Smoke dust purification system

A technology for dust purification and outer casing, which is applied in chemical instruments and methods, dispersed particle filtration, instruments, etc., and can solve problems such as health hazards for workers, pollution of tunnels, and difficulty in dispersing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

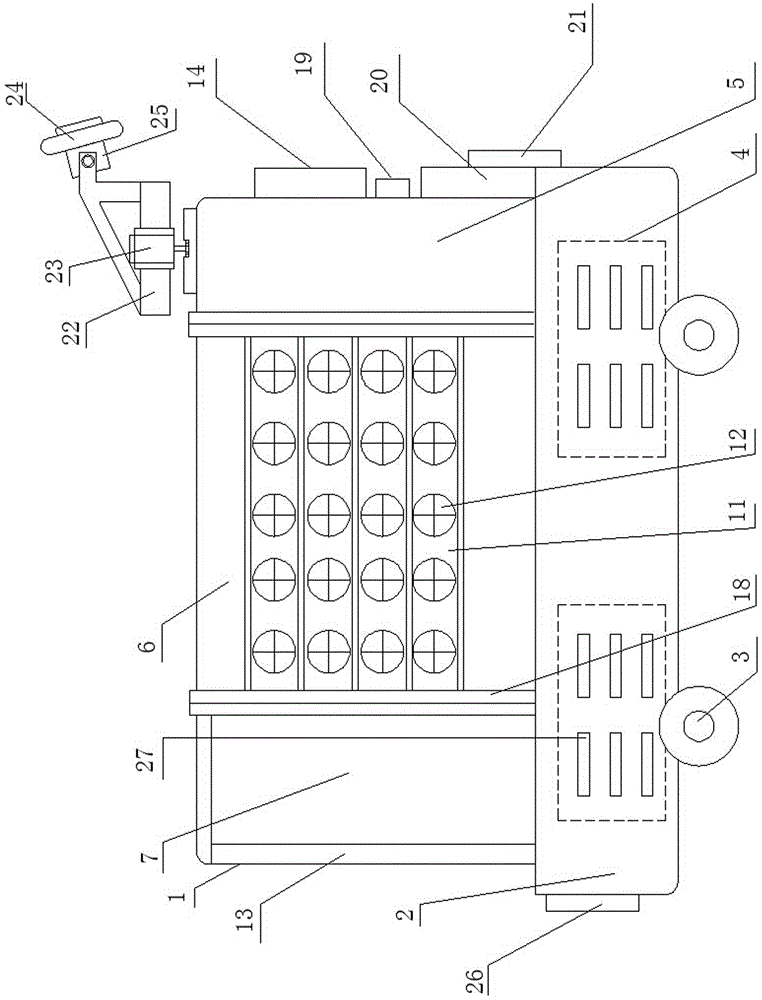

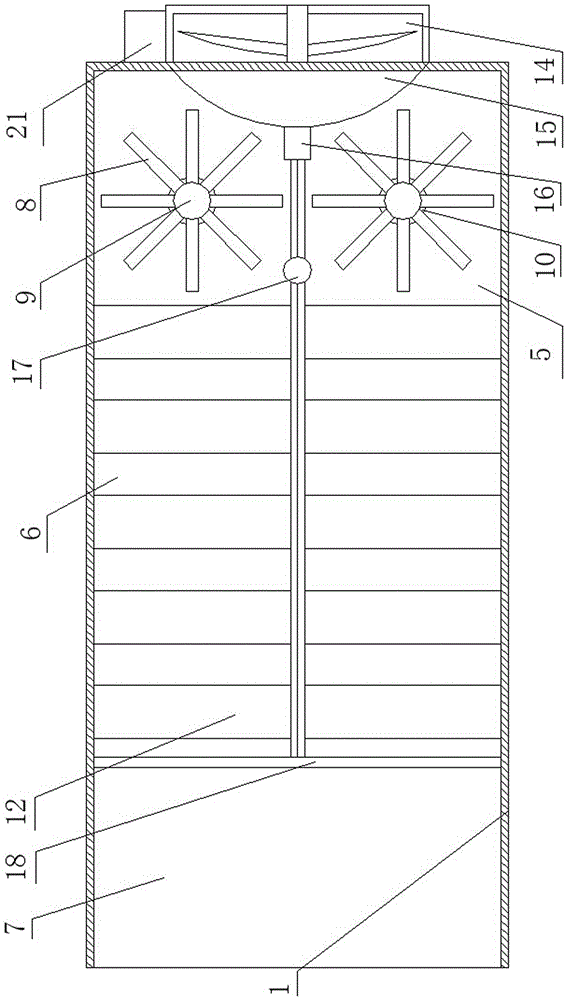

[0068] A smoke and dust purification system, which consists of: an outer casing, a camera, and a stepping motor. The outer casing 1 is loaded into an open compartment 2, and an all-terrain tire 3 is arranged at the bottom of the open compartment 2. The above-mentioned open compartment 2 is loaded with a battery pack 4, the upper end of the battery pack 4 is provided with an outer casing 1, and the outer casing 1 is sequentially composed of filter chamber I5, filter chamber II6 and ash collection bin 7 from front to back. The filter chamber I5 is filled with a rotating filter plate 8, the rotating filter plate 8 is installed on the rotating shaft 9, and the rotating shaft 9 is installed in the shaft sleeve 10, and the shaft sleeves 10 are respectively arranged in the filter chamber I5 top and bottom;

[0069] The housing of the filter chamber II6 is provided with a plurality of ports 11, and each port 11 is filled with two ends of a group of filter cartridges 12, and each group...

Embodiment 2

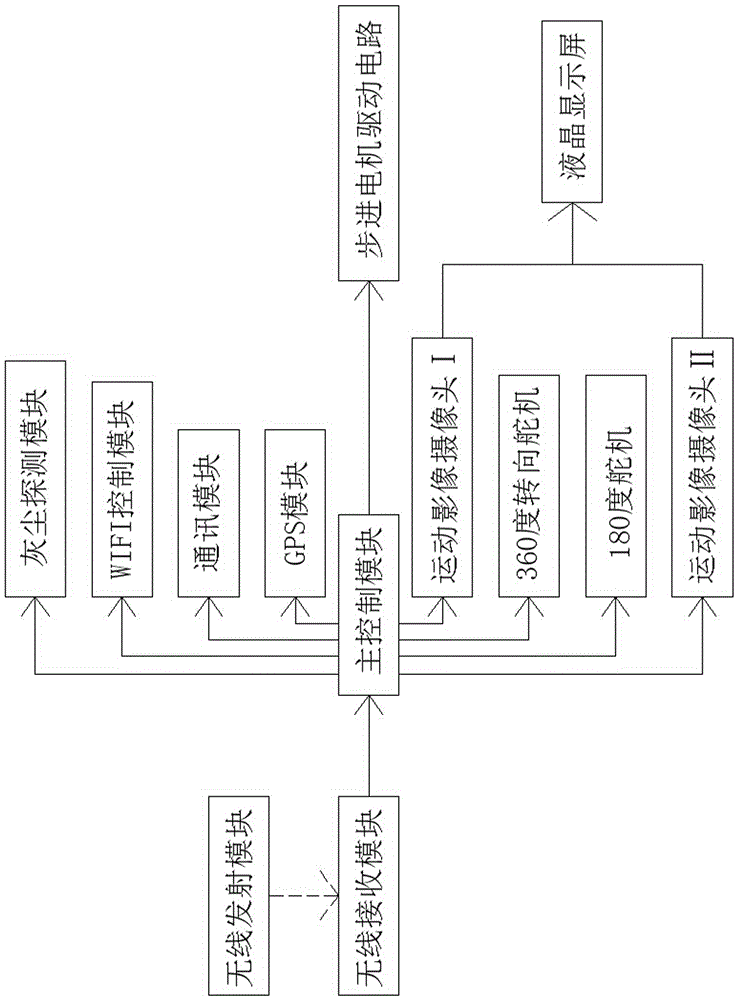

