Steam box and method of adjusting temperature and humidity of paper

A steam box and steam technology, applied in papermaking, paper machines, wetting devices, etc., can solve the problems of destroying the papermaking environment, increasing steam overflow, and increasing investment costs, so as to reduce steam overflow, increase temperature or humidity, and increase utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

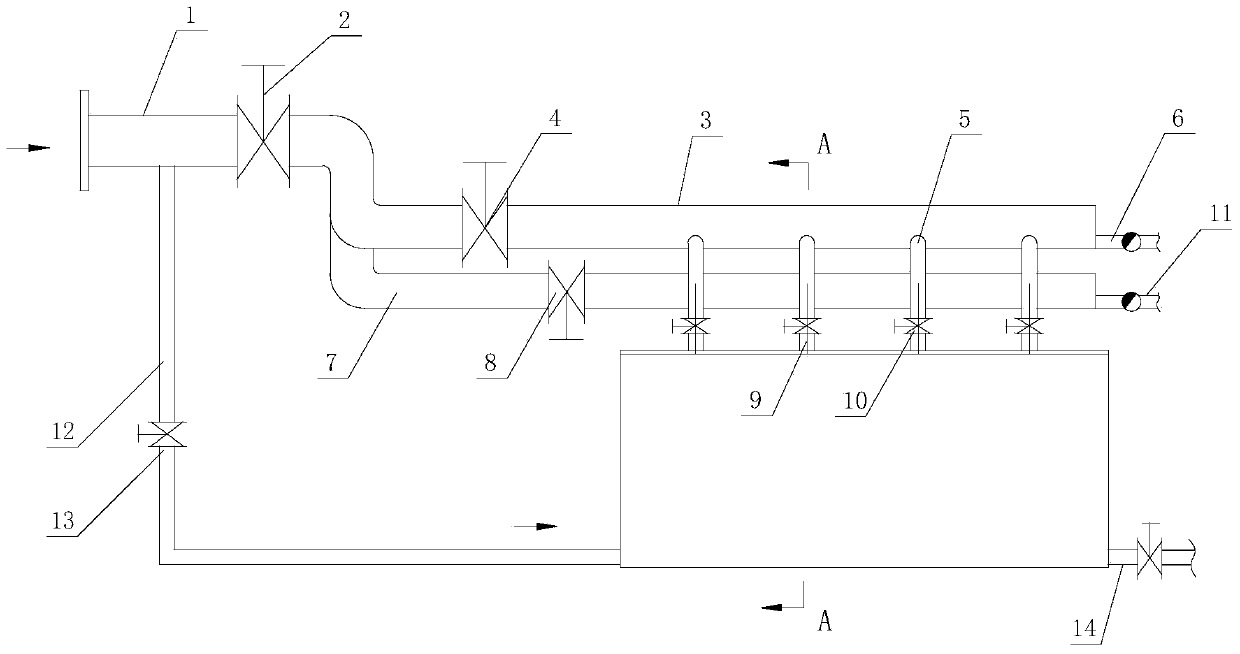

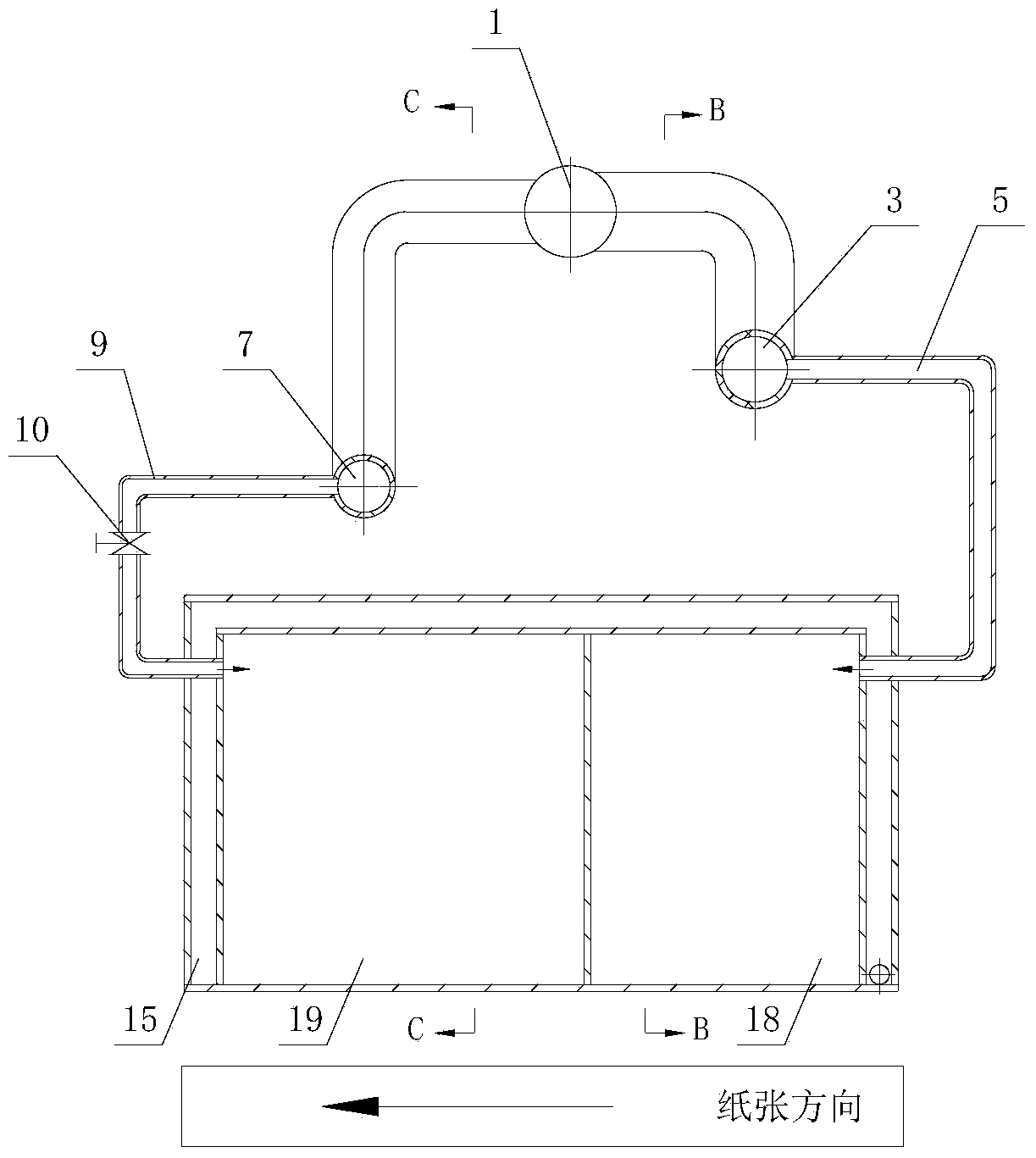

[0039] Such as Figures 1 to 5 shown. The steam box of the present invention comprises a steam main pipe 1 connected with the steam box, and a main pipe control valve 2 is arranged on the steam main pipe 1; on the steam main pipe 1, with the main pipe control valve 2 as a boundary, it is divided into an upstream pipeline and a downstream pipeline;

