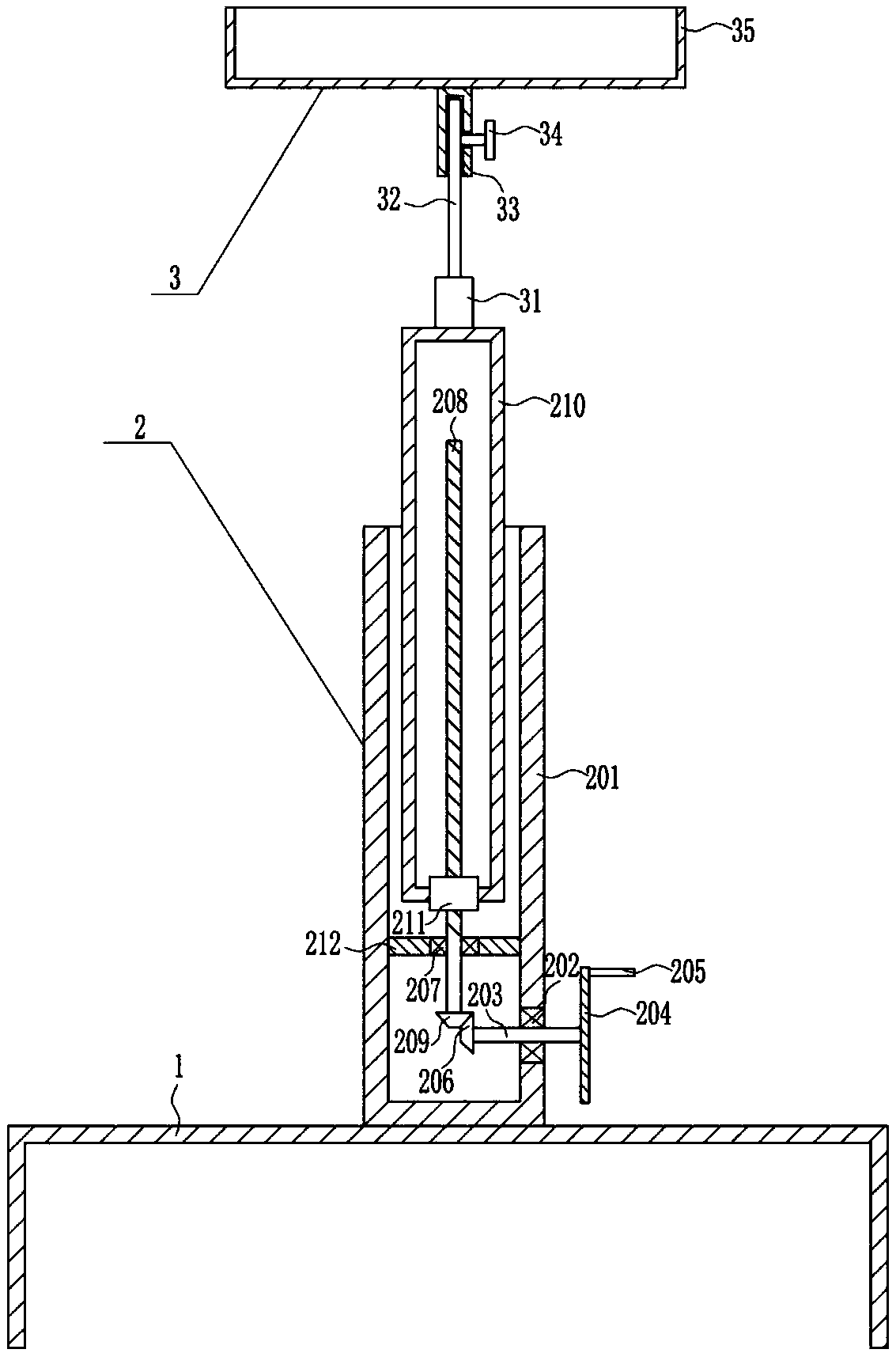

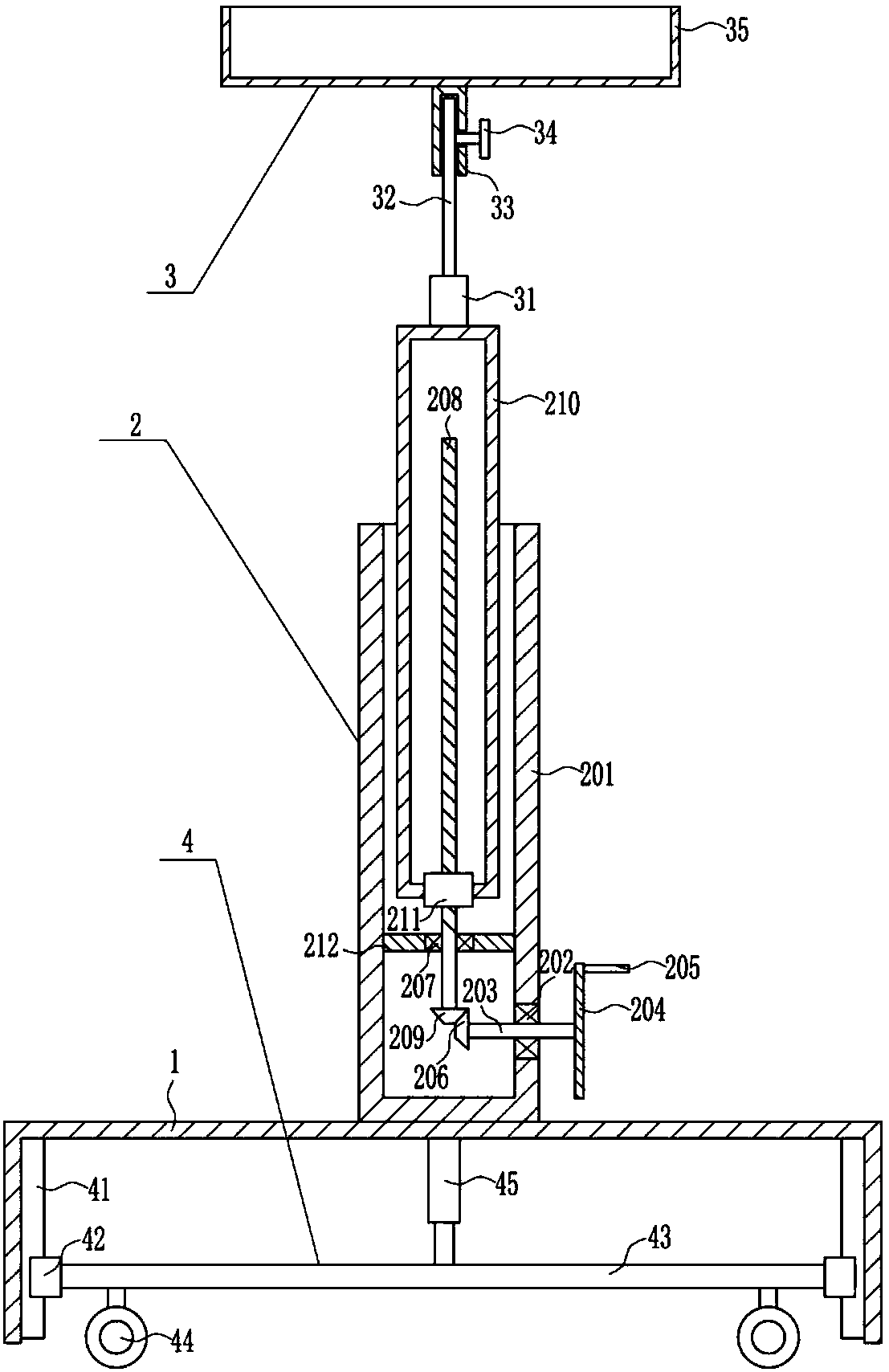

Flying dust monitoring device for construction monitoring

InactiveCN107842694AEasy to moveShorten the timeStands/trestlesParticle suspension analysisTime efficientArchitectural engineering

Owner:查宇

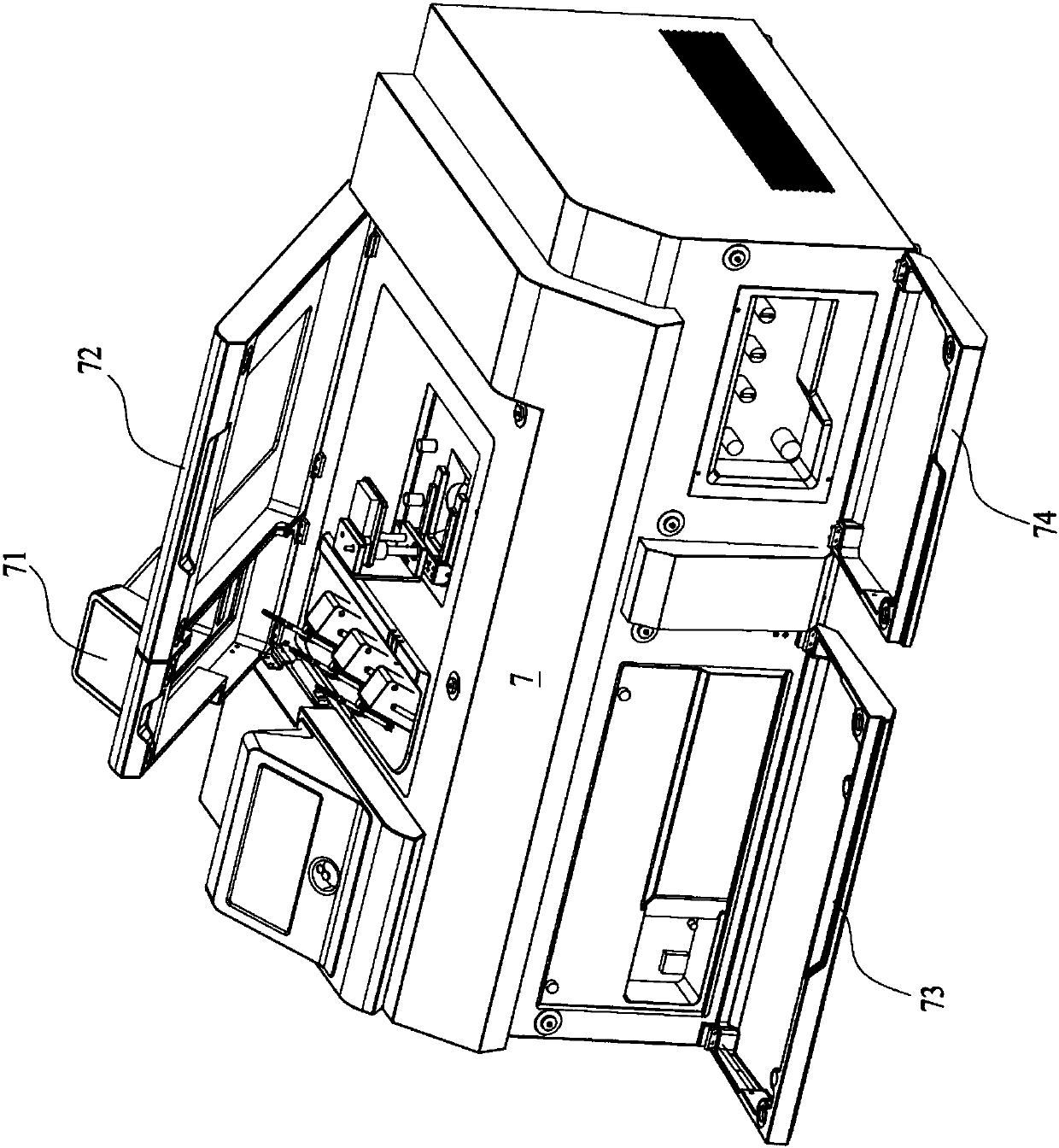

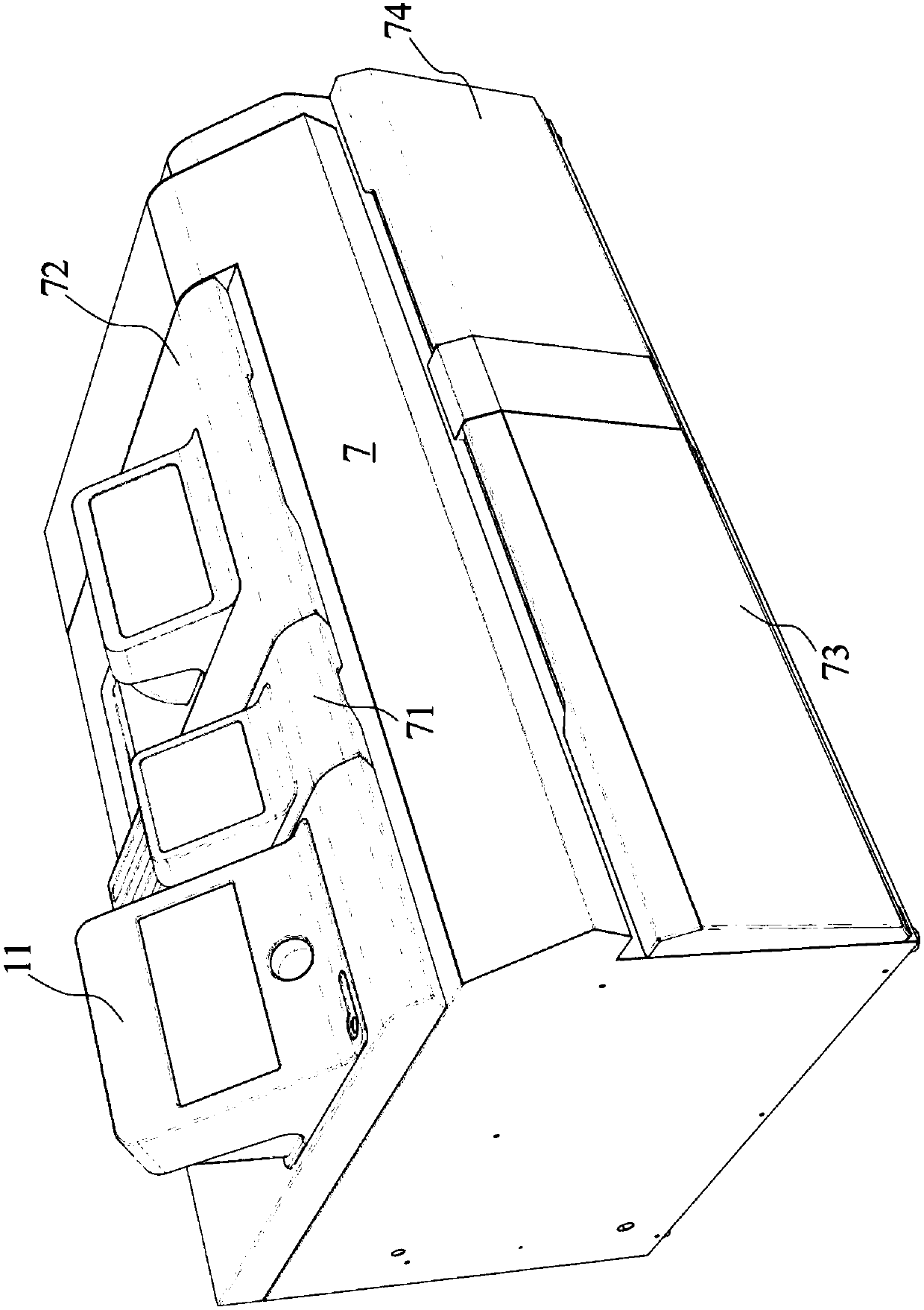

High-throughput screening apparatus using droplet micro-fluidic chip

PendingCN108020490ADetection is simple and applicableGood for reinjectionBioreactor/fermenter combinationsBiological substance pretreatmentsHigh-Throughput Screening MethodsFluorescence

The invention provides a high-throughput screening apparatus using a droplet micro-fluidic chip. The apparatus comprises: a rack; a micro-fluidic control system constructed to control a fluid supply device for supplying a droplet-containing fluid to the droplet micro-fluidic chip; a photoelectric detection system comprising an incident light generation device for limiting outgoing and incident light paths, a preferable laser excitation device and a fluorescence detection device for limiting a fluorescent light path; an electric screening system constructed to connect the droplet micro-fluidicchip in order to screen droplets flowing through the droplet micro-fluidic chip; and one or more controllers constructed to receive a signal from the fluorescence detection device, compare the signalwith a predetermined threshold and control the electric screening system to perform droplet screening according to the obtained comparison result.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

