Tubular pile end-plate-free and pulling resistant functional assembly

A technology of functional components and free of end plates, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of occupying large end plates and hoops, high labor intensity of workers, and occupation of storage space, etc., and achieves the reduction of steel consumption , Reduce the labor intensity of workers and take up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

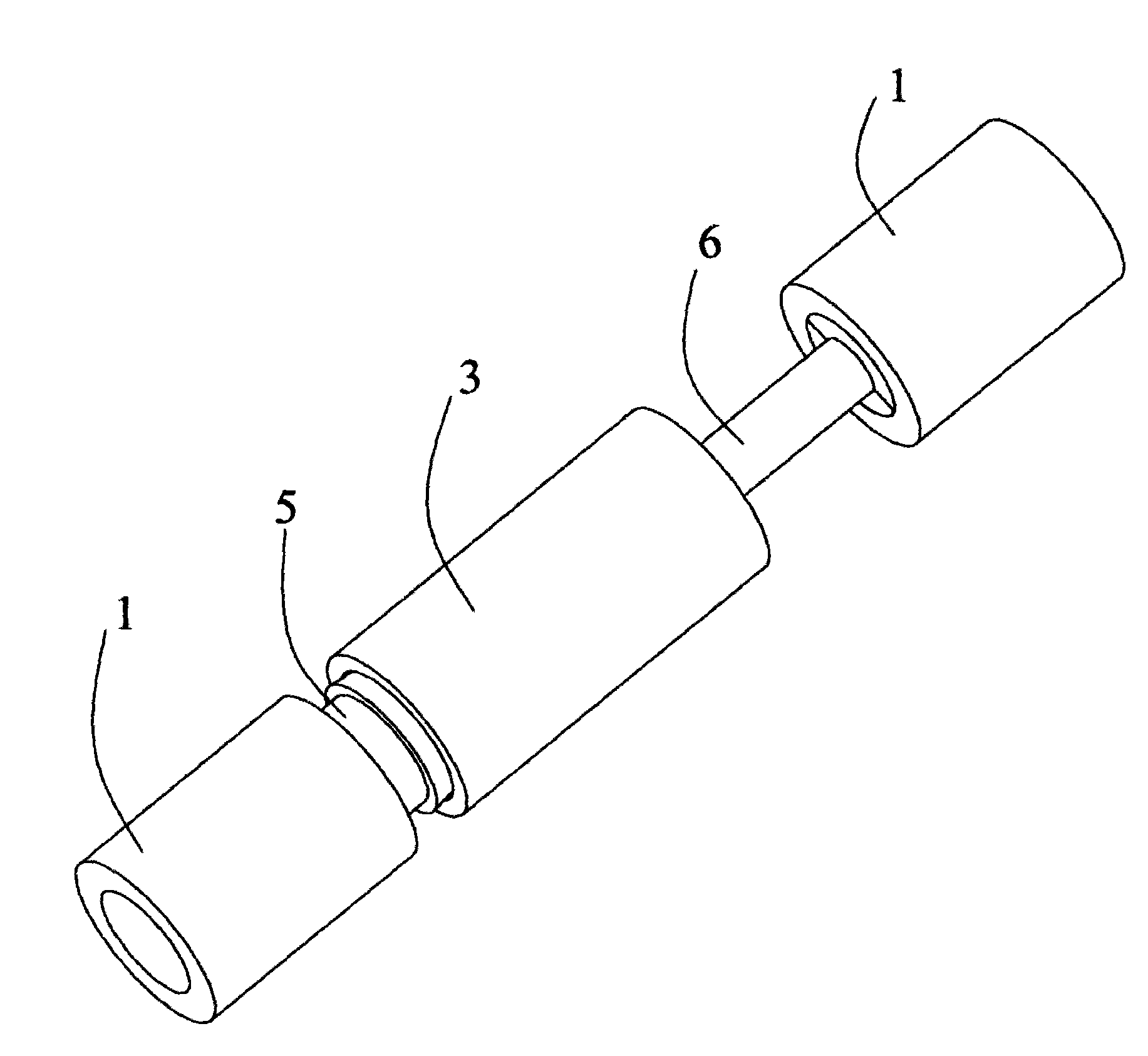

