Preparation method of nano low-silver high-efficiency positive silver conductor paste for crystalline silicon solar energy

A technology of silver conductor paste and solar energy, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, semiconductor devices, electrical components, etc., and can solve the problem of affecting photoelectric conversion performance, high consumption of precious metal silver, and rough paste fineness, etc. Problems, to achieve the effect of improving photoelectric conversion efficiency, improving application performance, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

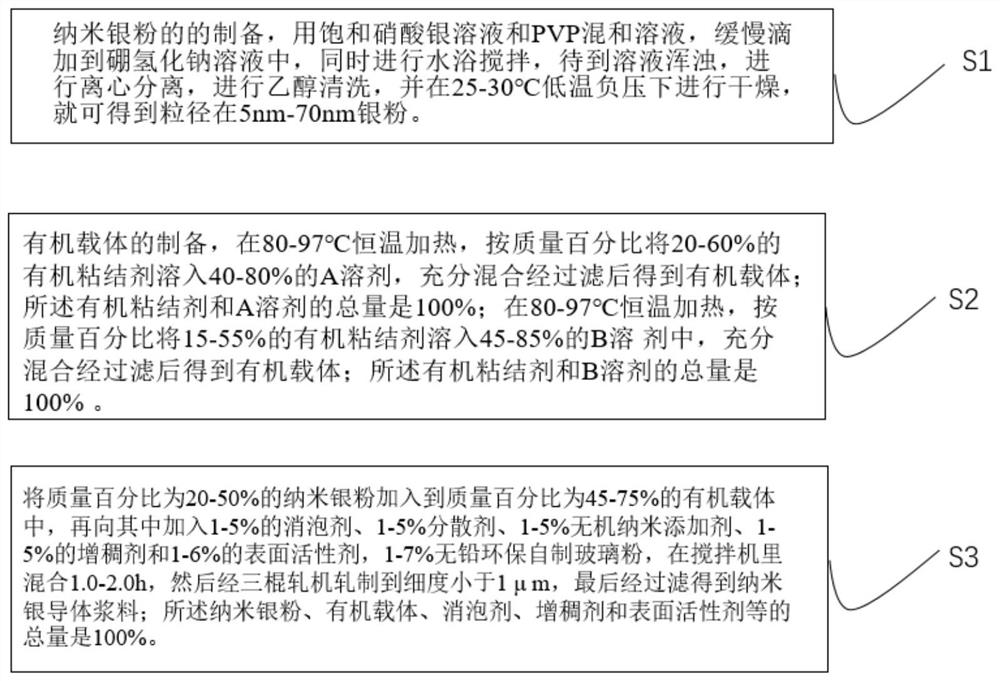

[0028] A nanometer low-silver crystalline silicon-containing front-side silver conductor paste for solar energy and a preparation method thereof, the specific preparation of which is completed according to the following process steps:

[0029] First, slowly drop 500ml of saturated silver nitrate solution and PVP mixed solution into the sodium borohydride solution, and at the same time, stir in a 50°C water bath. Press and dry to obtain silver powder with a particle size of 5nm-10nm. Weigh 35g of the silver powder, then add 45g of polyester resin into 55g of n-butanol, and heat it at a constant temperature at 85°C until it is completely dissolved. Obtain organic carrier through filtration; Finally the nanometer silver powder of 35g is joined in the organic carrier of 55g, add 1g dispersion agent, add 2g nano zinc oxide, add the antifoaming agent of 1g, the thickening agent of 2g and the tensio-active agent of 2g, Add 2g of lead-free environmentally friendly self-made glass powd...

Embodiment 2

[0031] A nanometer low-silver crystalline silicon-containing front-side silver conductor paste for solar energy and a preparation method thereof, the specific preparation of which is completed according to the following process steps:

[0032] First, slowly add 500ml of saturated silver nitrate solution and PVP mixed solution into the sodium borohydride solution dropwise, and at the same time, stir in a water bath at 55°C. Press and dry to obtain silver powder with a particle size of 12nm-15nm. Weigh 40g of the silver powder, then add 50g of polyurethane resin to 50g of isoprene glycol, and heat it at a constant temperature at 88°C until it is completely dissolved. Obtain organic carrier through filtration; Finally the nano-silver powder of 40g is joined in the organic carrier of 47g, add 2g dispersant, add 3g nano-zinc oxide, add the defoamer of 1g and the thickening agent of 2g and the tensio-active agent of 2g, Add 3g of lead-free environmentally friendly self-made glass po...

Embodiment 3

[0034] A nanometer low silver-containing crystalline silicon solar energy back silver conductor paste and a preparation method thereof, the specific preparation of which is completed according to the following process steps:

[0035] First, slowly add 500ml of saturated silver nitrate solution and PVP mixed solution to the sodium borohydride solution dropwise, and at the same time, stir in a 60°C water bath. Press and dry to obtain silver powder with a particle size of 10nm-15nm. Weigh 45g of the silver powder, then add 60g of epoxy resin to 40g of diethylene glycol butyl ether acetate, and keep the temperature at 90°C Heat until completely dissolved, and filter to obtain an organic carrier; finally, add 45g of nano-silver powder to 37g of organic carrier, add 2g of dispersant, add 4g of nano-titanium dioxide, add 2g of defoamer, 3g of thickener and 3g of Surfactant, add 4g of lead-free environmental protection self-made glass powder, mix in a planetary or other mixer for 150 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com