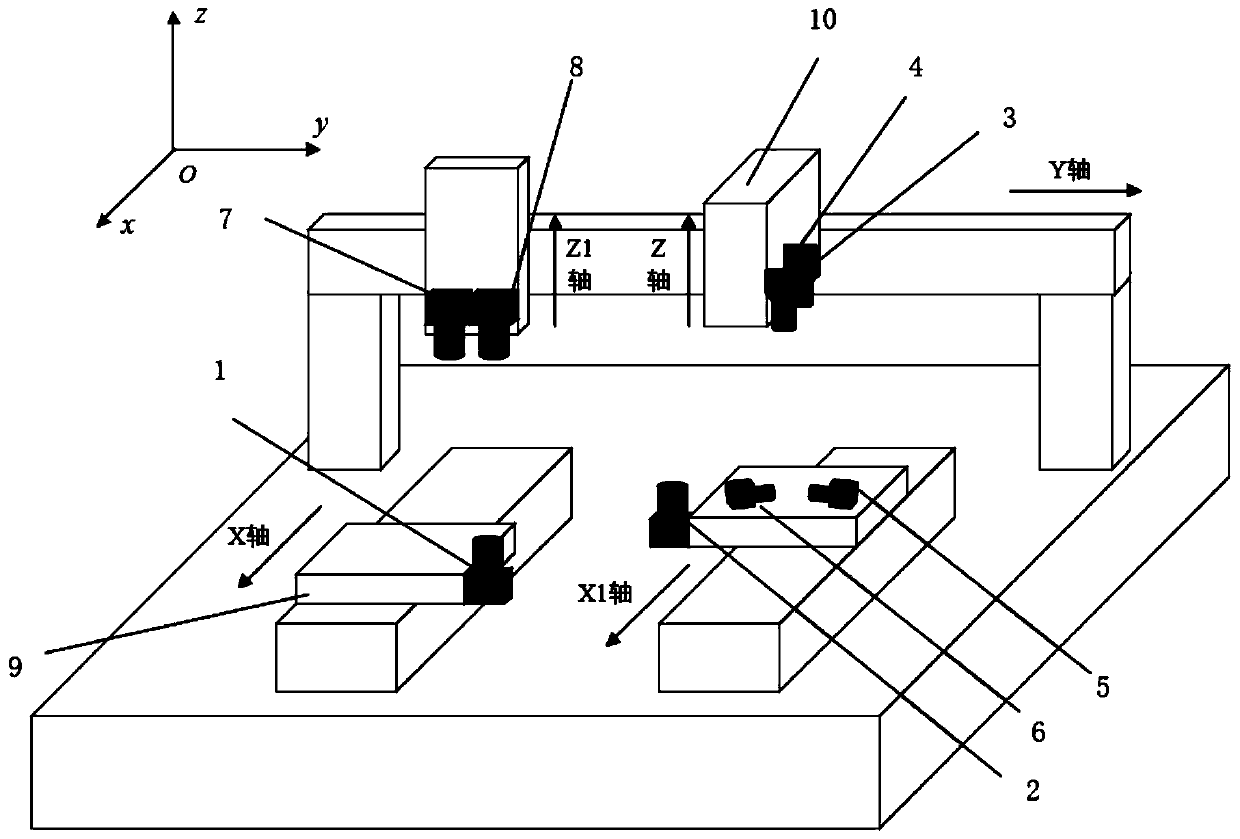

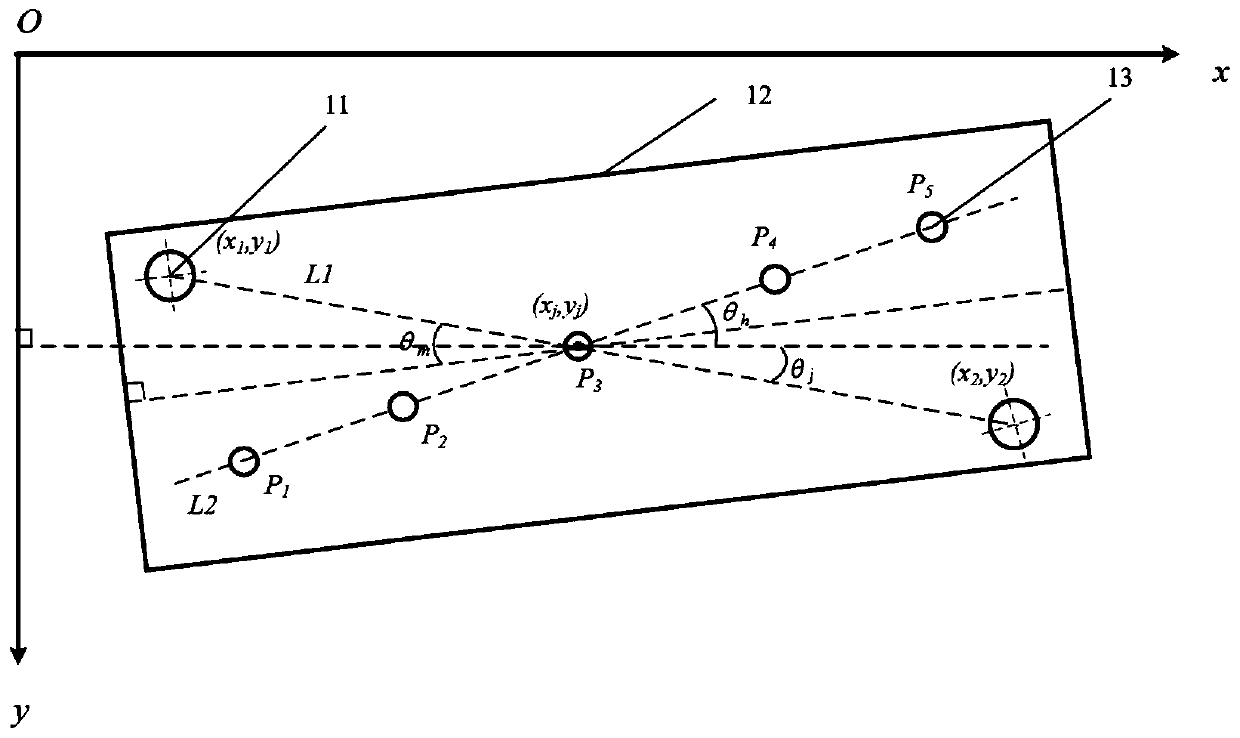

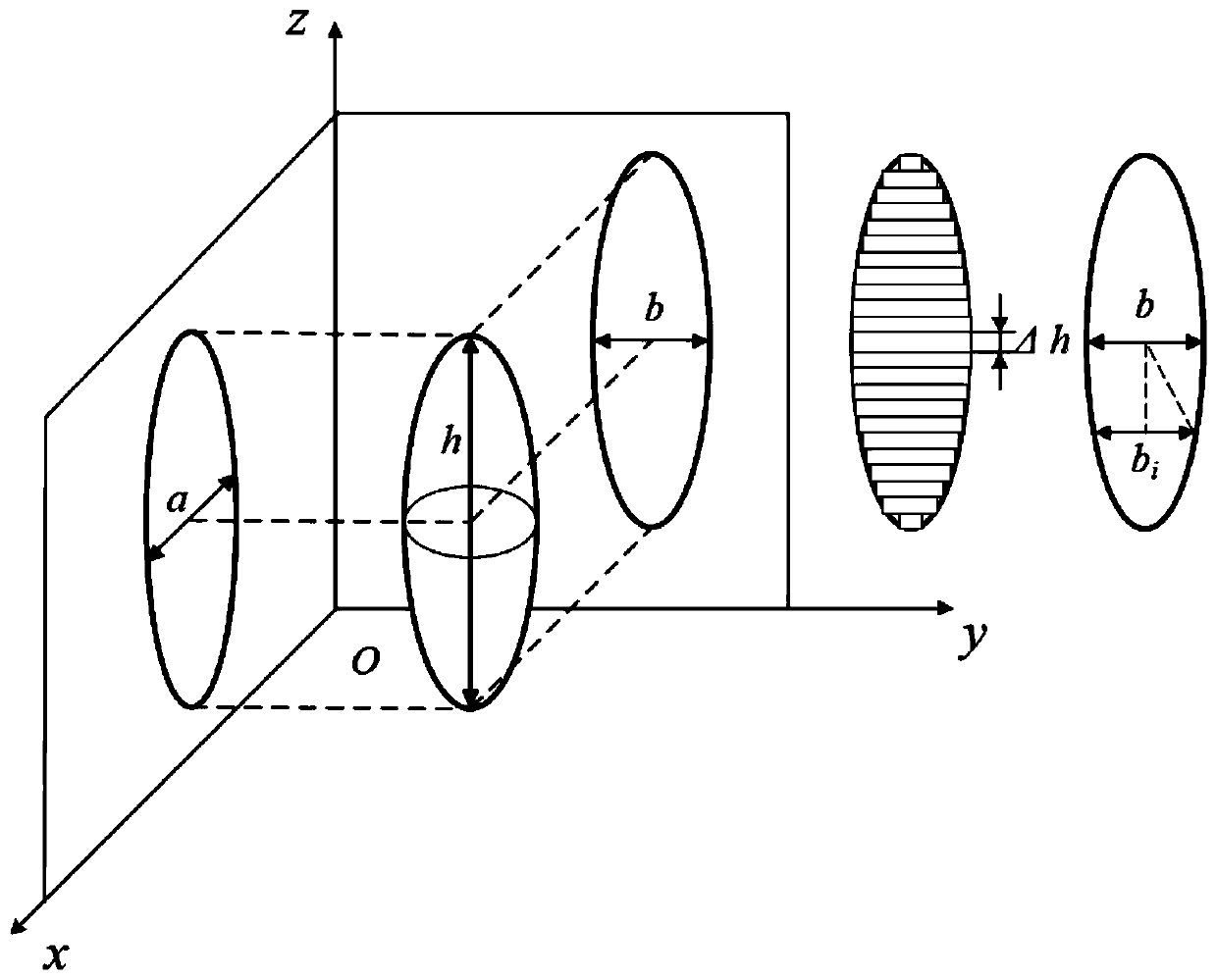

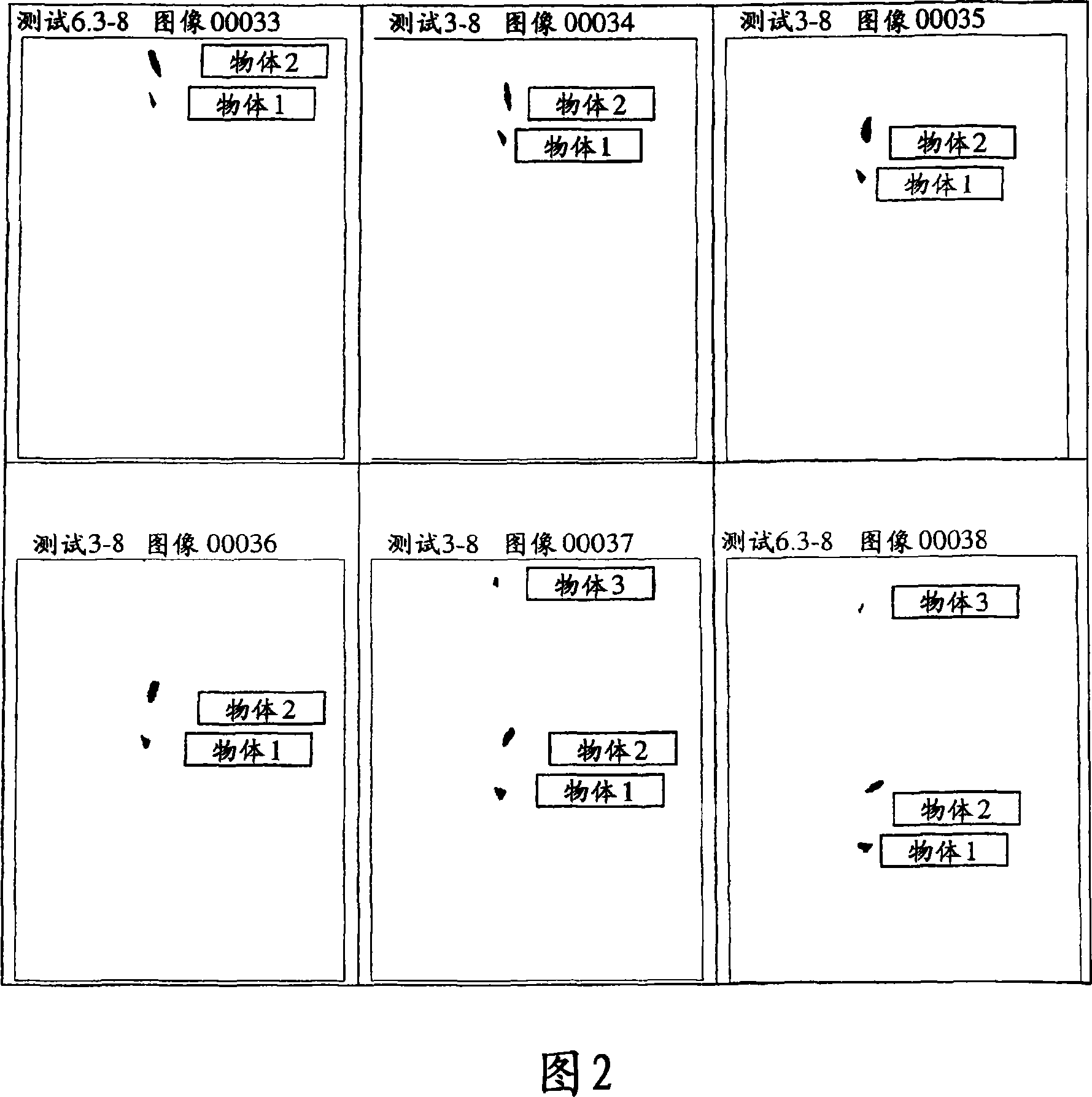

Multi-view vision inspection system and method for ink-jet printing

ActiveCN111397539AImprove detection accuracyImprove printing efficiencyUsing optical meansOther printing apparatusVision inspectionVisual inspection

The invention belongs to the technical field related to ink-jet printing visual inspection, and discloses a multi-view visual inspection system and method for ink-jet printing, and the method mainly comprises the following steps: (1) firstly, detecting and determining the installation angle of a nozzle; then, performing trial printing to detect and determine the volume, speed and angle of flying ink drops; and finally, detecting and determining the deflection angle of the spray orifice array, the position and angle of the substrate and the offset distance of ink dripping points; and (2) carrying out ink-jet printing according to the obtained parameters, and carrying out liquid film detection on the printed substrate by adopting a predefined defect type after the substrate is printed. Various control parameters required by the whole ink-jet printing process can be detected, the defect that only a single module can be detected in an existing ink-jet printing detection method can be effectively overcome, and higher-precision and higher-efficiency detection of the whole ink-jet printing process is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

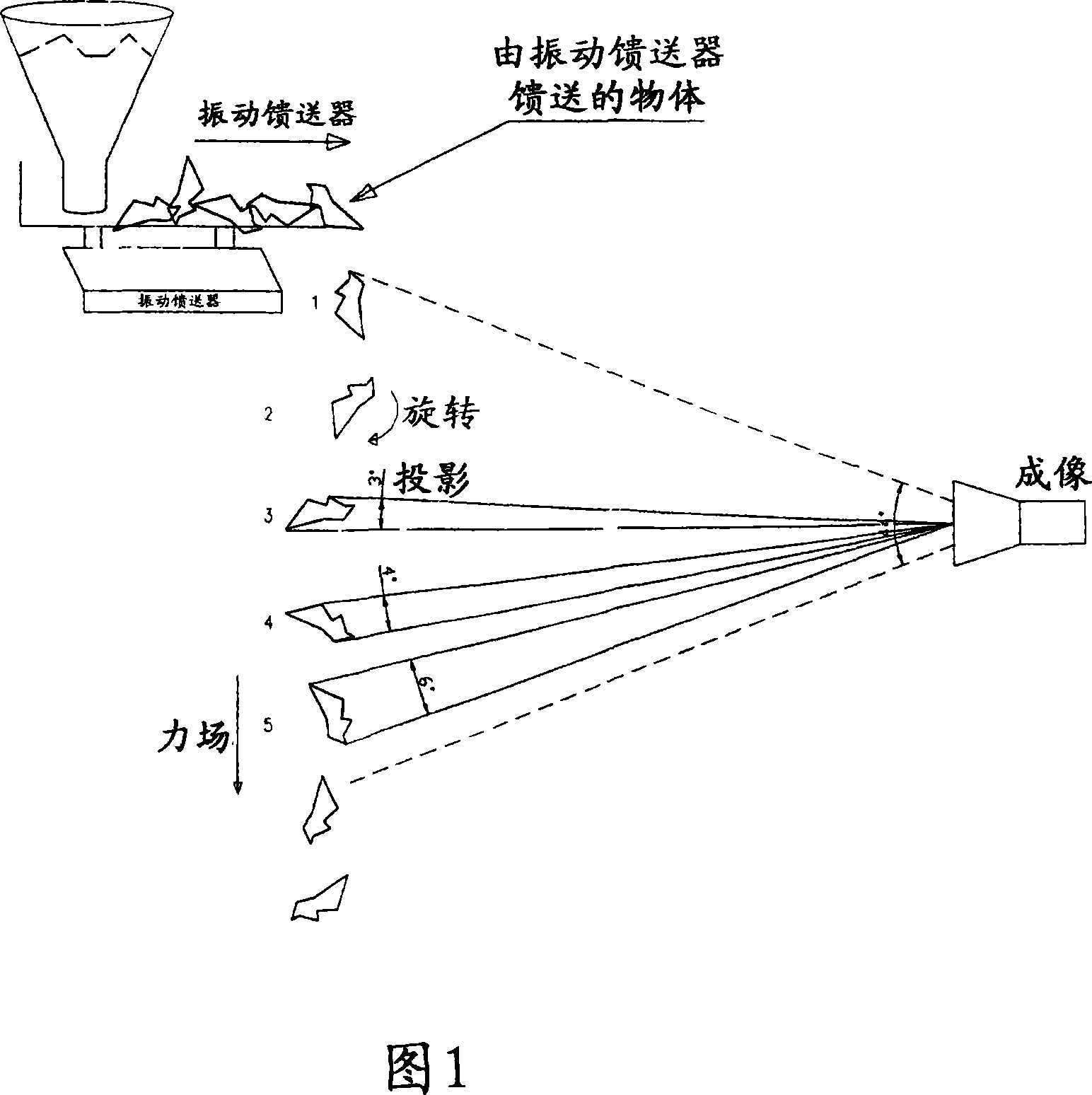

Object analysis method and apparatus

A method and an apparatus for analysing at least one object, comprising at least one means for capturing images of said at least one object and means for generating a relative mutual movement between said at least one image capturing means and said at least one object, and further comprising means for processing and analysing images captured by the image capturing means. The relative mutual movement involves a mutual rotational movement between said at least one object and said image capturing means, thus establishing two or more images of said object(s) at various angular positions relative the image capturing means for further processing and analysis in a computer based image analyser.

Owner:麦奇克莱驰股份有限公司

Apparatus and method for detecting hazardous substance on a surface of an object

InactiveUS20140345364A1Increase speedReduce laborWithdrawing sample devicesParticle suspension analysisHazardous substanceExplosive material

