Large ratio of depth to width tungsten electrode inert gas-shielded welding technique

A tungsten inert gas and inert gas technology, used in welding media, manufacturing tools, welding equipment, etc., can solve the problems of complex process, low welding efficiency, shallow penetration of TIG welding, etc., and achieve clean weld surface and welding efficiency. Improve and shape the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

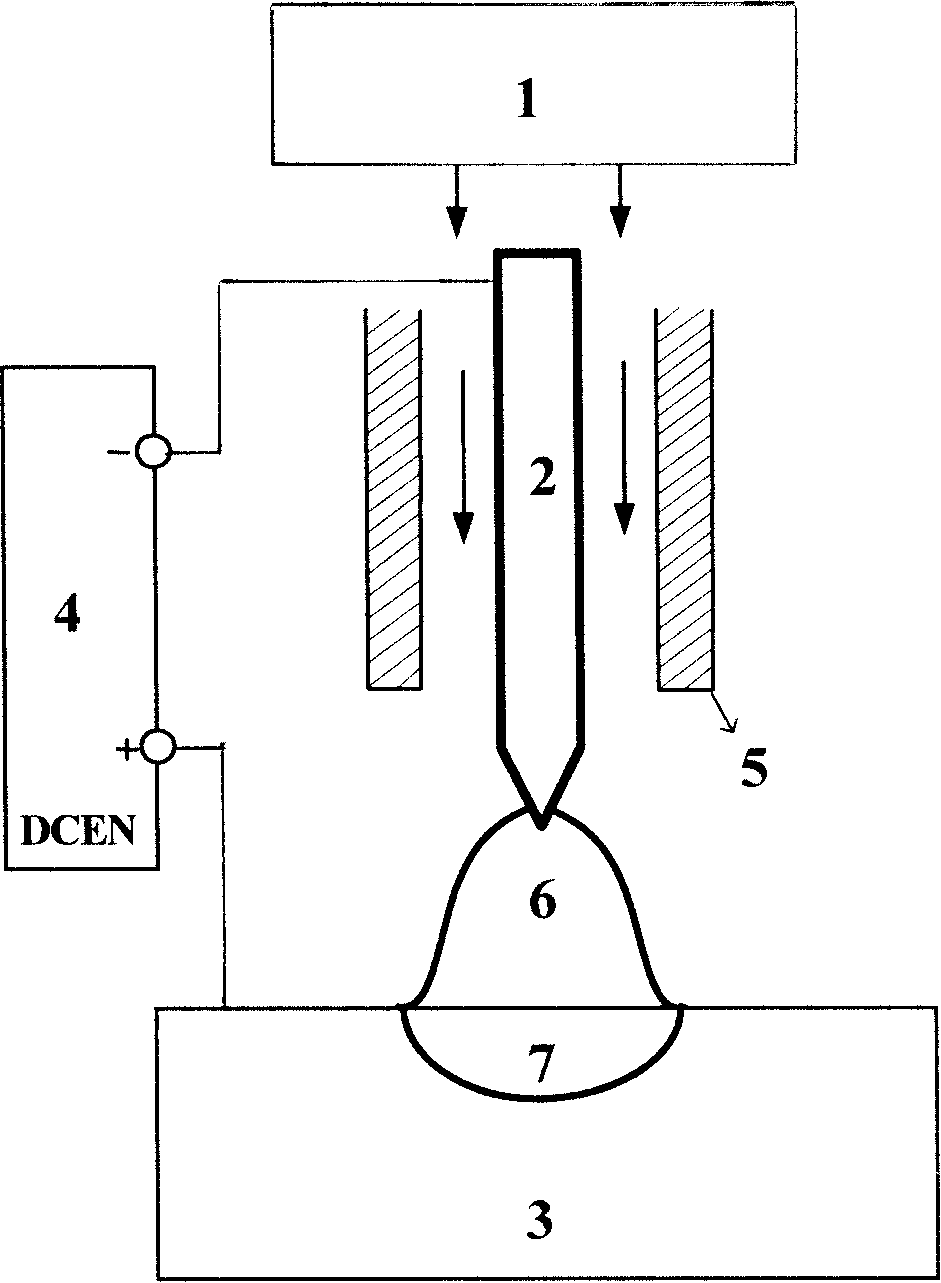

Method used

Image

Examples

Embodiment

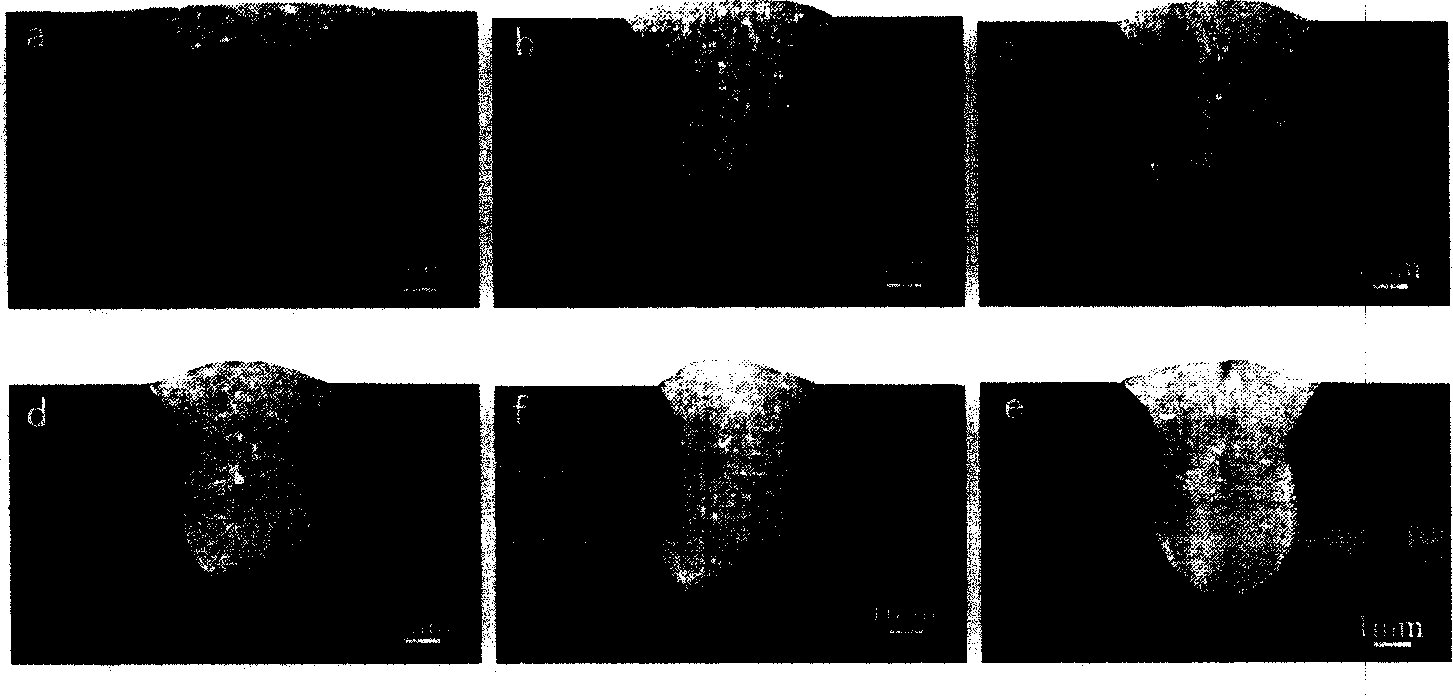

