High-strength pultruded profile and preparation method thereof

A technology of pultruded profiles and high strength, which is applied in the field of materials, can solve problems such as the performance degradation of pultruded profiles, and achieve the effects of improving cohesiveness, mechanical properties, and transverse strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

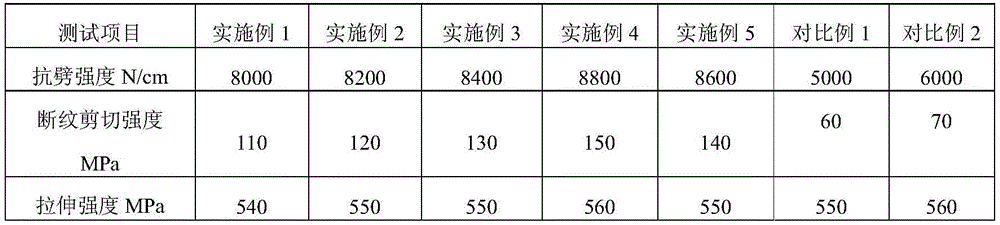

Examples

Embodiment 1

[0056] 1) Resin preparation: 100 parts by mass of epoxy resin, 85 parts by mass of methyltetrahydrophthalic anhydride, 3 parts by mass of zinc stearate, 0.5 parts by mass of silane coupling agent, and 1 part by mass of boron trifluoride amine complex salt were placed in In the dispersion tank, the resin matrix was obtained after stirring for 60 minutes under the condition of 500 rpm.

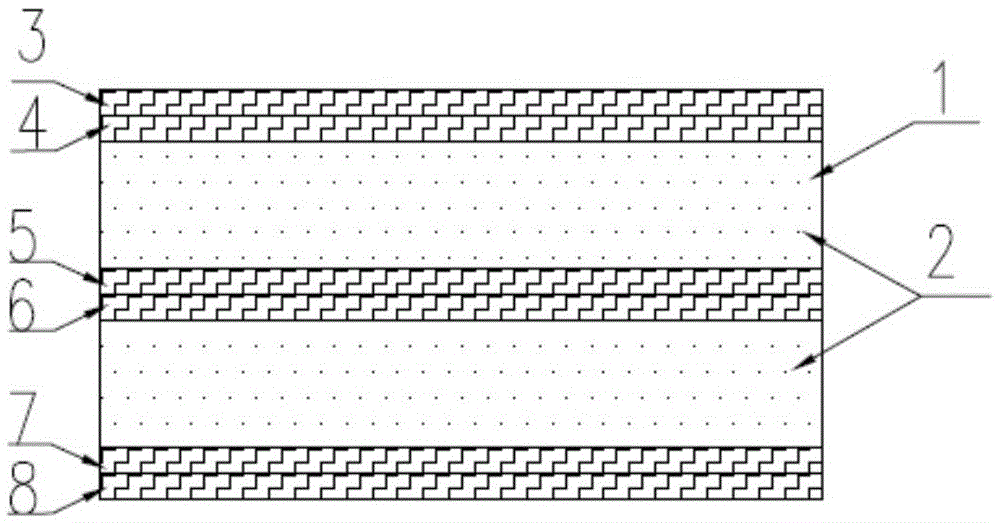

[0057] 2) Preparation of multi-axial fabric sizing gray cloth

[0058] Using the resin matrix prepared in step 1), the multi-axial fabric was impregnated with glue by a gluing machine, and baked in an oven at 120° C. for 3 minutes for semi-curing to prepare a multi-axial fabric glued gray cloth. The multiaxial fabric is a continuous fiber mat, and the multiaxial fabric gluing gray cloths 3, 4, 5, 6, 7, and 8 are respectively one layer of continuous fiber mat gluing gray cloth.

[0060] Utilize the drying room to dry the glass fiber and the multiaxial fabric sizing...

Embodiment 2

[0066] Compared with Example 1, the only difference is that the multiaxial fabric is a composite felt, and the multiaxial fabric glued gray cloths 3, 4, 5, 6, 7, and 8 are respectively one layer of composite felt. Rubber gray cloth.

Embodiment 3

[0068] Compared with Example 1, the only difference is that the multiaxial fabric is a knitted felt, and the multiaxial fabric sizing gray cloths 3, 4, 5, 6, 7, and 8 are respectively one layer of knitted felt. Rubber gray cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com