Owner:NUCTECH CO LTD

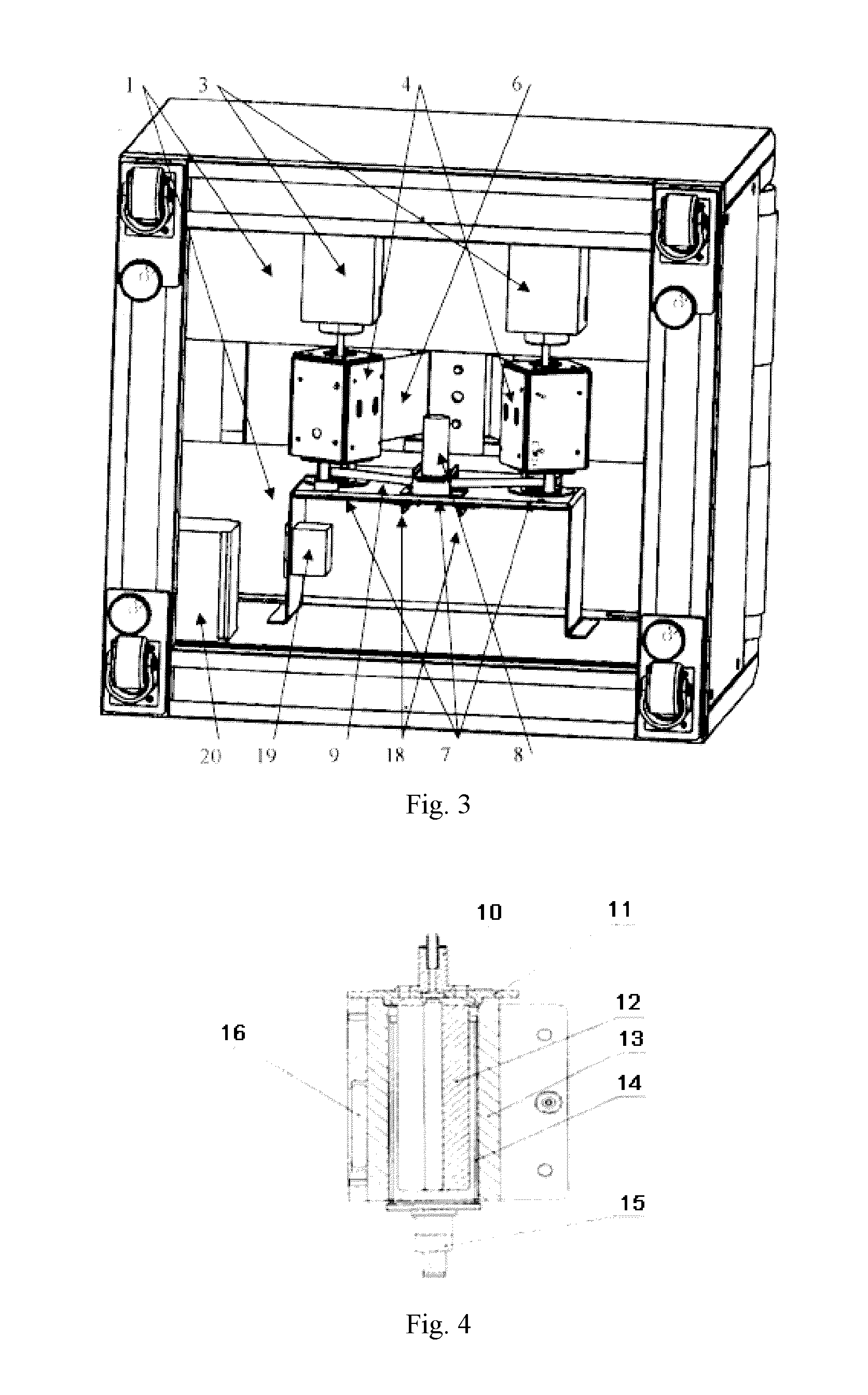

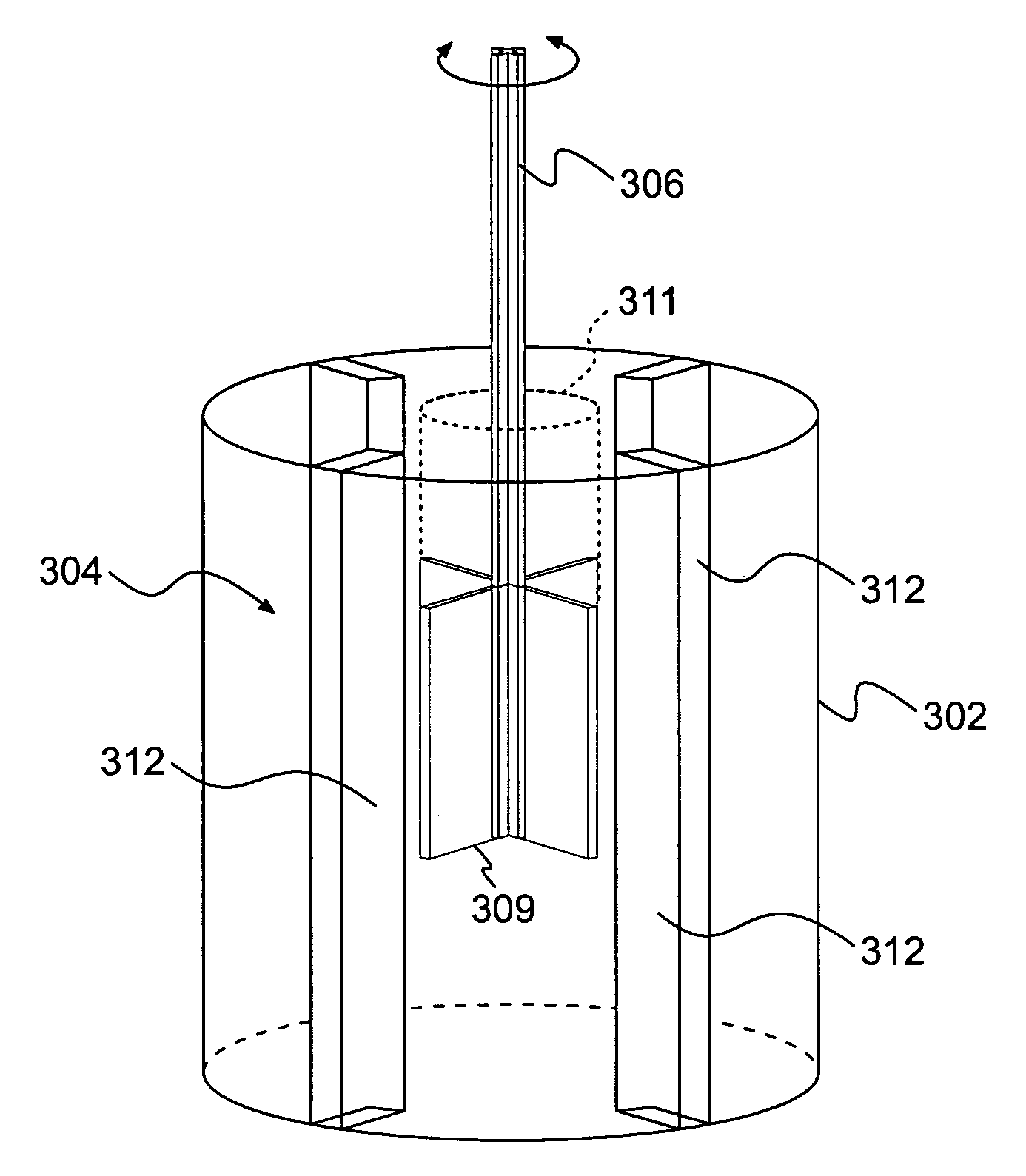

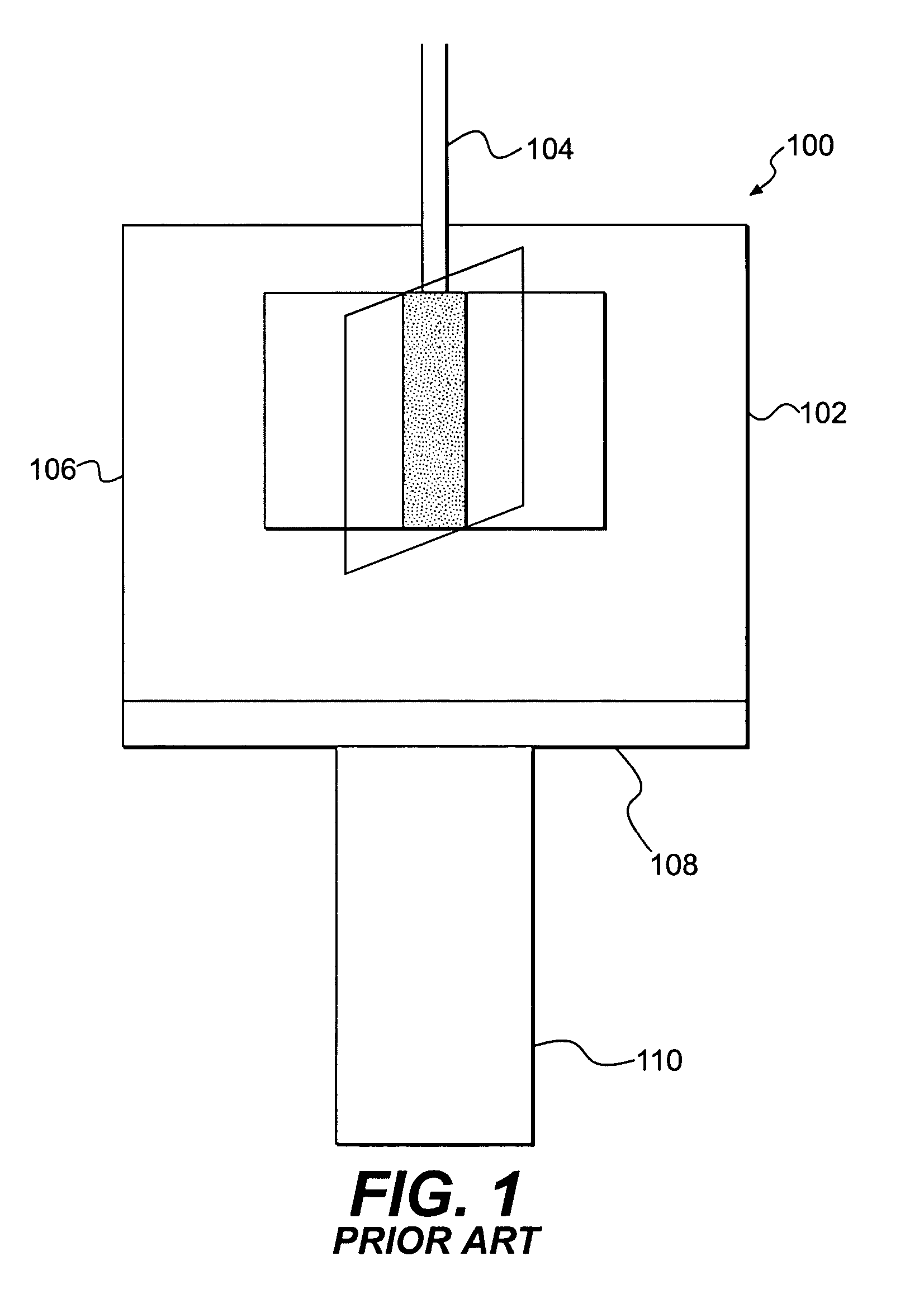

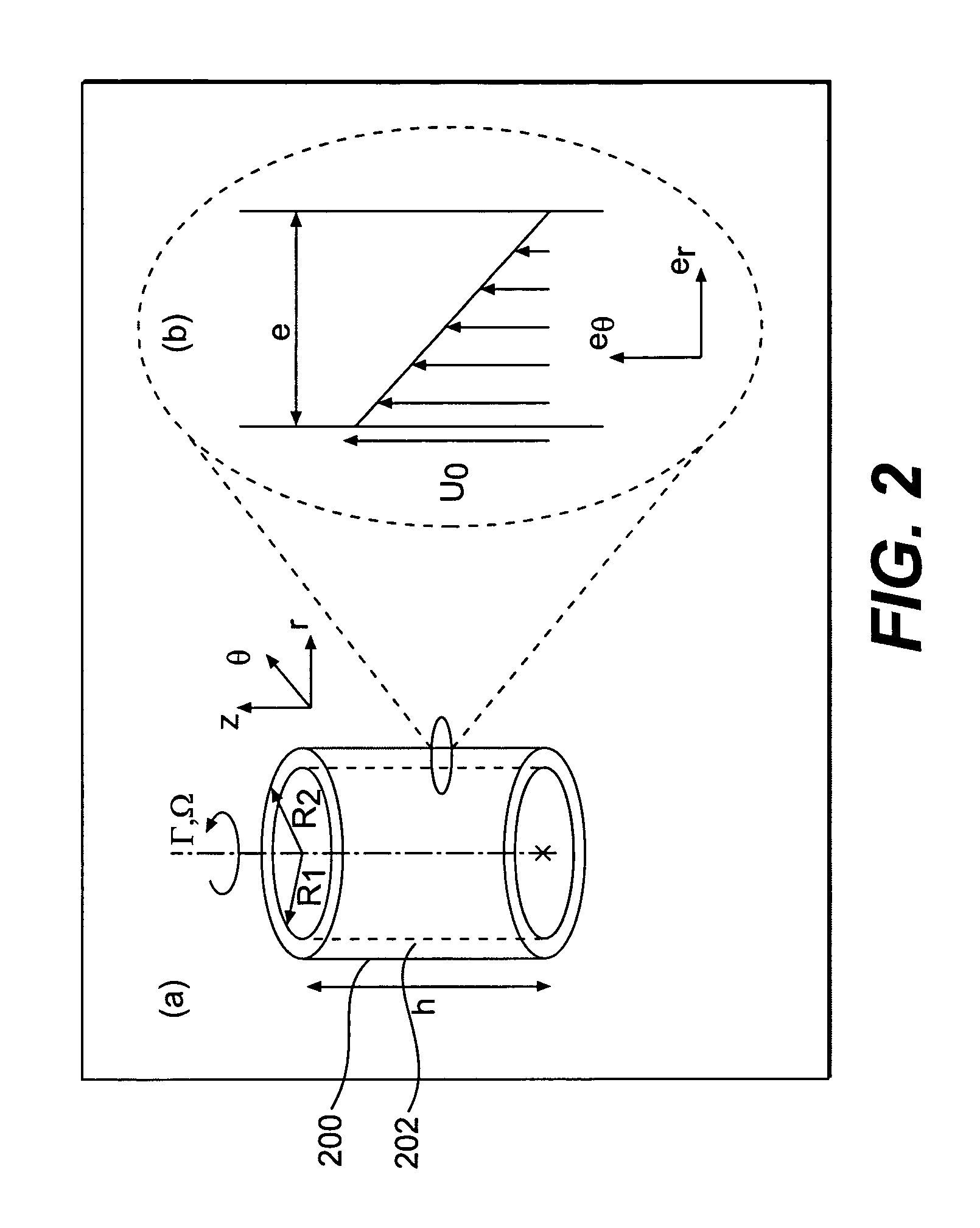

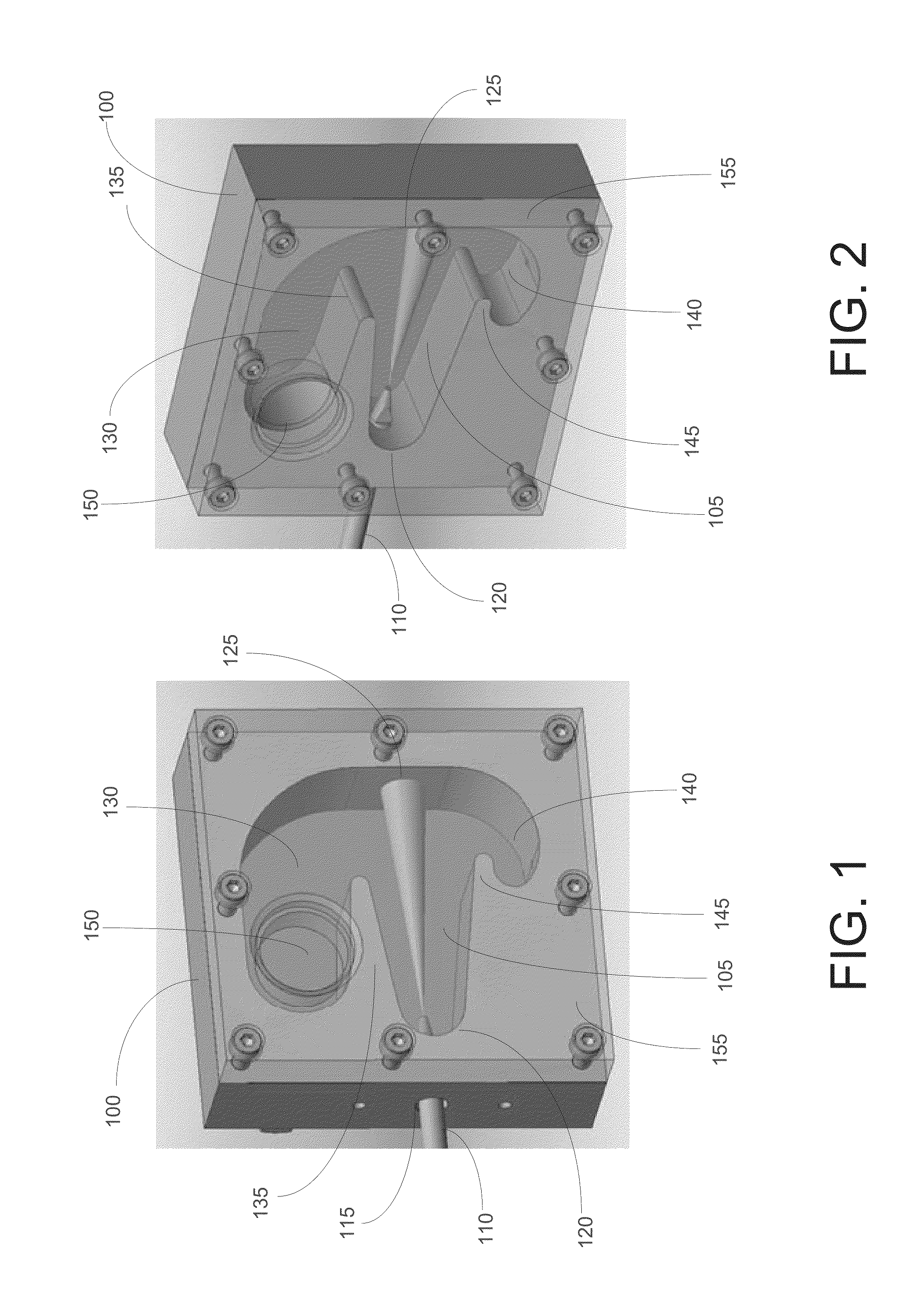

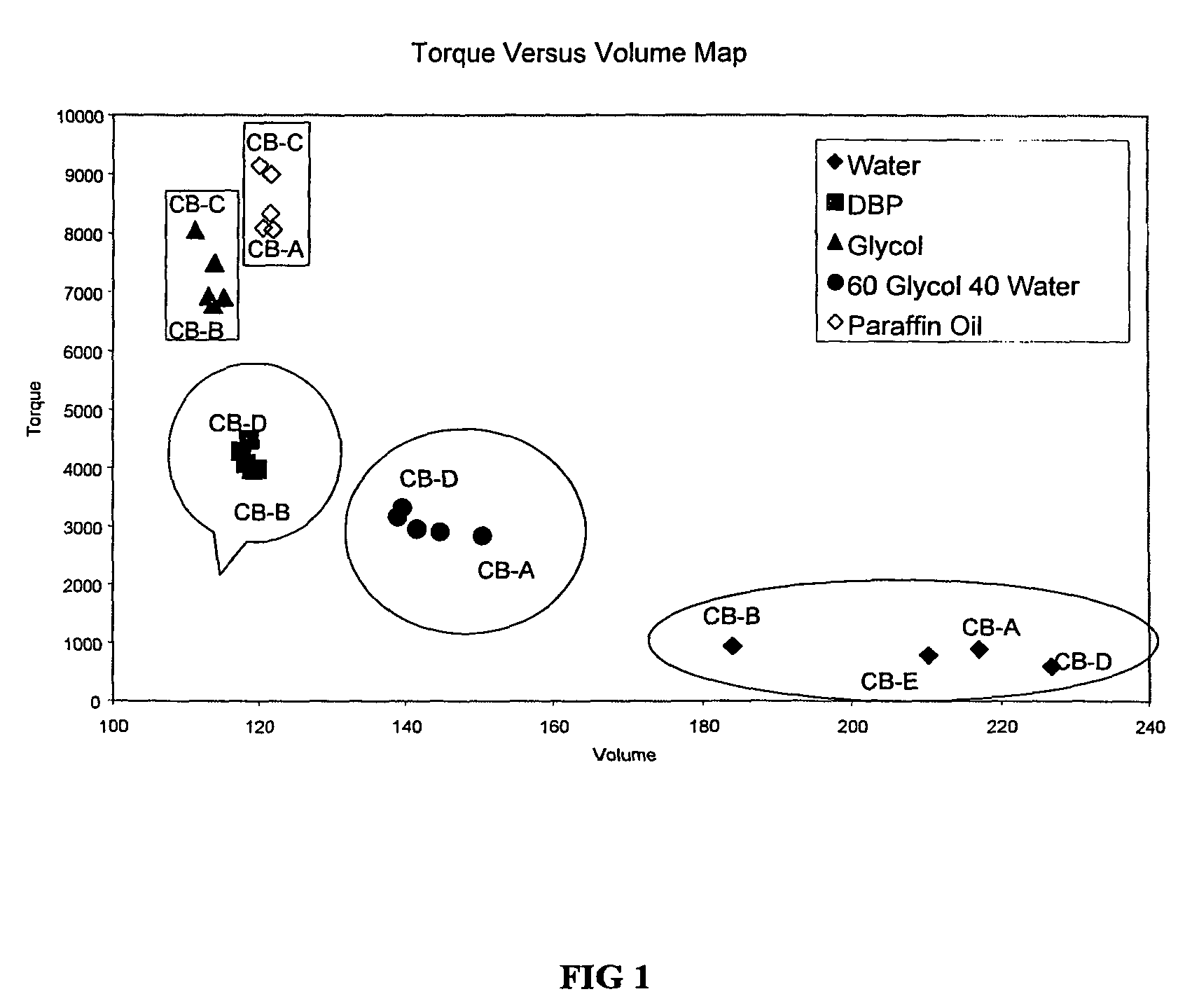

System and method for rheological characterization of granular materials

InactiveUS6971262B1Well representedPrevent slippingShaking/oscillating/vibrating mixersSubsonic/sonic/ultrasonic wave measurementAccelerometerEngineering

A system for characterizing rheological properties of granular material. A cylindrical measurement cup containing granular material is subject to a uniform vibration induced by a vibration exciter at a user-determined frequency. At the same time, a rotation or an oscillation of a rotating vane tool is performed within the powder and a response measured. Baffles are affixed to the inner wall of the measurement cup to prevent slippage of the granular material during measurement. An energy imparted to the system from the vibration exciter can be measured by an accelerometer coupled to the measurement cup. When sufficient vibrational energy is supplied to the system, a powder contained therein achieves a particle “temperature” sufficient such that the powder behaves as an ergodic system. The visco-elastic properties of the ergodic powder can be reproducibly measured in accordance with known methodology used in molecular fluids, where the powder “temperature” can be varied by changing the vibration frequency or amplitude.

