Lithium ion battery positive electrode slurry, preparation method thereof and lithium ion battery

A lithium-ion battery and positive electrode slurry technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve problems such as fast capacity decay, affecting the conductivity of lithium-ion batteries, and changes in the viscosity of positive electrode slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

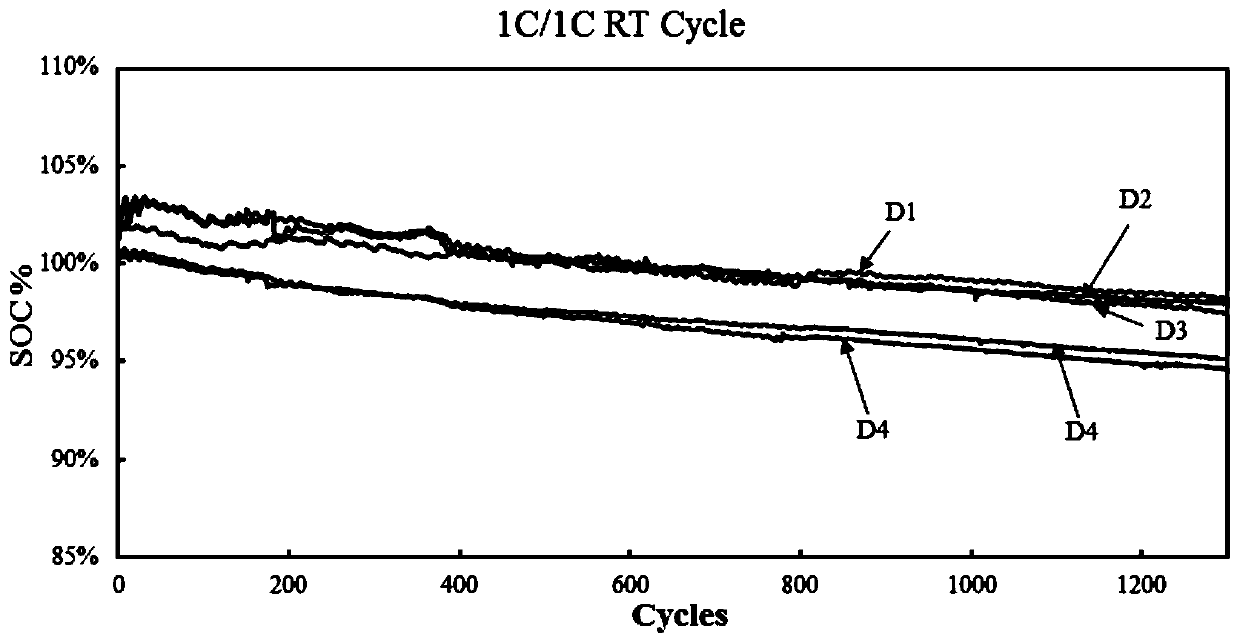

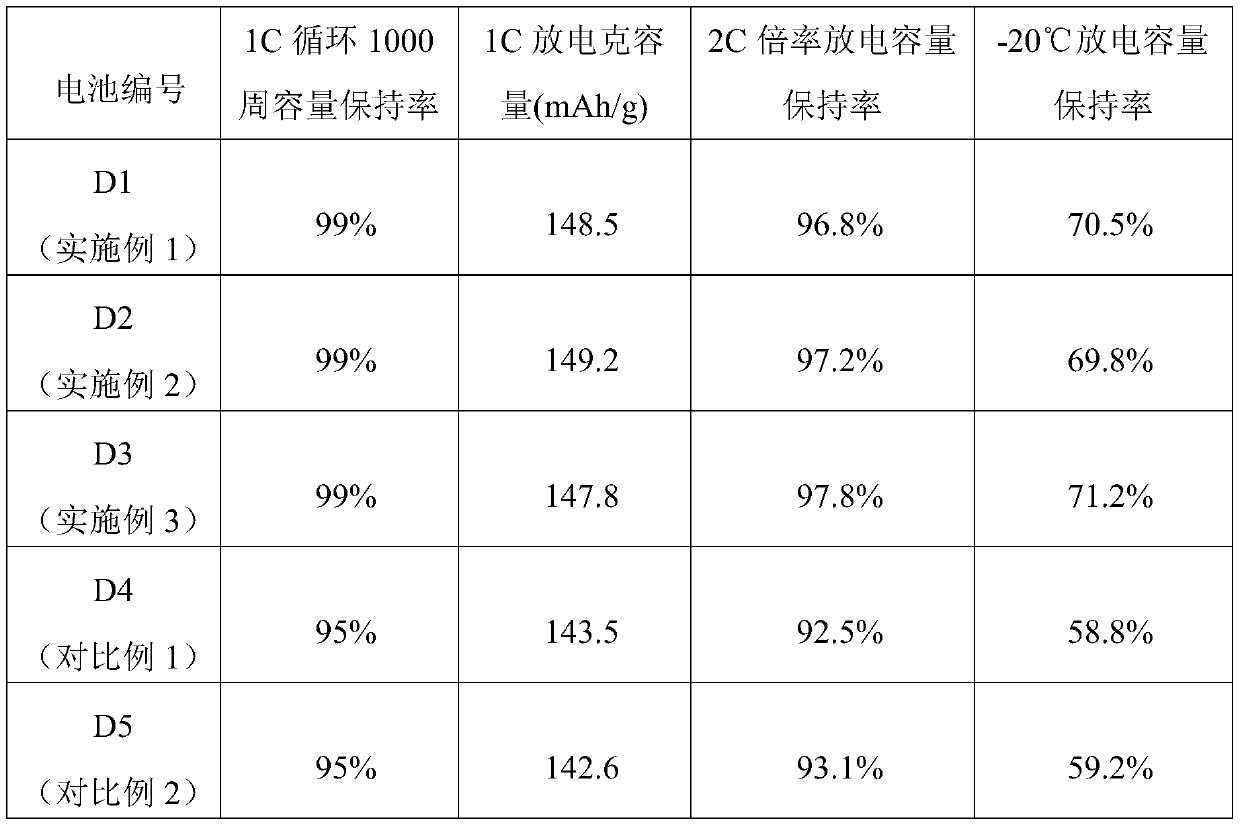

Embodiment 1

[0074] In this embodiment, the total mass of the positive electrode material is 100%, and the raw materials are weighed according to the following raw material composition and mass percentage: 50% of the positive electrode active material, 44% of the solvent, 2.5% of the binder, and 2% of the conductive agent. With dispersant 1.5%. Specifically, in this embodiment:

[0075] The positive active material is lithium iron phosphate;

[0076] The solvent is a mixture of N-methylpyrrolidone and deionized water, wherein N-methylpyrrolidone accounts for 95% of the solvent volume, and deionized water accounts for 5% of the solvent volume;

[0077] The binder A is PVDF, the binder B is polytetrafluoroethylene, and PVDF and polytetrafluoroethylene account for 80% and 20% of the total mass of the binder respectively;

[0078] The conductive agent A is selected from SP, and the conductive agent B is selected from graphene, and the percentages of SP and graphene accounting for the total w...

Embodiment 2

[0086] In this embodiment, the total mass of the positive electrode material is 100%, and the raw materials are weighed according to the following raw material composition and mass percentage: 57% positive electrode active material, 40% solvent, 0.5% binder, and 1.0% conductive agent With dispersant 1.5%. Specifically, in this embodiment:

