Preparation method of molybdenum trioxide-polypyrrole-polyaniline ternary composite material

A molybdenum trioxide and composite material technology, applied in electrical components, circuits, battery electrodes, etc., can solve problems such as application process limitation and weak transmission rate, and achieve effective dispersion, inhibition of agglomeration, and favorable conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of molybdenum trioxide-polypyrrole-polyaniline ternary composite material, concrete steps are:

[0035] 1. Preparation of molybdenum trioxide nanobelts by hydrothermal method:

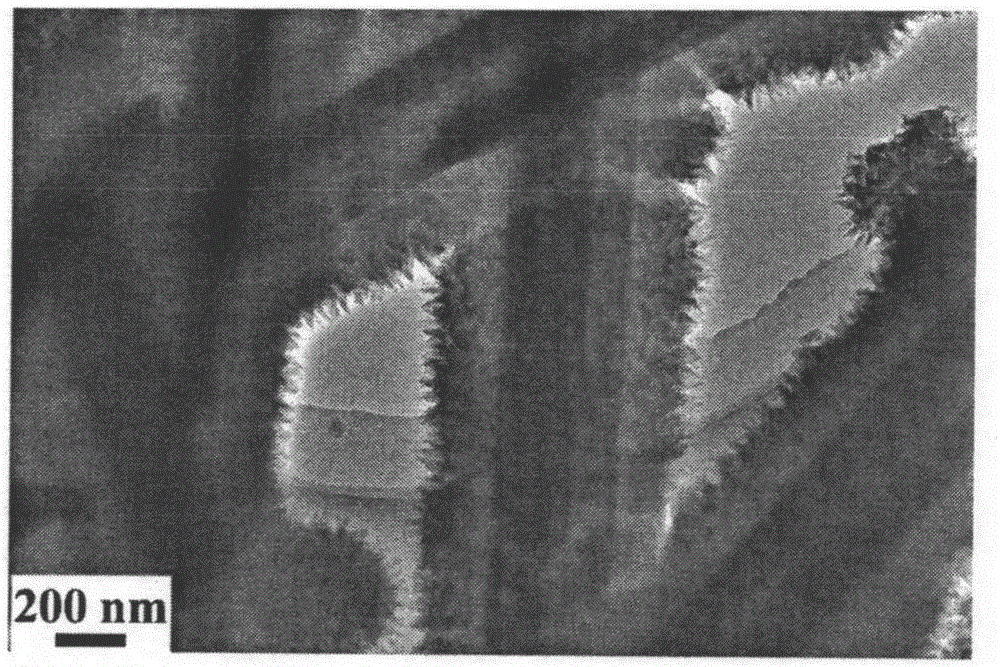

[0036] Add 1.21g of sodium molybdate and 0.6g of sodium chloride into 60mL of deionized water to obtain a solution, keep stirring for 10 minutes to obtain a uniform dispersion, add 3mol / L hydrochloric acid solution to adjust the pH to 1, transfer to a hydrothermal kettle in an oven The hydrothermal reaction was carried out at 180°C, and the reaction time was 24h. When the reaction kettle was cooled down to room temperature, the obtained dispersion liquid was subjected to suction filtration to separate the light blue precipitate, and the obtained solid was washed with deionized water. Dry in an oven at 60° C. for 24 hours to obtain molybdenum trioxide nanobelts.