Owner:WATERS INVESTMENTS

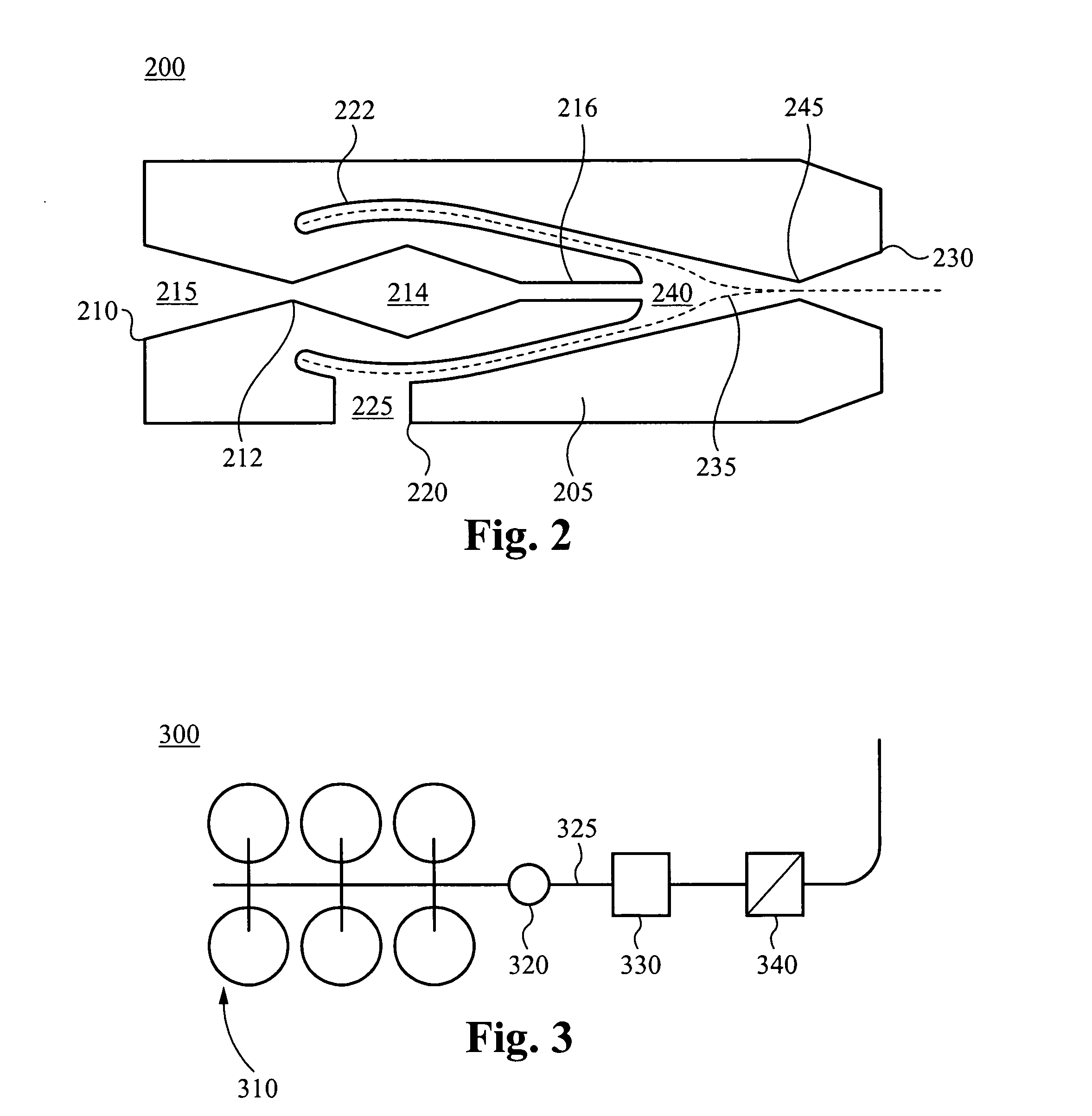

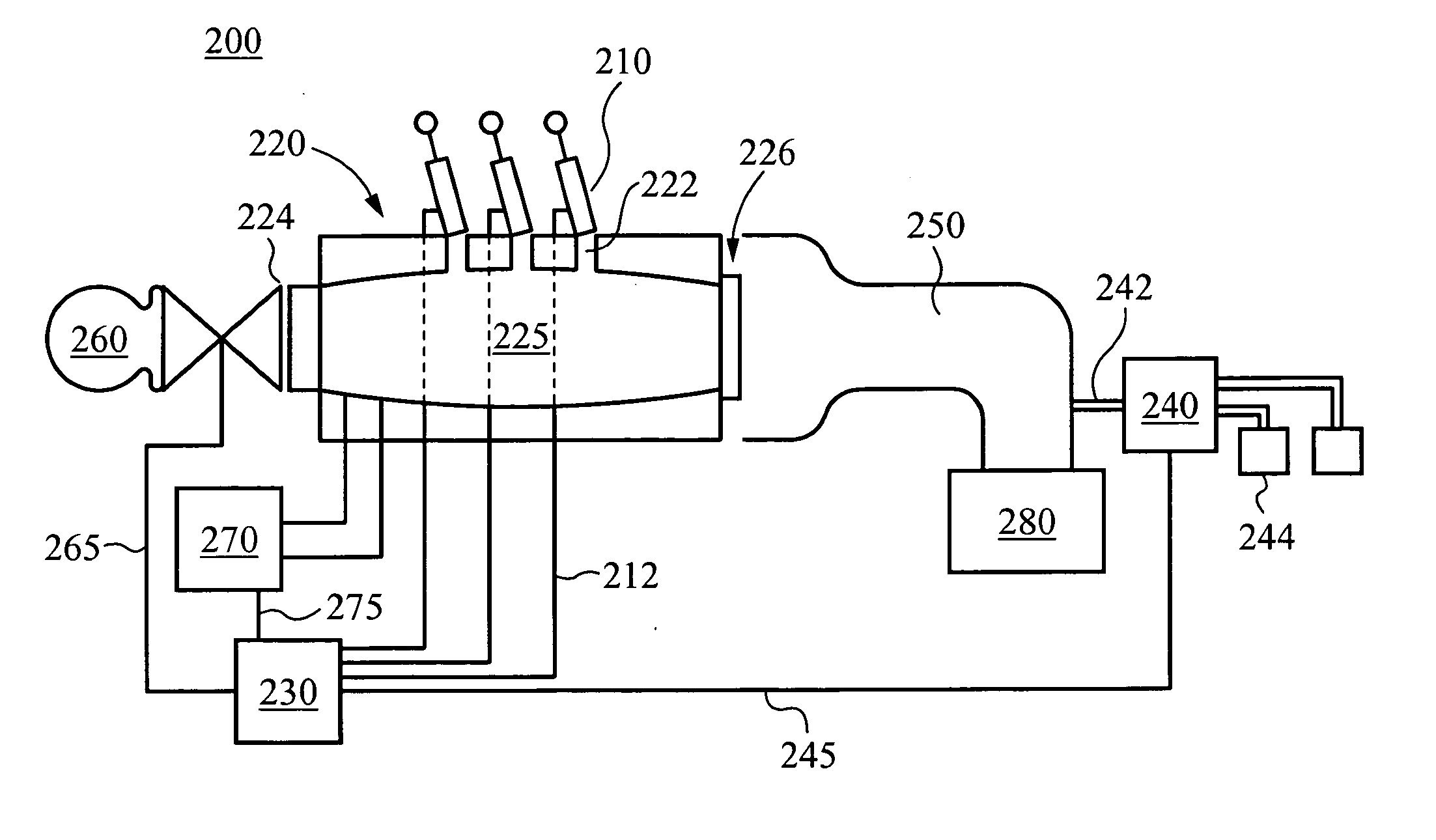

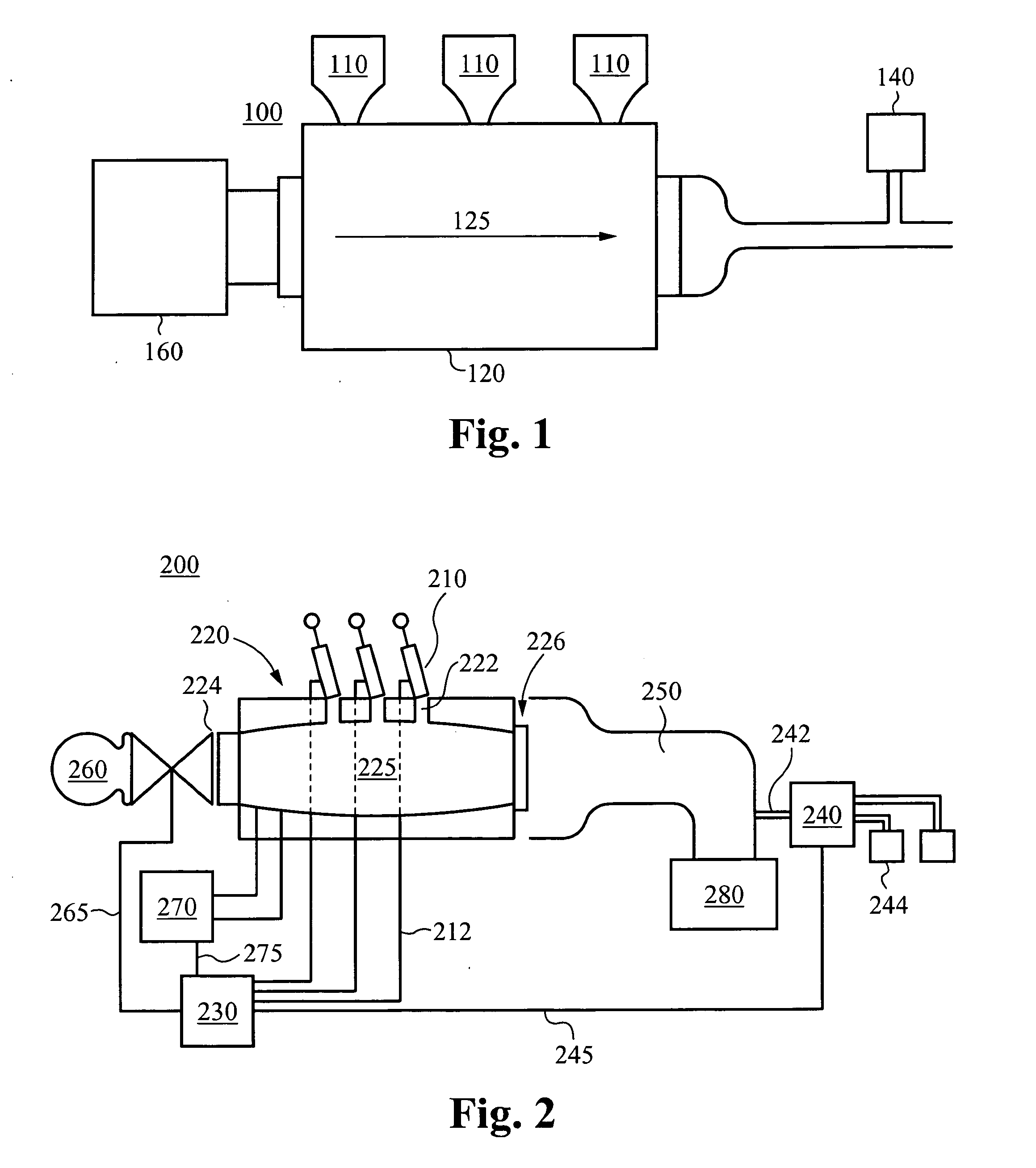

Analysis and sorting of motile cells

InactiveUS20140248656A1Easy to identifyEasy selectionBioreactor/fermenter combinationsBiological substance pretreatmentsMicrofluidic channelFlagellum motility

A method for sorting motile cells includes introducing an initial population of motile cells into an inlet port of a microfluidic channel, the initial population of motile cells having a first average motility; incubating the population of motile cells in the microfluidic channel; and collecting a sorted population of motile cells at an outlet port of the microfluidic channel. The sorted population of motile cells has a second average motility higher than the first average motility.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