[0087] The positive active material is lithium iron phosphate;

[0088] The solvent is a mixture of N-methylpyrrolidone and deionized water, wherein N-methylpyrrolidone accounts for 89% of the solvent volume, and deionized water accounts for 11% of the solvent volume;

[0089] The binder A is selected from PVDF, and the binder B is selected from polytetrafluoroethylene, and PVDF and polytetrafluoroethylene account for 90% and 10% of the total mass of the binder respectively;

[0090] The conductive agent A is selected from SP, and the conductive agent B is selected from graphene, and the percentages of SP and graphene accounting for the t...

Embodiment 3

[0098] In this embodiment, the total mass of the positive electrode material is 100%, and the raw materials are weighed according to the following raw material composition and mass percentage: 45% positive electrode active material, 50% solvent, 2.0% binder, and 1.0% conductive agent With dispersant 2.0%. Specifically, in this embodiment:

[0099] The positive active material is lithium iron phosphate;

[0100] The solvent is a mixture of N-methylpyrrolidone and deionized water, wherein N-methylpyrrolidone accounts for 97% of the solvent volume, and deionized water accounts for 3% of the solvent volume;

[0101] The binder A is PVDF, the binder B is polytetrafluoroethylene, and PVDF and polytetrafluoroethylene account for 85% and 15% of the total mass of the binder respectively;

[0102] The conductive agent A is selected from SP, and the conductive agent B is selected from graphene, and the percentages of SP and graphene accounting for the total weight of the conductive age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com