Preparation method of high-capacity monocrystalline type ternary cathode material

A cathode material, high-capacity technology, used in chemical instruments and methods, electrical components, battery electrodes, etc., can solve problems such as unfavorable filling, affecting the electrical properties of materials, deterioration of electrical properties and safety properties of materials, and increasing infiltration and storage. , improve and safety performance, is conducive to the effect of radial diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

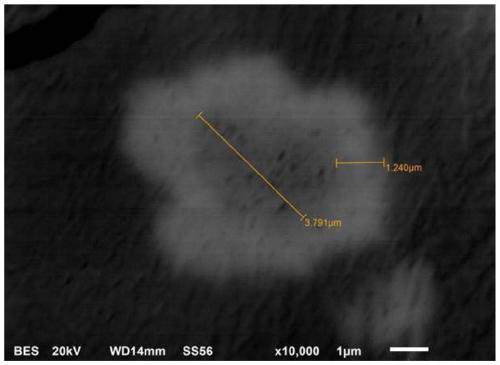

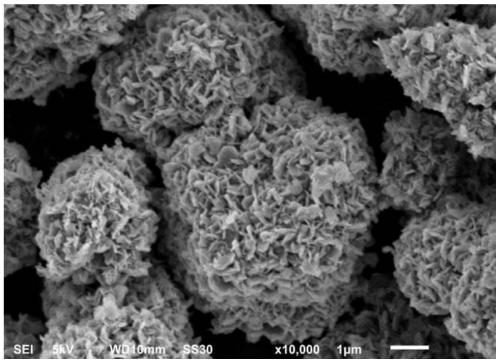

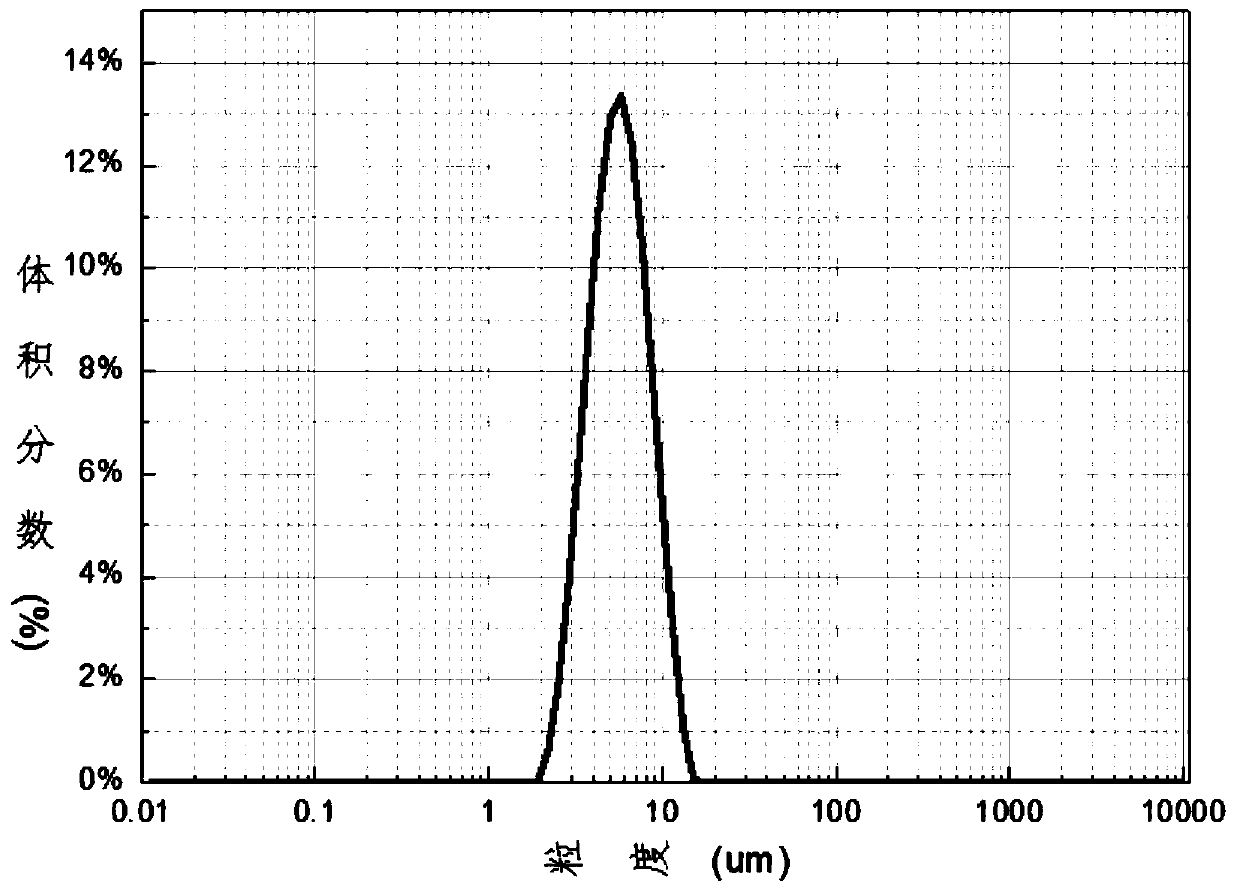

[0041] Example: see attached Figure 1~5 As shown, a method for preparing a high-capacity single crystal ternary positive electrode material; including the following steps in turn:

[0042] Step 1, reaction preparation, to the reactor (6m 3 ) into pure water (1500L) and complexing agent as the bottom liquid; and continue to feed inert gas so that the oxygen concentration of the entire reaction system in the reactor remains ≤200ppm, the time for feeding the inert gas is ≥6h, and the reaction temperature Control at 40-60°C, preferably 50°C; the complexing agent is preferably ammonia water, so that the ammonia concentration of the bottom liquid is controlled at 0.05-1.0mol / L. The inert gas is used as a protective gas, nitrogen, argon, helium, etc. can be selected, and the gas flow rate is controlled at 2~6m 3 / h.

[0043] Then, the reaction starts, the stirring is started and the nickel-cobalt-manganese salt solution, the alkali solution and the ammonia water are pumped into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com