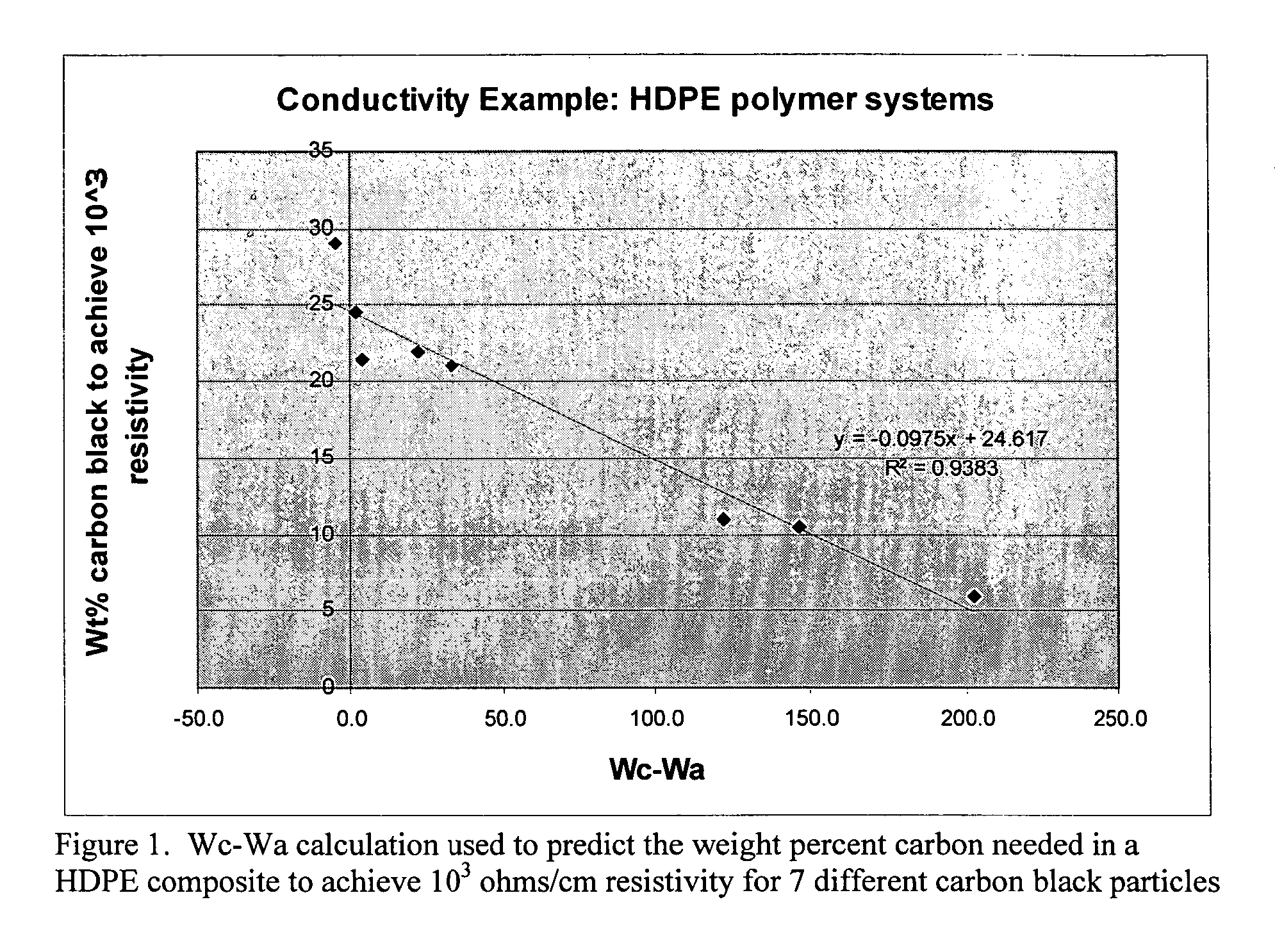

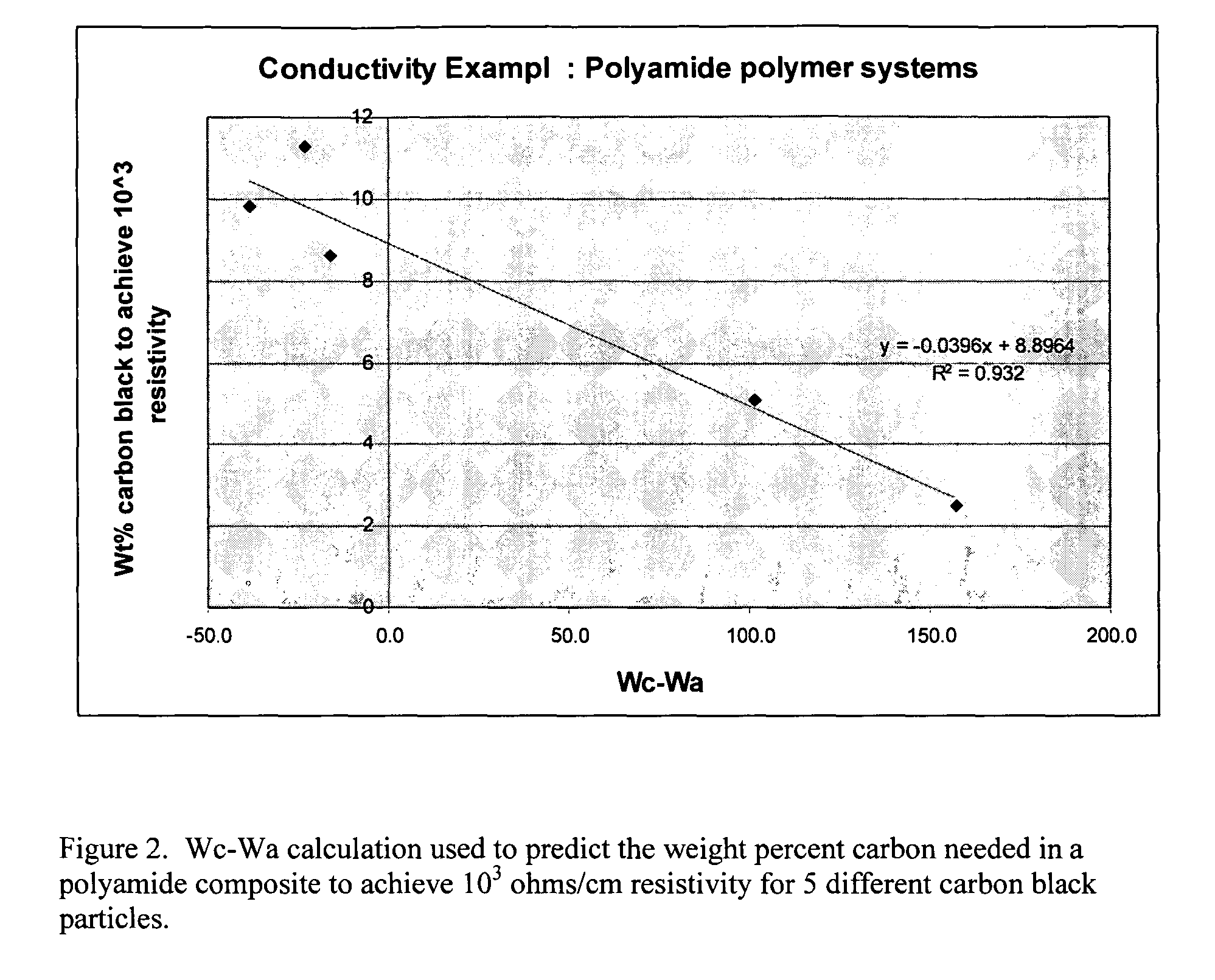

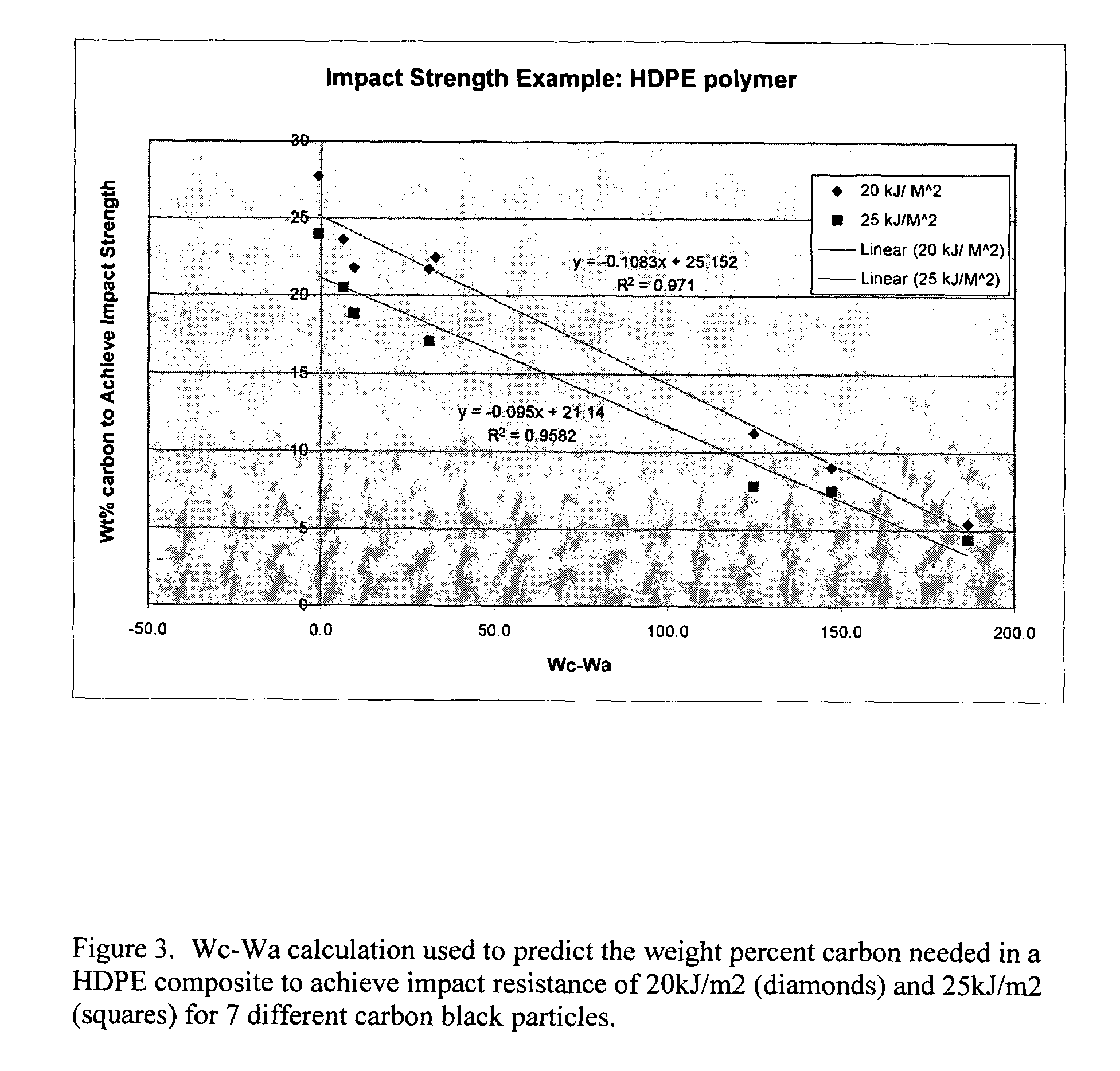

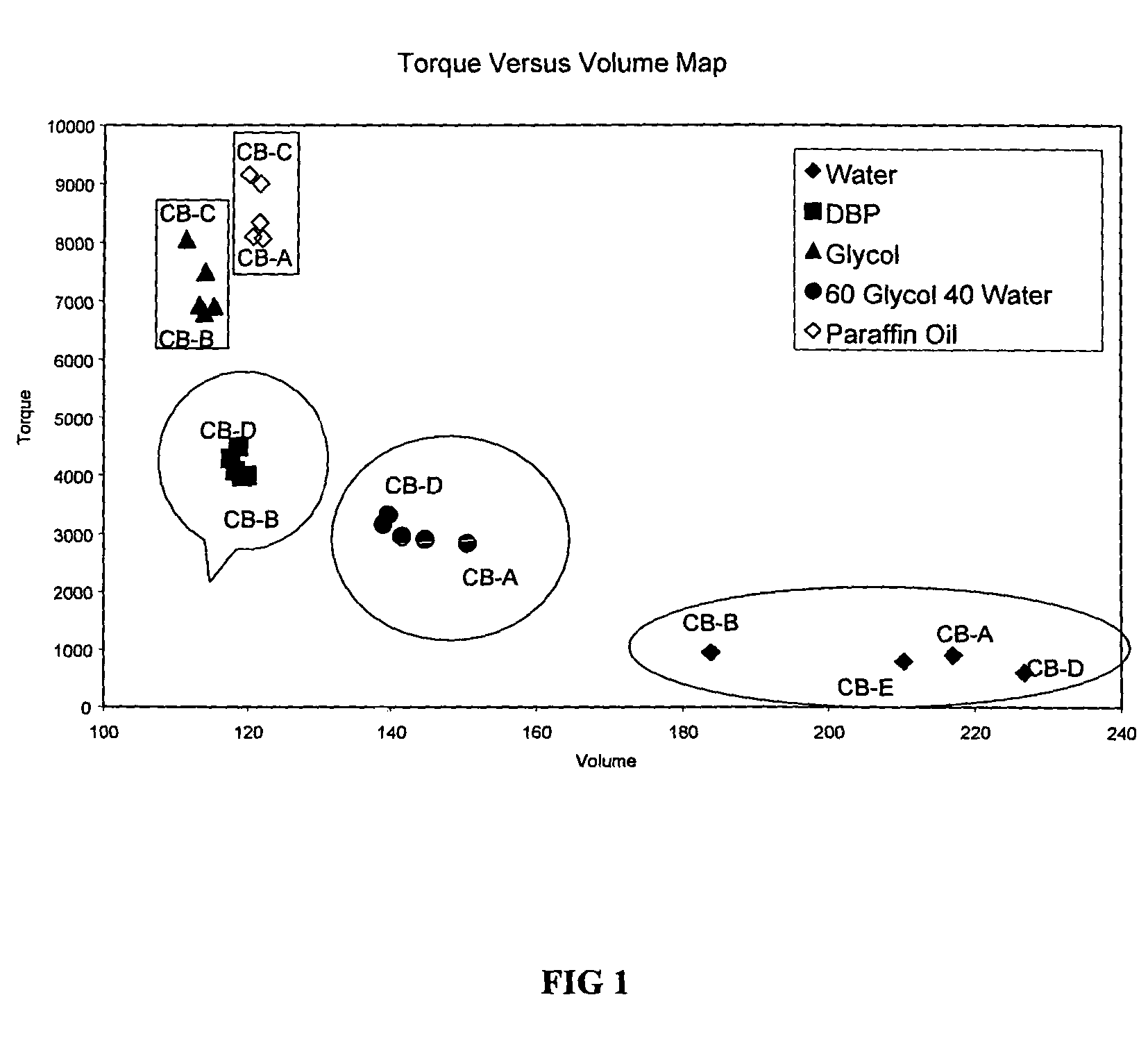

Methods of selecting and developing a particulate material

The present invention relates to a method of selecting and / or developing particulate material for a composition comprising the particulate material and a matrix by using at least one homogeneous interaction parameter alone or in combination with at least one heterogeneous interaction parameter. These parameters may comprise at least one interfacial potential property value, at least one value derived from an interfacial potential property value, at least one component of an interfacial potential property value, or combinations thereof for a particulate material and for the matrix. Process and performance maps, as well as methods for mapping, are also disclosed.

Owner:CABOT CORP

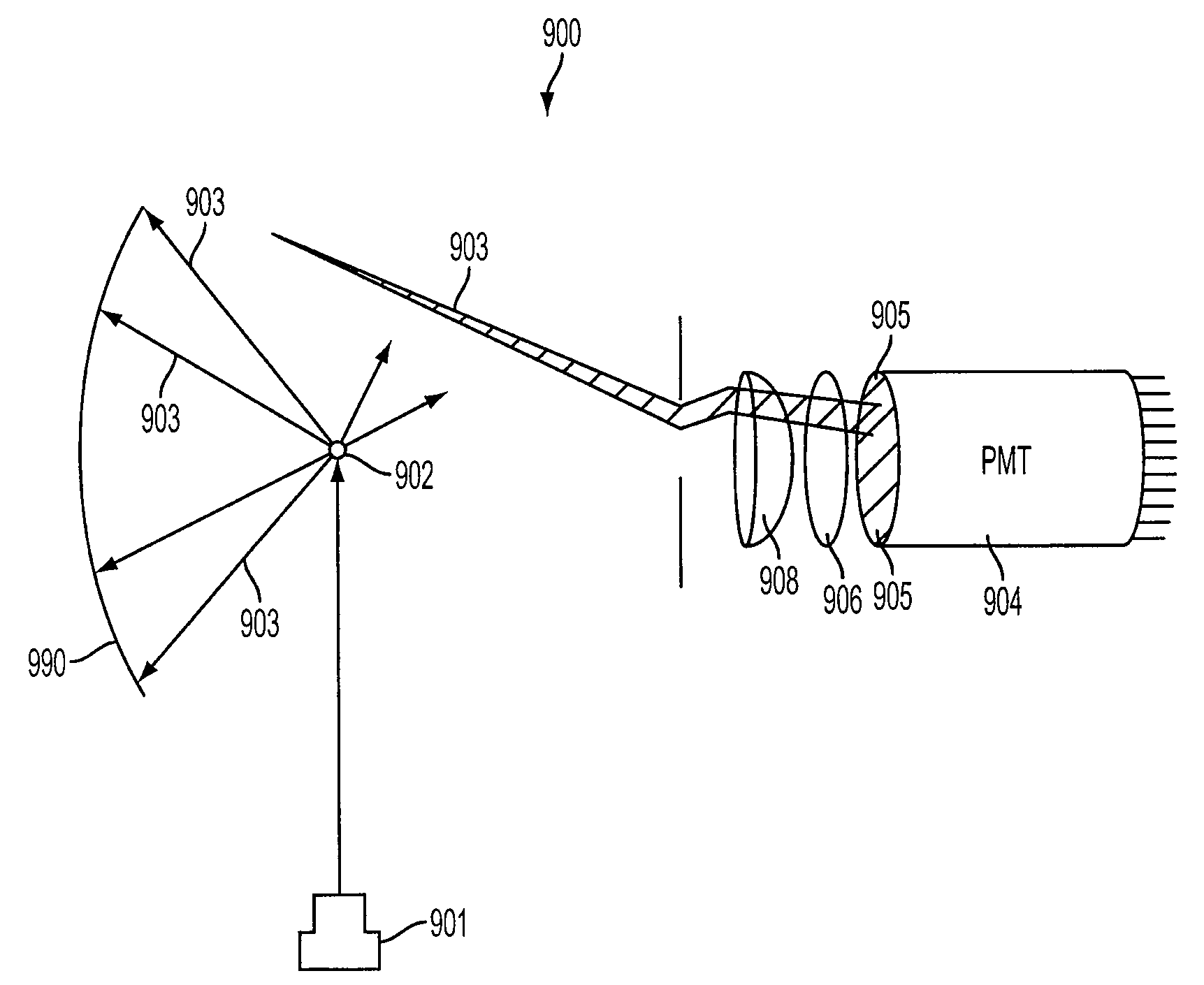

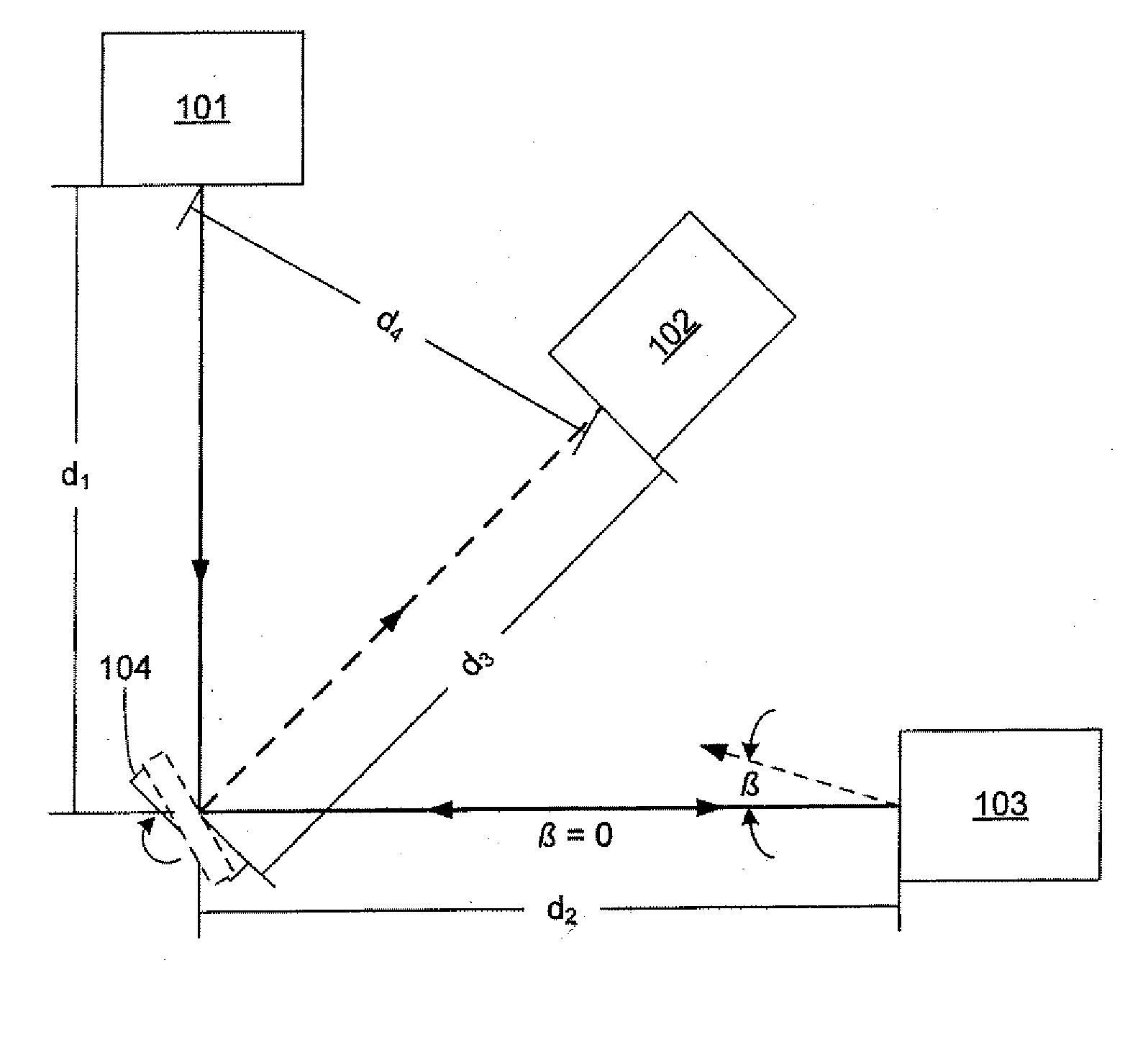

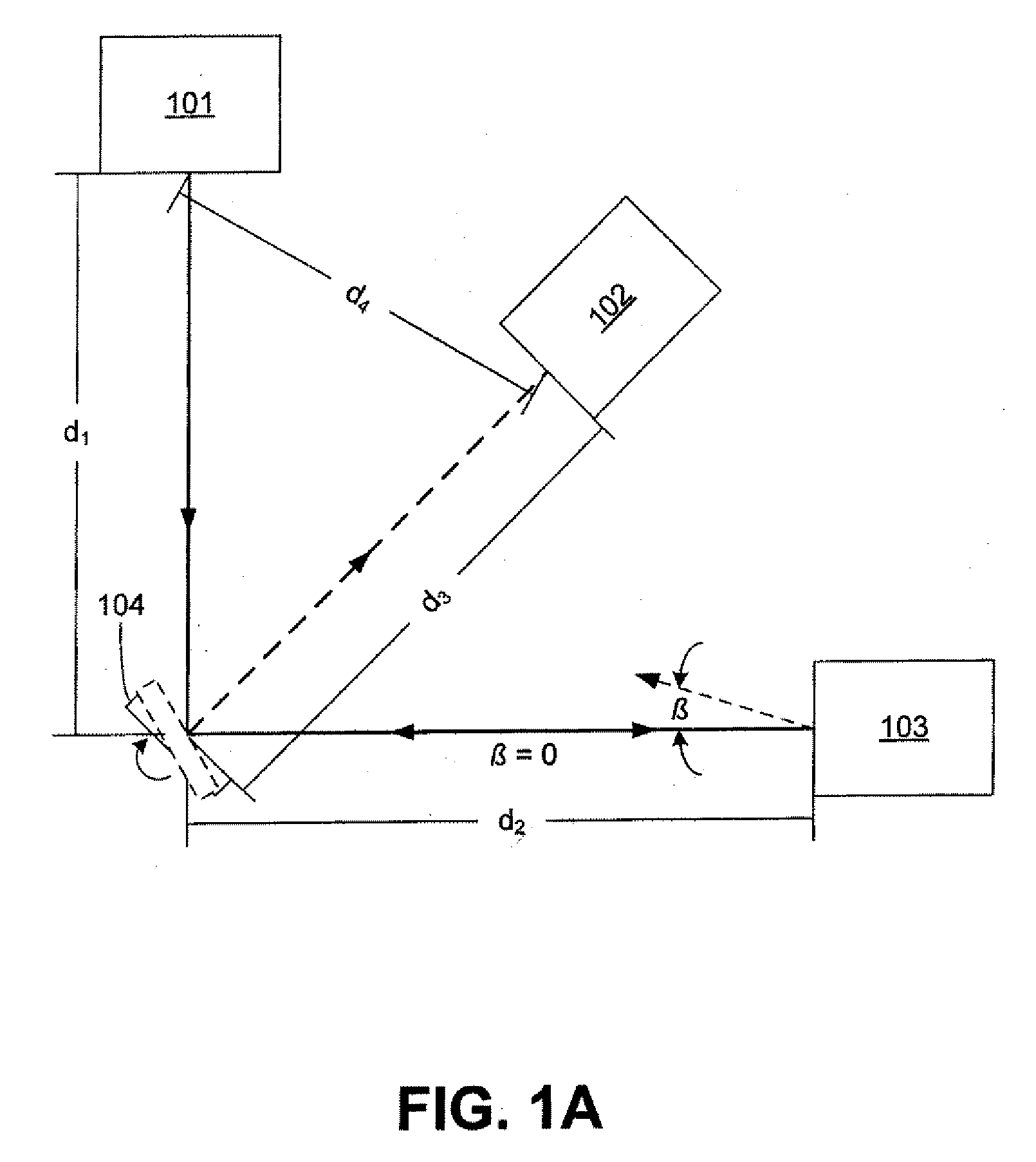

Systems for measuring backscattered light using finite speed of light

InactiveUS20100067007A1Optical rangefindersPolarisation-affecting propertiesPhysical separationSpeed of light

A system for measuring backscattered light from a sample is given. Light is output from a light source towards a rotating mirror, and then reflected by the rotating mirror towards the sample. The sample reflects backscattered light back towards the rotating mirror, which, having moved during the time it took for the light to propagate from the mirror to the sample and back, reflects the backscattered light to a detector located at a physical separation from the light source. The detected backscattered light may be analyzed to determine various properties of the sample.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Methods of providing product consistency

ActiveUS7776602B2Provide consistencyPigmenting treatmentFlow propertiesProperty valueParticulate material

The present invention relates to a method of providing product consistency of a particulate material or the product containing the same, by measuring and / or analyzing at least one interfacial potential property value of the particulate material. The method may be used as a QA / QC method to insure product consistency.

