Pole piece, preparation method thereof and lithium ion battery

A lithium-ion battery and pole piece technology, which is applied in the field of battery preparation, can solve the problems of difficult penetration of pore-forming agents and poor pore-making effects, and achieve the effects of reducing resistivity, improving wetting and absorption effects, and improving rolling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

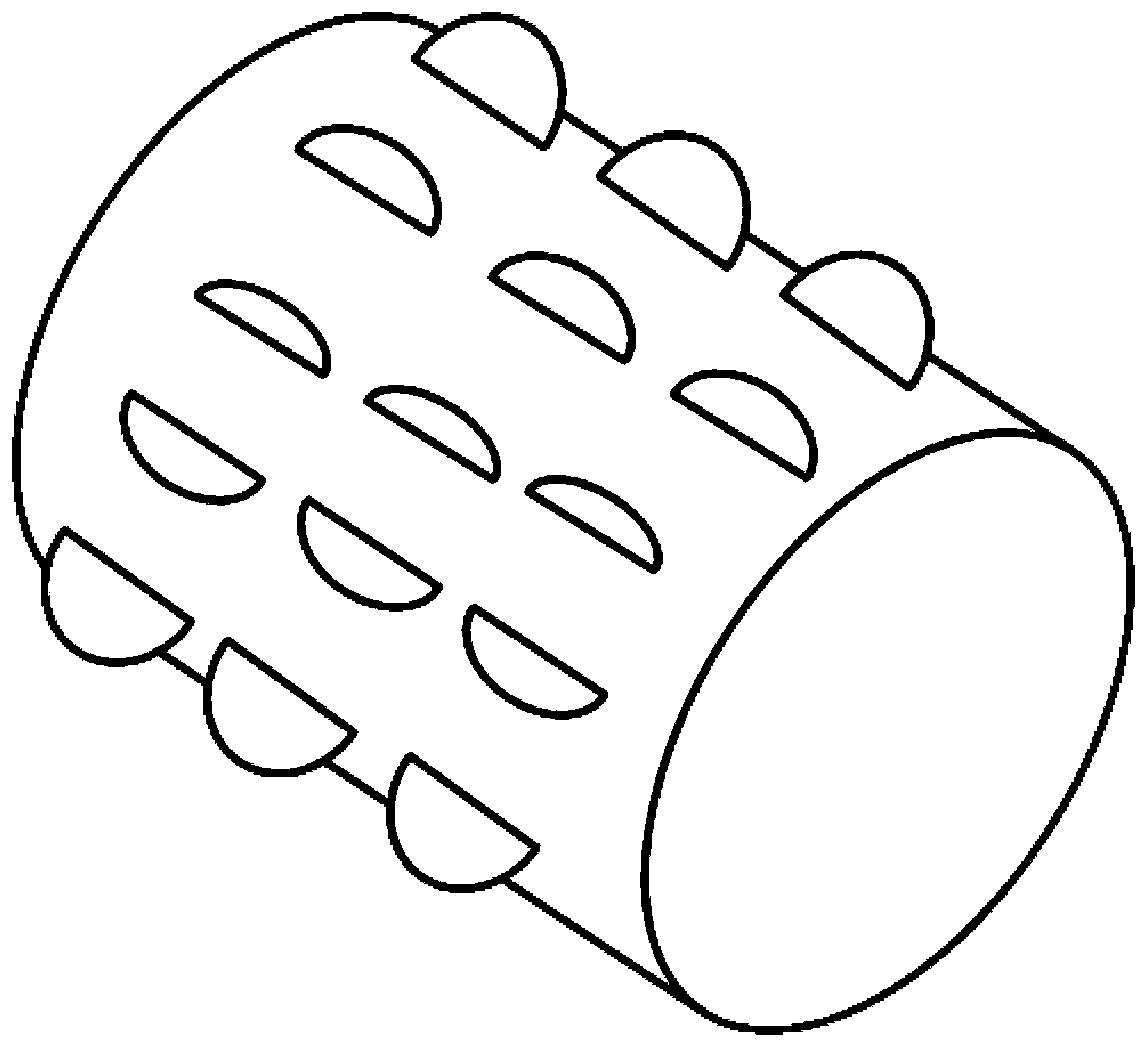

Image

Examples

Embodiment 1

[0080] (1) camphor is mixed with nitrogen methyl pyrrolidone to obtain a positive electrode pore-forming solution with a concentration of 2.5mol / L, and oxalic acid is mixed with water to obtain a negative electrode pore-formed solution with a concentration of 0.5mol / L;

[0081] (2) According to the ratio of positive electrode active component (lithium iron phosphate): positive electrode binder (PVDF): positive electrode conductive agent (conductive graphite) at 8:1:1, mix with solvent NMP to prepare positive electrode slurry, and then mix positive electrode slurry Coated on both sides of the positive electrode current collector (aluminum foil) to obtain a coated positive electrode sheet, the single surface density of the coated positive electrode sheet is 20mg / cm 2 , the density of both sides is 40mg / cm 2 ;

[0082] (3) Negative electrode slurry is prepared by negative electrode active component (artificial graphite): negative electrode binder (SBR): dispersant (CMC): negativ...

Embodiment 2

[0088] The difference from Example 1 is that the concentration of the positive electrode pore-forming solution in step (1) is 2 mol / L.

Embodiment 3

[0090] The difference from Example 1 is that the concentration of the positive electrode pore-forming solution in step (1) is 3 mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single sided density | aaaaa | aaaaa |

| Double sided density | aaaaa | aaaaa |

| Single sided density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com