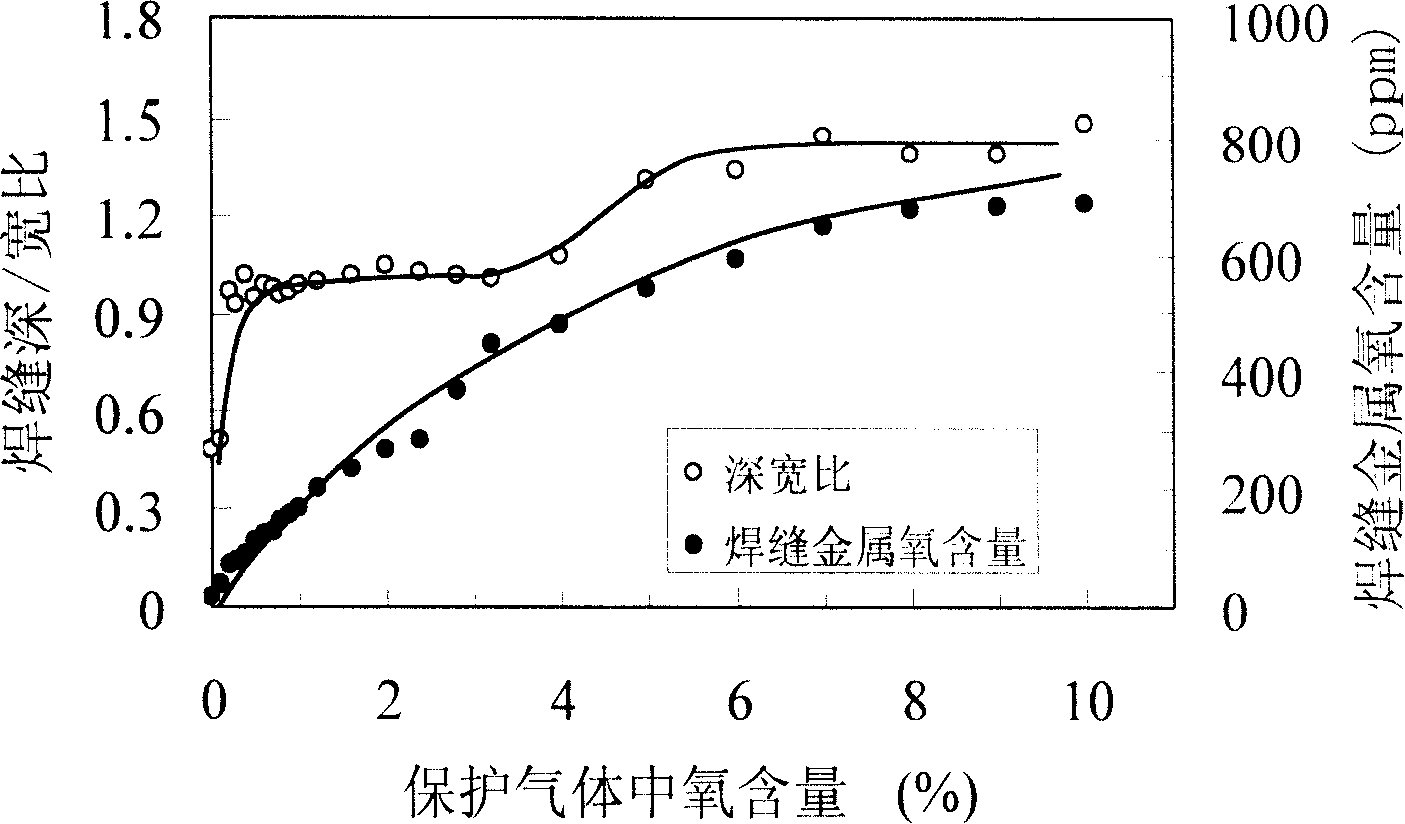

[0040] In this embodiment, SUS304 stainless steel is used as the base material, and under different welding specifications (welding current, welding speed and arc length), He-O 2 and He-CO 2 For the welding experiment under the protection of mixed gas, the gas flow rate in this embodiment is 10 L / Min. Welding experiments were carried out on an AC-DC dual-purpose digital TIG welding machine, using DC reverse connection. The changing range of welding current is 80A~250A, and the shape change of molten pool can be found in Figure 7 a-i. Under the protection of pure He, when the welding current is 80A, 140A and 250A, the morphology of the molten pool is shallow and wide (see Figure 7 a-c). In He-0.4%O 2 Under protection, the molten pool morphology becomes deep and narrow (see Figure 7 d-f, the welding current is 80A, 140A, 250A respectively). In He-0.6% CO 2 Under protection, the molten pool morphology when the welding current is 80A, 140A and 250A see Figure 7 g-i. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com