Owner:CABOT CORP

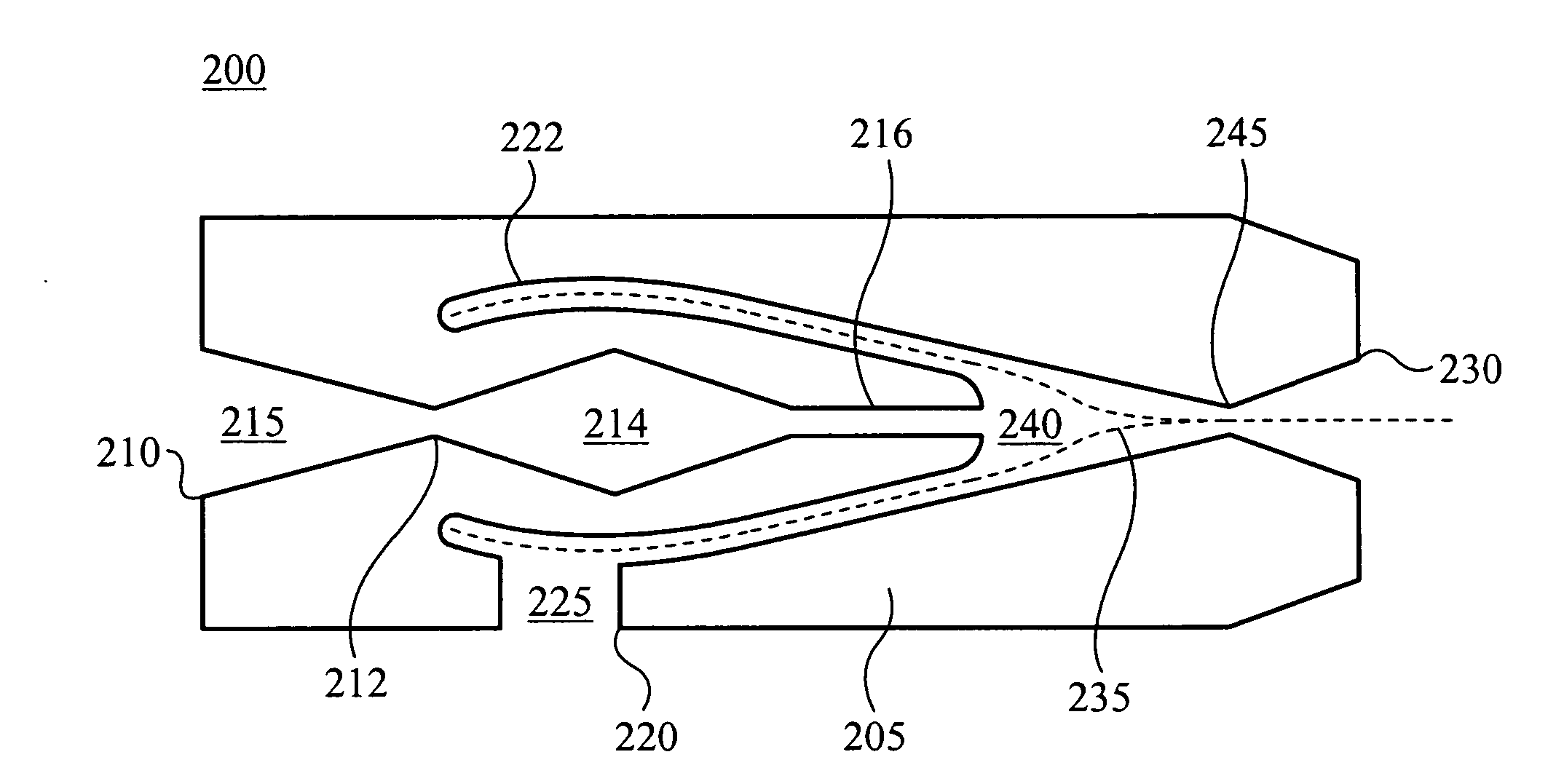

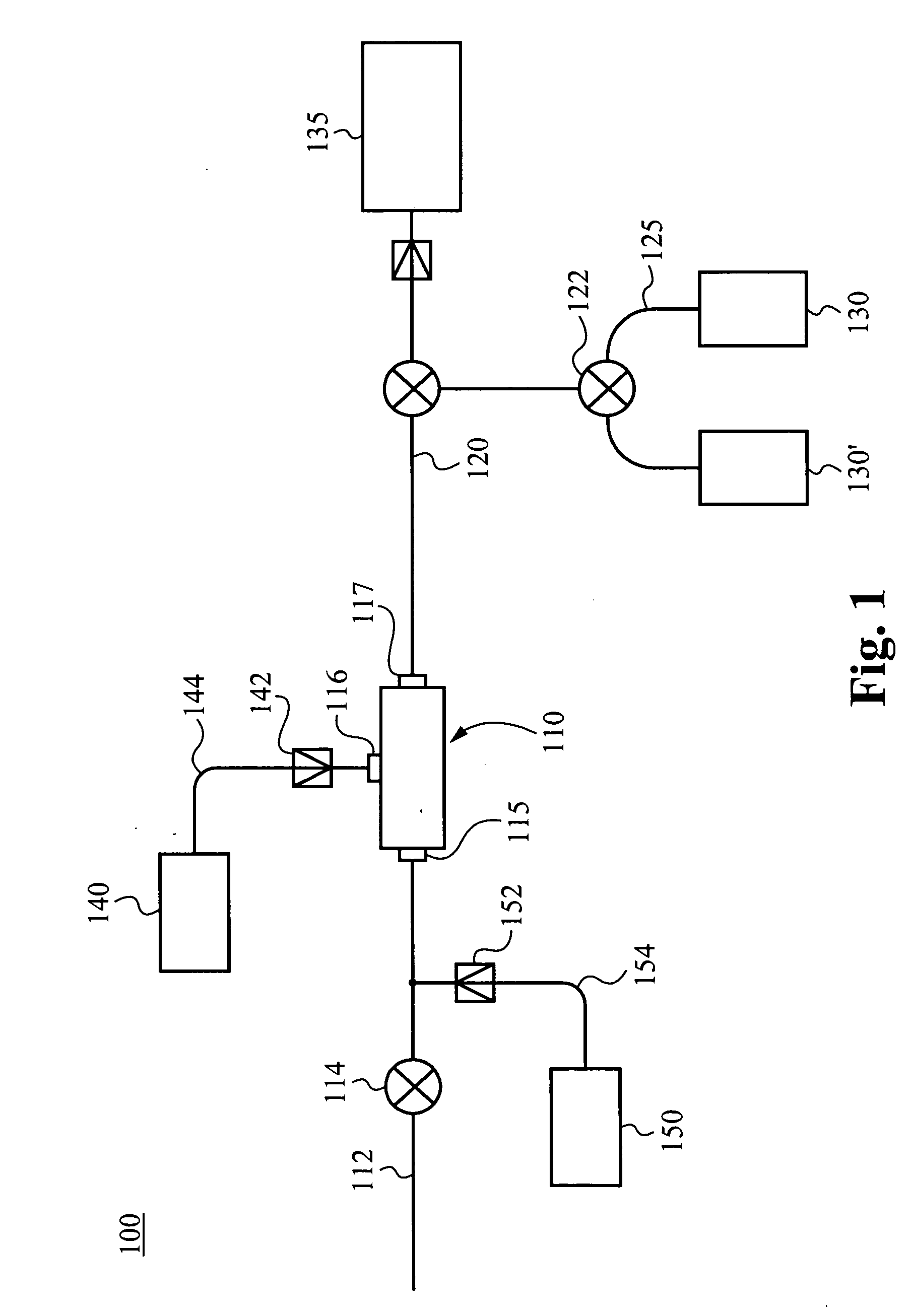

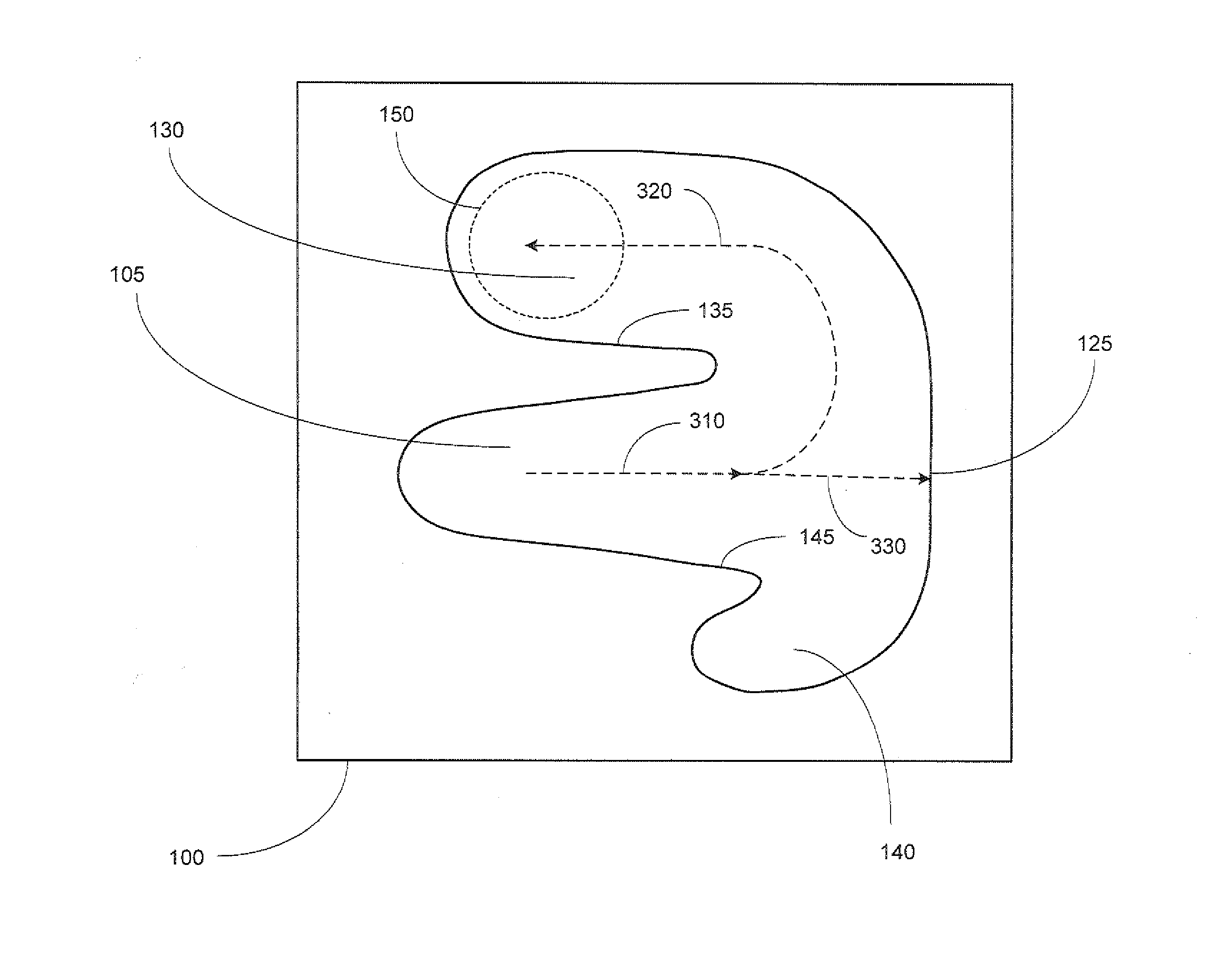

Nebulizer for Charged Aerosol Detection (CAD) System

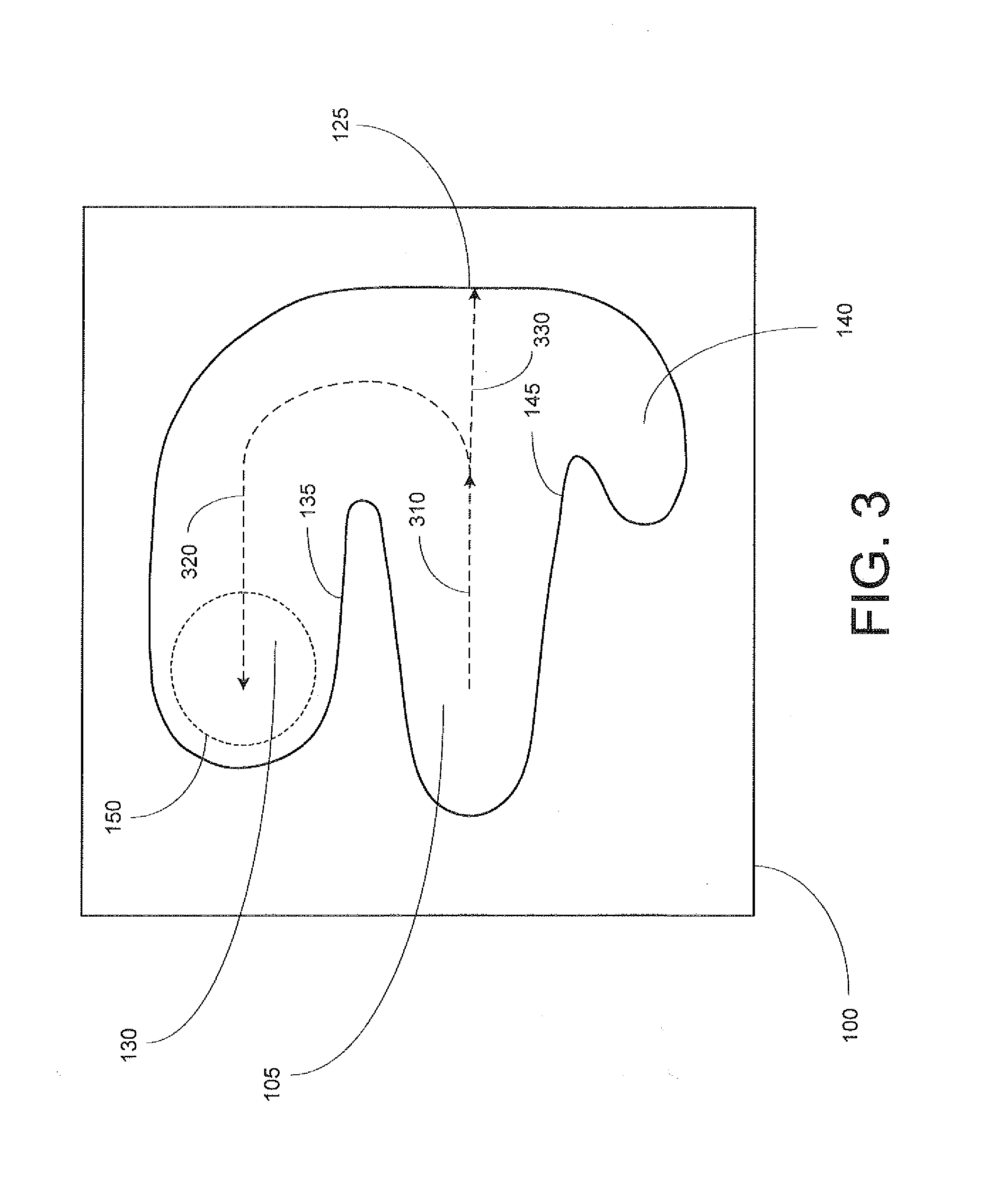

A nebulizer for a charged aerosol detection (CAD) system is disclosed. The nebulizer is provided with a spray emitter for generating a spray of droplets within a central region of a spray chamber. The central region is separated from an upper region by a horizontally projecting rib, which defines a passageway between the central and upper regions. The major direction of droplet travel within the upper region is substantially reversed with respect to the major direction of droplet travel within the central region. Larger droplets are unable to negotiate the turn from the central to upper regions and impinge on a rear surface of the spray chamber. Removal of larger droplets has the advantageous effect of enabling the detector to sense a smaller range of particle sizes, which establishes a relatively steady electrical current at the detector.

