Method for preparing suspension micro-sensitive structure based on aluminum sacrificial layer process

A sensitive structure and sacrificial layer technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as bulk silicon damage, low yield, and narrow space structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

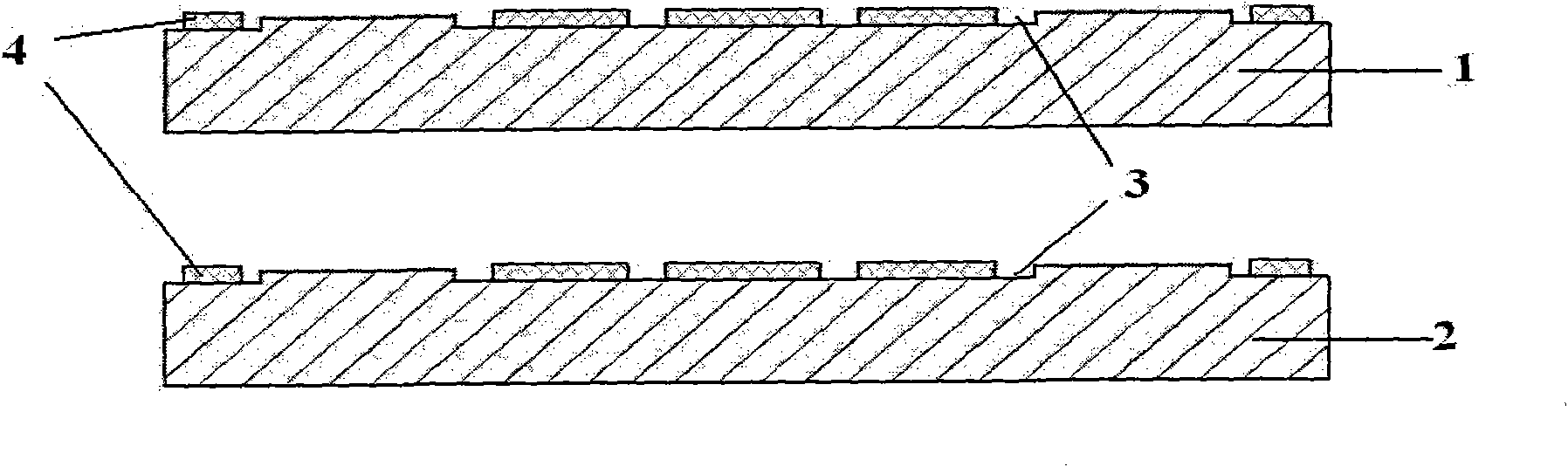

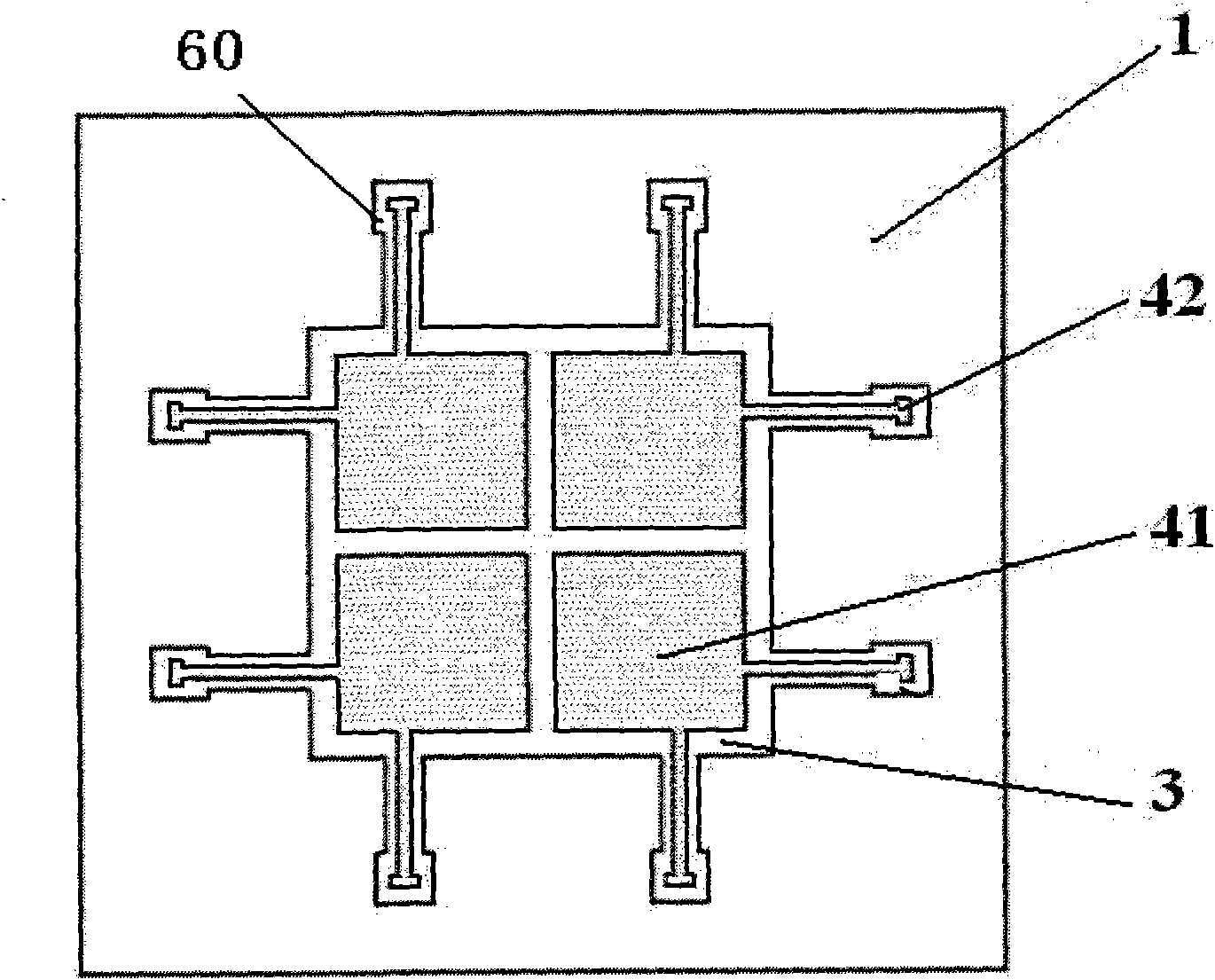

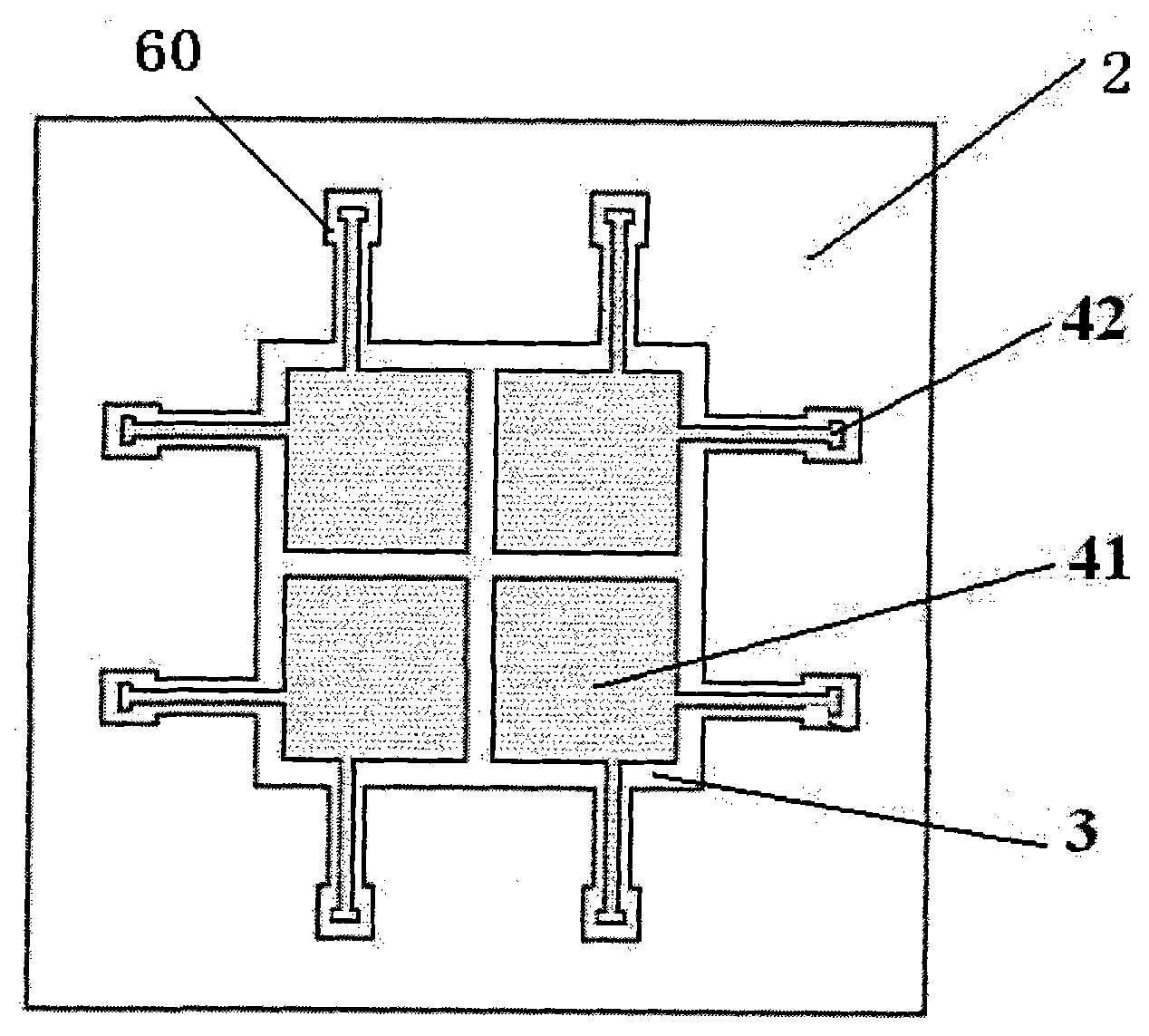

[0028] The preparation method of the suspended micro-sensitive structure based on the aluminum sacrificial layer technology in this embodiment, the steps are as follows:

[0029] Step 1: Etch three 120nm-deep electrode grooves 3 on the surface of the top glass 1 and the bottom glass 2 respectively with buffered hydrofluoric acid BHF wet method, each electrode groove 3 has an outwardly extending Lead groove 60, and in order from left to right, the size and longitudinal position of each pair of electrode grooves 3 corresponding to the top glass 1 and the bottom glass 2 are consistent, so that each pair of electrode grooves 3 constitutes a differential electric groove groove, and then sputter 170nm thick titanium gold