Battery electrolyte ultrasonic injection equipment and method

A technology of injecting equipment and ultrasonic waves, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of plate performance fluctuation, failure, space for multiple battery parts, etc., to improve absorption and infiltration, accelerate absorption and infiltration, The effect of more absorption space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

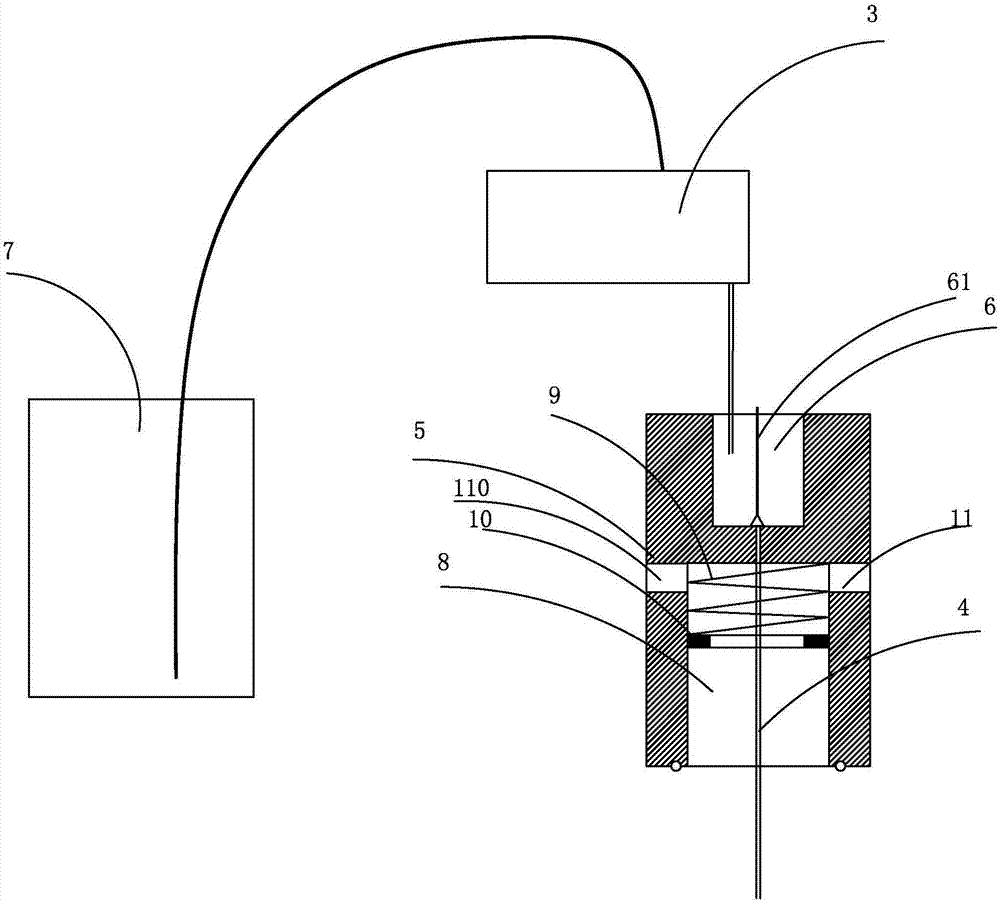

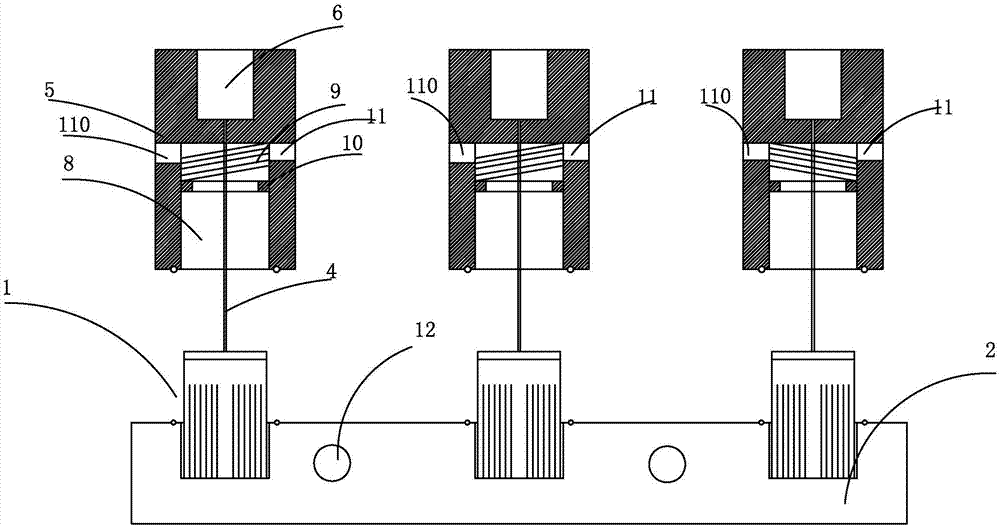

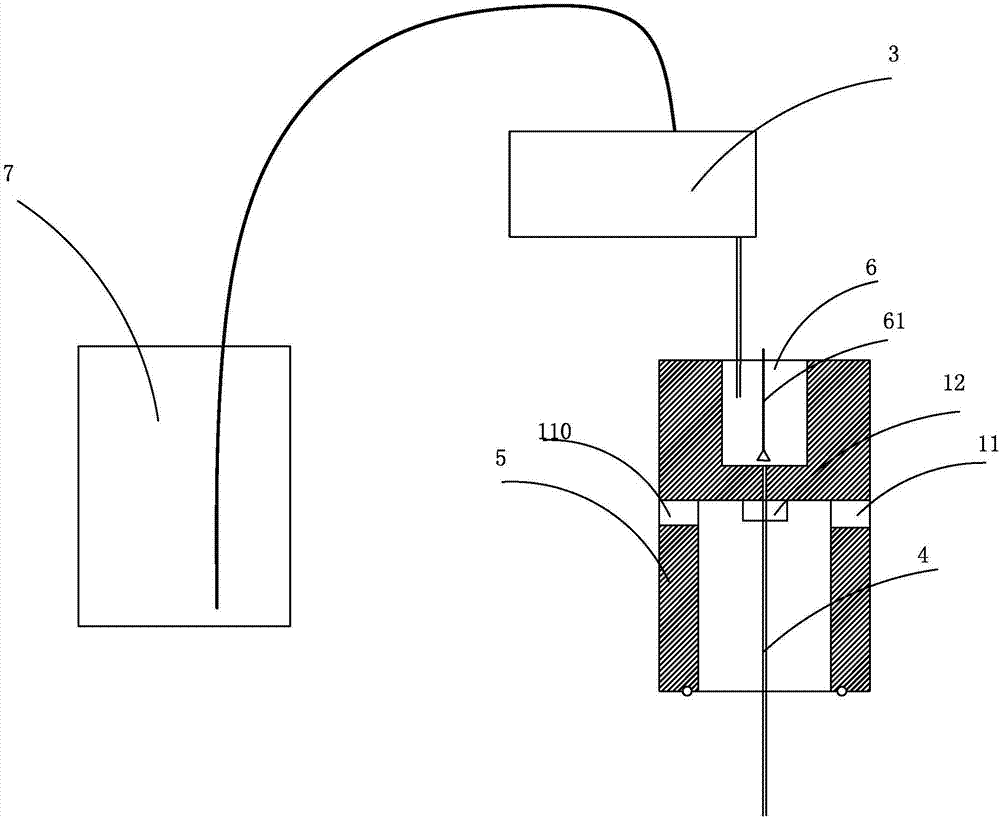

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0058] Ultrasonic liquid injection can solve two problems in the traditional battery liquid injection process.

[0059] The first problem is the diffusion of the electrolyte between the plates: on the one hand, the ultrasonic waves vibrate the plates, forming gaps in an instant, and then closing them instantly. The gaps are generated and closed in an instant to form a pump valve effect, which greatly accelerates Diffusion of electrolyte between electrodes and inside electrodes.

[0060] Another problem is the penetration and infiltration of the electrolyte in the plate: the process of the electrolyte being absorbed by the plate is the process of penetrating into the micropore gap of the plate and wetting the surface of the plate, and these micropores of the plate On the one hand, due to the existence of air in the gap, especially the air in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com