Novel three-return-stroke water tube boiler

A water-tube boiler, three-return technology, applied in water-tube steam boilers, steam boilers, combustion methods, etc., can solve the problems of large boiler footprint, waste of land resources, and increased steel consumption, and achieve the overall footprint The effect of reducing, improving heat exchange efficiency, and reducing steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

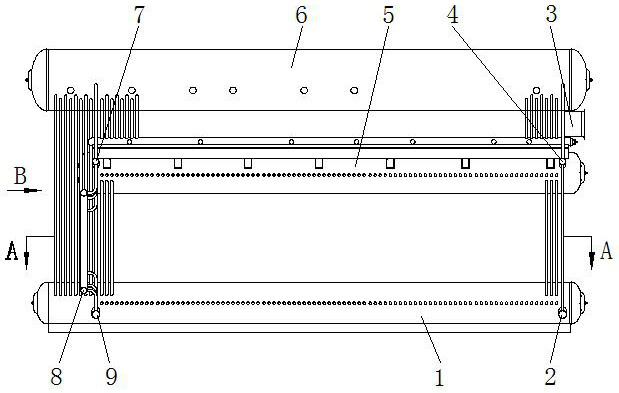

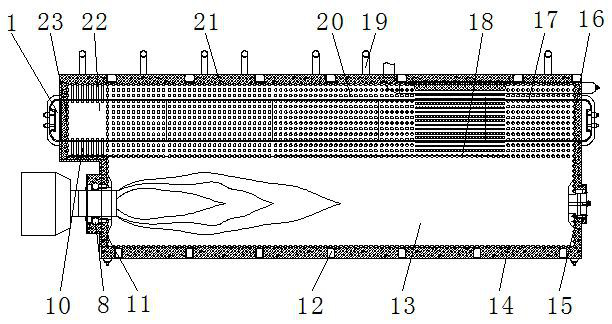

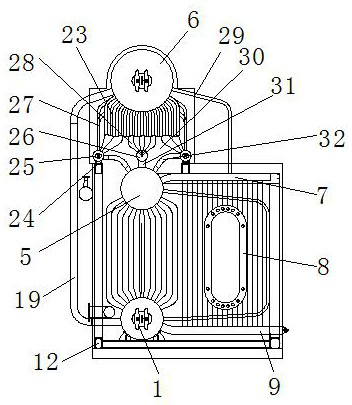

[0019] see Figure 1-3, the present invention provides a technical solution: a new three-pass water tube boiler, including a first return furnace 13, a second return structure 17, a third return structure 30, a smoke outlet channel 22, a supporting steel frame 12, and an intermediate drum 5 , the upper drum 6 and the lower drum 1, the lower drum 1 and the middle drum 5 are arranged on the support steel frame 12, the lower drum 1 is located below the middle drum 5, and the inner wall of the first return furnace 13 is provided with Furnace front membrane wall 11, furnace rear membrane wall 15, right membrane wall 14 and middle membrane wall 18, furnace front membrane wall 11, furnace rear membrane wall 15, right membrane wall 14 and middle membrane wall 18 communicates with the middle drum 5 and the lower drum 1, and the top and bottom of the left side of the first return furnace 13 are respectively provided with a front membrane wall header 7 and a furnace front membrane wall h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com