alloy in each electrode groove 3 to form four electrodes 41, and sputter outwardly extending leads 42 into the corresponding electrode groove 3 on the outer side of each electrode 41 lead groove 60, the width of each lead 42 is 35 μm, and the interval between adjace...

Embodiment 2

[0040] The preparation method of the suspended micro-sensitive structure based on the aluminum sacrificial layer technology in this embodiment, the steps are as follows:

[0041] Step 1: Etch three 140nm-deep electrode grooves 3 on the surface of the top glass 1 and the bottom glass 2 respectively with buffered hydrofluoric acid BHF wet method, each electrode groove 3 has an outwardly extending Lead groove 60, and in order from left to right, the size and longitudinal position of each pair of electrode grooves 3 corresponding to the top glass 1 and the bottom glass 2 are consistent, so that each pair of electrode grooves 3 constitutes a differential electric groove groove, and then sputter 190nm thick titanium gold alloy in each electrode groove 3 to form four electrodes 41, and sputter outwardly extending leads 42 into the corresponding electrode groove 3 on the outer side of each electrode 41 lead groove 60, the width of each lead 42 is 40 μm, and the interval between adjace...

Embodiment 3

[0052] The preparation method of the suspended micro-sensitive structure based on the aluminum sacrificial layer technology in this embodiment, the steps are as follows:

[0053] Step 1: Etch three 155nm-deep electrode grooves 3 on the surface of the top glass 1 and the bottom glass 2 respectively with buffered hydrofluoric acid BHF wet method, and the outer side of each electrode groove 3 has an outwardly extending Lead groove 60, and in order from left to right, the size and longitudinal position of each pair of electrode grooves 3 corresponding to the top glass 1 and the bottom glass 2 are consistent, so that each pair of electrode grooves 3 constitutes a differential electric groove groove, and then sputter 205nm thick titanium gold alloy in each electrode groove 3 to form four electrodes 41, and sputter outwardly extending leads 42 into the corresponding electrode groove 3 on the outer side of each electrode 41 lead groove 60, the width of each lead 42 is 45 μm, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com