Multifunctional floor waxing machine

A multi-functional, floor technology, applied in the direction of cleaning floors, carpets, machine parts, etc., can solve the problems of inconvenient use, single function of the floor waxing machine, etc., to achieve convenient disassembly process, avoid unevenness and waste, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

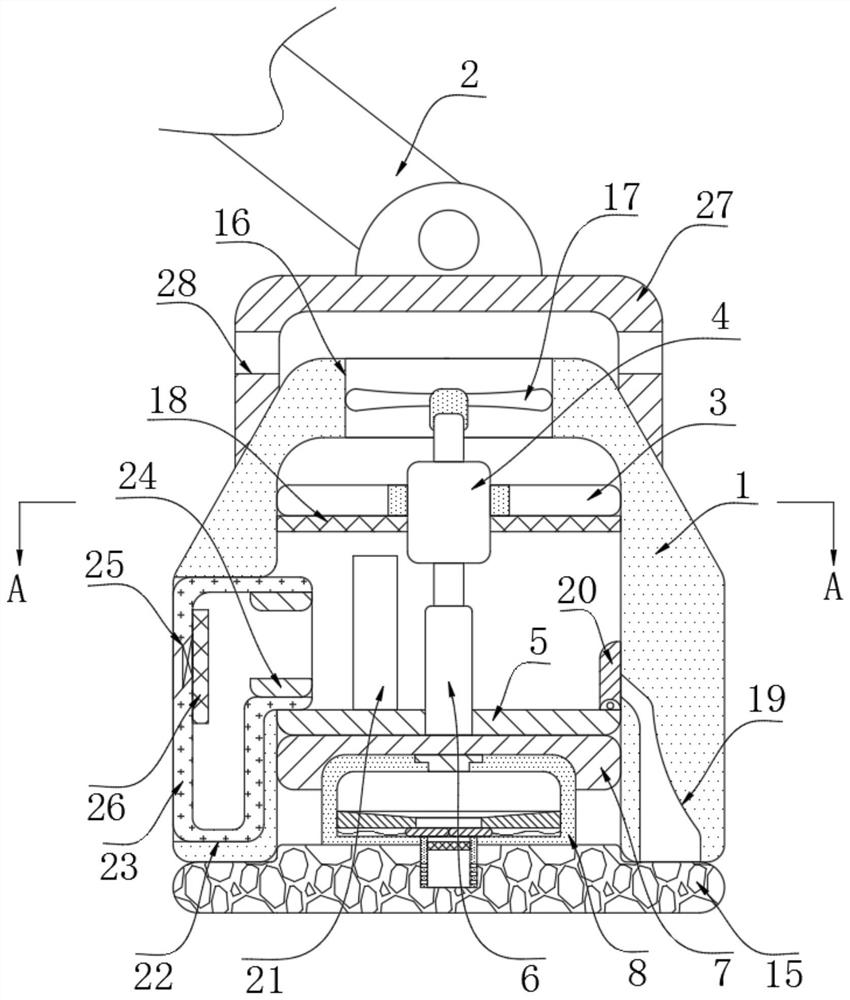

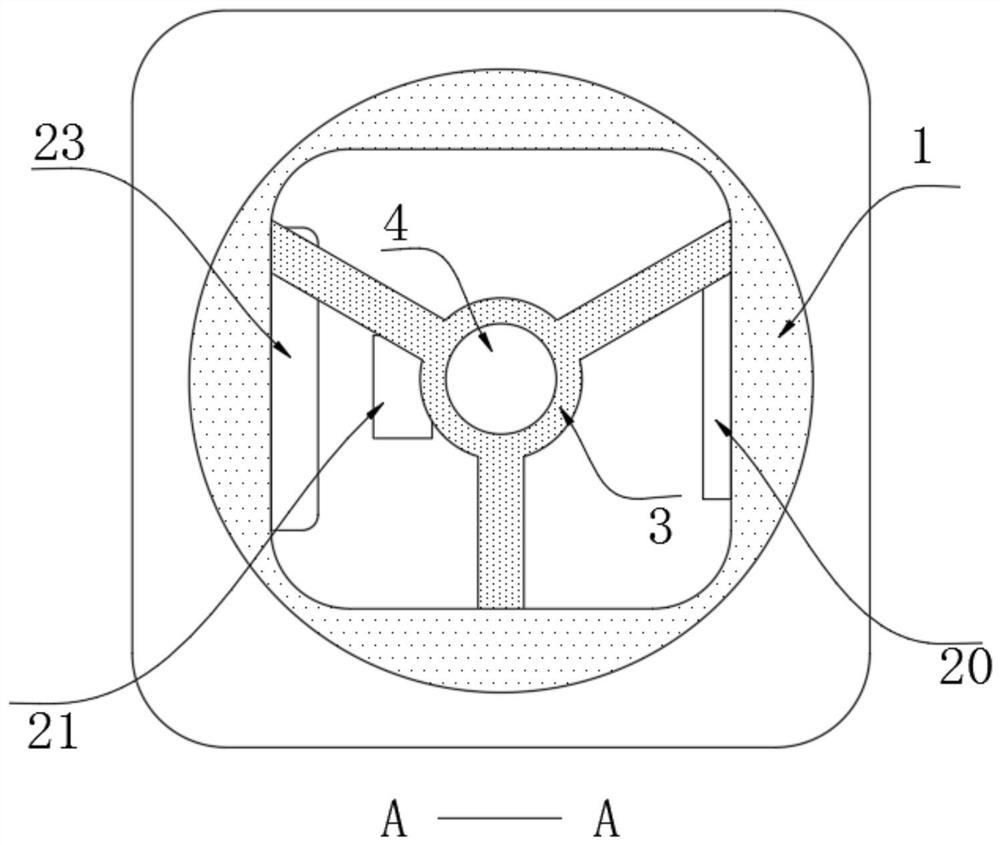

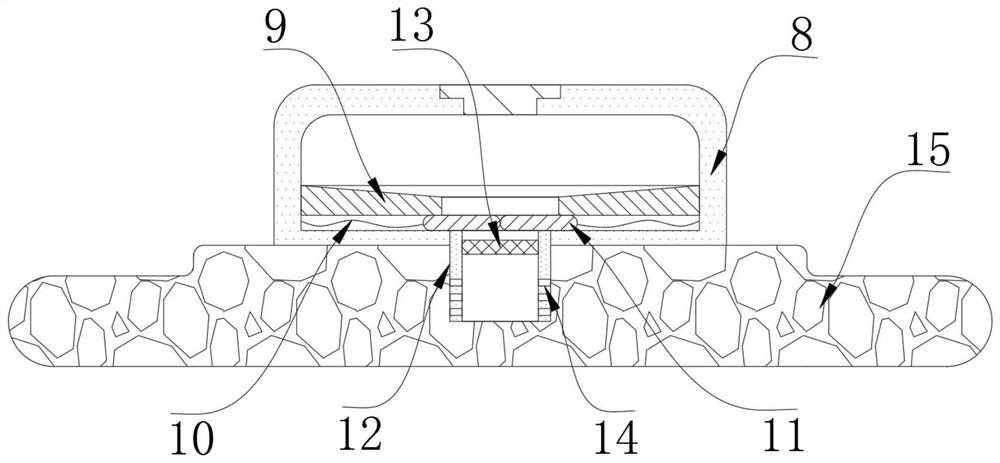

[0020] refer to Figure 1-3 , a multifunctional floor waxing machine, comprising a casing 1, a protective cover 27 is fixed on the upper end of the casing 1, a pull rod 2 is rotatably connected to the upper end of the protective cover 27, a plurality of air holes 28 are provided on the side wall of the protective cover 27, and the casing The inner wall of 1 is equipped with a fixed frame 3, the center of the fixed frame 3 is fixed with a double-headed motor 4, the output shaft at the lower end of the double-headed motor 4 is fixed with a transmission shaft 6, the inner wall of the shell 1 is fixed with a partition 5, and the transmission shaft 6 runs through The partition plate 5 is connected with the installation block 7 through the rotation of the one-way bearing. The bottom of the installation block 7 offsets the storage box 8. The inside of the storage box 8 is provided with a slow release mechanism, and the bottom of the storage box 8 is fixed with a sponge 15;

[0021] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com