On-line monitoring system and method for crushing of cereals in grain tank of combine harvester

A technology of combine harvester and monitoring system, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of high accuracy, inability to obtain grain breakage in real time, etc., and achieve the effects of fast accuracy, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

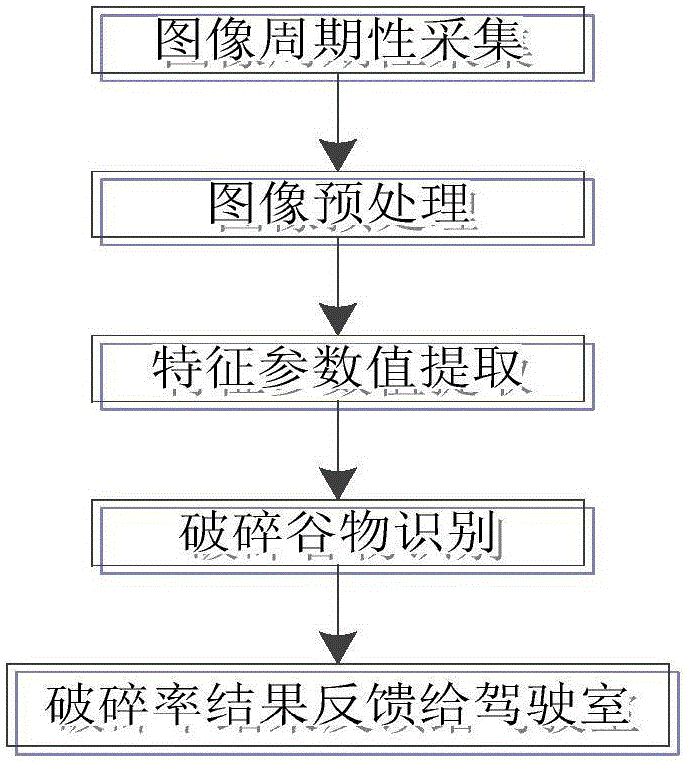

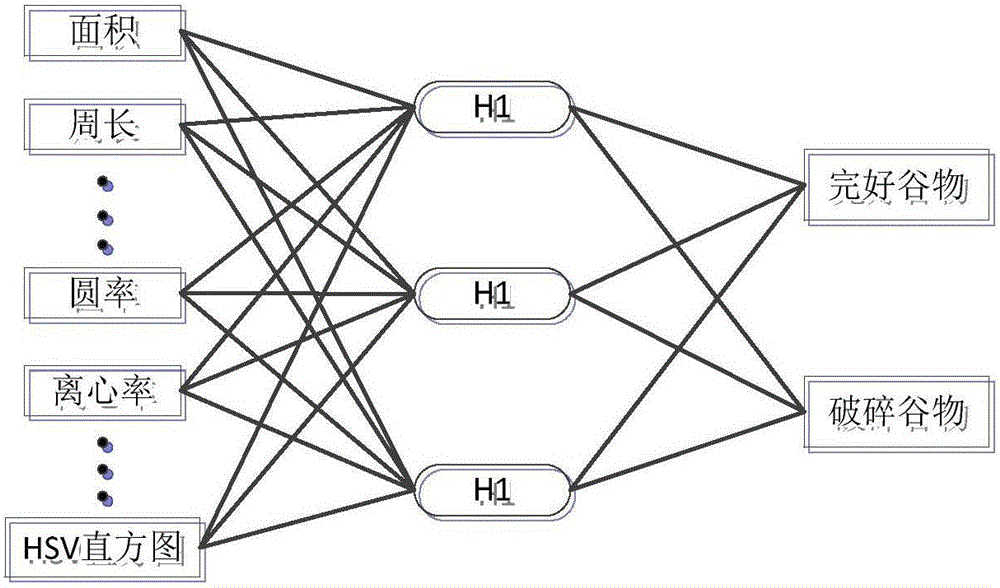

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

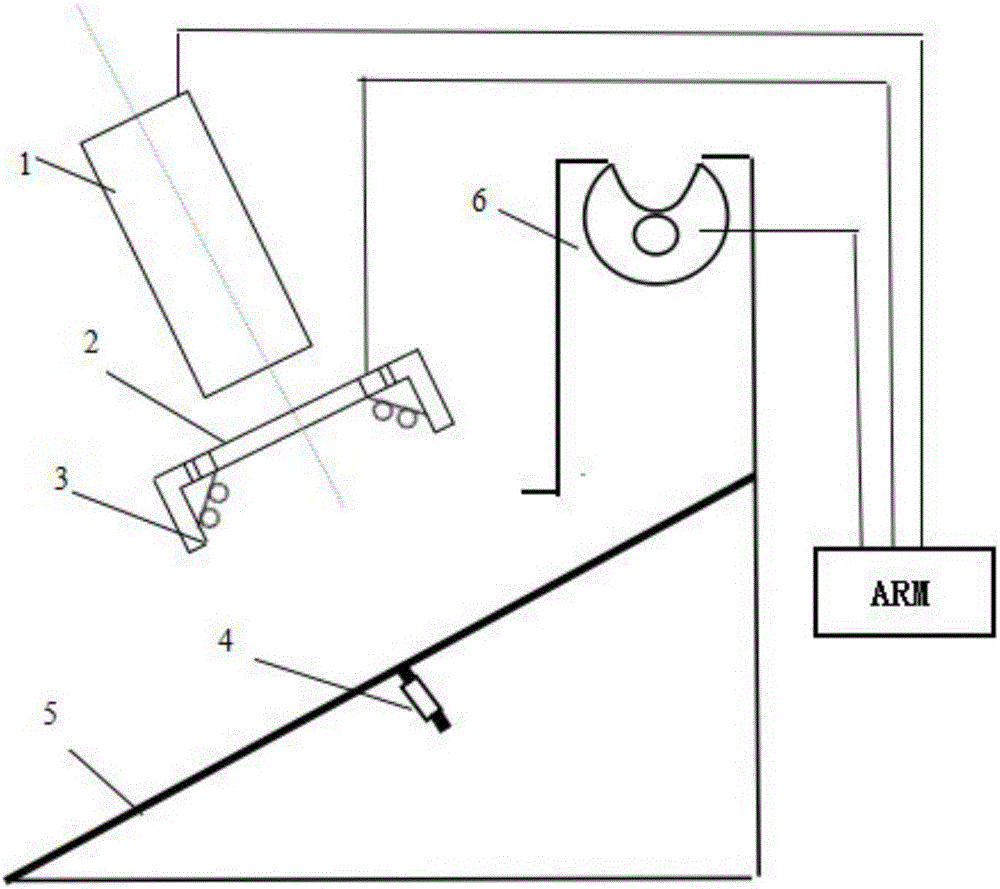

[0033] Such as figure 1 with figure 2 As shown, an on-line monitoring system for grain breaking in the grain tank of a combine harvester, including a grain conveying mechanism, an image capture unit and a processor ARM; the whole device system is located in the grain tank of a combine The broken rate can judge the working condition of the combine harvester.

[0034] The grain conveying mechanism comprises a drum 6, an inclined conveyor belt 5 and an exciter 4; the drum 6 is located at the outlet of the granary, the entrance of the inclined conveyor belt 5 is located below the drum 6, and the bottom middle position of the inclined conveyor belt 5 is equipped with an exciter 4; The grain conveying mechanism is used for conveying the grain in the grain box to the photogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com