Owner:DIONEX CORP

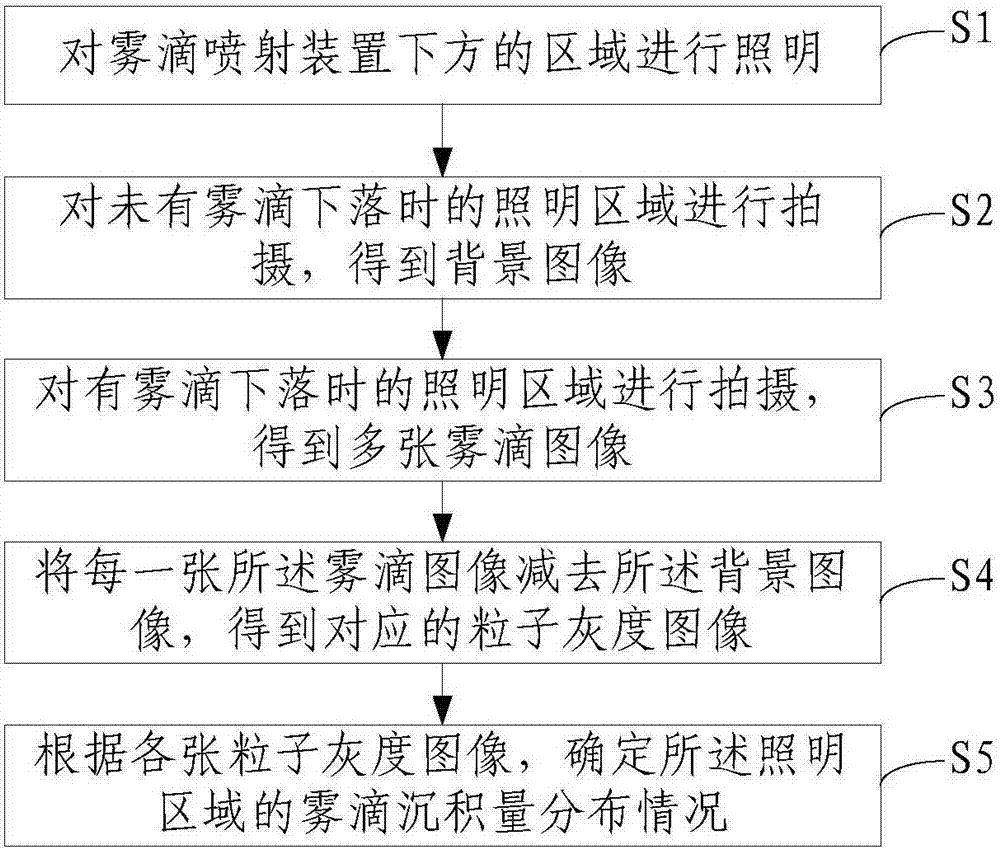

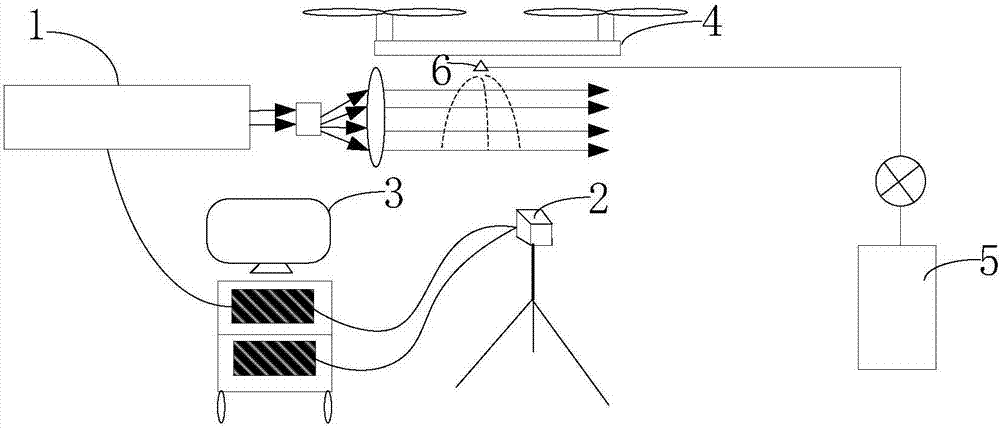

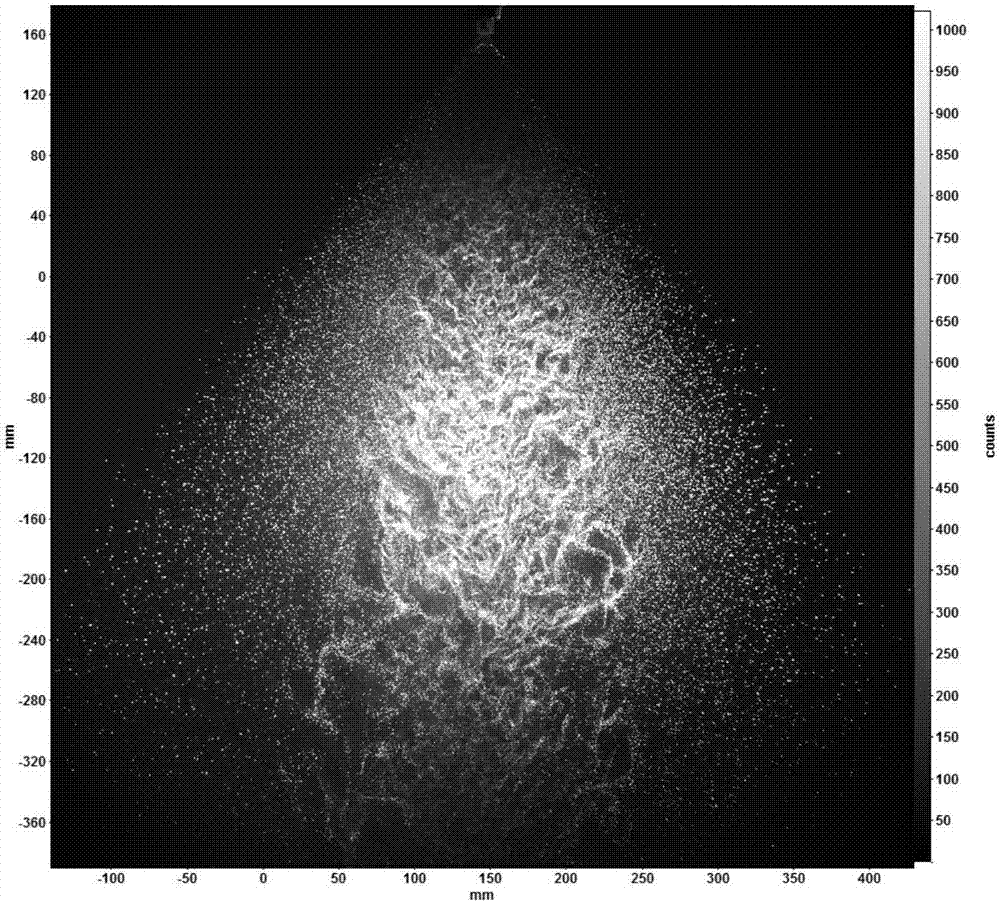

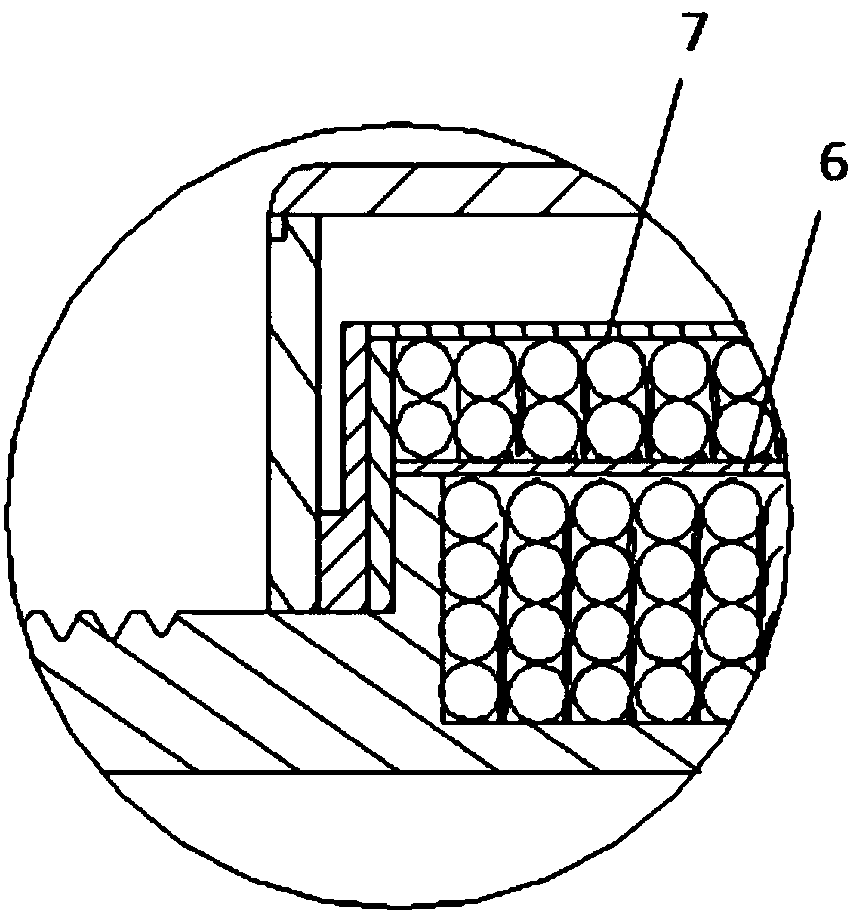

Method, device and system for measuring deposition distribution condition of fog drops

ActiveCN107063949AEliminate measurement effectsWill not interfere with the wind fieldImage enhancementImage analysisBackground imageStreamflow

The invention relates to a method, device and system for measuring the deposition distribution condition of fog drops. The method comprises the steps of illuminating an area at the lower part of a fog drop spray device; shooting the illuminated area when no fog drop falls off to obtain a background image; shooting the illuminated area when the fog drops fall off to obtain multiple fog drop images; subtracting the background image from each fog drop image to obtain a corresponding particle grey image; and determining the distribution condition of the fog drop deposition amount of the illuminated area according to various particle grey images. According to the method, device and system for measuring the deposition distribution condition of the fog drops, motion of a wind farm and the fog drops is not disturbed, and the method, the device and the system are suitable for small-range, long-term and large-flow spray tests, and are especially suitable for analysis of the deposition distribution of the fog drops under the influence of downwash flow of a rotor.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

Methods and devices for sorting cells and other biological particulates

An optical pattern-driven light induced dielectrophoresis (DEP) apparatus and separation methods are described which provide for the manipulation of particles or cells and selection based on traits correlated with the DEP response. Embodiments of the apparatus use DEP electric field patterns in combination with microfluidic laminar flows to measure response, separate, segregate and extract particles from heterogeneous mixtures according to the relative response of the particles to one or more DEP fields without damaging living cells. The methods are particularly suited for selecting and extracting the best sperm and embryo candidates based on fitness for use with existing artificial reproduction procedures and excluding defective or non-viable gametes.

Owner:RGT UNIV OF CALIFORNIA

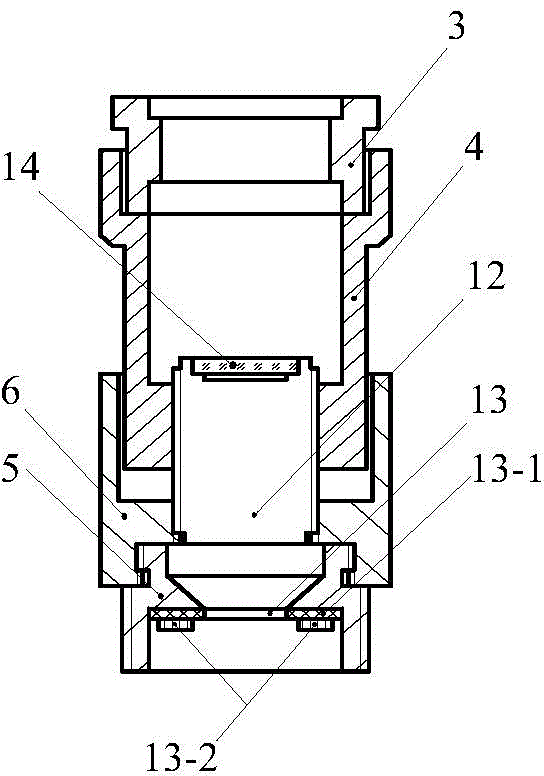

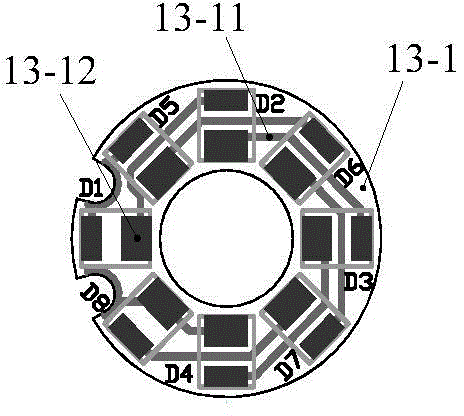

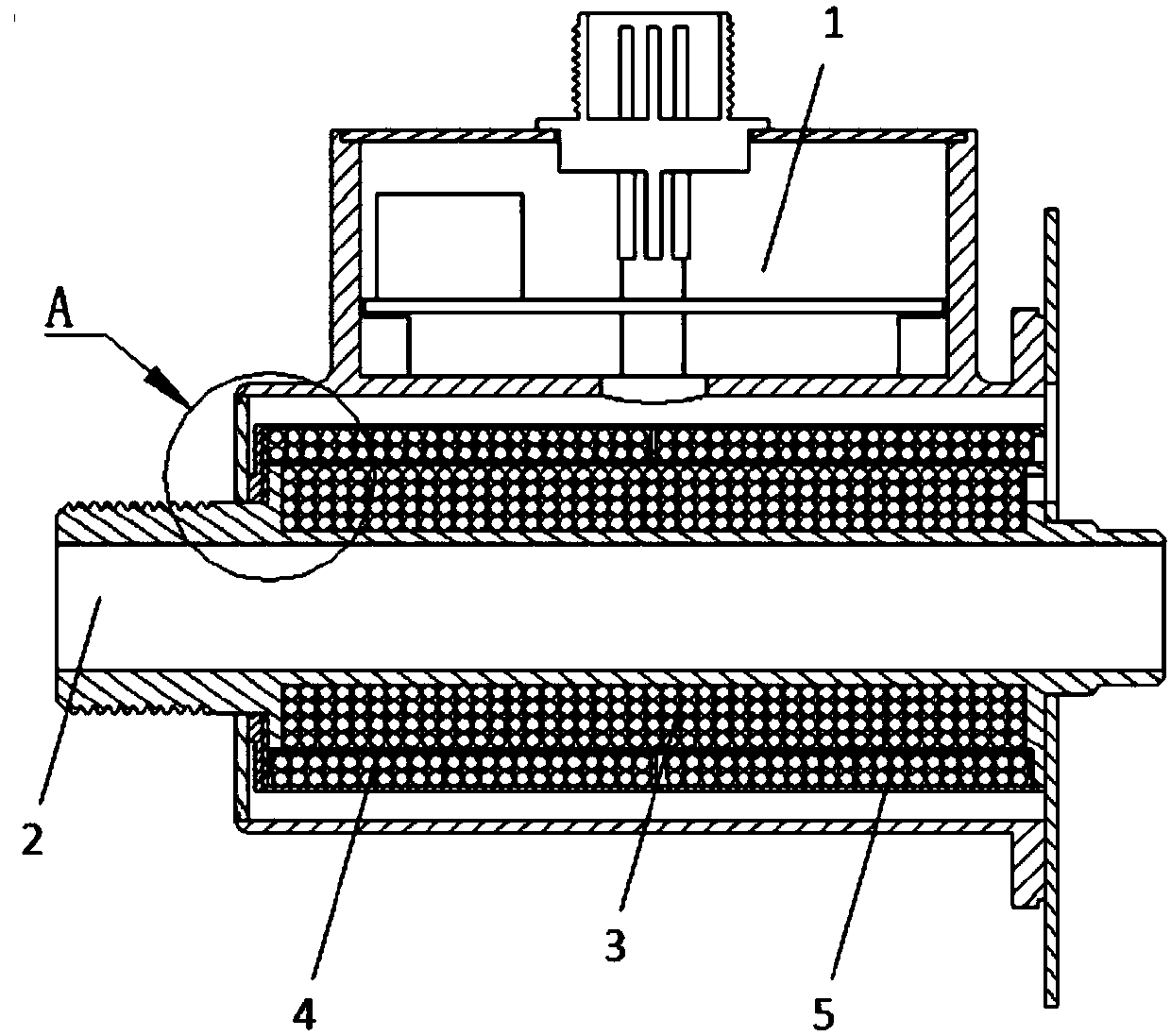

Magnetic induction particle detection device and concentration detection method

ActiveCN107907455AShorten the lengthEasy to installParticle suspension analysisParticle and sedimentation analysisVoltage amplitudeMetal particle

The invention provides a magnetic induction particle detection device and a concentration detection method. The detection device comprises a signal detection system, a detection pipeline, an excitation coil and a positive even number of induction coils, wherein the excitation coil is connected with a signal processing system and wound on the detection pipeline; and the induction coils are connected with the signal processing system and are sequentially and reversely wound on the excitation coil. The device can facilitate preparation and installation and can improve the detection precision. Themethod comprises the following steps: S1, obtaining an output signal of the signal detection system to obtain a voltage amplitude change condition; and S2, detecting the metal particle concentrationaccording to the obtained voltage amplitude change condition. Through the method, the accuracy of calculation can be improved.

Owner:FATRI UNITED TESTING & CONTROL QUANZHOU TECH CO LTD

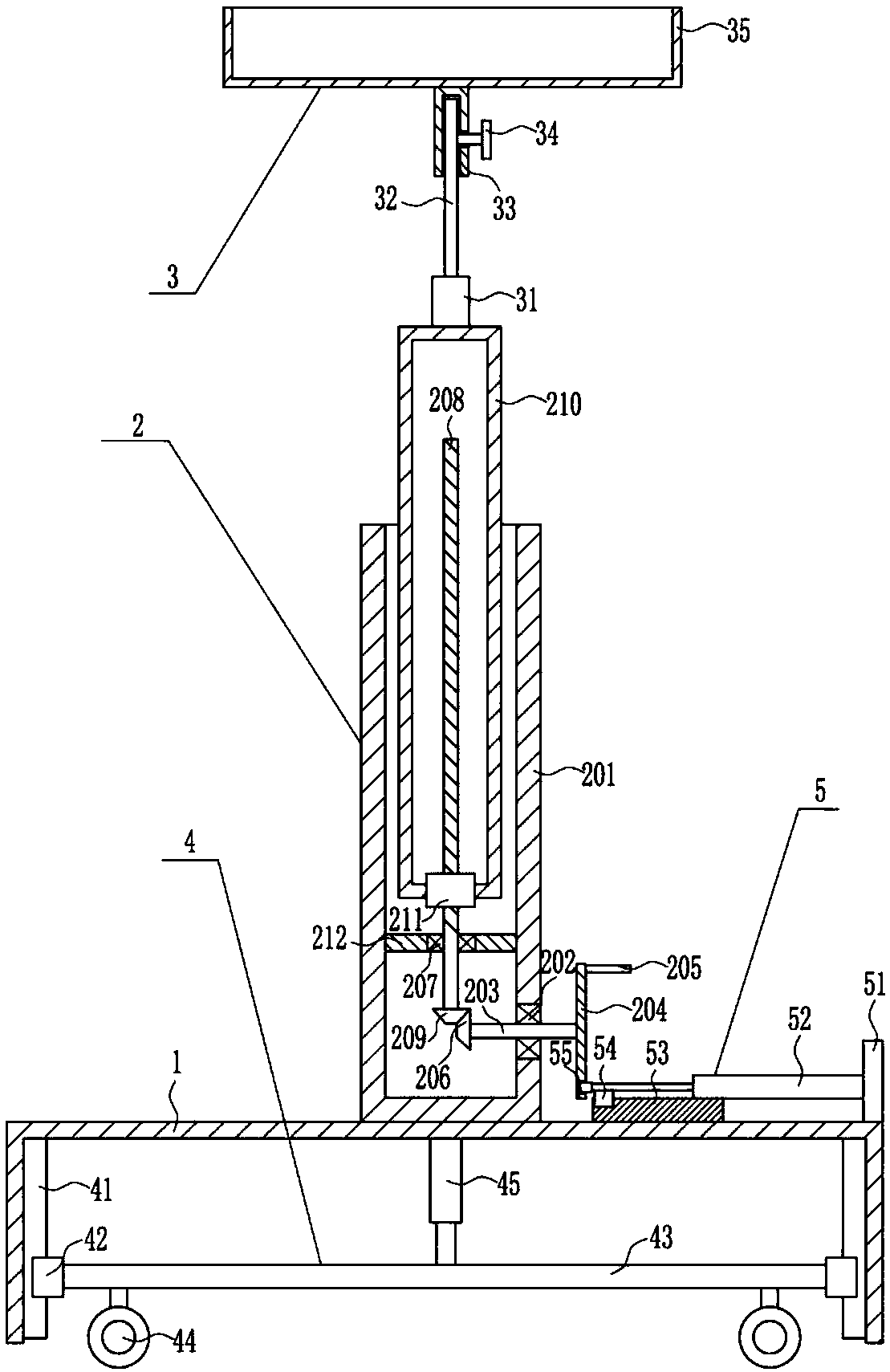

Device and method for bulk granule collision falling point distribution and collision recovery coefficient measurement

PendingCN107144500AInvestigating material hardnessParticle and sedimentation analysisEngineeringMechanical engineering

The invention relates to the field of agriculture, in particular relates to a bulk granule collision testing device. A device for bulk granule collision falling point distribution and collision recovery coefficient measurement comprises a material falling mechanism, a collision mechanism, a falling material collecting mechanism and an analysis mechanism, wherein the collision mechanism is positioned below the material falling mechanism, the material falling mechanism is used for placing a to-be-measured granule from a high place into the collision mechanism, and the material falling mechanism is provided with a material falling hole having a size matched with the size of the to-be-measured granule; the collision mechanism is used for colliding the granule flowing out from the material falling mechanism into the falling material collecting mechanism, the falling material collecting mechanism is positioned at the material falling place of the granule after collision, and the falling material collecting mechanism is used for separately collecting the granules coming out of the collision mechanism by; and the analysis mechanism is used for quantitative analysis of the granules in the material falling mechanism. The device and the method disclosed by the invention are convenient for collision falling point distribution and collision recovery coefficient measurement of bulk granules. The structure is simple, and the operation is convenient.

