MVR (Mechanical Vapor Recompression) superheated steam sludge continuous drying system and working method

A working method, drying system technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. the effect of improving the drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

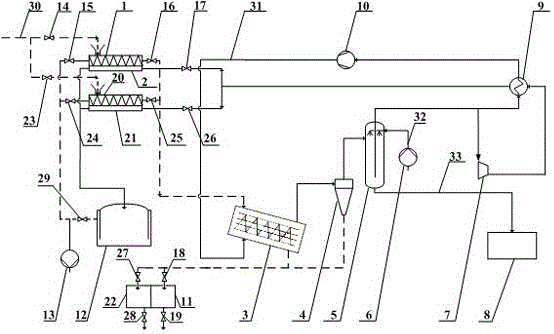

[0015] Refer below figure 1 Explain the working process of a MVR superheated steam sludge continuous drying system.

[0016] First close the first valve 14, the seventh valve 23, the sixth valve 19, the twelfth valve 28, open the second valve 15, the third valve 16, the fourth valve 17, the fifth valve 18, the eighth valve 24, the second valve The ninth valve 25, the tenth valve 26, the eleventh valve 27, and the thirteenth valve 29 are vacuumed by the vacuum pump 13, so that the dryer is in a negative pressure working state.

[0017] Then close the second valve 15, the third valve 16, the fourth valve 17, the fifth valve 18, the eighth valve 24, the ninth valve 25, the tenth valve 26, the eleventh valve 27, the thirteenth valve 29, open The first valve 14, the seventh valve 23, the sludge 30 to be dried enters the first feeding device 1 and the second feeding device 20, closes the first valve 14, the seventh valve 23, opens the second valve 15, the eighth valve Valve 24, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com