[0040] The outside of the steam box is provided with a preheating chamber 15; the preheating chamber 15 is connected to the upstream pipeline of the steam main pipe 1 through a preheating branch pipe 12, and a preheating control valve 12 is provided on the pipeline of the preheating branch pipe 12;

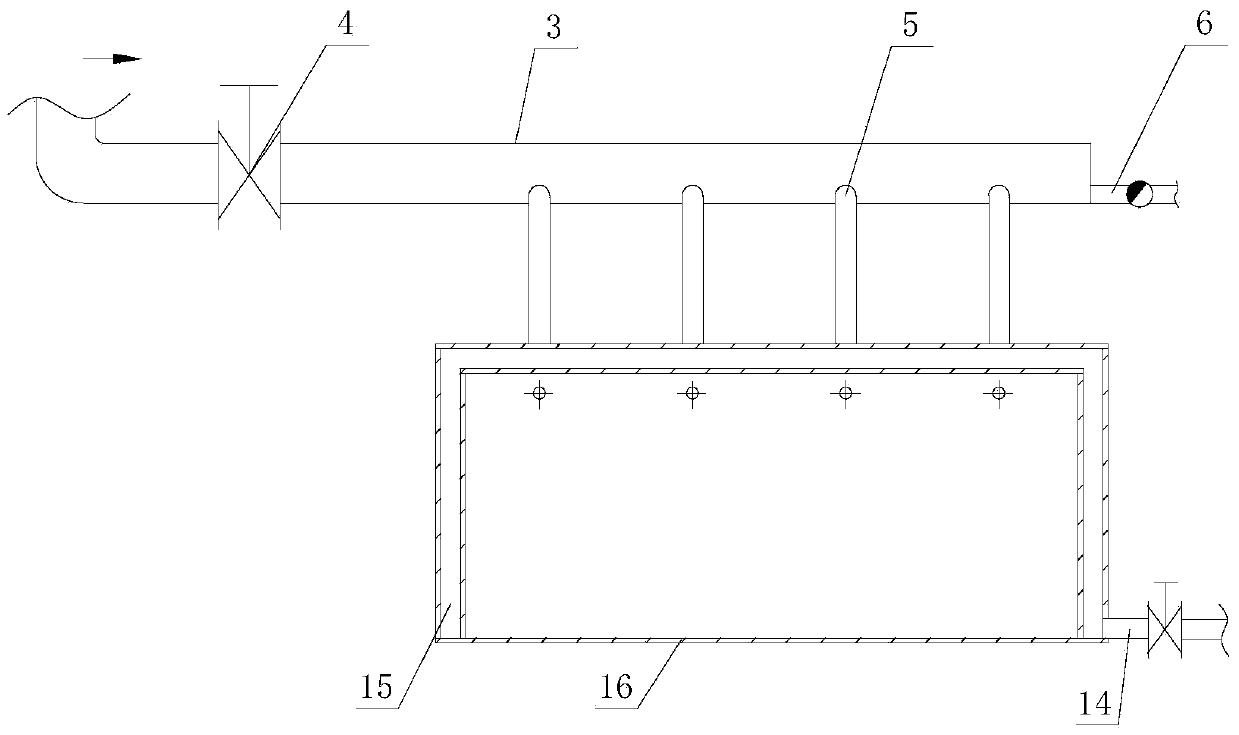

[0041] The steam box includes: a constant flow area 18 and an adjustment area 19 in sequence along the advancing direction of the paper, and a perforated plate 16 is arranged at the bottom of the constant flow area 18 and the adjustment area 19; the perforated plate 16 allows the steam to be evenly sprayed onto the paper .

[0042] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com