Automatic verification system for performance of insulation monitoring module

An automatic verification and insulation monitoring technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of cumbersome operation and low verification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

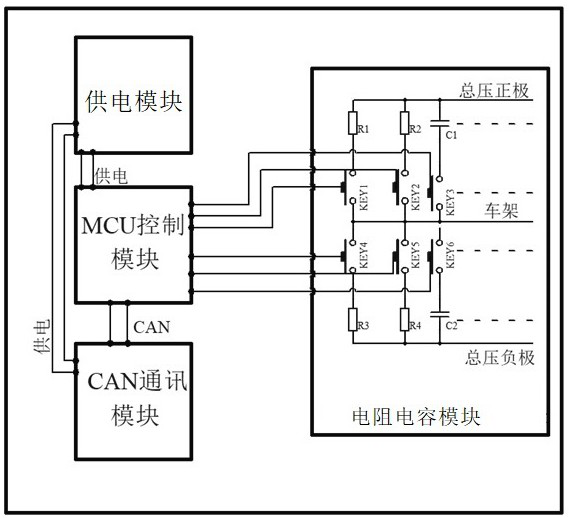

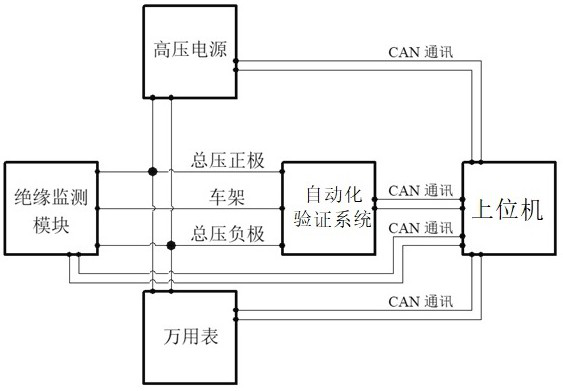

[0022] Such as figure 1 As shown, the automatic verification system for the performance of the insulation monitoring module in this embodiment includes a power supply module, a resistor and capacitor module, a CAN communication module and an MCU control module.

[0023] The power supply module can be powered by ordinary 12V or 24V power supply, which is the same as the low-voltage lead-acid power supply platform of new energy vehicles, which is in line with practical applications. Then it is converted to 5V through the circuit, which can supply power to the MCU control module and CAN communication module.

[0024] Resistor-capacitance module, including several resistors R1, R2..., several capacitors C1, C2... and several electronically controlled switches KEY1, KEY2..., one end of some resistors R1, R2... and capacitor C1... are respectively connected to insulated The other end of the main positive line of the monitoring module and the high-voltage power supply is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com