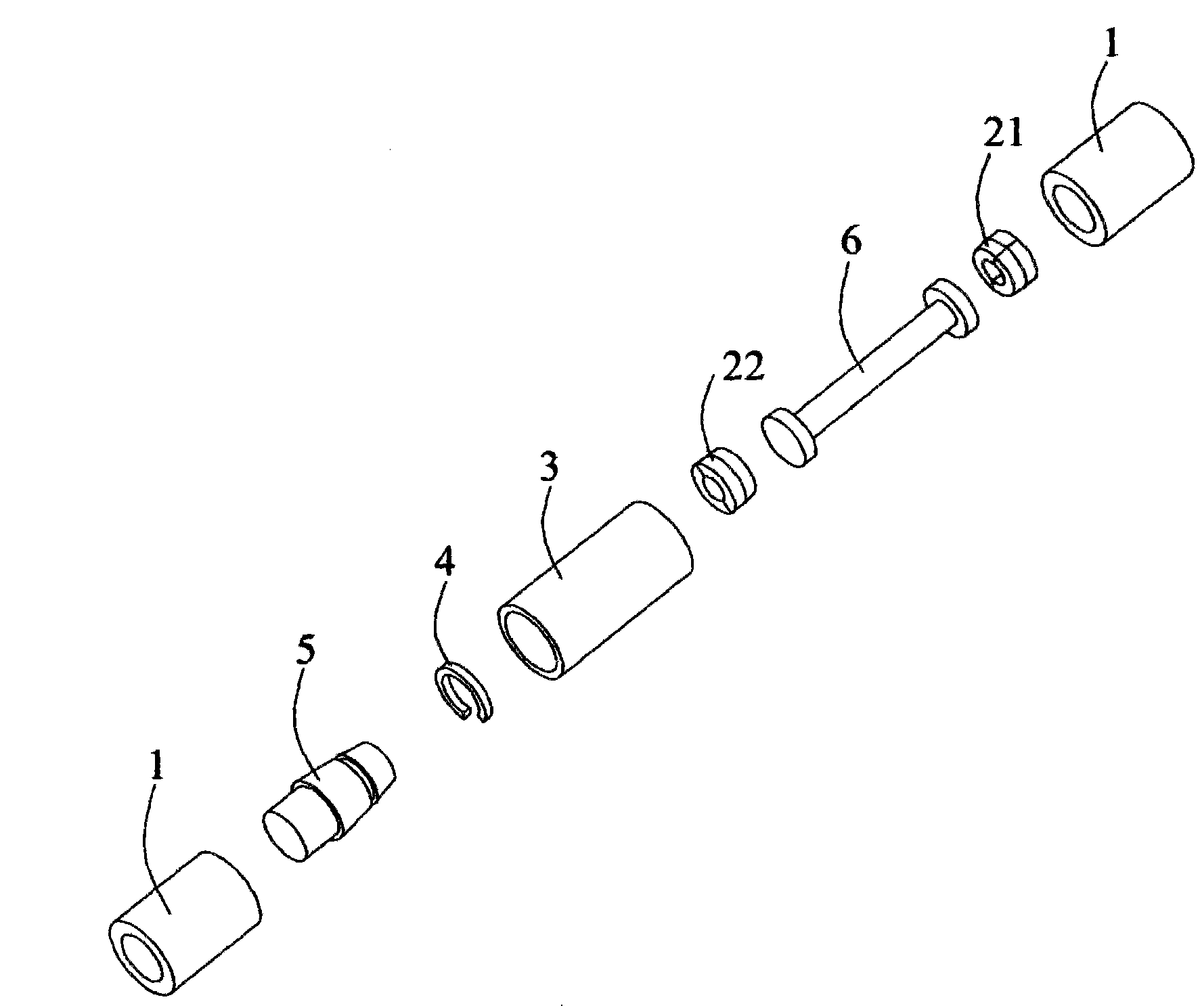

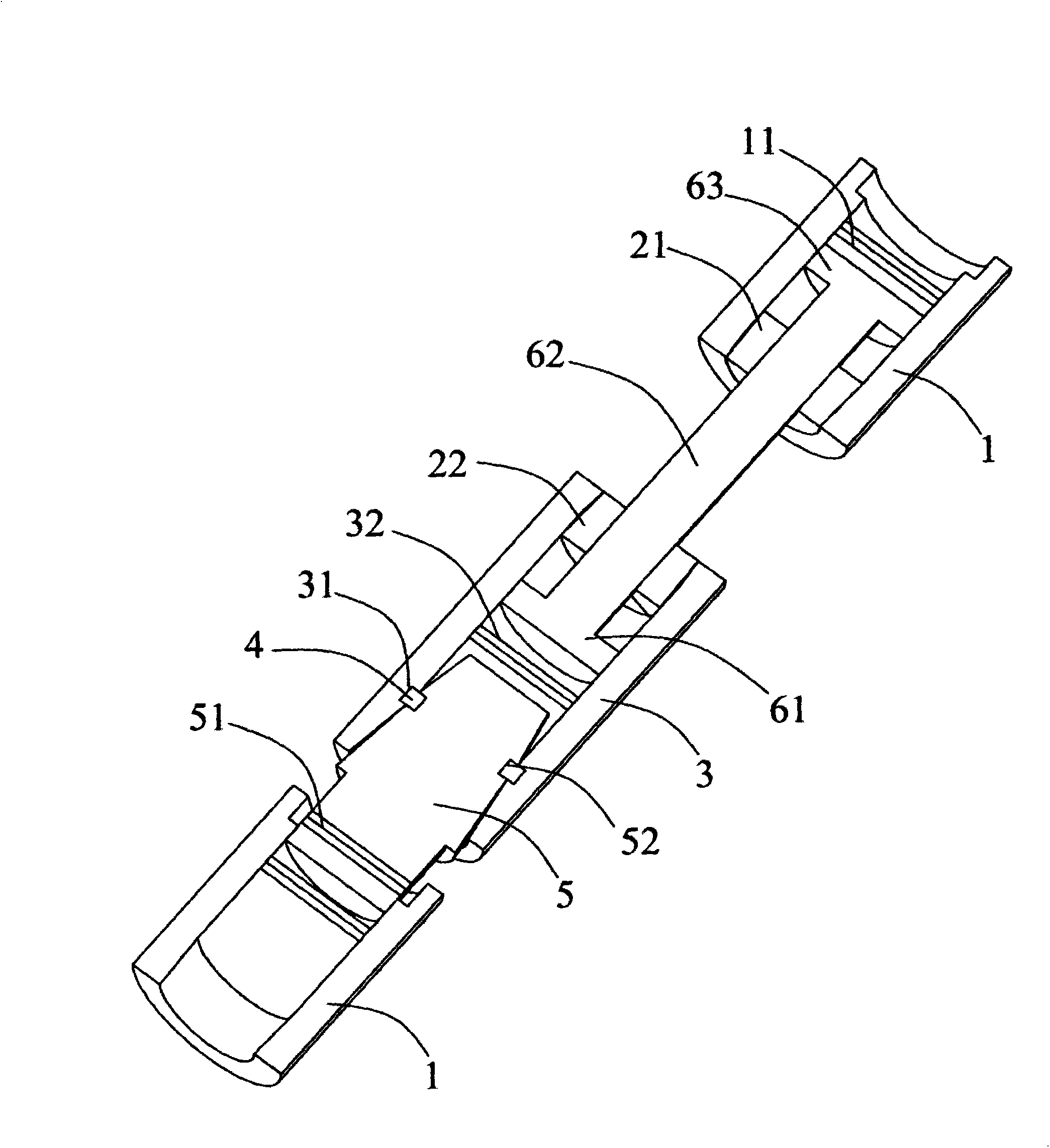

[0023] Such as Figure 1 to Figure 3 As shown, in accordance with the present invention, a pipe pile without end plate and anti-pull functional assembly includes a short nut 1 , a lock clip, a long nut 3 , a retaining spring 4 , and a connecting bolt 5 .

[0024] The lock clip includes a first lock clip 21 and a second lock clip 22, and each lock clip is a cylinder with an inclined tapered cylindrical surface. The short nut 1 is a hollow cylinder, the end of the short nut 1 with a large opening is provided with a first internal thread 11 , and the end of the short nut with a small opening is provided with a taper for matching with the first lock clip 21 . Long nut 3 is also a kind of hollow cylinder, and the large end of long nut 3 opening is provided with the first jumper groove 31, and the small end of long nut 3 opening is provided with the taper th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com