Double-layer backheating type micro-combustor

A micro-combustion and burner technology, applied in the direction of burners, gas fuel burners, combustion types, etc., can solve the problems of insufficient uniformity of wall surface temperature distribution, low utilization rate of mixed gas combustion space, complex structure, etc., to achieve The effect of improving uniformity, expanding the stable combustion flow rate range, and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

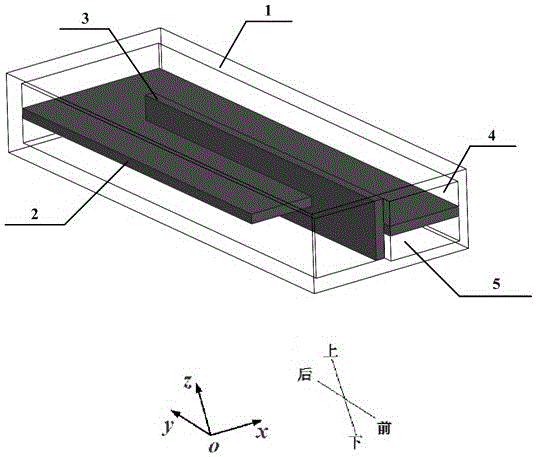

[0027] Such as figure 1 The double-layer regenerative micro-burner shown includes: 1. the outer wall of the burner, 2. a transverse heat-conducting partition, 3. a longitudinal heat-conducting partition, 4. an air inlet, and 5. an air outlet.

[0028] A double-layer regenerative micro burner according to the present invention comprises a burner wall 1, a transverse heat conduction partition 2, a longitudinal heat conduction partition 3, an air inlet 4 and an air outlet 5, and the burner wall is divided into 1 It is the upper, lower, left and right four walls and the front wall; the right side of the front wall of the burner is provided with a rectangular through hole;

[0029] The inside of the burner is provided with a transverse heat conduction partition 2 and a longitudinal heat conduction partition 3;

[0030] The width of the transverse heat-conducting partition 2 is equal to the width of the burner, and a slit with a length shorter than the length of the burner and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com