Visual online image ferrography imaging system

An imaging system and ferrography technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve problems such as uneven illumination, limited imaging range, and difficulty in extracting wear particle feature information, so as to enhance the acquisition ability, Effects of improving image quality and increasing illumination range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

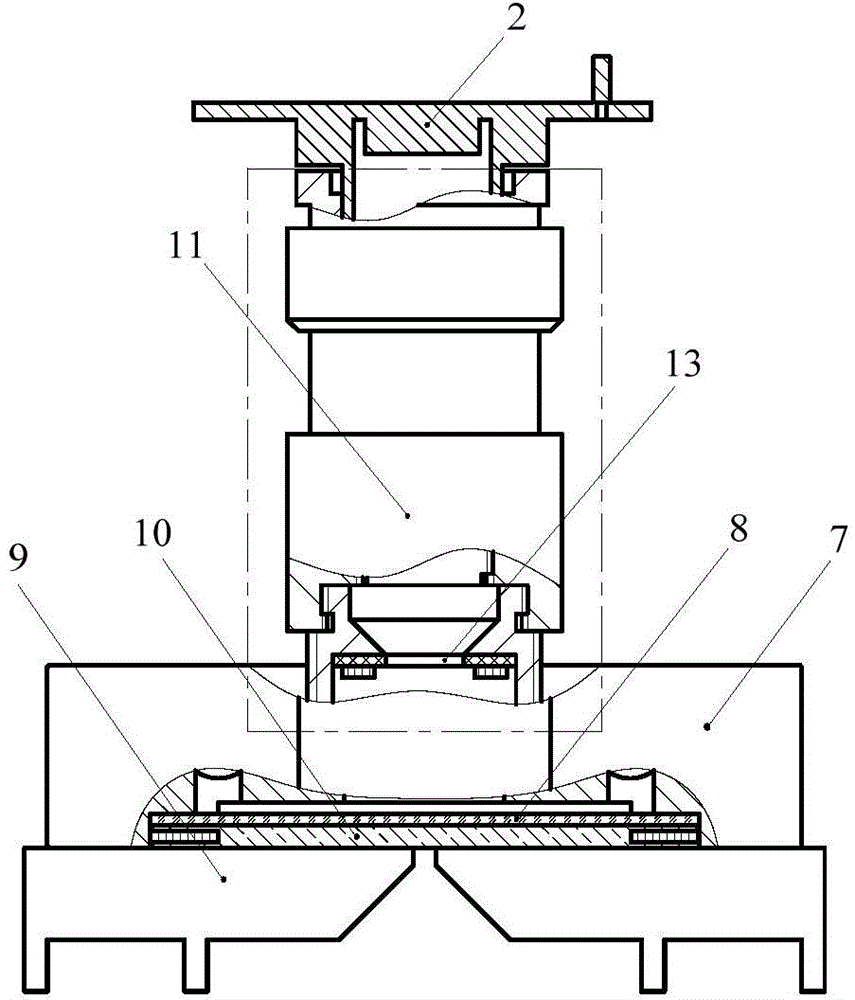

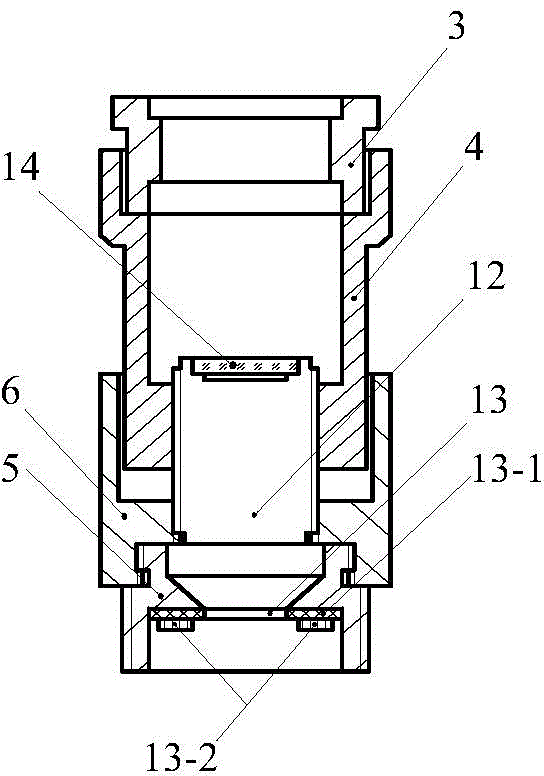

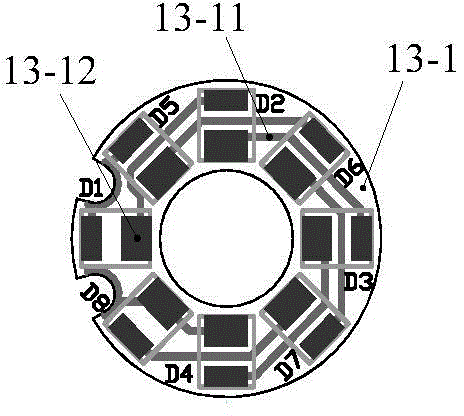

[0022] refer to figure 1 , the online image visible ferrography imaging system of the present invention comprises image acquisition device 2, lens seat, focusing mechanism 11, LED annular reflective light source 13 and two-color ultra-thin LED backlight source 10, and image acquisition device 2 passes lens seat cover Connected and fixed on the upper part of the focusing mechanism 11, the bottom of the focusing mechanism 11 is connected with the oil flow channel 7 in the ferrogram through threads, and the LED ring-shaped reflective light source 13 is fixedly connected with the threaded lens barrel 5 in the focusing mechanism 11, two-color The ultra-thin LED backlight source 10 is bonded to the deposited glass slide 8 of the oil flow channel 7 in the ferrogram.

[0023] refer to figure 2 , it should be noted that the image acquisition device 2 is an M12 interface CCD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com