Owner:ZHEJIANG UNIV OF TECH

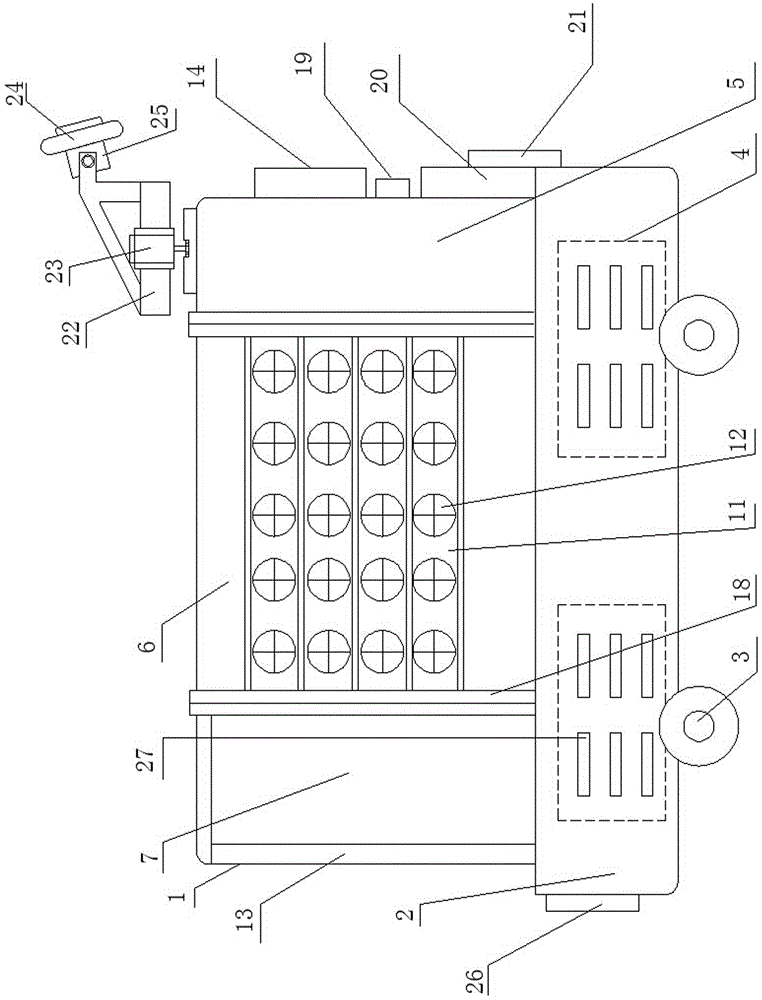

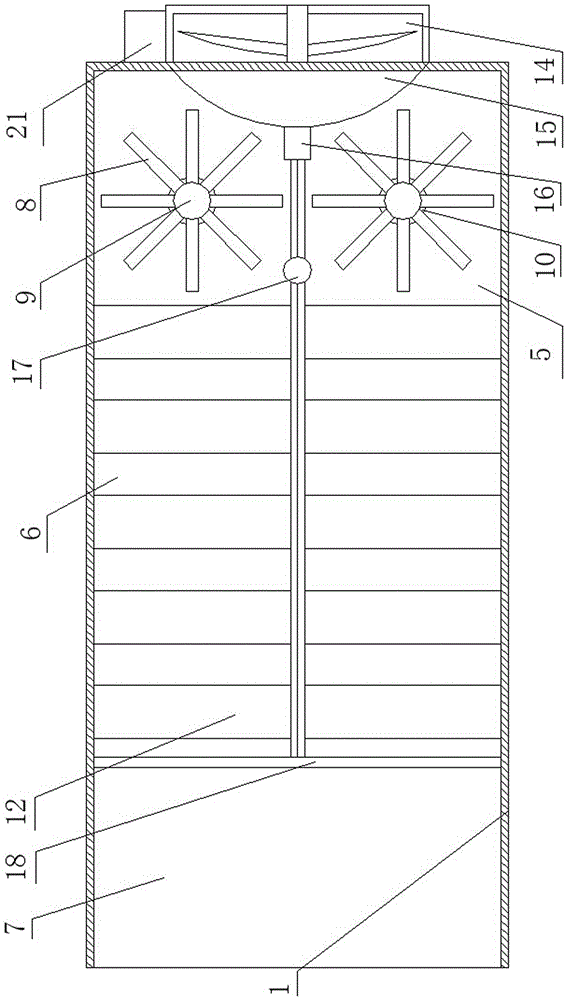

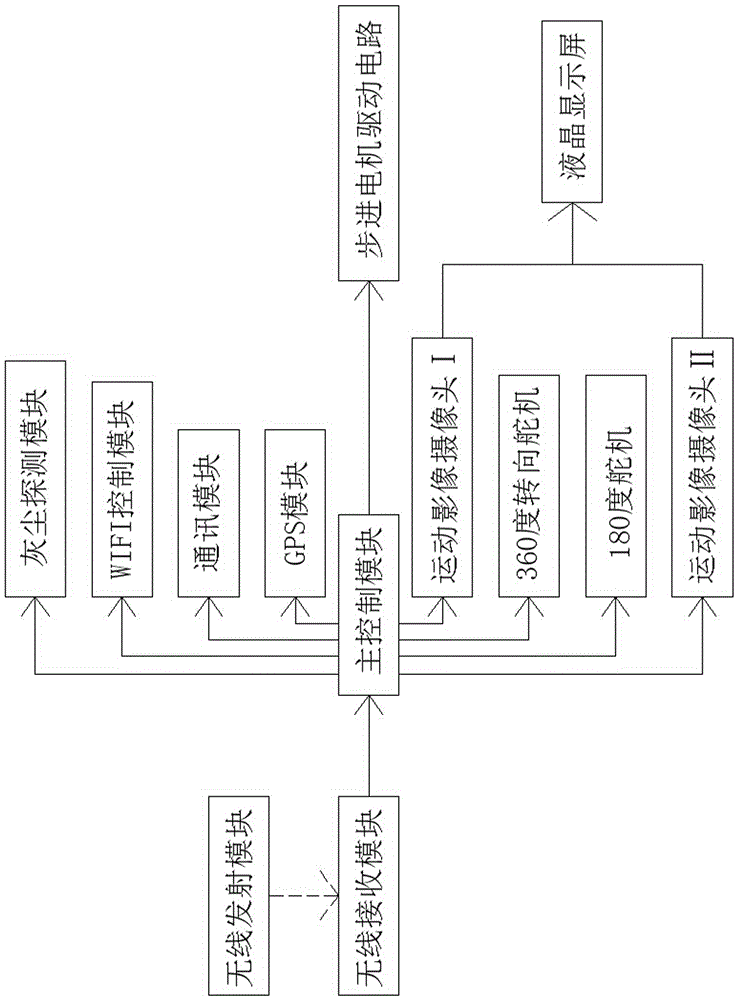

Smoke dust purification system

ActiveCN106512586AEasy to useIncrease profitDispersed particle filtrationTransportation and packagingEngineeringMuffler

The invention relates to a smoke dust purification system. A fan is arranged at the head end of a filter chamber I; an air bag is arranged inside the head end of the filter chamber I; the air bag is matched with the fan for use; a pulse generator is arranged on the air bag and is connected with an electromagnetic valve through a lead wire; the electromagnetic valve is connected to a partition between a filter chamber II and an ash collection bin through a lead wire; a muffler is arranged below the fan; a motor is arranged below the muffler; a dust detector is arranged on the right side of the motor I; a motion image camera I is arranged at the tail end of a shell body; a 360-degree steering engine is arranged above the shell body; the 360-degree steering engine is controlled to rotate through a motor II; a 180-degree steering engine is arranged above the 360-degree steering engine; a motion image camera II is arranged on the 180-degree steering engine; a heat dissipation opening is formed in an open compartment and is matched with a battery pack for use. The smoke dust purification system is used for purifying smoke dust.

Owner:NORTH CHINA INST OF SCI & TECH

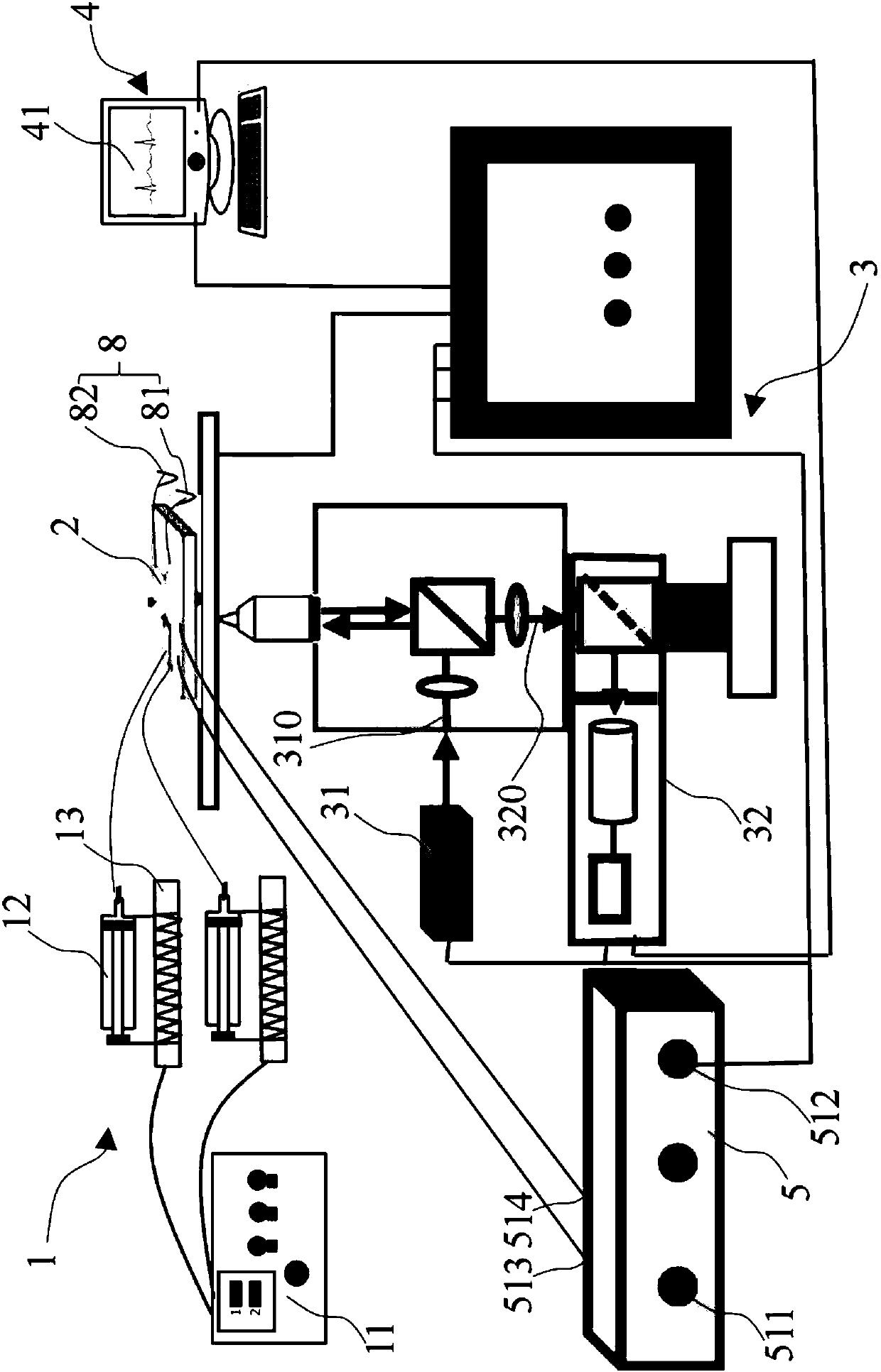

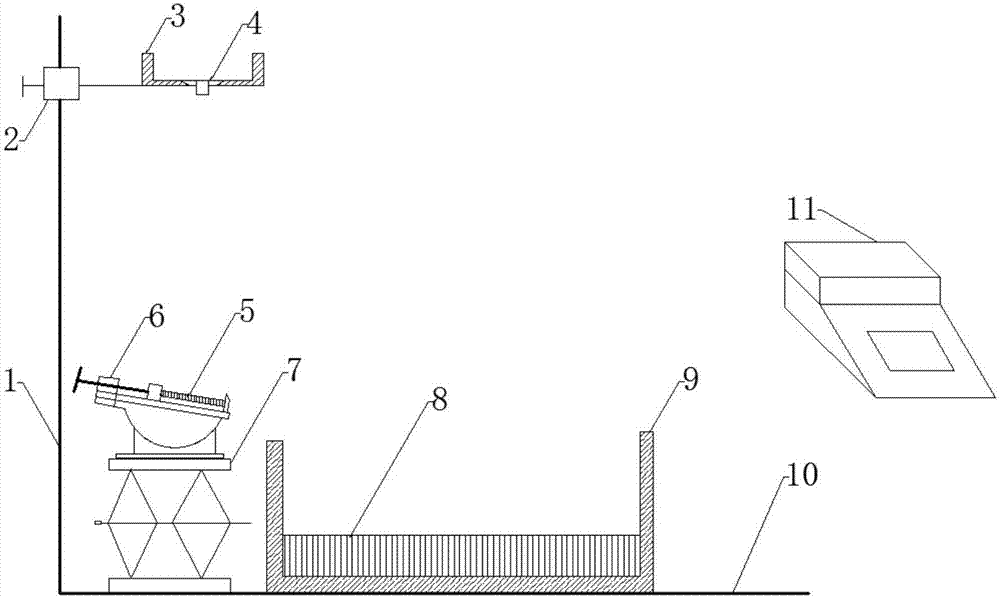

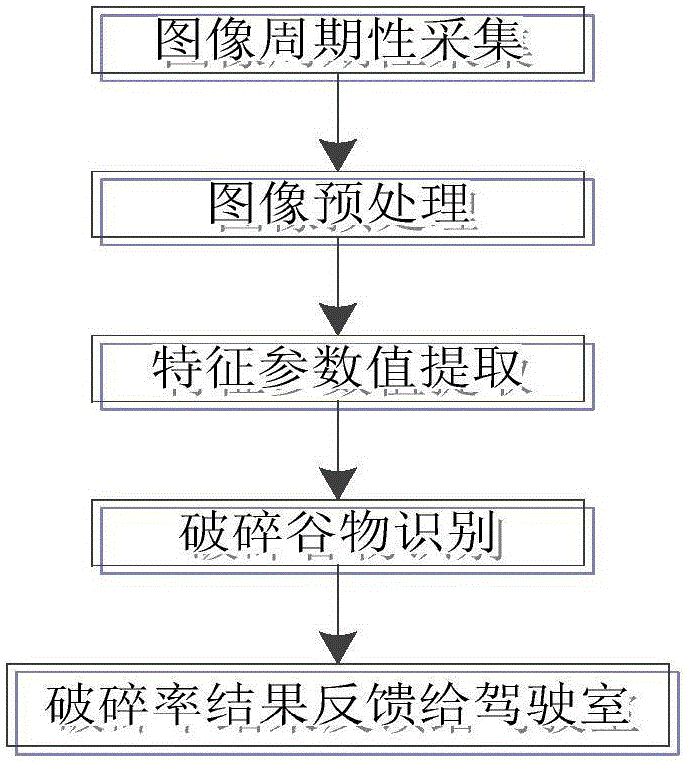

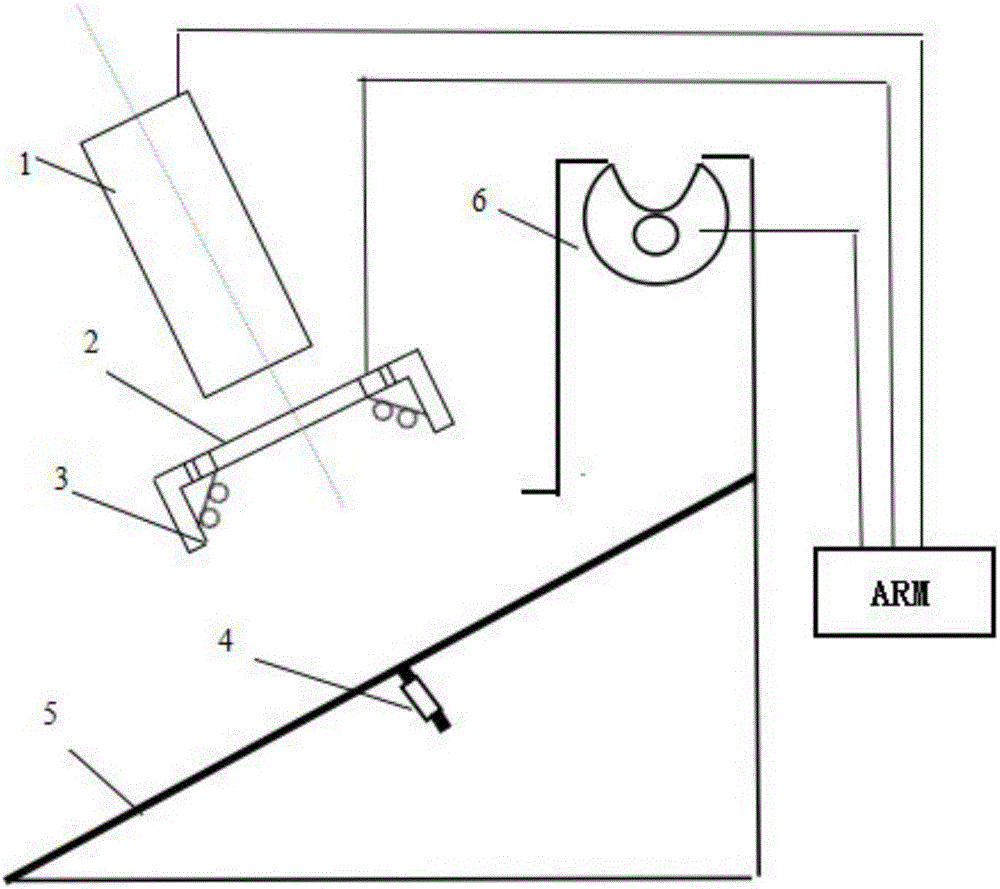

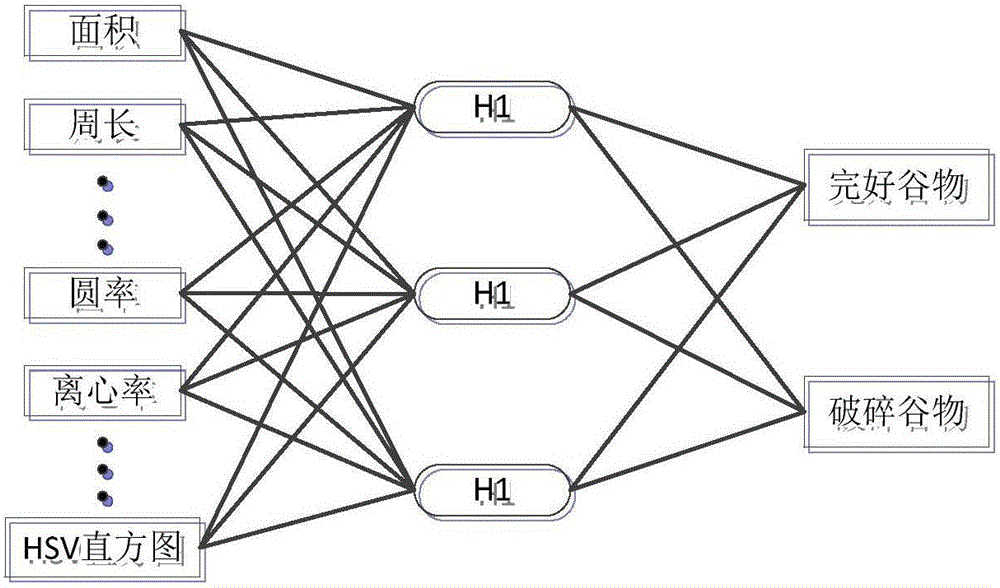

On-line monitoring system and method for crushing of cereals in grain tank of combine harvester

InactiveCN105806751AImprove broken rateBroken rateParticle and sedimentation analysisMonitoring systemData acquisition

The invention provides an on-line monitoring system for crushing of cereals in a grain tank of a combine harvester. The system comprises a cereal conveying mechanism, an image shooting unit and a processor ARM; the cereal conveying mechanism comprises a roller, an oblique conveying belt and a vibration exciter; the roller is located at a grain tank outlet, the oblique conveying belt is located below the roller, and the vibration exciter is mounted at the bottom of the oblique conveying belt; the image shooting unit is located above the oblique conveying belt in the direction perpendicular to the oblique conveying belt; the image shooting unit comprises a CCD camera, a lens, a light source and a data collection card in sequence; the image shooting unit is used for shooting the cereals periodically and transmitting shot images to the processor ARM; the roller, the CCD camera and the light source are all connected with the processor ARM; the processor ARM is used for controlling the roller, the CCD camera and the light source to be switched on and off and analyzing and processing the shot images transmitted by the image shooting unit. Through the device, the cereals can be monitored on line in real time, operation is easy and convenient, and the accuracy rate is high.

Owner:JIANGSU UNIV

Methods of specifying or identifying particulate material

The present invention relates to a method of specifying a batch, lot, or shipment of particulate material by using at least one interfacial potential property value to specify the batch, lot, or shipment of particulate material. A method of representing a grade, brand, or type of particulate material is also disclosed. At least one morphological value and / or chemical value may also be included. The values can be included on a product specification sheet.

Owner:CABOT CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com