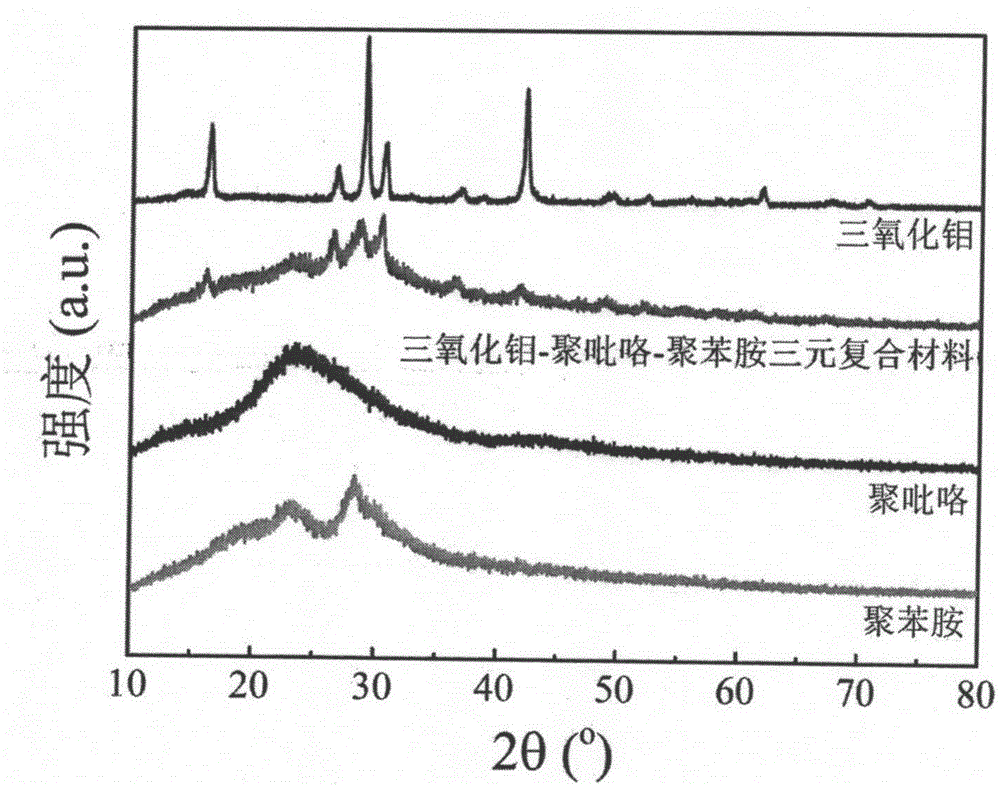

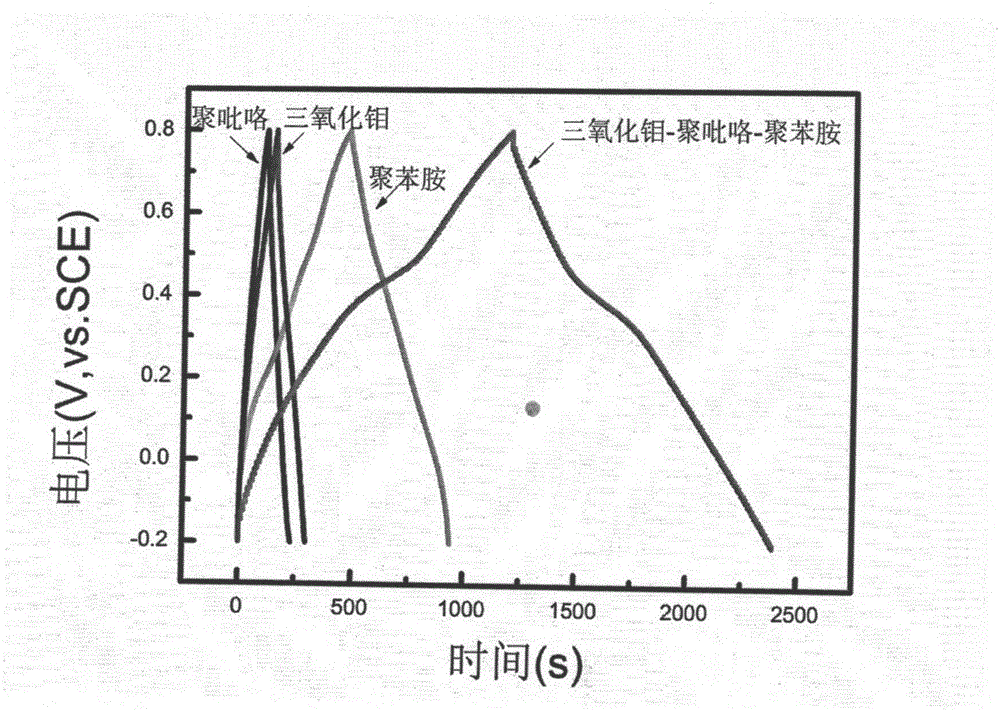

[0037] 2. In situ growth of polypyrrole on molybdenum trioxide nanobelts to obtain molybdenum trioxide-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com