[0078] In the smoke and dust purification system described in Embodiment 1, both the moving image camera II 25 and the moving image camera I 26 transmit signals to the liquid crystal display screen, and the moving image camera II 25 and the moving image camera I 26 receive signals from the main control module, The main control module transmits signals to 360-degree steering gear 22, 180-degree steering gear 24, GPS module, communication module, WIFI control module and dust detection module;

[0079] The main control module receives the signal from the wireless receiving module, and the wireless receiving module receives the instruction signal from the wireless transmitting module.

Embodiment 3

[0081] In the smoke and dust purification system described in Embodiment 2, the dust detection module includes a dust sensor, the dust sensor receives an air signal, and the dust sensor transmits the signal to a weak signal conditioning circuit, and the weak signal conditioning circuit The signal is transmitted to the signal amplification circuit, and the signal amplification circuit transmits the signal to the analog-to-digital conversion circuit, and the analog-to-digital conversion circuit transmits the signal to the microprocessor, and the microprocessor transmits the signal to the upper computer Communication module, sound and light prompt circuit, relay control switch, data serial port, display screen and monitoring reset module;

[0082] The microprocessor receives the input signal of the keyboard and the control signal of the clock module;

[0083] The relay control switch transmits the signal to the frequency converter, and the frequency converter controls the work of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com